In-situ tensile sample preparation method for mechanical performance testing of tsv copper interconnection materials

A technology of material mechanics and in-situ stretching, which is applied in the field of in-situ stretching sample preparation for mechanical performance testing of TSV copper interconnect materials, can solve problems such as inability to infer the properties of tiny samples, and achieve convenient and effective tensile strength and manufacturing methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

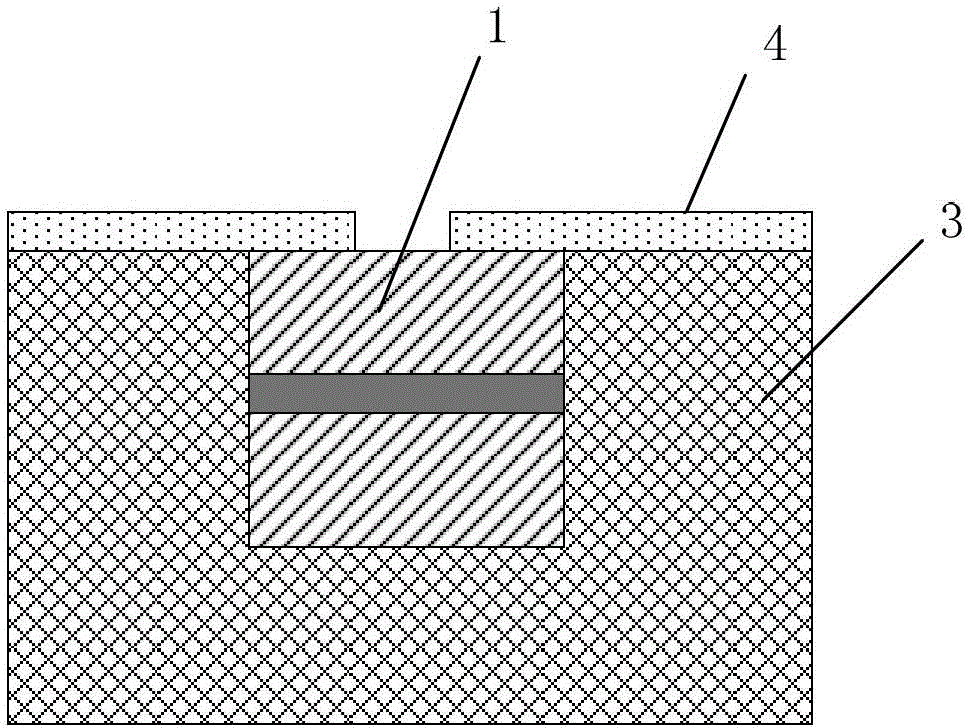

[0020] Such as Figure 6 As shown, the in-situ tensile sample produced by the present invention includes a TSV copper column 2 , a silicon wafer 1 at both ends of the copper column and a sample clamping end 5 . The specific preparation method is as follows:

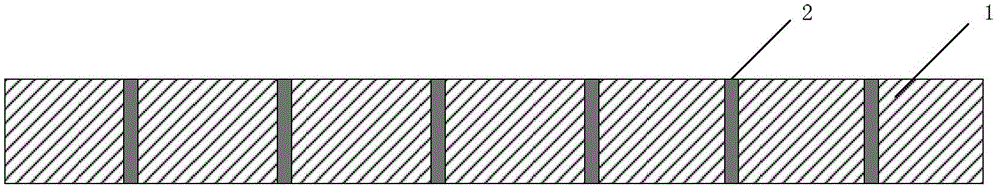

[0021] one. Prepare a silicon wafer filled with TSV copper plating, such as figure 1 shown. The silicon wafer thickness is 200-500μm. TSV via holes have a diameter of 20-50 μm and a height of 200-500 μm.

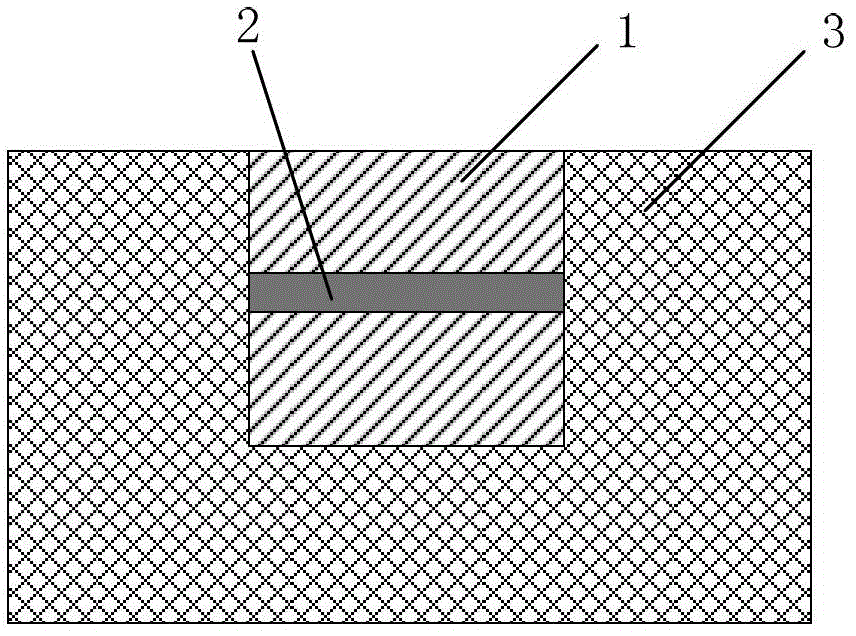

[0022] two. right figure 1 The silicon wafer is diced, so that there is at least one TSV copper pillar 2 ( figure 2 1 in the middle), and fix the silicon chip 1 on the carrier 3, such as figure 2 As shown; the carrying device 3 has a groove structure, and the size of the groove is the same as the size of the cut silicon wafer. The upper surfaces of the silicon wafers are on the same plane, and the TSV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com