Fiber-reinforced ceramic composite material comprising a matrix with a nanolayered microstructure

a fiber reinforced ceramic and composite material technology, applied in the direction of synthetic resin layered products, ceramic layered products, transportation and packaging, etc., can solve the problems of low failure strain, limited use of ceramic matrix composite materials, ceramics as structural materials, etc., to increase strength and toughness, the effect of increasing the resistance to matrix cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

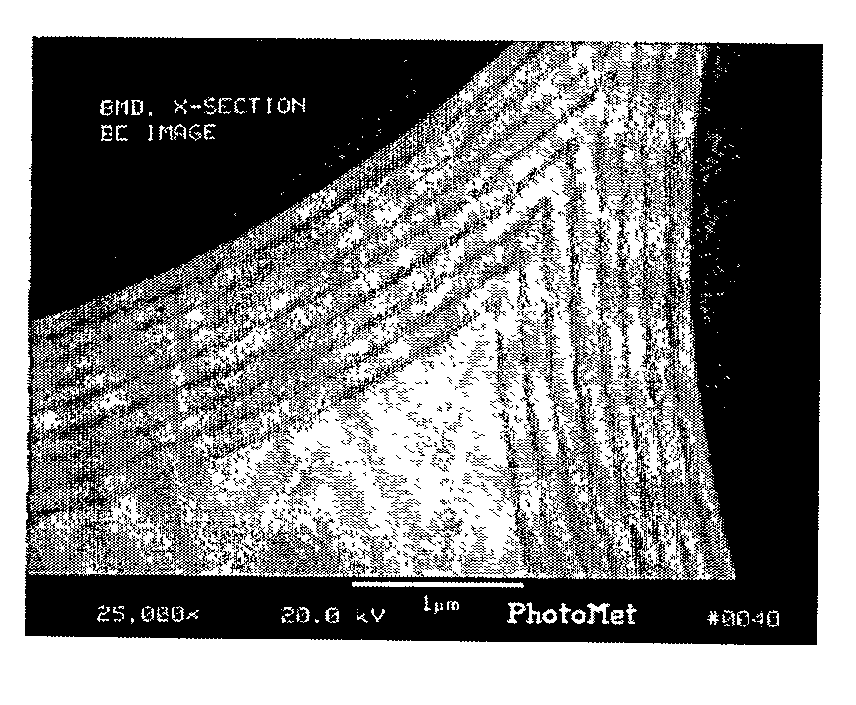

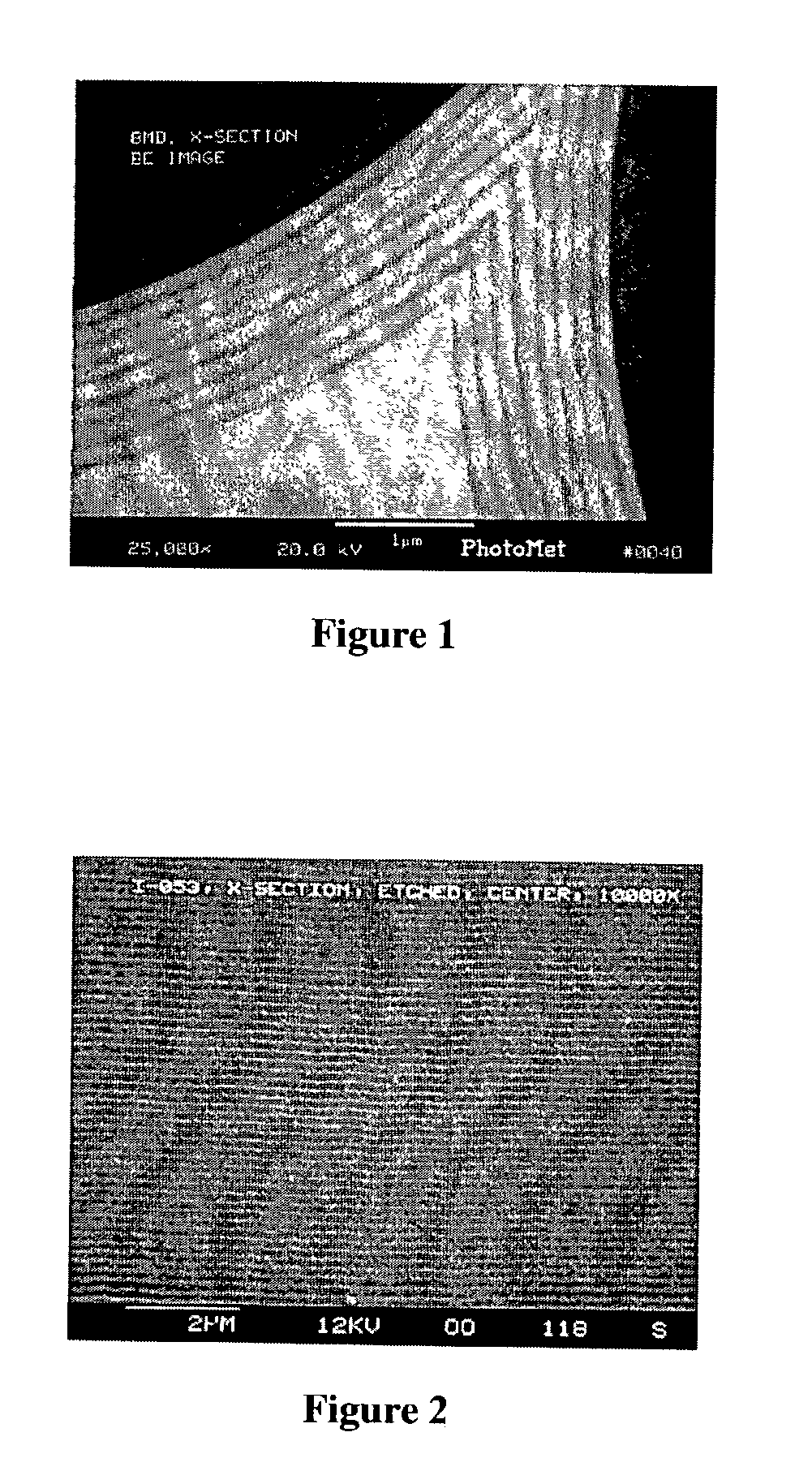

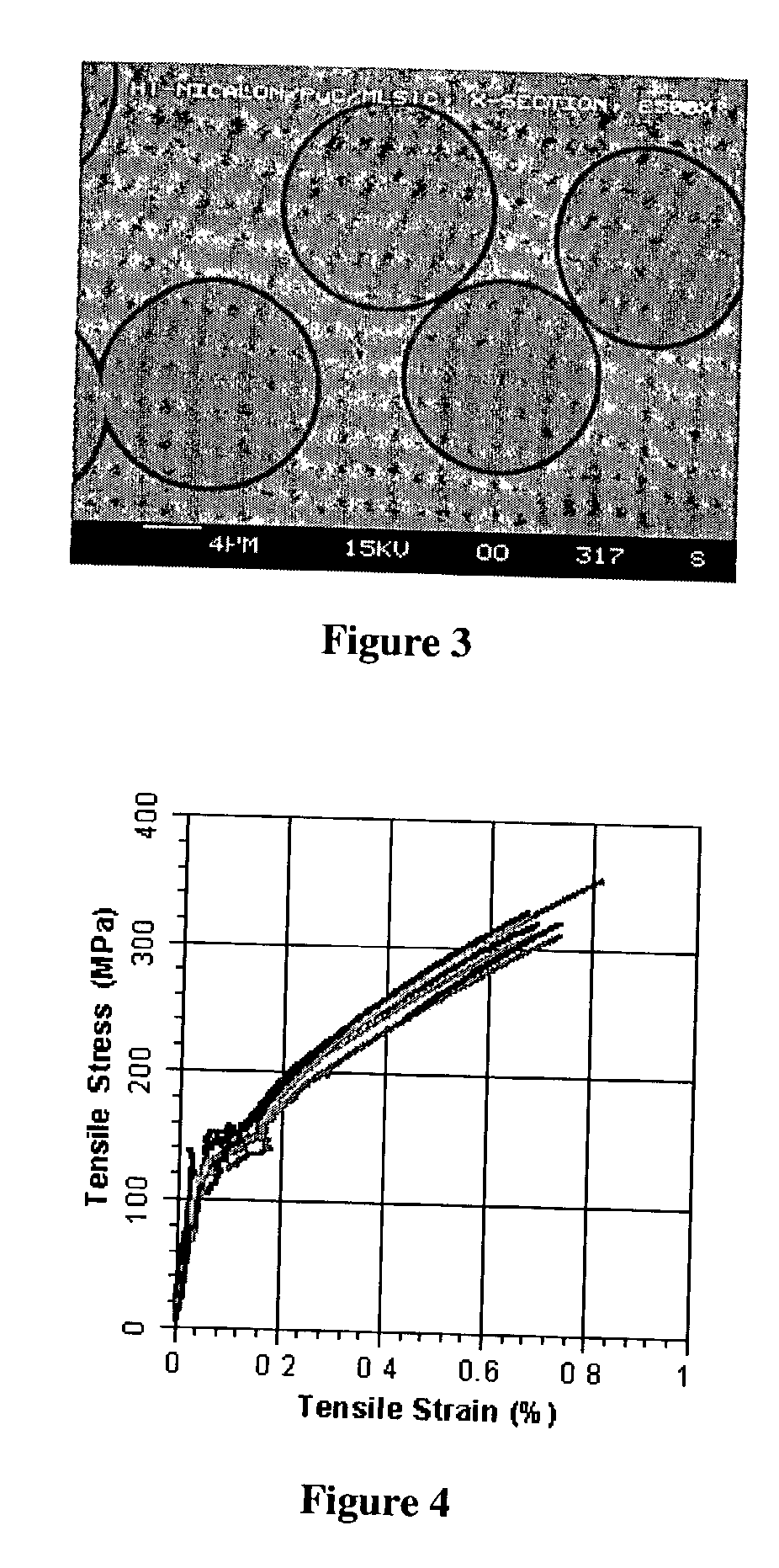

[0046] A preferred method and resultant ceramic composite material of the present invention will now be described by way of example using a Hi-Nicalon silicon carbide (SiC) fiber-reinforced SiC matrix composite (SiC / SiC) material system produced by methods of chemical vapor infiltration (CVI). The SiC / SiC composite material system is selected for its desired nonlinear tensile stress-strain behavior and well-defined matrix cracking strength, or proportional limit. The CVI-based processing technique for fiber coating and matrix densification is selected for its ability to produce very high purity materials with outstanding control and uniformity of deposited material stoichiometry, morphology and thickness.

[0047] A first step in producing ceramic matrix composite materials according to the present invention is the fabrication of a suitable fiber reinforcing preform. For this example, fibrous preforms are fabricated by stacking 8 plies of plain weave Hi-Nicalon SiC woven fabric in a b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com