A method for evaluating the mechanical properties of ultra-thin ti/al two-layer density gradient materials

A technology of gradient materials and evaluation methods, which is applied in the direction of testing material strength, analyzing materials, and strength properties by applying stable tension/pressure. Material tensile strength and other issues, to achieve the effect of saving testing costs and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

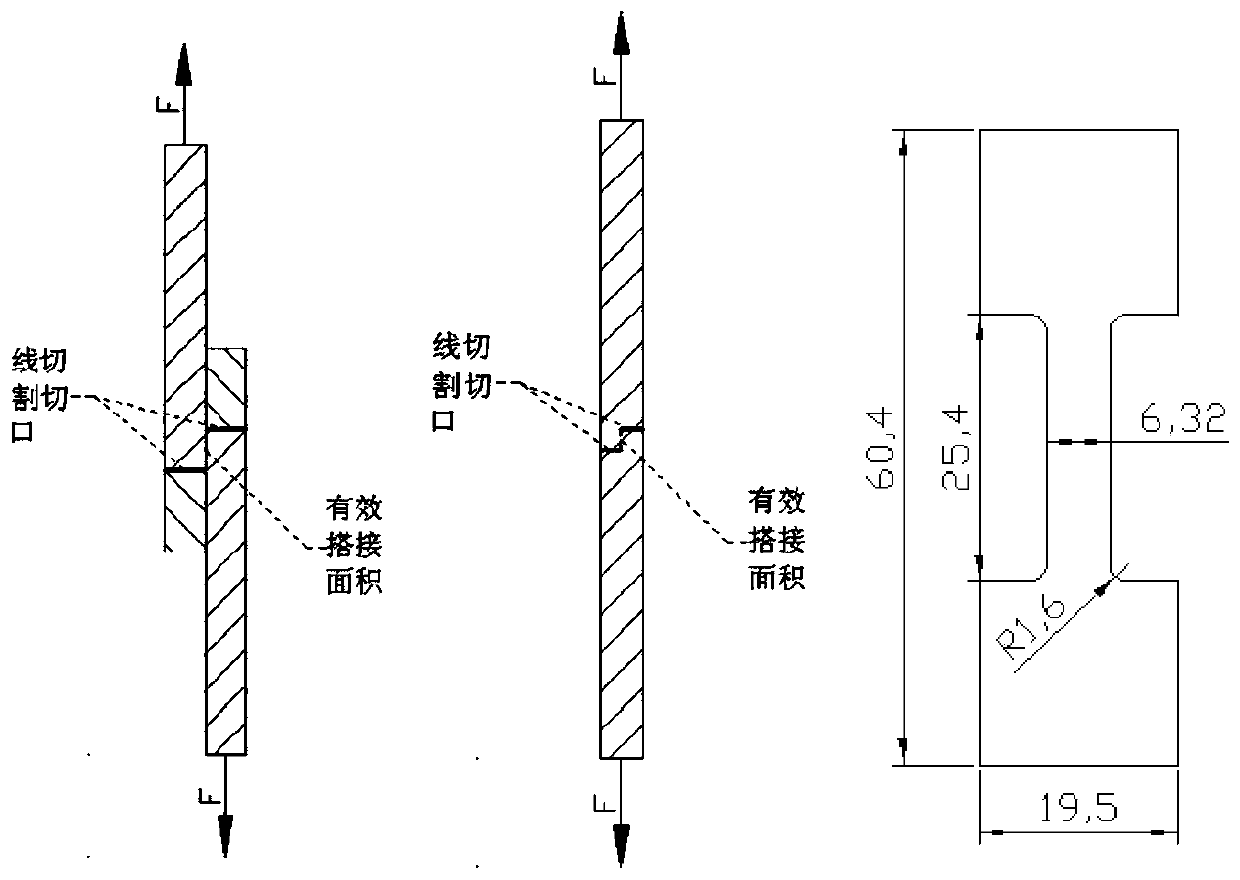

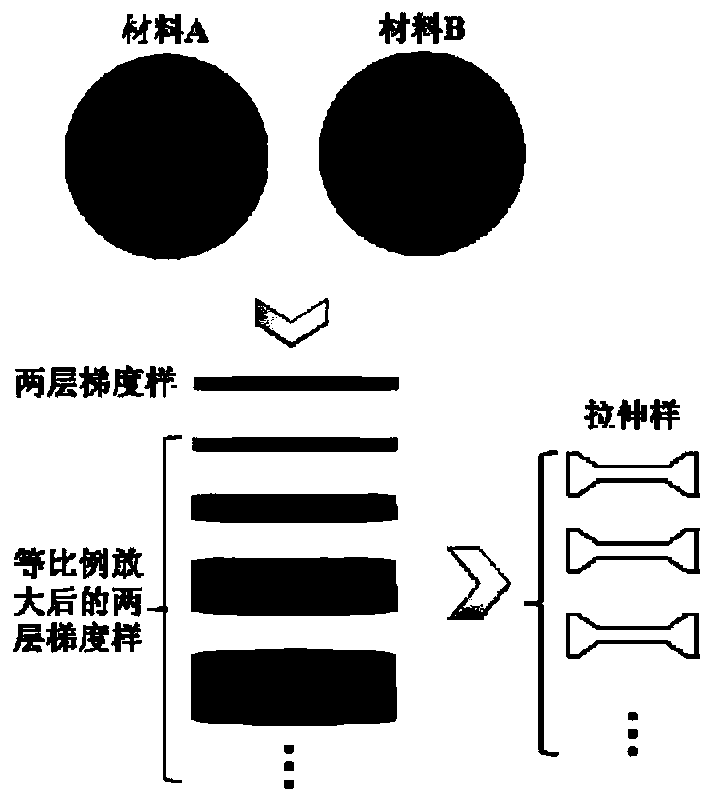

[0036] Ti / Al (thickness 0.3mm / 0.2mm) two-layer gradient material tensile strength test

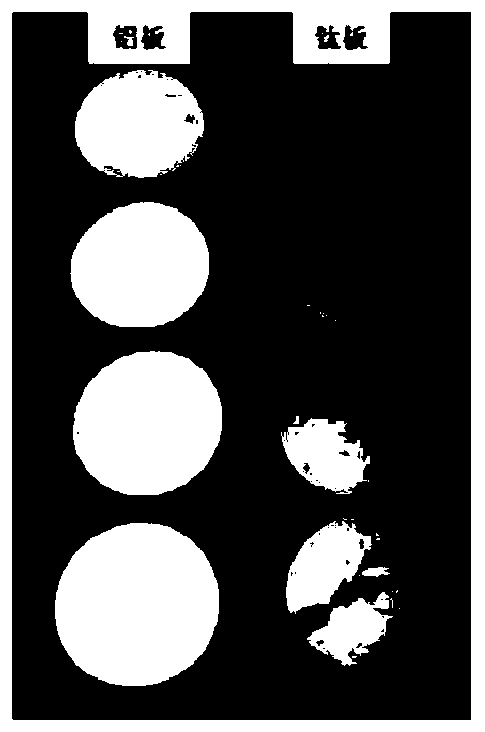

[0037] according to figure 2 The process shown in the preparation of Ti / Al two-layer gradient material: first process a series of titanium plates with a diameter of Φ40mm and different thicknesses (thicknesses are 0.45mm, 0.48mm, 0.51mm, 0.54mm, 0.57mm, 0.6mm, 0.9mm, 1.2mm, 1.5mm, 1.8mm, 2.1mm) and aluminum plate (the thickness is 0.3mm, 0.32mm, 0.34mm, 0.36mm, 0.38mm, 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.4mm ). The titanium plate is a TC4 titanium alloy plate that meets the standard composition, and the aluminum plate is a 2A12-T4 aluminum alloy that meets the standard composition.

[0038] Secondly, grind and polish the surfaces to be welded of a series of titanium plates and aluminum plates with a diameter of Φ40mm of different thicknesses to remove the oxide film on the surface of the plates. Sandpapers of 80 mesh, 240 mesh, 600 mesh, 1000 mesh, and 1500 mesh were used in turn to p...

Embodiment 2

[0041] Ti / Al (thickness 0.2mm / 0.3mm) two-layer gradient material tensile strength test

[0042] according to figure 2 The process shown in the preparation of Ti / Al two-layer gradient material: first process a series of titanium plates with different thicknesses of diameter Φ40mm (thicknesses are 0.3mm, 0.32mm, 0.34mm, 0.36mm, 0.38mm, 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.4mm) and aluminum plate (the thickness is 0.45mm, 0.48mm, 0.51mm, 0.54mm, 0.57mm, 0.6mm, 0.9mm, 1.2mm, 1.5mm, 1.8mm, 2.1mm ). The titanium plate is a TC4 titanium alloy plate that meets the standard composition, and the aluminum plate is a 2A12-T4 aluminum alloy that meets the standard composition.

[0043] Secondly, grind and polish the surfaces to be welded of a series of titanium plates and aluminum plates with a diameter of Φ40mm of different thicknesses to remove the oxide film on the surface of the plates. Sandpapers of 80 mesh, 240 mesh, 600 mesh, 1000 mesh, and 1500 mesh were used in turn to polish ...

Embodiment 3

[0046] Ti / Al (thickness 0.2mm / 0.4mm) two-layer gradient material tensile strength test

[0047] according to figure 2 The process shown in the preparation of Ti / Al two-layer gradient material: first process a series of titanium plates with different thicknesses of diameter Φ40mm (thicknesses are 0.3mm, 0.32mm, 0.34mm, 0.36mm, 0.38mm, 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.4mm) and aluminum plate (the thickness is 0.6mm, 0.64mm, 0.68mm, 0.72mm, 0.76mm, 0.8mm, 1.2mm, 1.6mm, 2.0mm, 2.4mm, 2.8mm ). The titanium plate is a TC4 titanium alloy plate that meets the standard composition, and the aluminum plate is a 2A12-T4 aluminum alloy that meets the standard composition.

[0048] Secondly, grind and polish the surfaces to be welded of a series of titanium plates and aluminum plates with a diameter of Φ40mm of different thicknesses to remove the oxide film on the surface of the plates. Sandpapers of 80 mesh, 240 mesh, 600 mesh, 1000 mesh, and 1500 mesh were used in turn to polish t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com