Tungsten-doped boride-coated lithium battery anode material and preparation method thereof

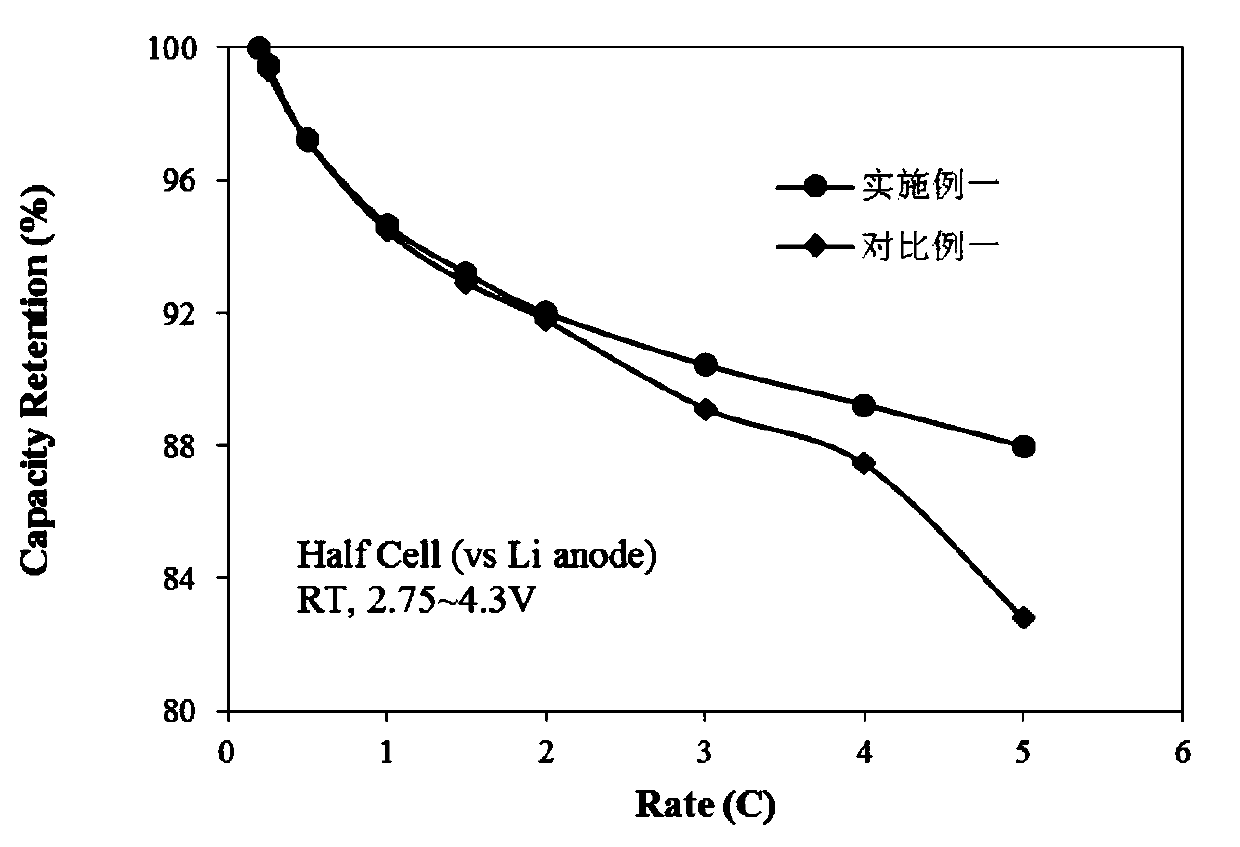

A cathode material, tungsten doping technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of unsatisfactory rate performance of nickel cobalt lithium manganate ternary material, achieve fast ion transmission properties, shorten transmission distance , the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the tungsten-doped boride-coated lithium battery cathode material provided by the present invention comprises the following steps:

[0020] 1) Dissolve the tungsten source in water, spray it into the mixed raw material of the ternary precursor and the lithium source, stir for a period of time and evaporate to dryness to obtain a dry material.

[0021] The tungsten source mentioned here is ammonium metatungstate, the lithium source is lithium hydroxide or lithium carbonate, and the amount of tungsten element added is 500-7000ppm, that is, the tungsten element accounts for 5 / 10,000 to 70 / 10,000 of the ternary precursor by mass ratio. In the process of evaporating to dryness to obtain dry materials, the heating temperature is 50-100° C., and the heating time is 0.5-3 hours.

[0022] 2) Put the above dry material into a sagger and roast for a period of time to obtain a tungsten-doped ternary positive electrode material.

[0023] Here, the calcinat...

Embodiment 1

[0029] Mix and stir 150g of ternary nickel-cobalt-manganese precursor and 71.8g of lithium hydroxide evenly, add 1.4g of ammonium metatungstate into 10mL of water, spray it into the above mixed raw material, stir at 90°C for 0.5h to form a dry material, and transfer it to a horse Heat treatment at 800°C for 12 hours in a Furnace, and after cooling, a tungsten-doped ternary positive electrode material was obtained. Add 0.75g of magnesium boride to the above-mentioned tungsten-doped positive electrode material, stir evenly, and sinter at 600°C for 6 hours. After cooling, a tungsten-doped ternary material was obtained. The nickel-cobalt-manganese ternary cathode material coated with magnesium boride and its electron microscope photos are as follows: figure 1 shown.

Embodiment 2

[0031] Mix and stir 150g of nickel-cobalt-manganese ternary precursor and 63.25g of lithium carbonate evenly, add 0.5g of ammonium metatungstate into 10mL of water, spray it into the above mixed raw materials, stir at 80°C for 1 hour to form a dry material, and transfer it to a muffle furnace Heat treatment at 900°C for 10 hours, and after cooling to obtain a tungsten-doped ternary positive electrode material, add 0.5g of magnesium boride to the above-mentioned tungsten-doped positive electrode material, stir evenly and sinter at 700°C for 5 hours, and obtain tungsten-doped, Magnesium boride-coated nickel-cobalt-manganese ternary cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com