Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

A technology of ceramic composite materials and inorganic fibers, applied in nuclear reactors, nuclear power generation, climate sustainability, etc., can solve problems such as high brittleness and insufficient reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

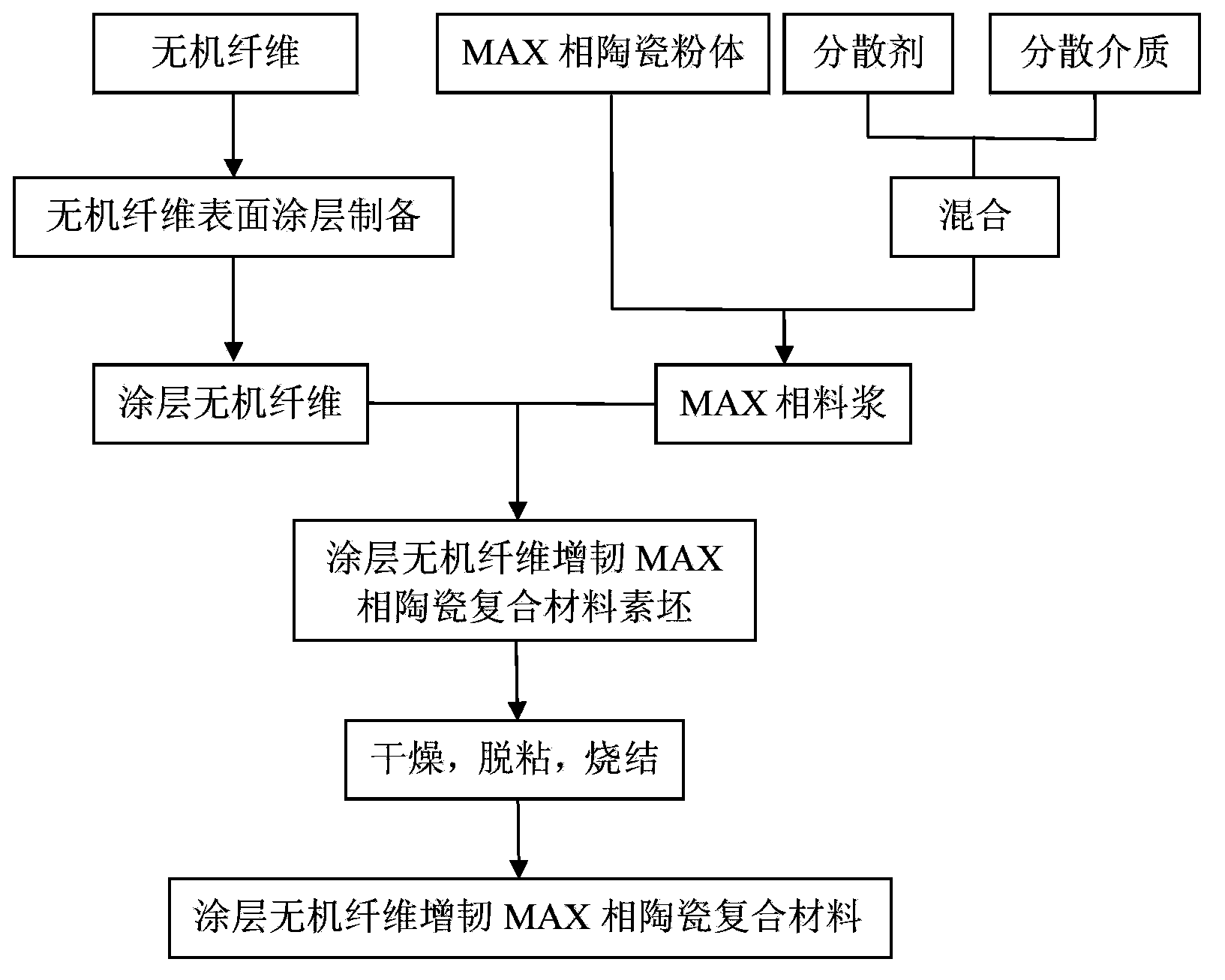

Method used

Image

Examples

Embodiment 1

[0101] In this embodiment, the coated inorganic fiber toughened MAX phase ceramic composite material is MAX phase ceramic material Ti 3 SiC 2 The coated inorganic fiber is the toughening phase, and the coated inorganic fiber accounts for 45% by volume; the coated inorganic fiber is fully dispersed in the matrix; the coated inorganic fiber is coated with C and SiC Bidirectional woven SiC two-dimensional cloth with overlapping coatings formed by overlapping. The total thickness of the coating is 600 nm.

[0102] The preparation of the above-mentioned coated inorganic fiber toughened MAX phase ceramic composite material comprises the following steps:

[0103] (1) The two-way woven SiC two-dimensional cloth was cut, and the overlapping coating formed by overlapping C and SiC was prepared on the fiber surface of the SiC two-dimensional cloth by chemical vapor deposition. The specific process conditions are as follows:

[0104] The carbon source of the C coating is ethylene, the...

Embodiment 2

[0113] In this example, the coated inorganic fiber toughened MAX phase ceramic composite material is MAX phase ceramic material Zr 2 PbC is the matrix, and the coated inorganic fiber is the toughening phase. According to the volume percentage, the coated inorganic fiber accounts for 80%; the coated inorganic fiber is fully dispersed in the matrix; the coated inorganic fiber is coated with C and Two-dimensional woven fabric of C fiber with overlapping coating formed by overlapping TiC. The total thickness of the coating is 800 nm.

[0114] The preparation process of the above-mentioned coated inorganic fiber toughened MAX phase ceramic composite material includes the following steps:

[0115] (1) Cut the C fiber two-dimensional woven fabric, and use the chemical vapor infiltration process to prepare an overlapping coating composed of C and TiC overlapping on the surface of the C fiber two-dimensional woven fabric, and the total number of layers of the coating is 10 layers . ...

Embodiment 3

[0123] In this embodiment, the coated inorganic fiber toughened MAX phase ceramic composite material is MAX phase ceramic material Ti 4 SiC 3 The coated inorganic fiber is the toughening phase, and the coated inorganic fiber accounts for 40% by volume; the coated inorganic fiber is fully dispersed in the matrix; the coated inorganic fiber is coated with C and SiC SiC fibers with overlapping coatings formed by overlapping. The total thickness of the coating is 250 nm.

[0124] The preparation process of the above-mentioned coated inorganic fiber toughened MAX phase ceramic composite material includes the following steps:

[0125] (1) Weigh chopped SiC fibers with a length of 2 mm to 5 mm, and prepare an overlapping coating formed by overlapping C and SiC on the surface of the SiC fibers by chemical formation vapor deposition. The specific process conditions are as follows:

[0126] The carbon source of C is acetylene, the deposition temperature is 950 °C, and the deposition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com