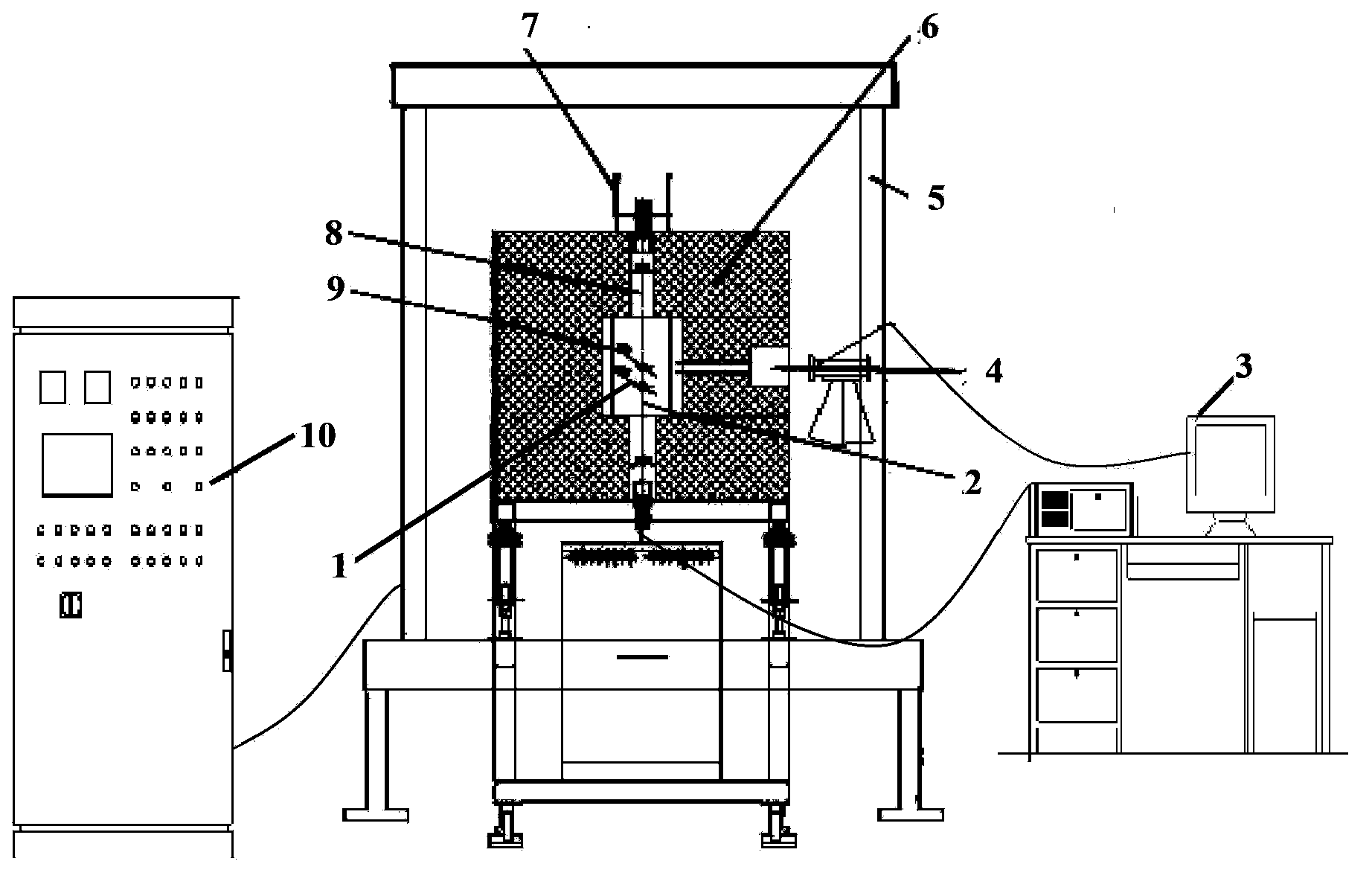

Device and method for testing mechanical property in ultrahigh temperature oxidation environment

A testing device and oxidizing environment technology, applied in the direction of using stable bending force to test material strength, using stable shear force to test material strength, using stable tension/compression to test material strength, etc., can solve difficult problems. Obtaining a uniform and stable oxidizing environment, uneven temperature field, poor experimental repeatability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

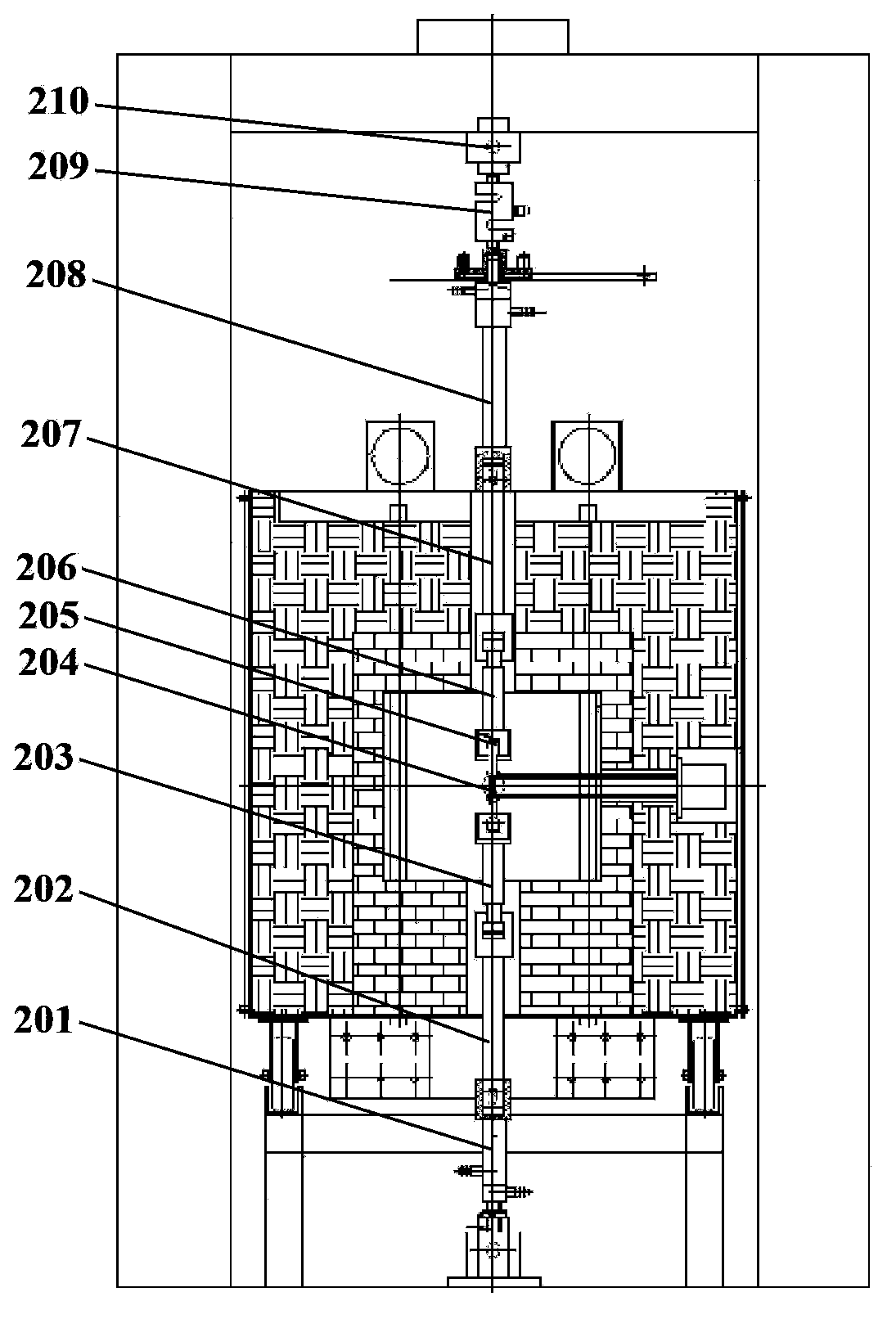

[0079] Embodiment 1: Measuring the tensile strength of a certain ultra-high temperature ceramic material

[0080] The specific experimental operation steps are:

[0081] (1) Take a test sample. The shape and size of the sample refer to the American ASTM C1295 standard. The gauge length of the sample is 30mm, and the cross-section within the gauge length is 5.97mm×2.98mm. On the upper and lower chucks connected by rods (such as figure 2 As shown), give the sample a small pre-tightening force (﹤20N) to keep it in the vertical direction; insert the ultra-high temperature extension into the furnace body, and the gauge length section of the ejector rod is in contact with the pre-sample; adjust the power supply, The heating process in the furnace is controlled by an ultra-high temperature ceramic heating element, and the temperature of the sample in the furnace is measured by an infrared thermometer to 1650 degrees, and then kept for 5 minutes;

[0082] (2) The loading bar loads ...

Embodiment 2

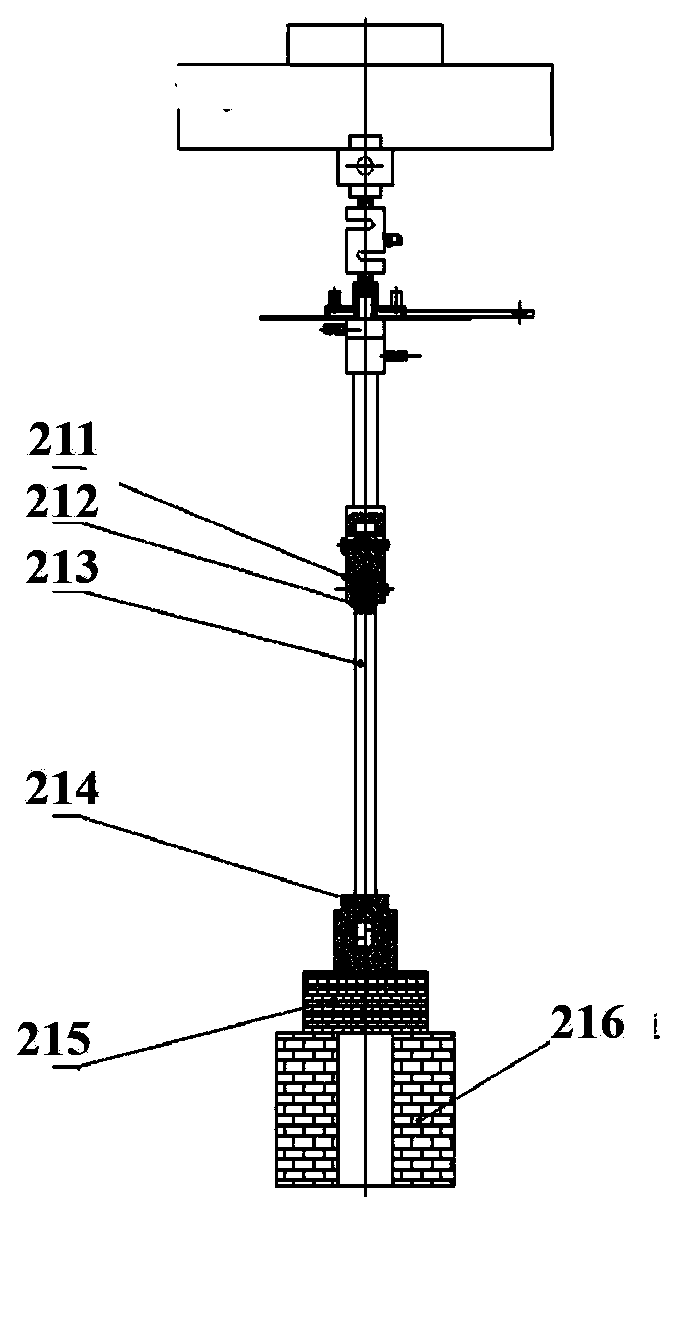

[0083] Example 2: Measuring the flexural strength of an ultra-high temperature ceramic material supporting a certain military product

[0084] The specific experimental operation steps are:

[0085] (1) Take a test sample, measure its size as 2.98mm×3.97mm×40.2mm, place the sample on the roller rod fixed on the fixture support (such as image 3 As shown), the span between the lower rollers is 20mm; adjust the power supply, heat the furnace through the ultra-high temperature ceramic heating element, use the infrared temperature measuring device to measure the temperature of the sample in the furnace to 1800 degrees, and keep it for 5 minutes;

[0086] (2) The upper roller rod loads the sample at the center of the sample at a speed of 0.5 mm / min until the sample breaks, and records the load-displacement curve (such as Figure 5 Shown), the corresponding critical load when the sample breaks is 154N; the calculated cantilever beam bending strength is 131MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com