Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Shorter ignition delay time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

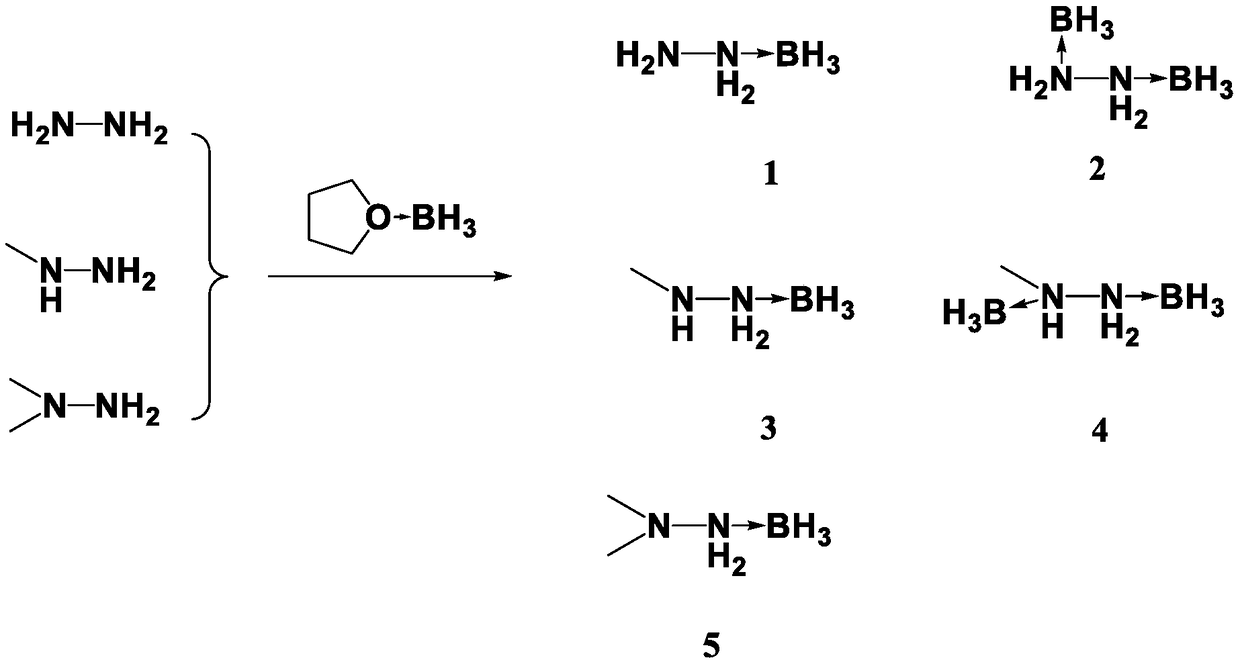

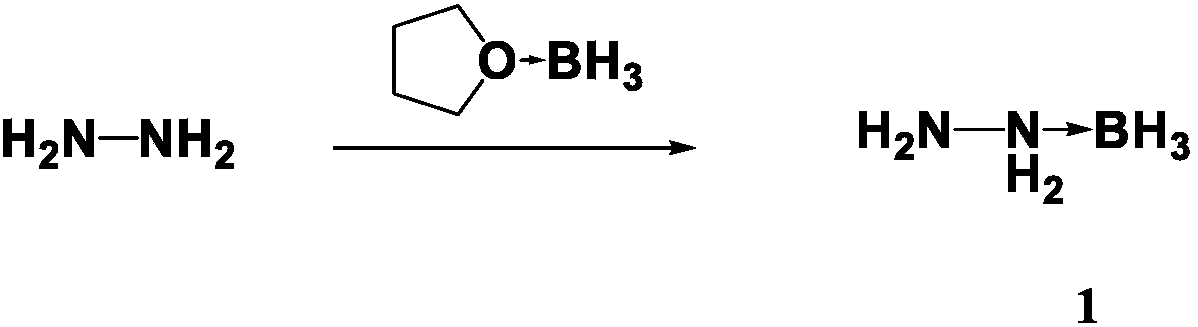

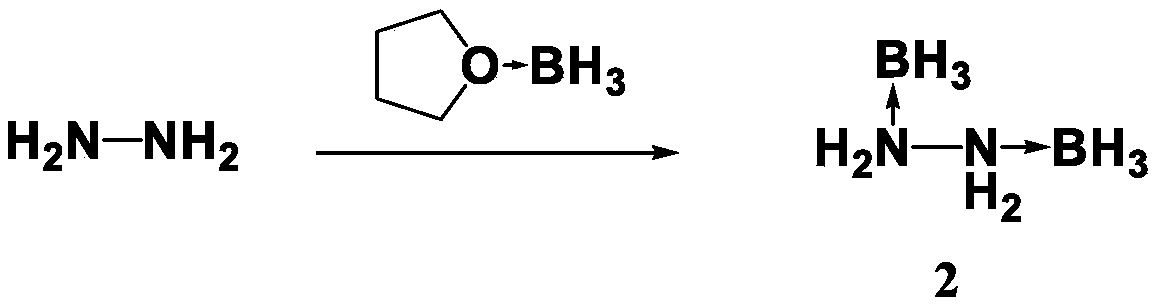

Preparation method for propellant fuel

InactiveCN108910843AShorter ignition delay timeHazard reductionOrganic chemistryHydrazineEvaporationIgnition delay

The invention discloses a preparation method for propellant fuel. The preparation method comprises the following steps: uniformly mixing hydrazine or a methyl derivative thereof with a tetrahydrofuransolution of borane to perform a reaction, and after the reaction, performing rotary evaporation on the tetrahydrofuran solution to obtain a first product; adding a first solvent into the first product, then performing washing, and then performing rotary evaporation to remove the first solvent, so as to obtain a hydrazinoborane derivative. According to the method, hydroboration is carried out on ahighly-volatile hydrazine fuel and a methylated derivative of hydrazine, the obtained borohydride of the hydrazine is a colorless non-volatile liquid or a white solid, has no volatility and greatly reduces hazard of the hydrazine fuel, and is a novel aerospace propellant fuel since the ignition delay time of the hydrazine borofluoride is extremely short.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

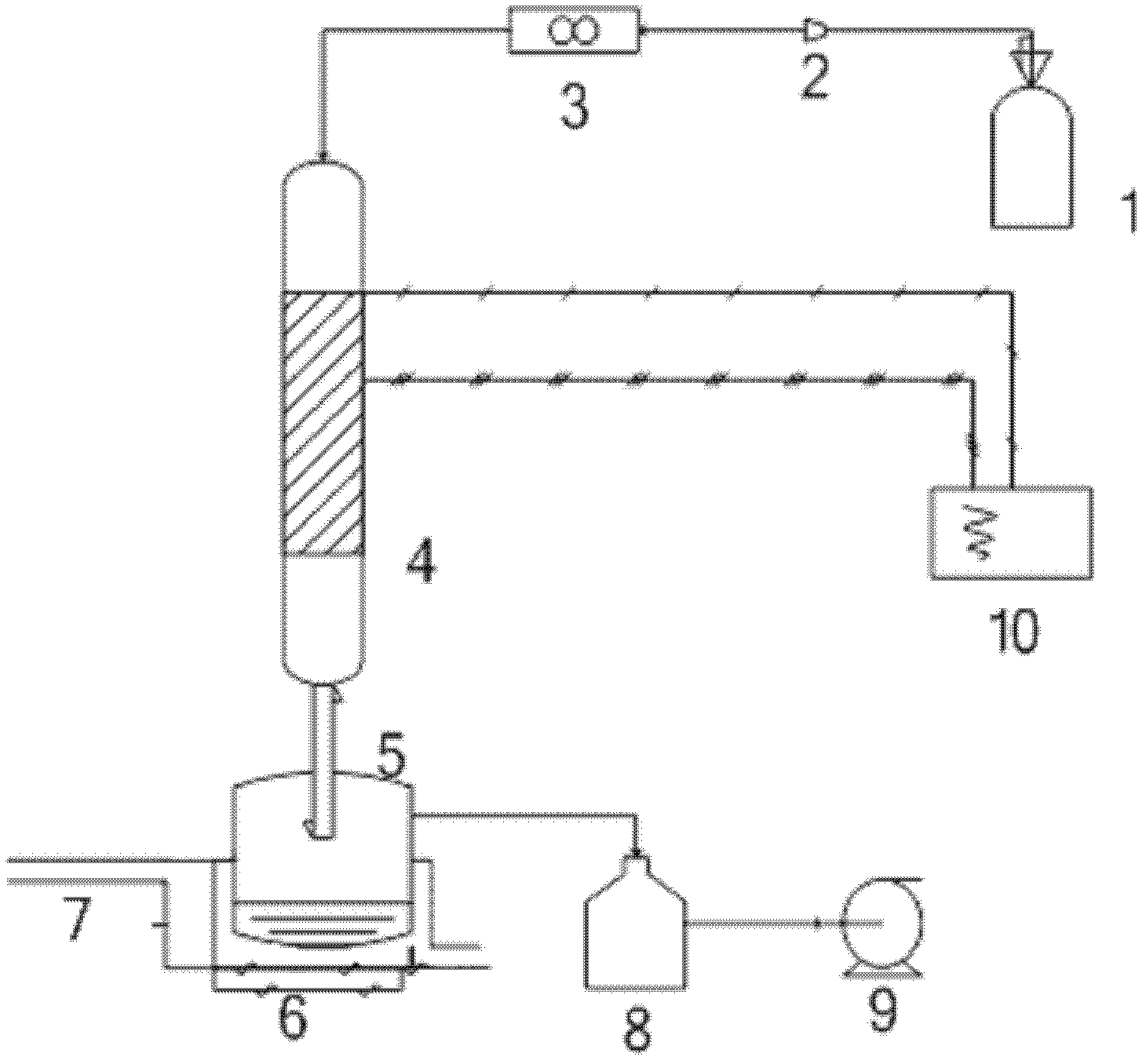

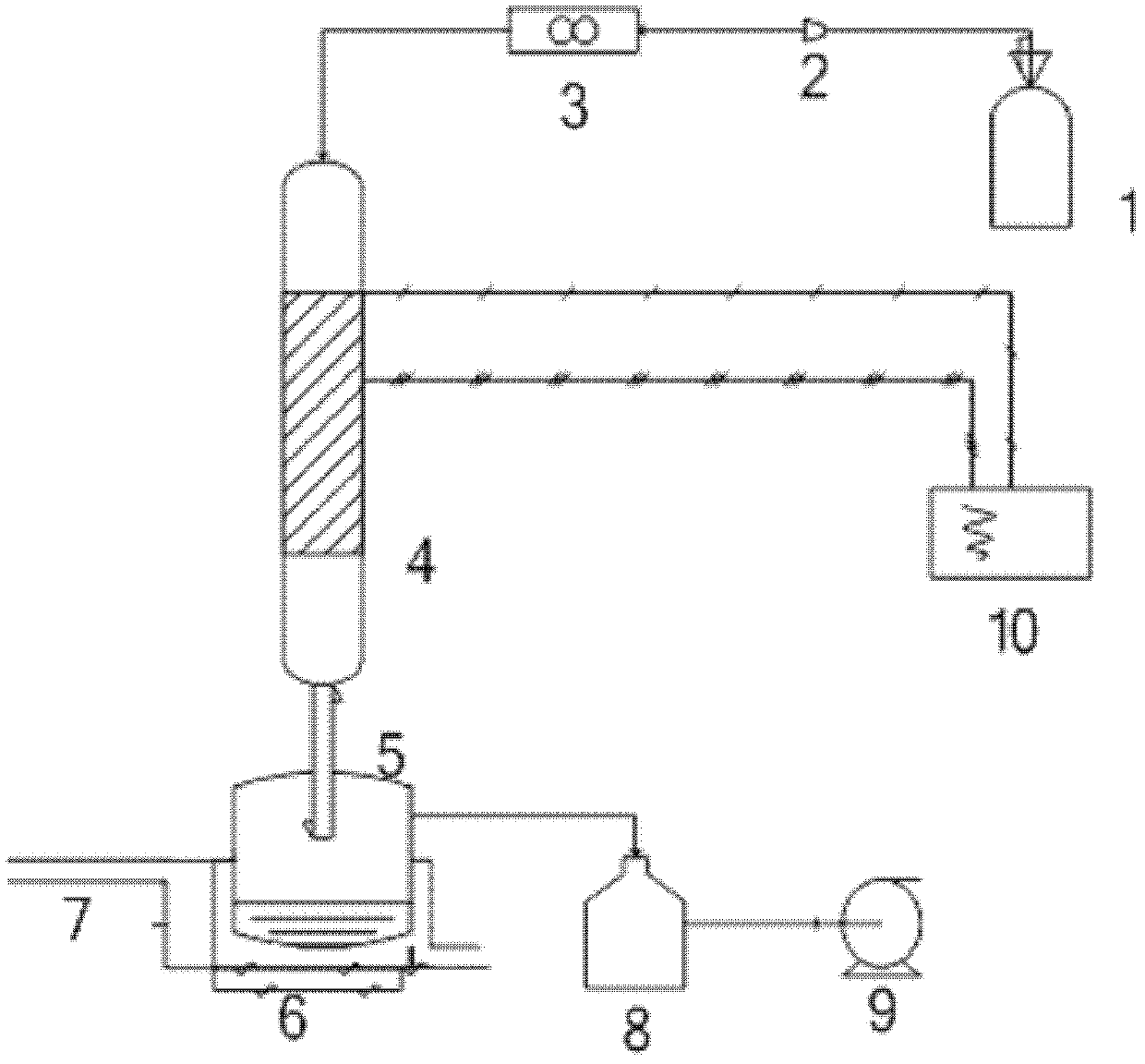

Method for coating micro/nano-metal powder by chemical vapor deposition

ActiveCN102581274ALow ignition temperatureShorter ignition delay timeChemical vapor deposition coatingThermal chemical vapor depositionIgnition delay

The invention discloses a method for coating micro / nano-metal powder by chemical vapor deposition, including: decomposing difluorocarbene precursor gas via a cracking pipe to generate difluorocarbene free radicals; contacting the generated difluorocarbene free radicals with micro / nano-metal powder, and due to polymerization between difluorocarbene free radicals, a compact polytetrafluoroethylene coating film is generated on the surface of micro / nano-metal powder. In allusion to disadvantages and defects of the application of micro / nano-metal powder in energy-containing materials, polytetrafluoroethylene is polymerized on the surface of metal powder by chemical vapor deposition in order to coat micro / nano-metal powder. In the invention, the ignition temperature of metal powder is effectively decreased, the ignition delay time is shortened, and the combustion speed of metal powder is improved; the surface of metal powder coated with polytetrafluoroethylene is highly hydrophobic, so that reactive metal powder can be effectively prevented from absorption of moisture and oxidation.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

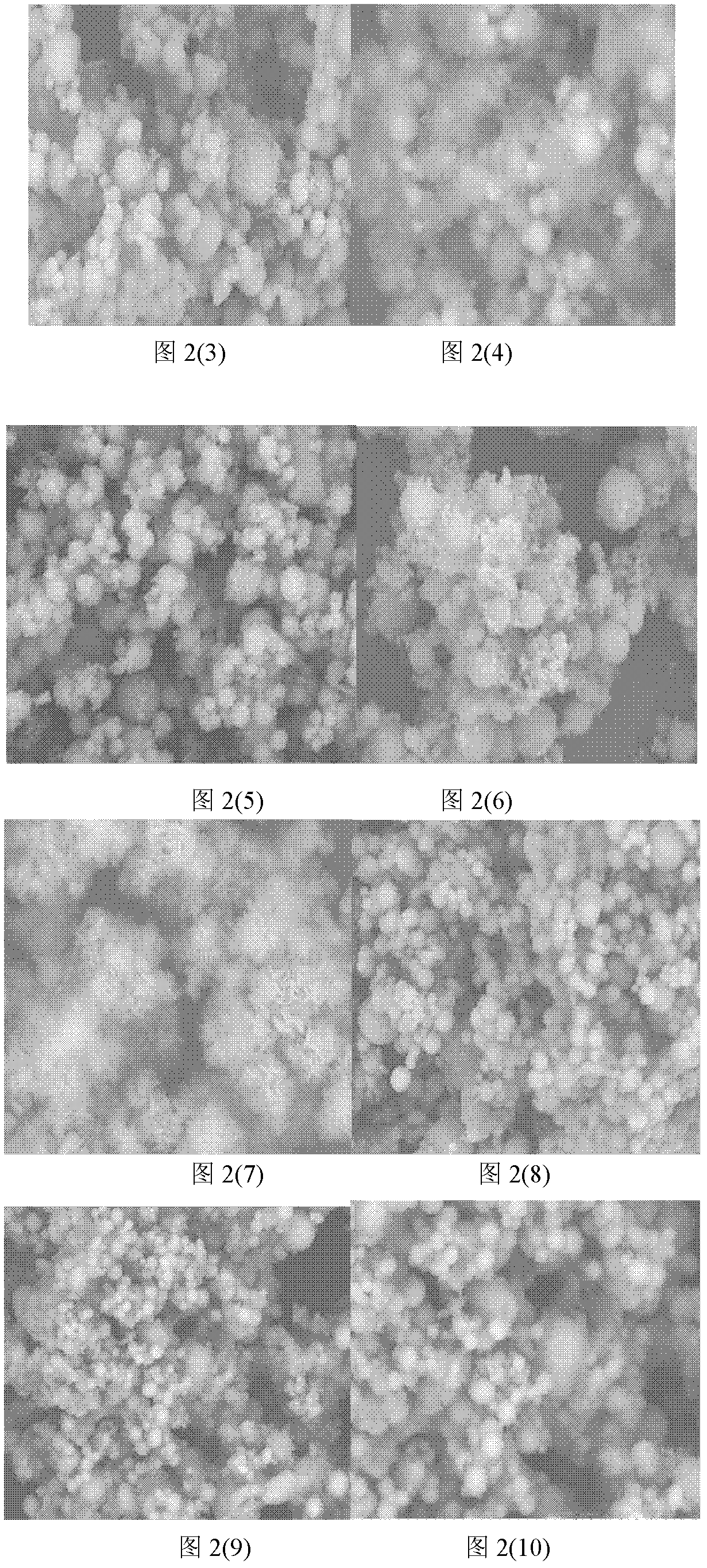

Process for producing cetane improvers from triglycerides

InactiveUS20010037598A1Good cetane boostReduce nitrogen contentOrganic chemistryLiquid carbonaceous fuelsAlcohol fuelNitration

Cetane improvers based on triglycerides and petroleum fractions are disclosed that are at least one half as effective as commercially sold cetane improvers. In each case, the cetane improvers are nitrates produced through the nitration of medium to long chain compounds containing a double bond. Applications include use with diesel and alcohol fuels intended for use in diesel engines. The nitrates have advantages due to their good performance relative to their nitrogen content. Observed properties of some products indicate they also have lubricity and / or detergency enhancing capabilities when used with diesel fuel.

Owner:UNIV OF KANSAS NON PROFIT EDUCATION INSTION THE

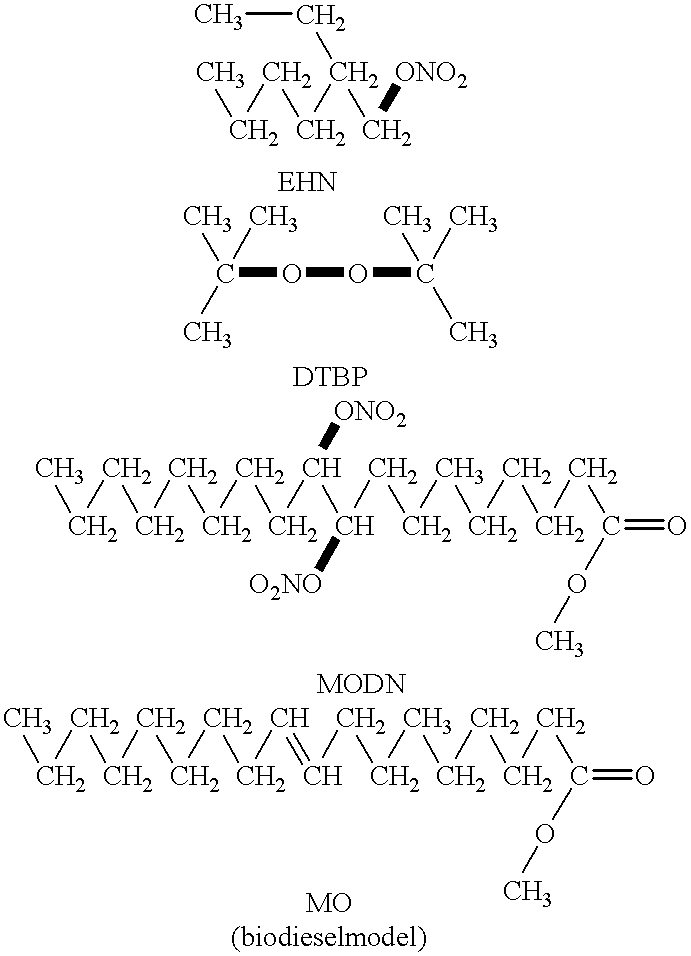

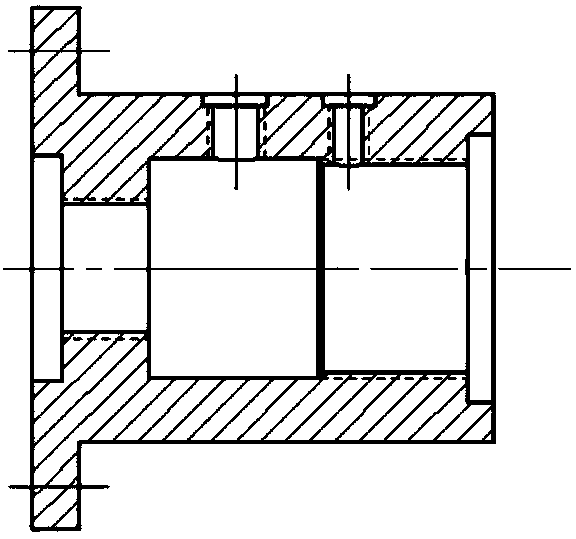

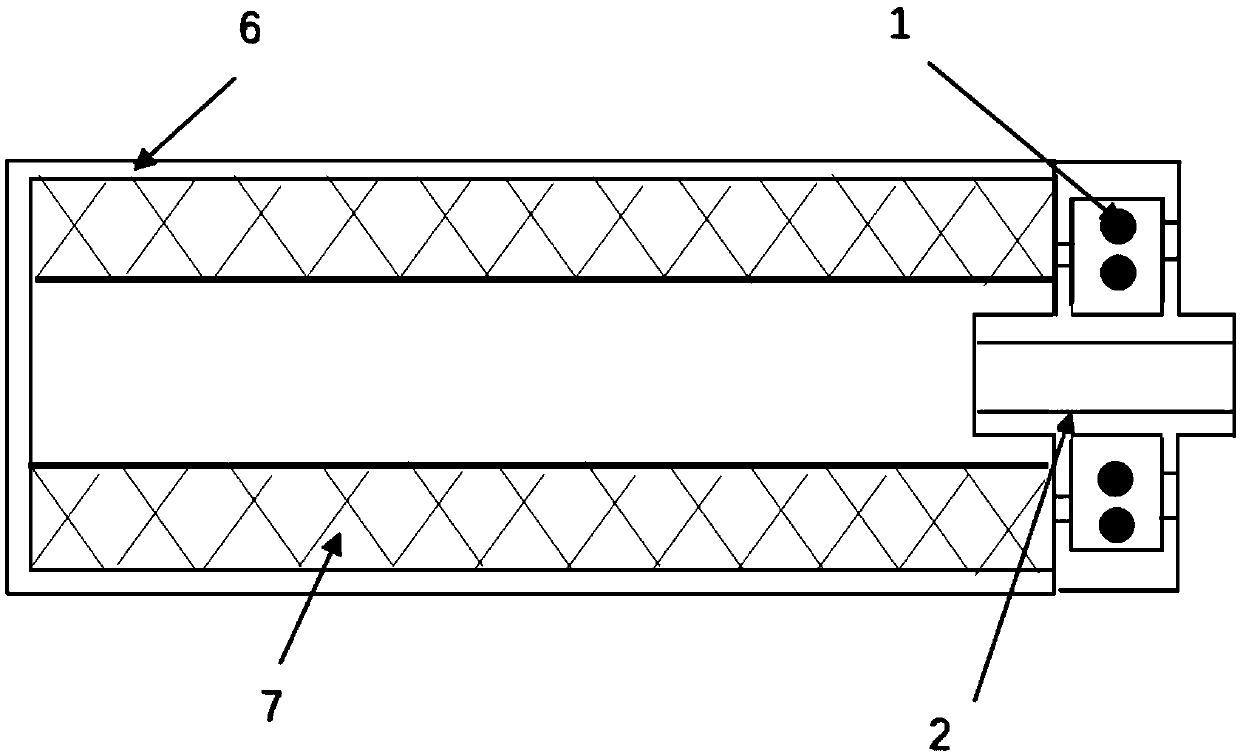

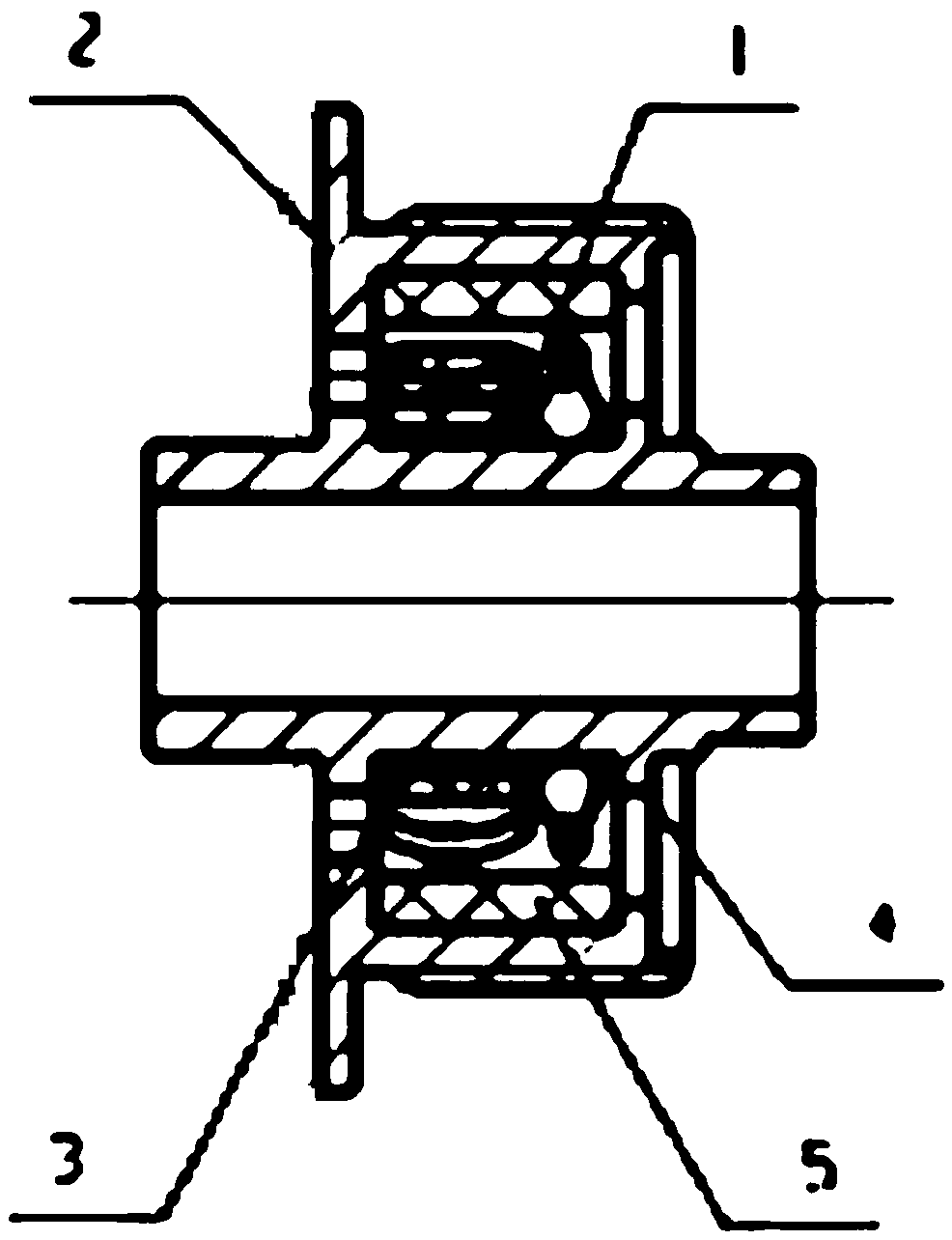

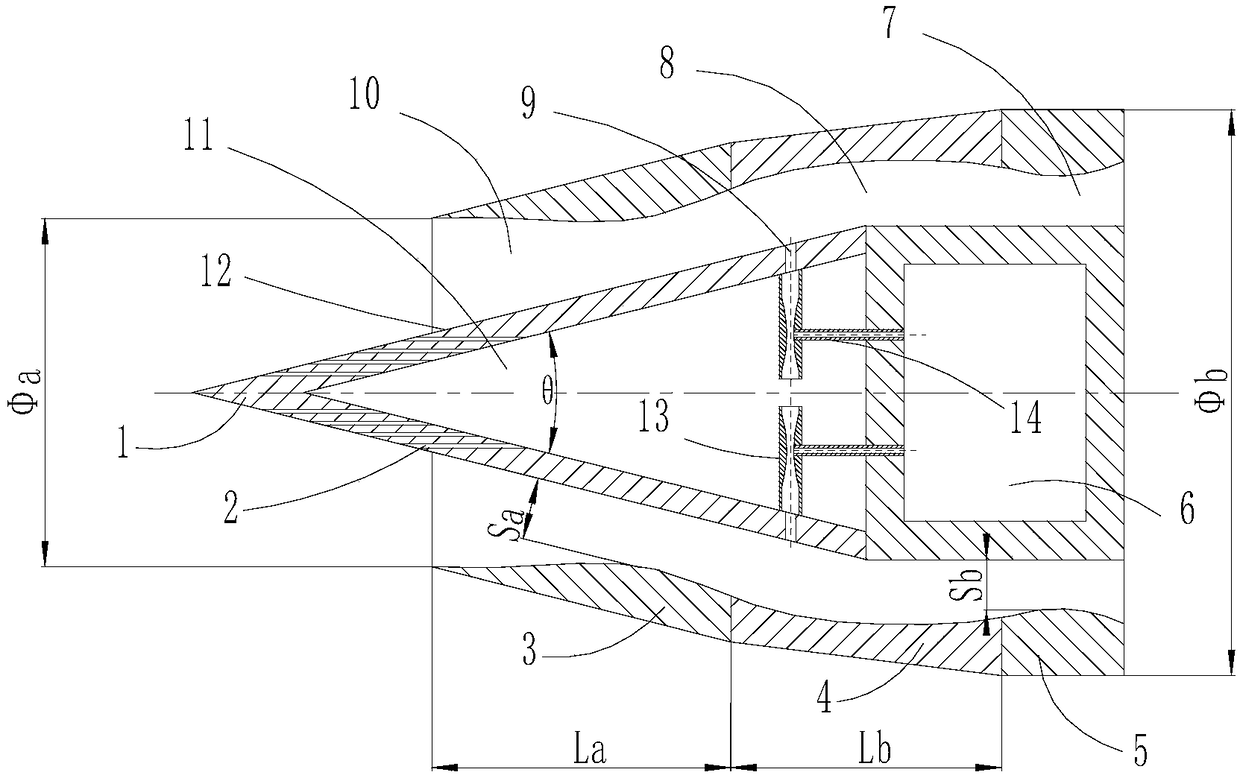

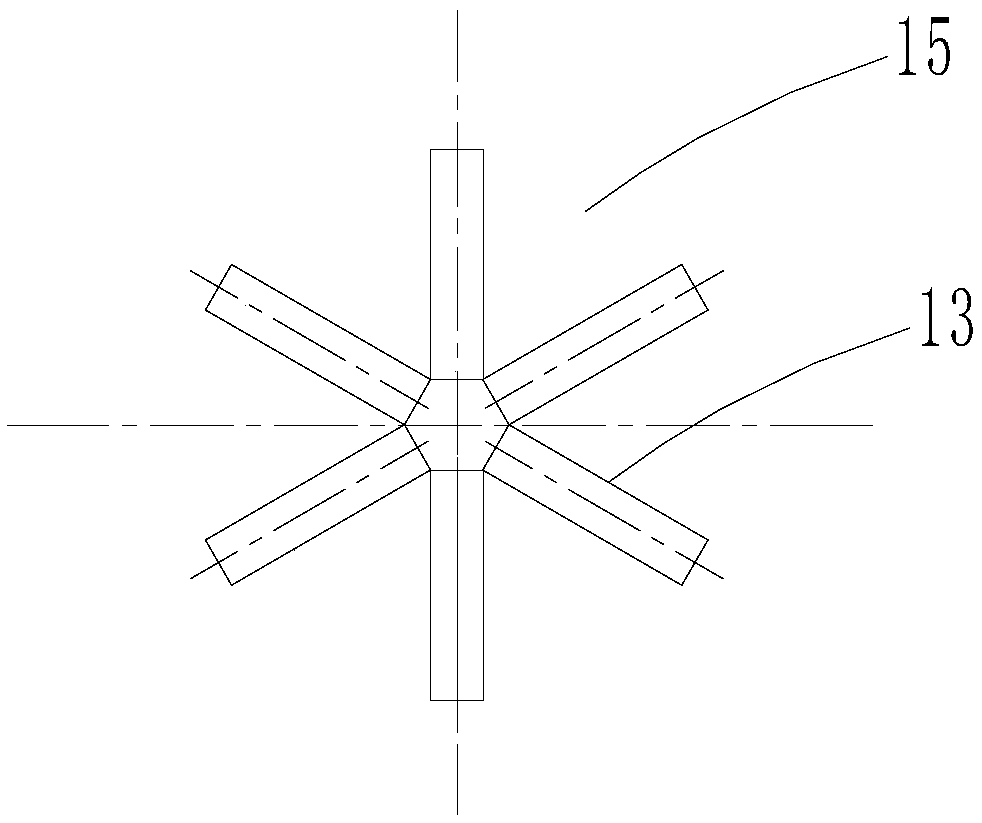

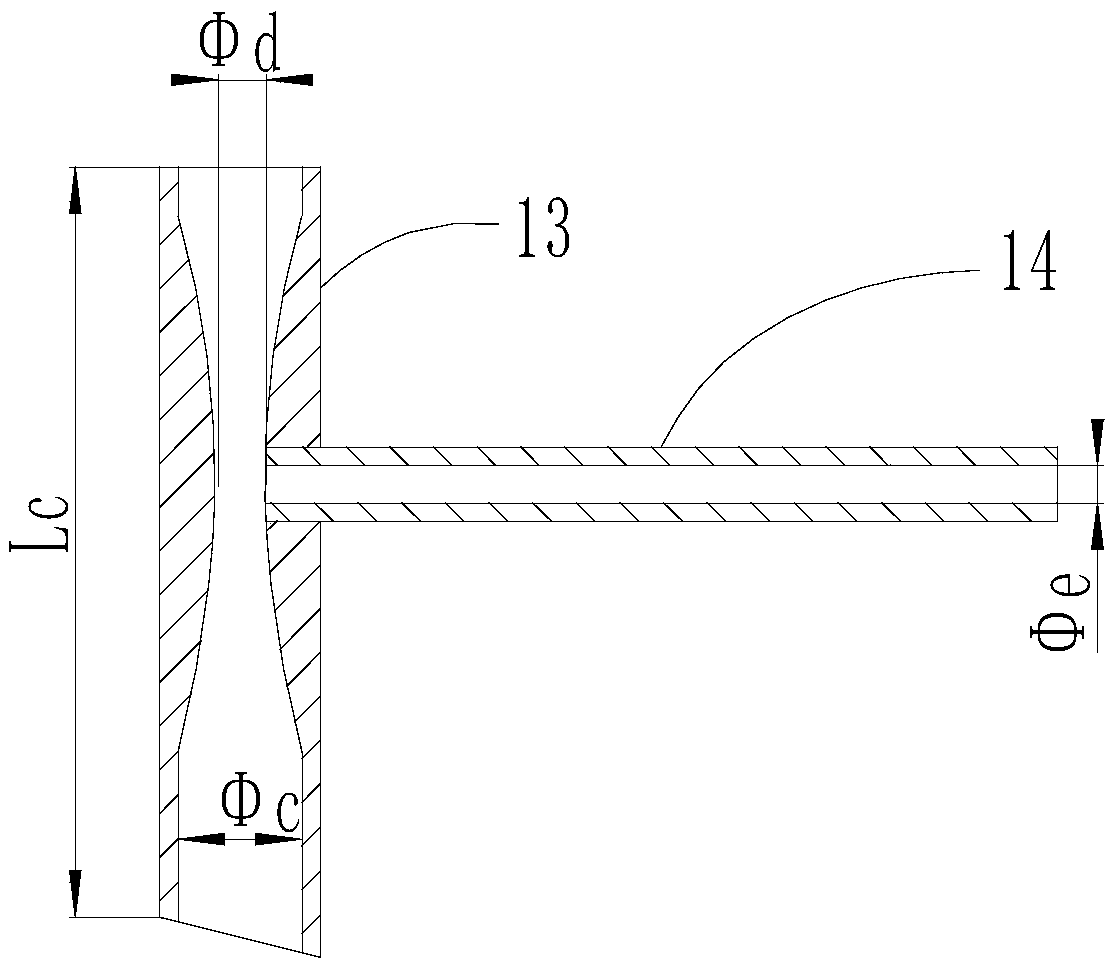

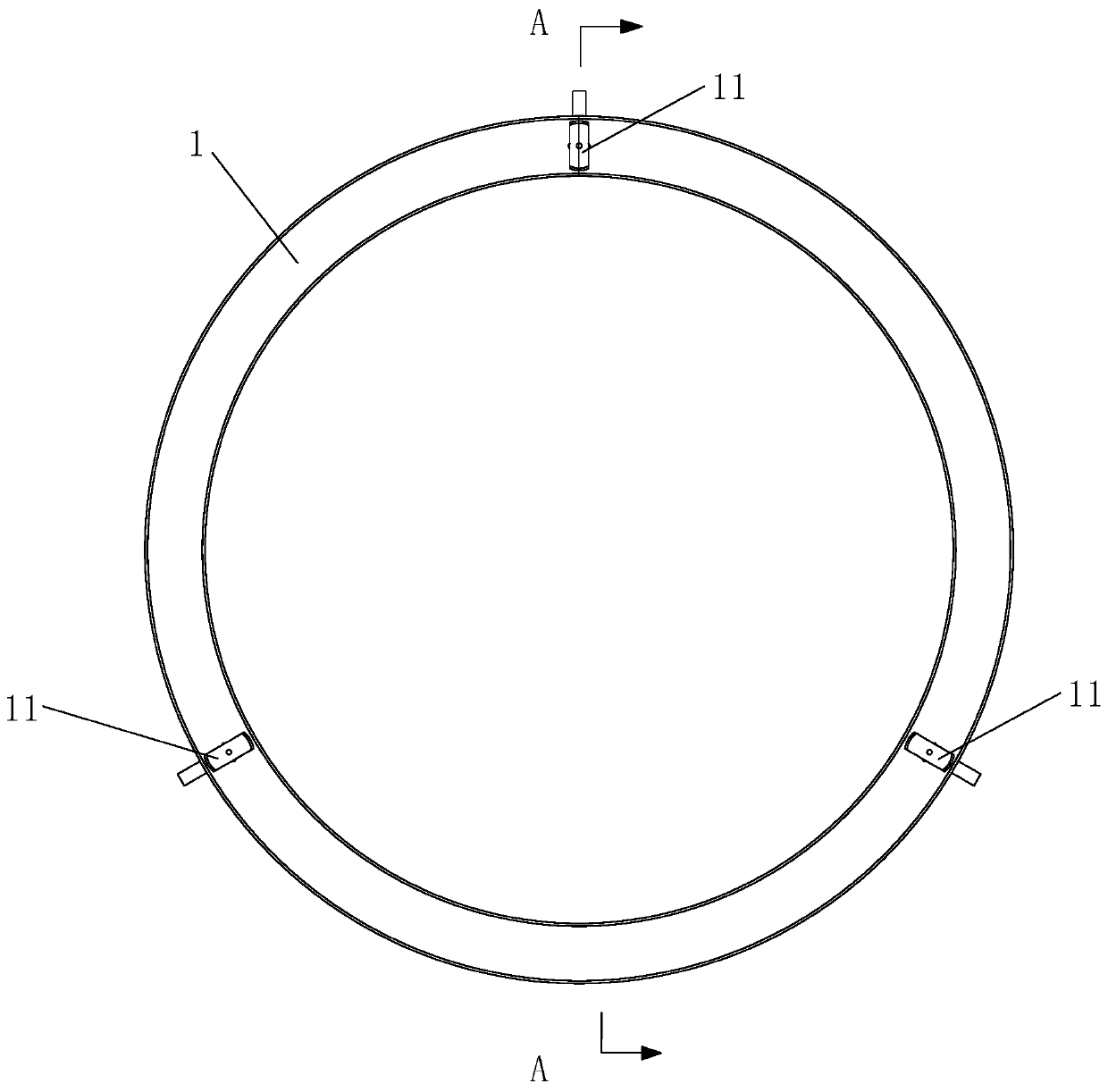

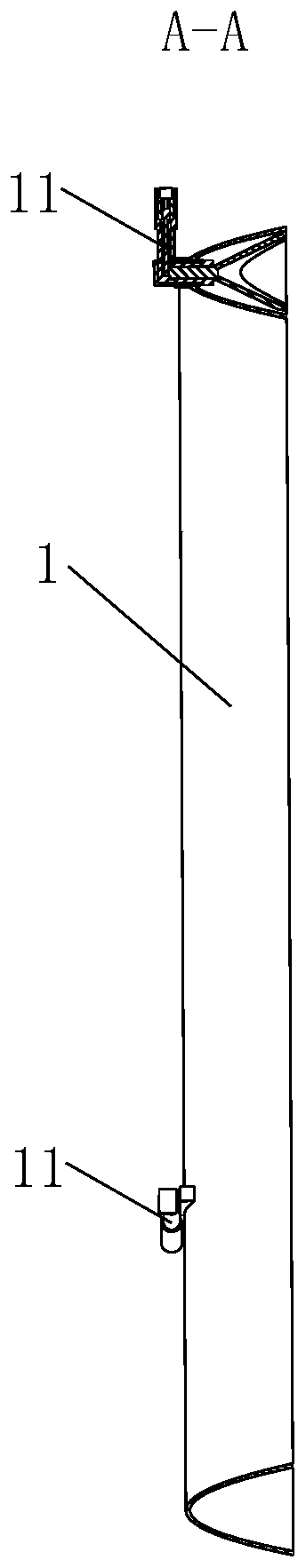

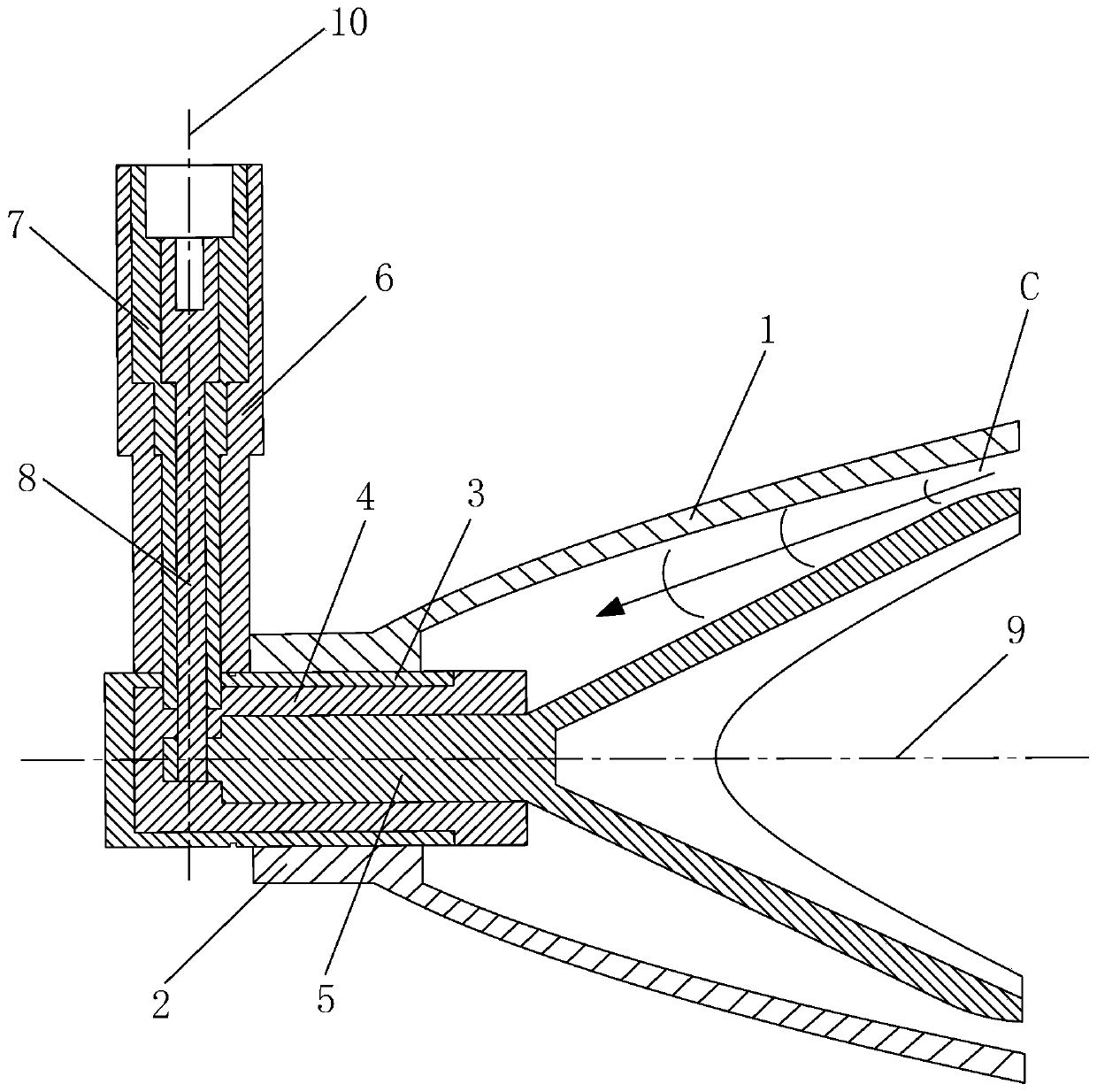

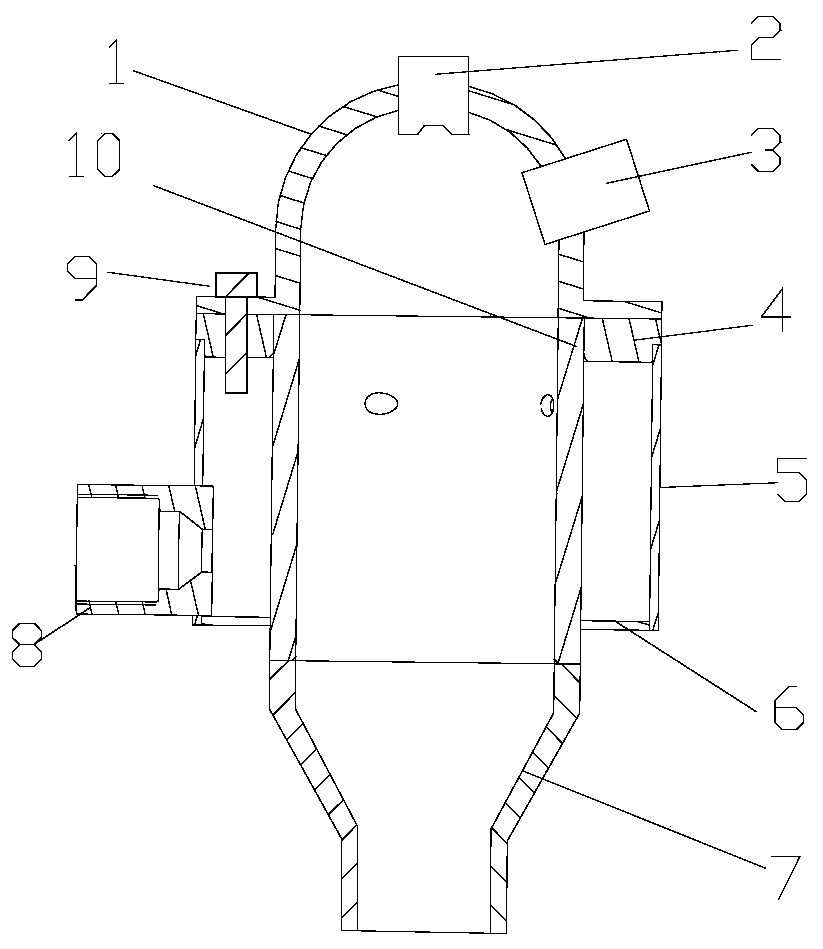

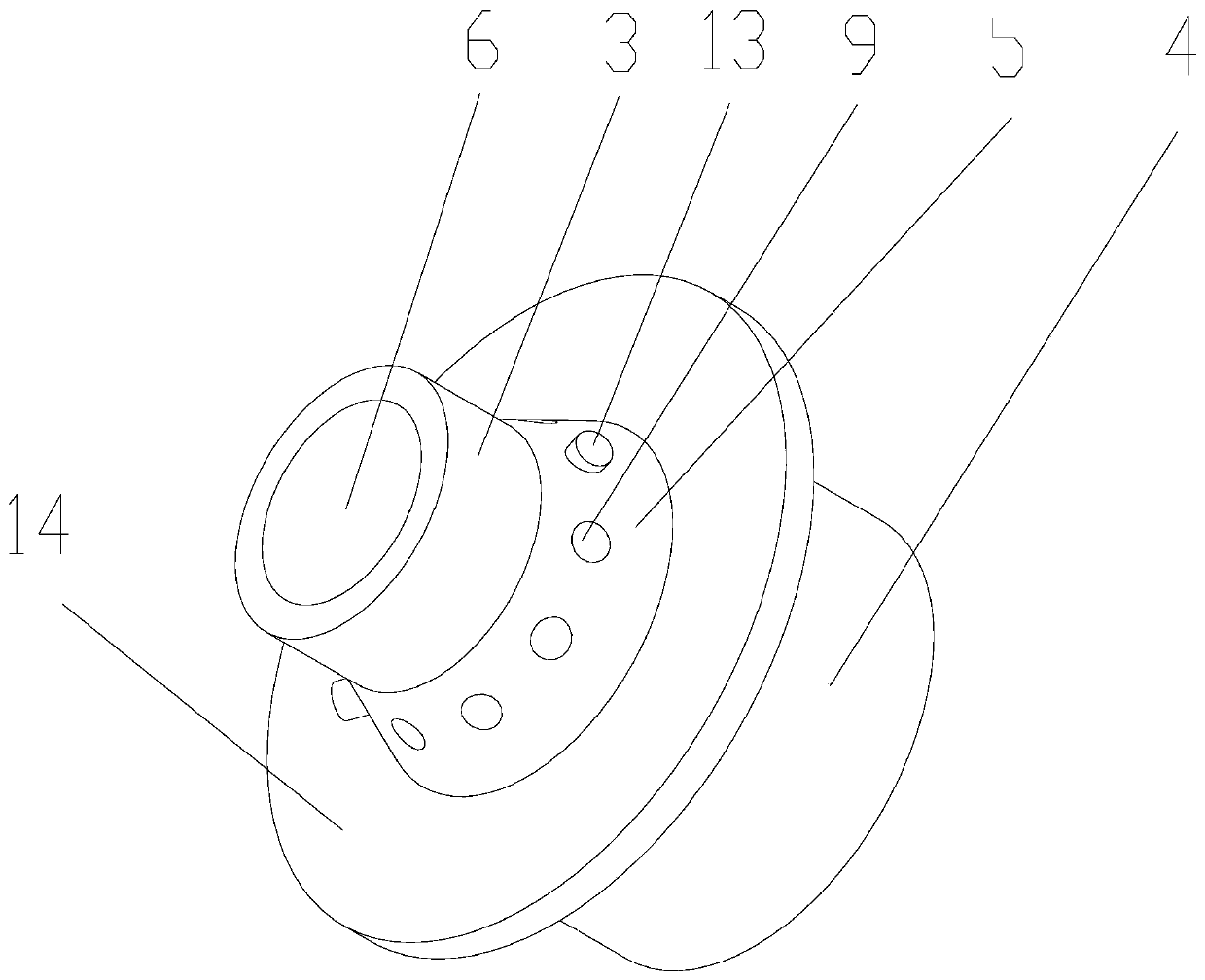

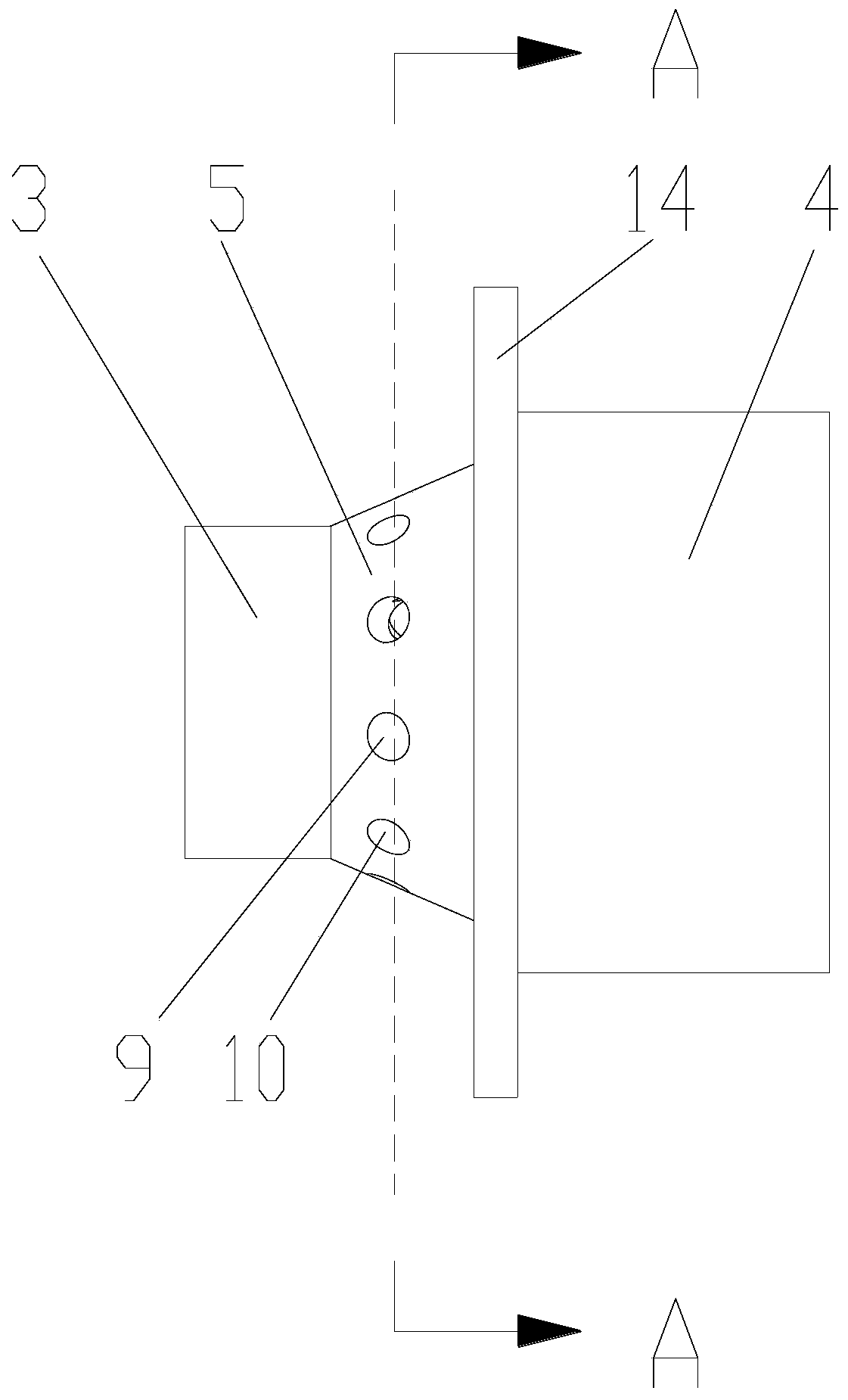

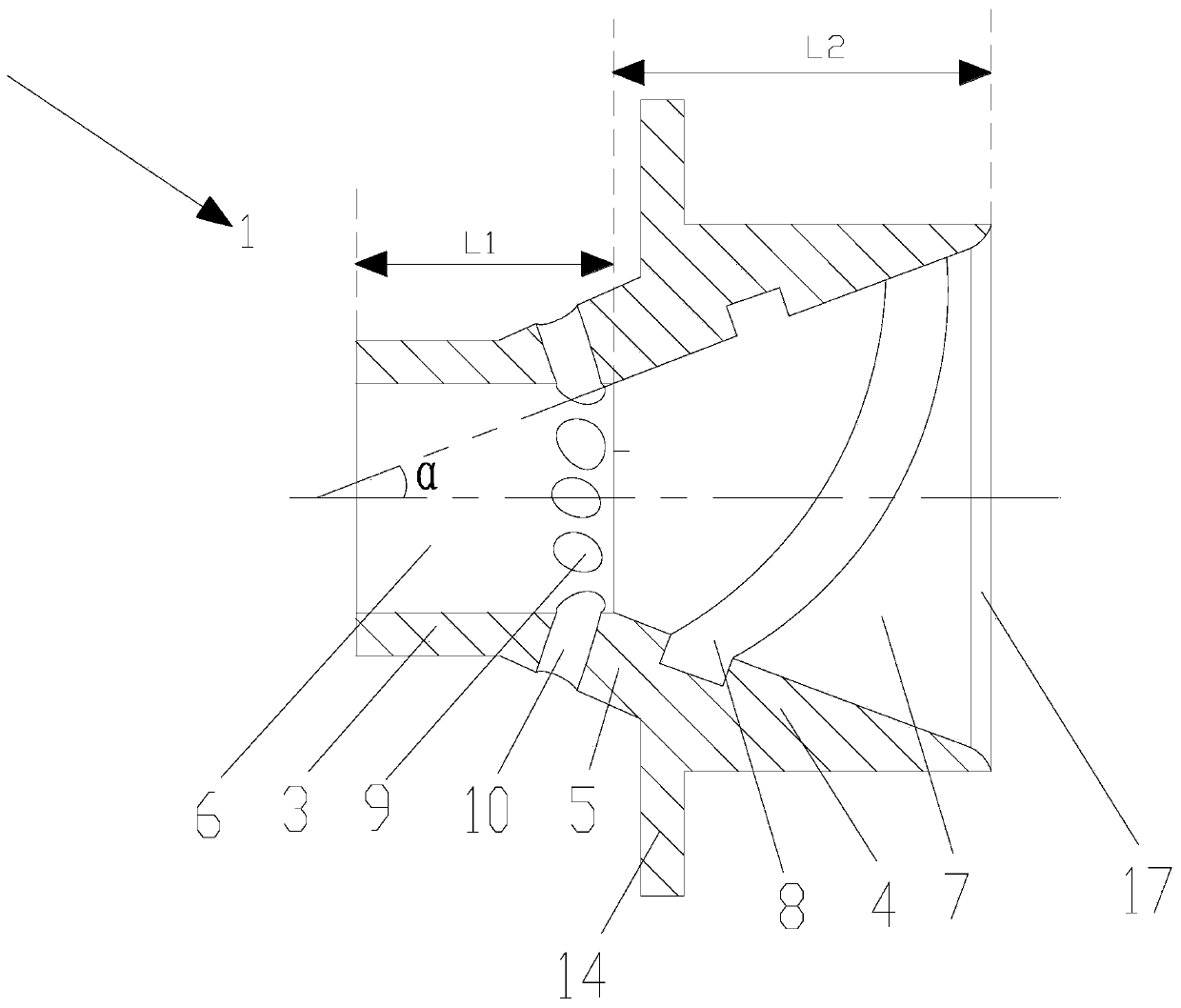

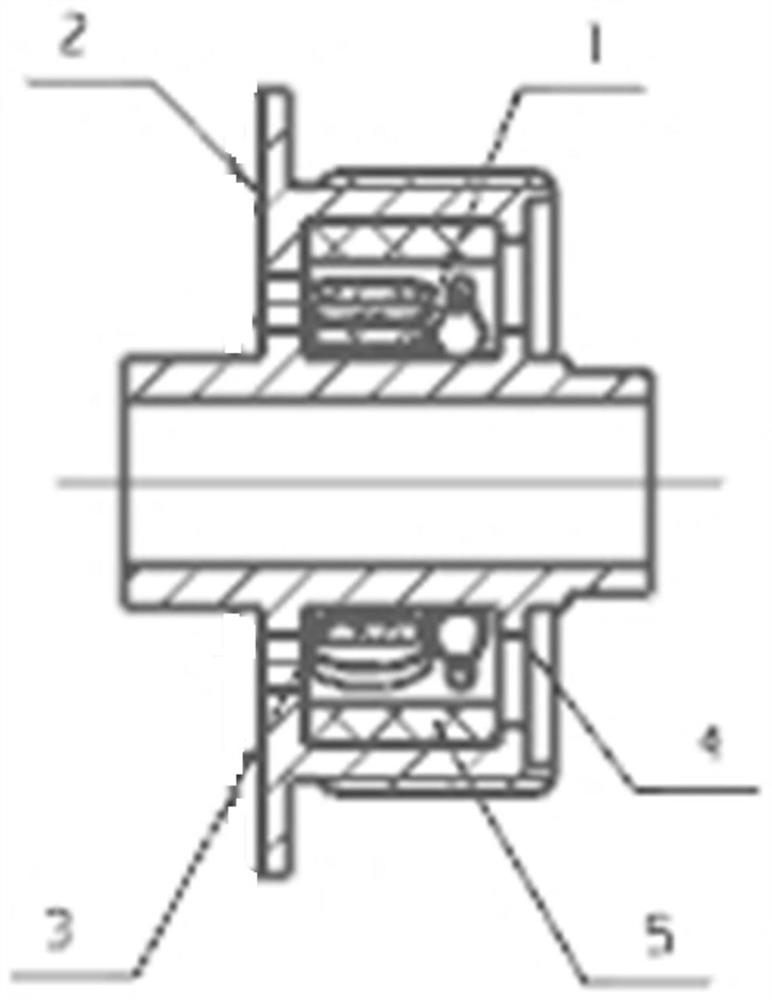

Sliding arc ignition device

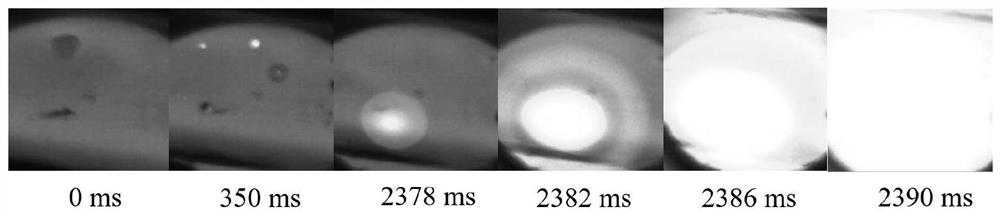

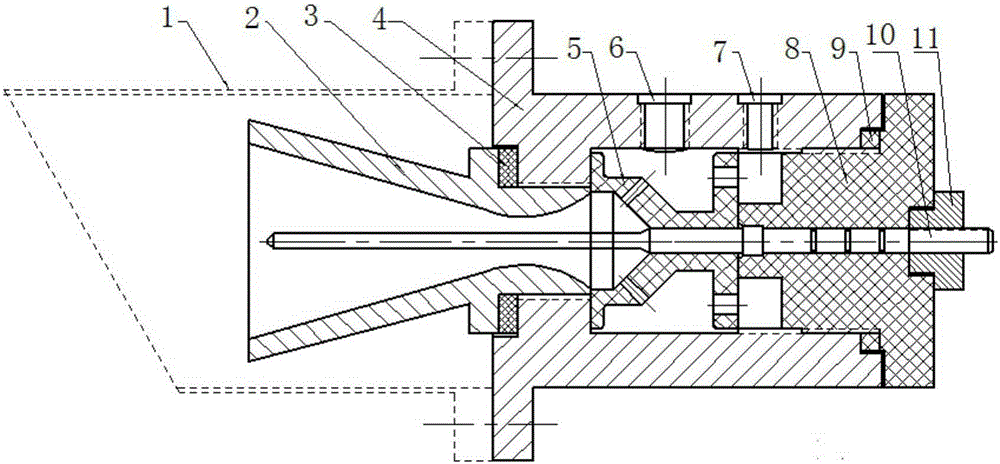

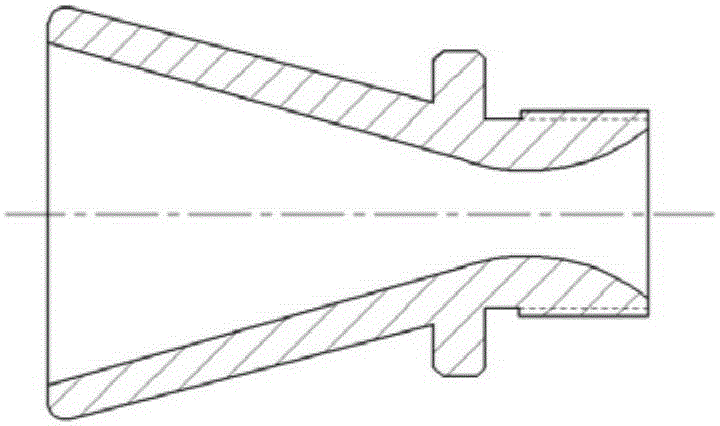

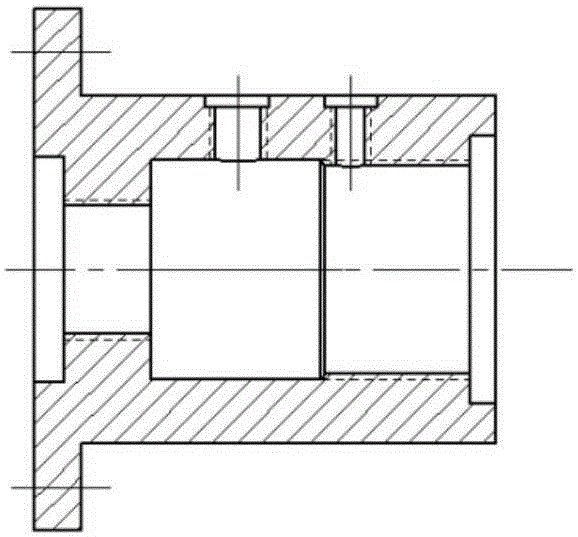

ActiveCN103925116AShorter ignition delay timePromote combustionGas turbine plantsRocket engine plantsFuel supplyIgnition delay

The invention discloses a sliding arc ignition device. The sliding arc ignition device comprises a contract-expansion type Laval nozzle, an outer shell, an air flow baffle, an electrode installation seat, a high-voltage anode and a locknut, wherein the contract-expansion type Laval nozzle and the electrode installation seat are fixed to the outer shell through threads, a hole is formed in a radial position of the outer shell, an air inlet connector is installed in the hole, the air flow baffle is clamped between the outer shell and the electrode installation seat, and the high-voltage anode is inserted into a central hole of the electrode installation seat, is stuck through sealants, is fixed through the locknut and is locked on the electrode installation seat. The sliding arc ignition device adopts an independent fuel inlet, the fuel supply can be increased after ignition succeeds, the fuel is catalyzed in a plasma region, and the functions of shortening ignition delay time and intensifying combustion are achieved. According to the design concept, a shell body serves as the installation base, machining difficulty is lowered, and when air flow baffles with different purposes are used, the air flow baffles can be placed in the outer shell without constraints, and assembling efficiency is improved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

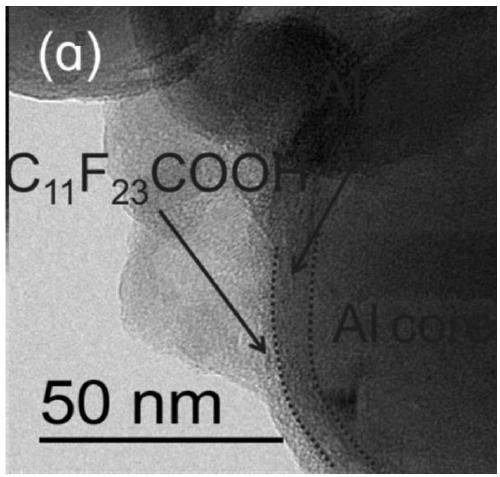

Aluminum powder surface self-activation method

InactiveCN109293463APrevent reoxidationRapid responseExplosive ingredient compoundingIgnition delayAluminium powder

The invention discloses an aluminum powder surface self-activation method. The method includes steps: adding aluminum powder into an anhydrous solvent, mixing, and stirring to disperse uniformly to form aluminum powder dispersion liquid; dissolving organic fluoride into a solvent to form organic fluorine solution, adding the organic fluorine solution into the aluminum powder dispersion liquid by acertain rate, and stirring to volatilize the solvent in which the organic fluoride is dissolved at a certain temperature, so that organic fluoride is slowly separated out by crystallization on the aluminum powder surface to form a compact surface activation layer; centrifugally separating to remove the solvent, washing, and performing vacuum drying at 60 DEG C to obtain organic fluorine surface self-activated aluminum powder. By forming of the organic fluorine self-activation layer on the aluminum powder surface, the aluminum powder ignition temperature can be effectively lowered while ignition delay time is shortened, combustion efficiency of aluminum powder in oxidants is improved while the energy releasing rate is increased, and the organic fluorine surface activation layer is effective in aluminum powder oxidation, so that stability is improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Combustion device

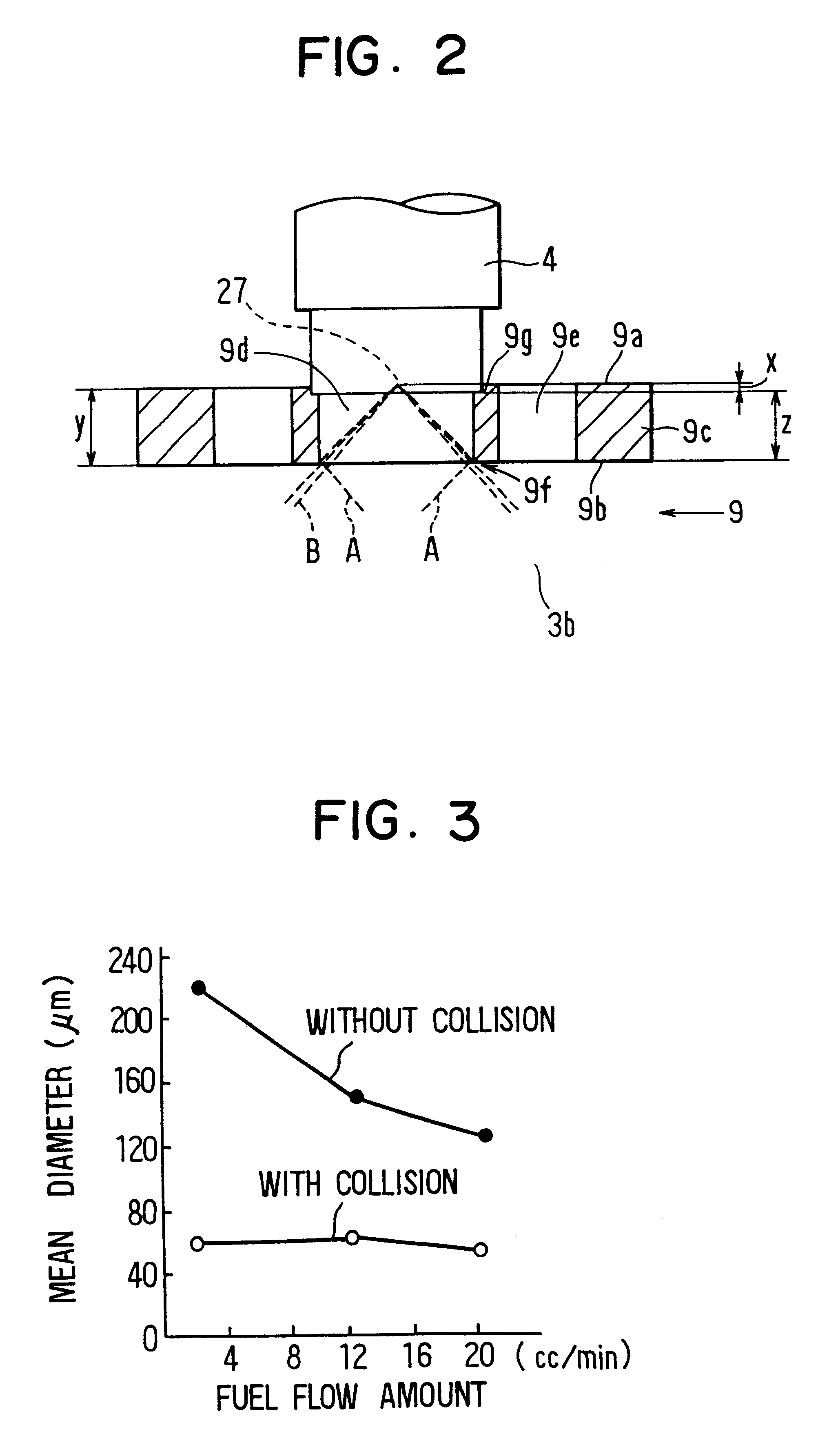

InactiveUS6402505B1Mixing performanceImprove performancePulsating combustionSpecial fuel supply arrangementsCombustion chamberFuel injection

In a combustion unit, a fuel collision member is disposed between a fuel injection valve and a combustion chamber. The fuel collision member is positioned so that, a part of fuel injected from said fuel injection valve is introduced into the combustion chamber while colliding with the fuel collision member, and the other part of fuel is directly introduced into the combustion chamber without colliding with the fuel collision member. Thus, fuel introduced into the combustion chamber is atomized while being introduced into the combustion chamber in a wide range.

Owner:DENSO CORP

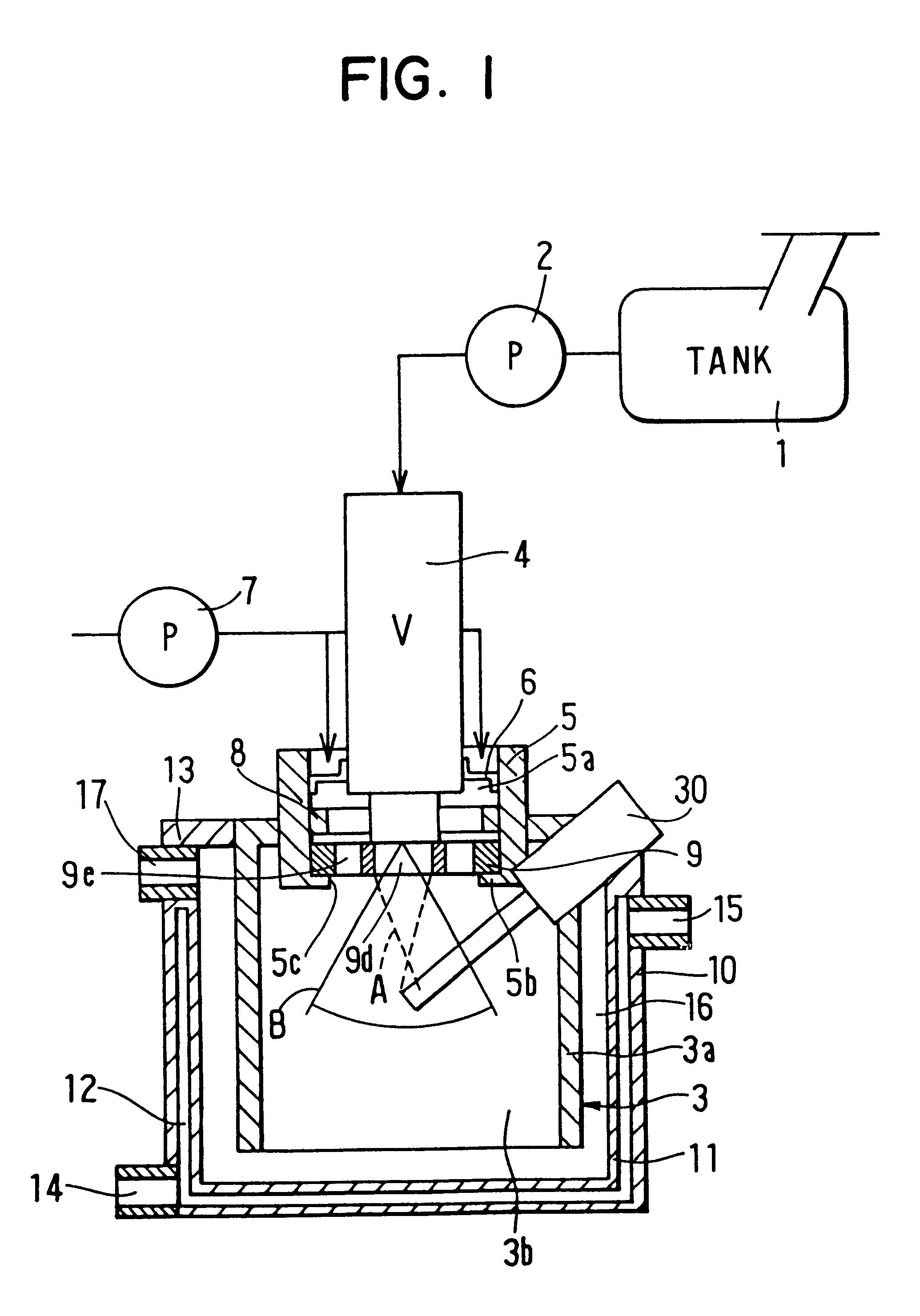

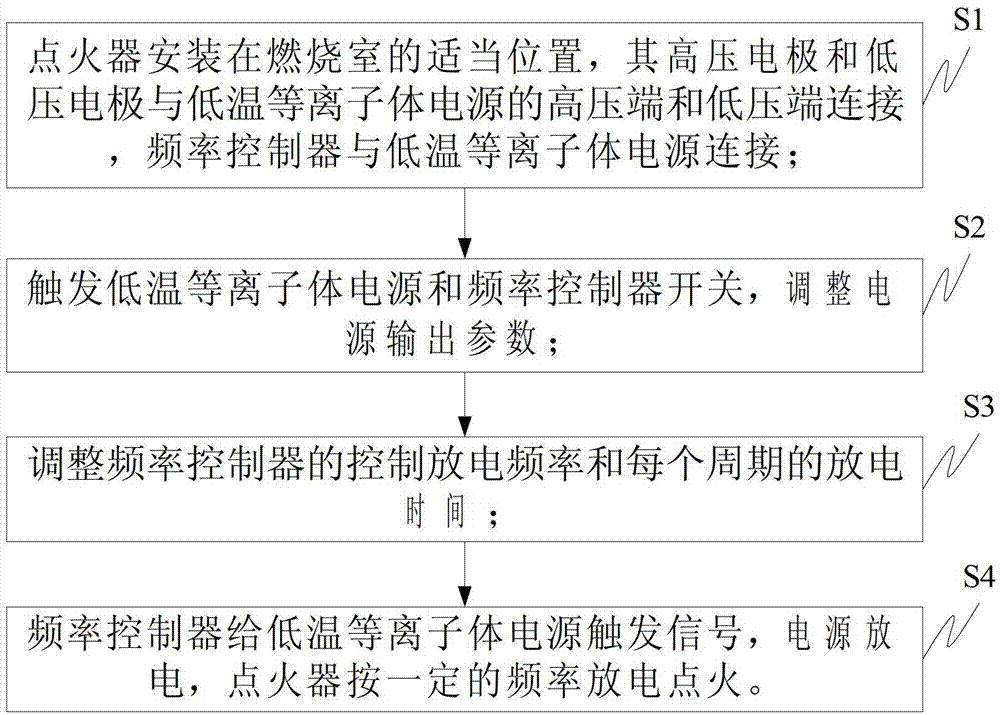

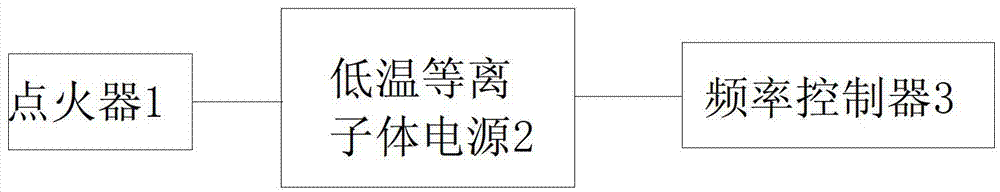

Periodic alternating current drive low-temperature plasma ignition method and system

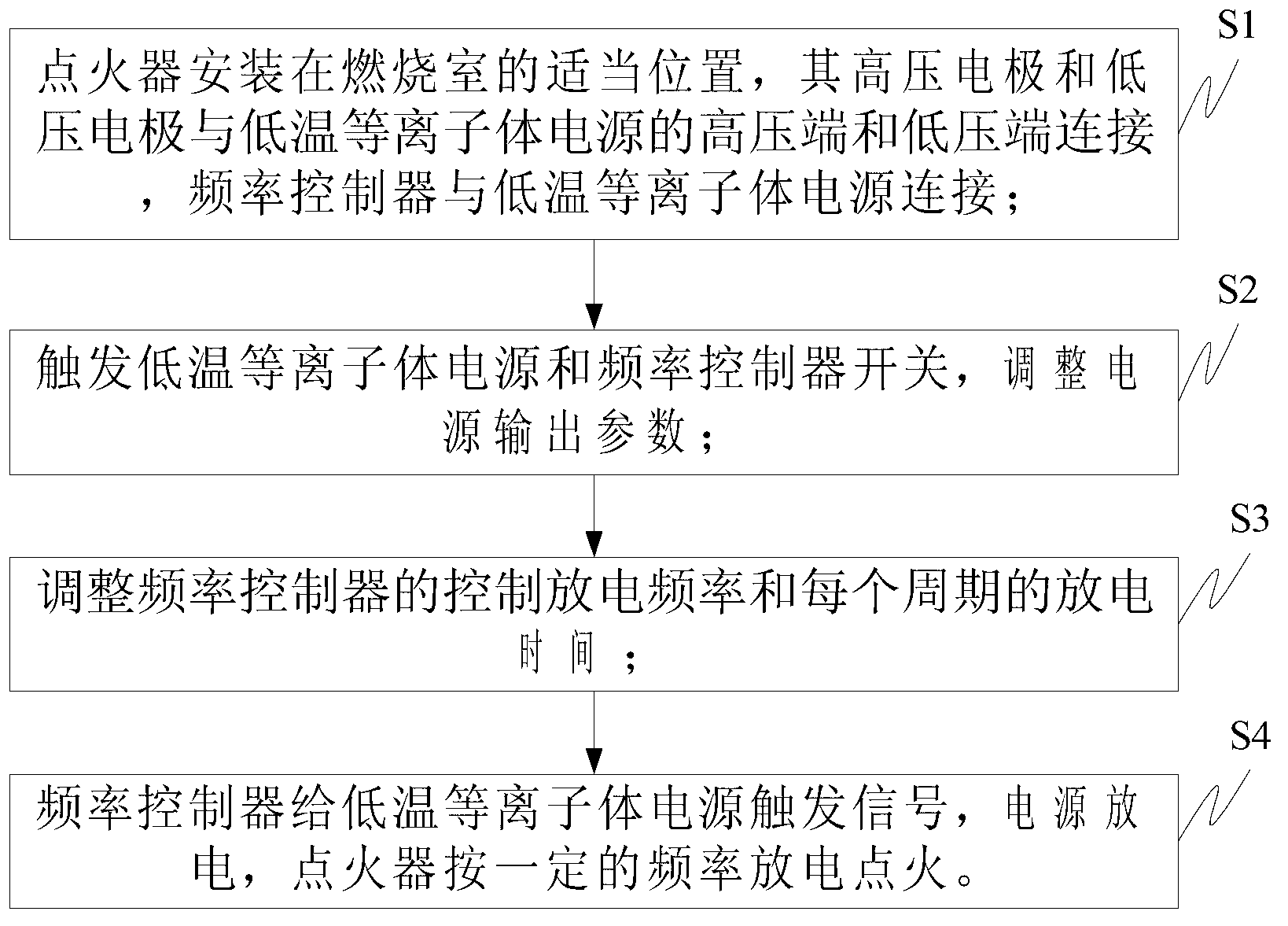

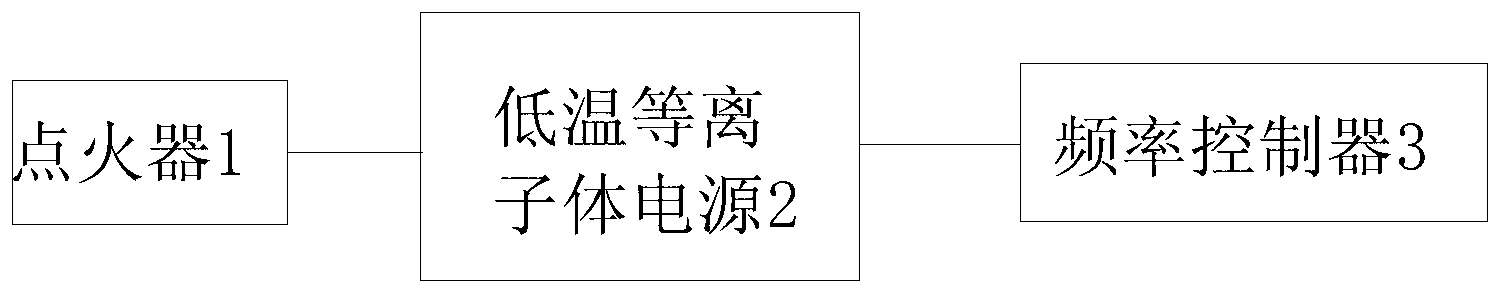

InactiveCN102705108AImprove performanceRealize large volume ignitionIntermittent jet plantsRocket engine plantsPeriodic alternatingCombustion chamber

The invention discloses a periodic alternating current drive low-temperature plasma ignition method and a periodic alternating current drive low-temperature plasma ignition device, an relates to the technical field of aerospace engine ignition, combustion and propulsion. The method comprises the following steps of: arranging an ignitor at a proper position of a combustion chamber, wherein a high voltage electrode and a low voltage electrode of the ignitor are connected with a high voltage end and a low voltage end of a low-temperature plasma power source, and a frequency controller is connected with the low-temperature plasma power source; triggering the low-temperature plasma power source and a frequency controller switch and adjusting power output parameters; adjusting control discharge frequency of the frequency controller and discharge time of each period; and providing a trigger signal to the low-temperature plasma power source by the frequency controller, discharging by the power source, and discharging to ignite according to certain frequency by the ignitor. The invention also discloses the corresponding periodic alternating current drive low-temperature plasma ignition device. The method and the device have the advantages of large-size ignition, capabilities of shortening ignition delay time, realizing high-efficiency reliable ignition in the aspects of high-altitude low-voltage supersonic speed combustion, lean burn and the like and improving the performance of an engine, industrial energy conservation and emission reduction.

Owner:PEKING UNIV

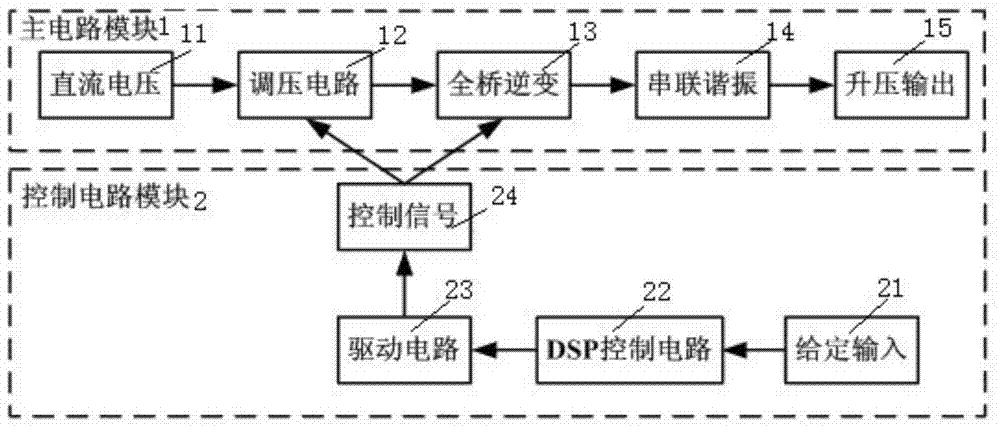

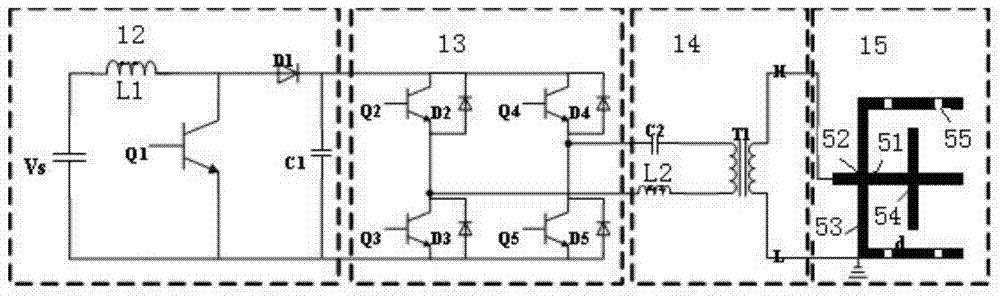

Low-temperature-plasma ignition power supply and ignition system

ActiveCN105201657AMeet ignition requirementsShorter ignition delay timeGas turbine plantsRocket engine plantsDigital signal processingOn board

The invention discloses a low-temperature-plasma ignition power supply. The low-temperature-plasma ignition power supply comprises a main circuit module and a control circuit module, wherein the main circuit module comprises a direct-current power supply, a voltage regulating circuit, a full-bridge inverter circuit, a series resonance circuit and a step-up output circuit which are sequentially connected, and the control circuit module comprises a given input control, a DSP (Digital Signal Processing) control circuit, a driving circuit and a control signal which are sequentially connected and is used for supplying control signals to a voltage regulating circuit switch and a full-bridge inversion switch in the main circuit module. A low-temperature-plasma ignition system is further disclosed and consists of the low-temperature-plasma ignition power supply and a boss discharge load. According to the power supply and the system, the low-temperature-plasma ignition power supply can generate low-temperature plasma according to certain frequency and pulse width; the energy consumption is low; the efficiency of ignition is high; laboratory power supplies are wide in parameter range and are adjustable; on-board power supplies are fixed in parameters; the size is small; the reliability is high, and thus the requirement of an engine for ignition is met.

Owner:PEKING UNIV

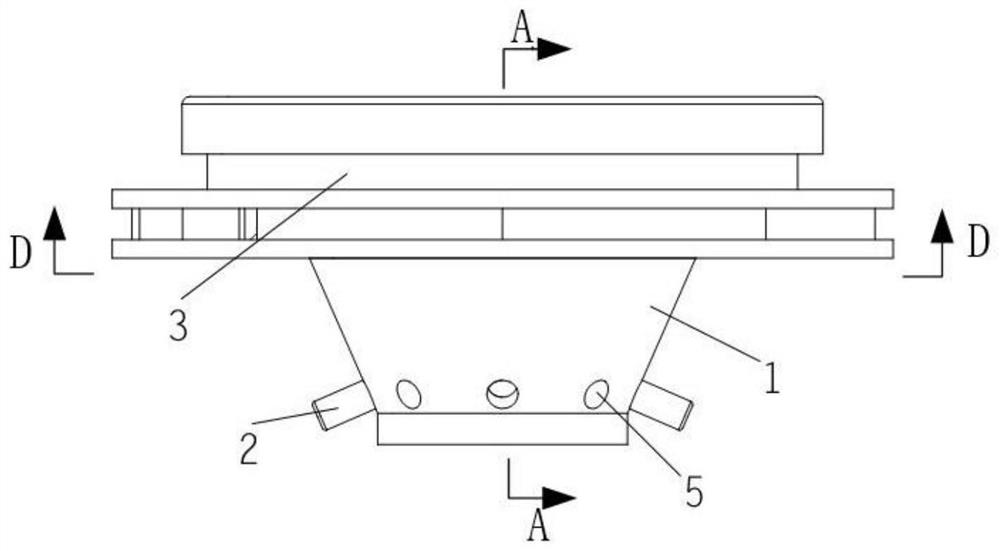

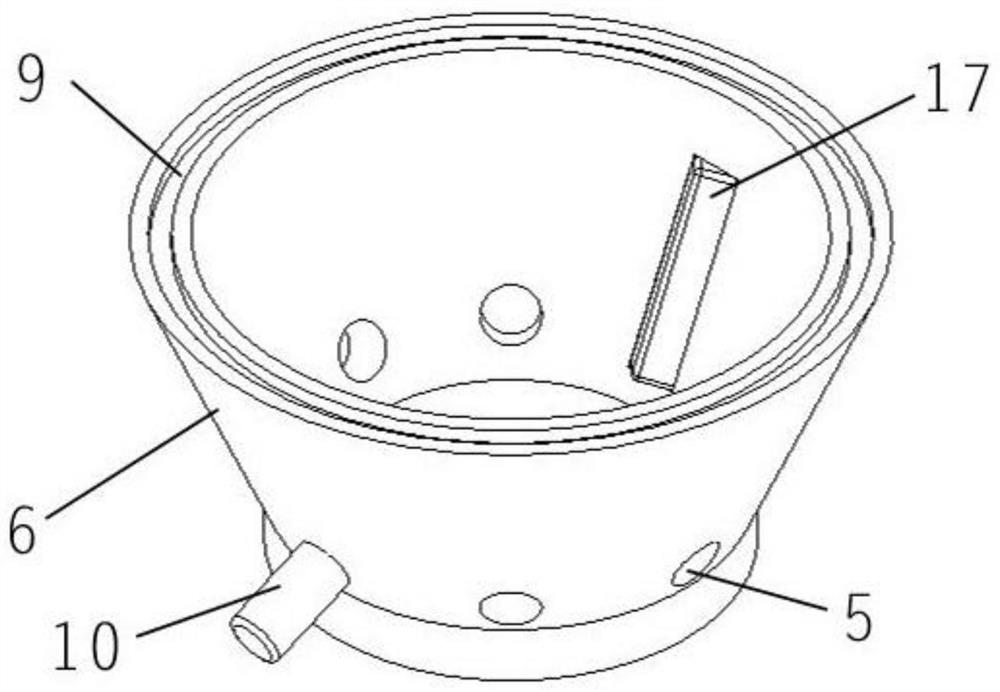

Filamentous arc plasma exciter based on swirl holes

ActiveCN111734532ASimple structureThe effect is obviousGas turbine plantsJet propulsion plantsCombustion chamberEngineering

Provided is a filamentous arc plasma exciter based on swirl holes. An inner layer plasma swirler and an outer layer swirler are of a split type structure. The plurality of swirl holes are evenly distributed in a shell body of the inner layer plasma swirler. Two to five electrodes are disposed in the swirl holes through electrode installing bases correspondingly and divide the circumference of theshell body of the inner layer plasma swirler into n equal-length arc sections. The outer layer swirler is disposed on the upper end face of the inner layer plasma swirler. The filamentous arc discharge as one type of plasma discharge has huge advantages in the aspect of ignition and combustion supporting of a combustion chamber of an aero-engine, and the plasma exciter is combined with the head portion of the combustion chamber, so that ignition and combustion supporting can be integrated, and meanwhile active particles generated by plasma discharge are easily mixed with fuel oil molecules. The filamentous arc plasma exciter overcomes the defect that sliding arc plasmas cannot realize discharging when an inlet air flow rate is 0, improves combustion efficiency, is simple in structure and does not need to be equipped with a special air supply system or a special oil supply system.

Owner:AIR FORCE UNIV PLA

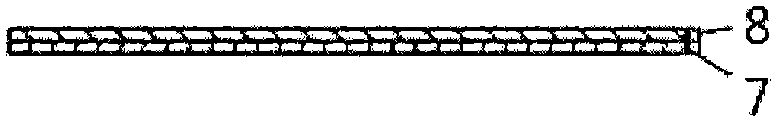

Palladium-ruthenium/aluminum-magnesium composite metal wire and preparation method thereof

The invention provides a palladium-ruthenium / aluminum-magnesium composite metal wire and a preparation method thereof. The composite metal wire takes a palladium-ruthenium alloy as a clad material and takes an aluminum-magnesium alloy as an inner core material. A preparation process comprises the following steps of: I, smelting the palladium-ruthenium alloy, and performing ingot casting to obtain a pipe blank; II, smelting the aluminum-magnesium alloy, and performing ingot casting to obtain a bar material; III, performing cold rolling and cold drawing on the pipe blank to obtain a palladium-ruthenium alloy pipe; IV, preparing aluminum-magnesium alloy filaments by cold drawing; V, continuously introducing the aluminum-magnesium alloy filaments into the palladium-ruthenium alloy pipe to obtain a blank piece; VI, swaging the blank piece to obtain a composite metal wire; and VII, performing cold drawing on the composite metal wire to obtain the palladium-ruthenium / aluminum-magnesium composite metal wire of a required size. The prepared palladium-ruthenium / aluminum-magnesium composite metal wire has high alloy reaction performance, and can be applied to a detonating cord of a detonator or an ignition device of an engine.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

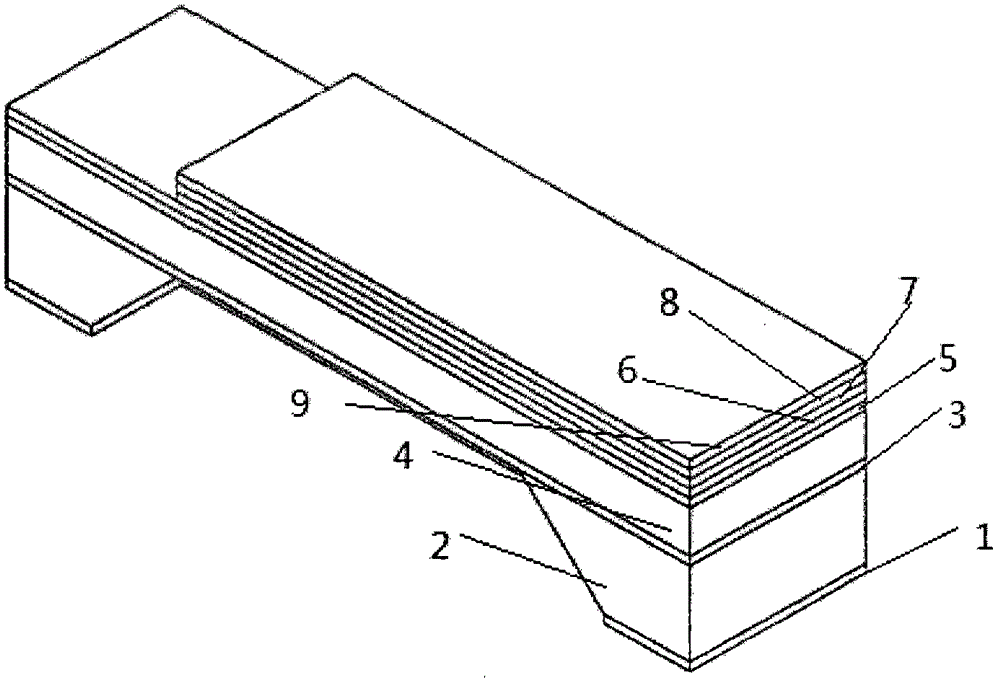

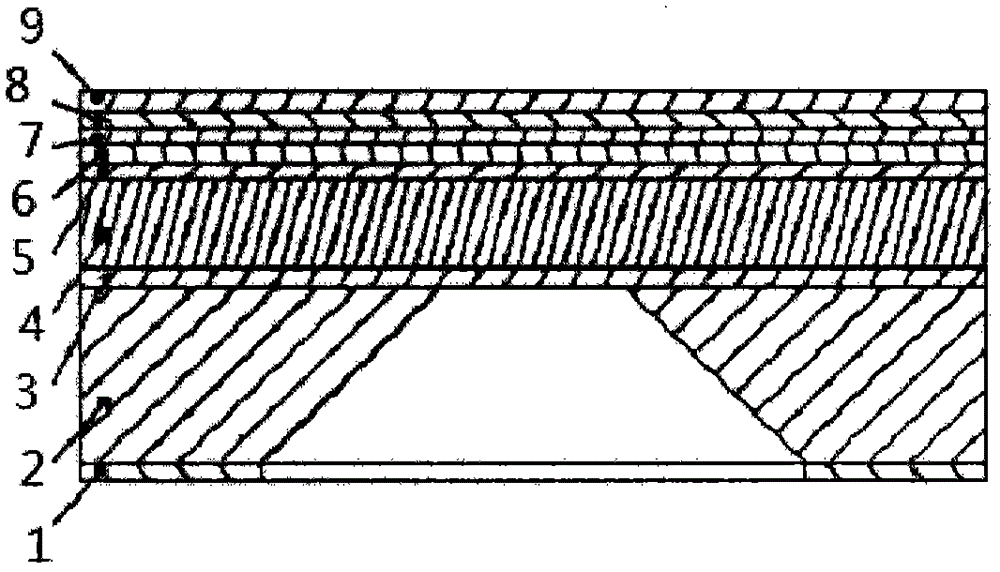

Energy containing metal bridged-film MEMS (Micro Electro Mechanical Systems) igniter and preparation method thereof for composite black body like energy concentrated structure

InactiveCN104692318AReduce heat lossImprove ignition performanceTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesSecondary radiationIgnition delay

The invention discloses an energy containing metal bridged-film MEMS (Micro Electro Mechanical Systems) igniter and a preparation method thereof for a composite black body like energy concentrated structure. The energy containing metal bridged-film MEMS igniter sequentially comprises a silicon dioxide base layer, a chamber layer, a leak-proof silicon dioxide layer, a secondary radiation layer, an insulating secondary radiation layer, a lower electrode gold layer, a cupric oxide layer, an aluminum layer, an upper electrode gold layer from bottom to top; the silicon dioxide base layer, the chamber layer, the leak-proof silicon dioxide layer and the secondary radiation layer form into the black body like energy concentrated structure; the structure of a middle chamber of the chamber layer is in a hollow cone shape to concentrate energy, reduce integral device heat capacity and enable the secondary radiation layer to suspend; the cupric oxide layer and the aluminum layer form into the energy containing metal bridged-film. According to the energy containing metal bridged-film MEMS igniter, heat dissipation of the energy containing metal bridged-film MEMS igniter is reduced and ignition output is improved due to addition of the black body like energy concentrated structure; the heat accumulation time is shortened and accordingly the ignition delay time is reduced and the ignition instant performance is improved; concentration is beneficial due to the fact that micromachining is easy to achieve.

Owner:ZHONGBEI UNIV

Pulse detonating combustion chamber and air turbine rocket engine based on pulse detonating

PendingCN111305972AReduce weightReduced pressurization capacity requirementsIntermittent jet plantsRocket engine plantsCombustion chamberMetallic aluminum

The invention discloses a pulse detonating combustion chamber and an air turbine rocket engine based on pulse detonating. The pulse detonating combustion chamber adopts an internal jet-flow tube ignition detonating way, and has better efficiency and feasibility in comparison with a transverse heat jet-flow ignition detonating method; internal heat jet-flow ignition is combined with a detonating way of mixing nano particles such as metal aluminum or titanium mixed in fuel oil, so that detonating waves within a relatively short distance and relatively short time can be achieved, and therefore, length of the detonating combustion chamber is shortened, working frequency of an engine is improved, and weight of the engine is reduced. Based on the pulse detonating combustion chamber, the air turbine rocket engine based on pulse detonating disclosed by the invention is improved in parameters such as thrust and specific pulse to certain extent in comparison with those of a conventional ART engine; while an overall pressure ratio of the engine is certain, PDC self-pressurization characteristic can reduce requirements, on pressurization ability of a gas compressor in a PD-ART engine, and grades of rotary parts can be reduced, engine weight is reduced, and therefore, a thrust-weight ratio is increased.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A low-temperature plasma ignition power supply and ignition system

ActiveCN105201657BMeet ignition requirementsShorter ignition delay timeGas turbine plantsRocket engine plantsControl signalEngineering

The invention discloses a low-temperature plasma ignition power supply, which includes a main circuit module and a control circuit module. The main circuit module includes a sequentially connected DC power supply, a voltage regulating circuit, a full-bridge inverter circuit, a series resonant circuit, and a boost output circuit. The control circuit module includes sequentially connected given input control, DSP control circuit, drive circuit, and control signal, which provide control signals for the voltage regulating circuit switch and the full-bridge inverter switch in the main circuit module. Also disclosed is a low-temperature plasma ignition system, which is composed of a low-temperature plasma ignition power supply and a boss discharge load. The invention realizes that the low-temperature plasma power supply generates low-temperature plasma according to a certain frequency and pulse width, has low energy consumption, high ignition efficiency, wide range and adjustable power supply parameters for laboratory use, fixed airborne power supply parameters, small volume and high reliability. High, to meet the ignition requirements of the engine.

Owner:PEKING UNIV

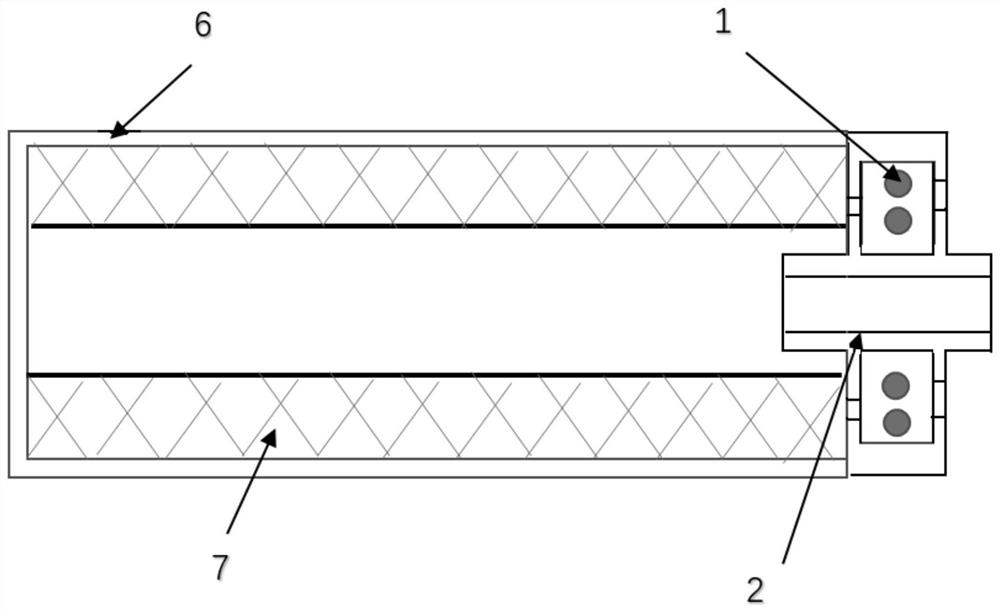

Gas generating device capable of being started quickly

ActiveCN109611215AIncrease space dwell timeIncrease startGas turbine plantsJet propulsion plantsCombustion chamberIgnition delay

The invention discloses a gas generating device capable of being started quickly, and belongs to the technical field of gas generating devices. The gas generating device comprises a powder box shell,ignition powder, a powder blocking sheet, a sealing sheet, a combustion chamber shell and a solid propellant; the ignition powder is installed in an annular cavity of the powder box shell to be used for igniting the solid propellant; the powder blocking sheet is installed in the annular cavity of the powder box shell, and an annular through hole in the left end of the powder box shell is closed; the sealing sheet is mounted on the right end surface of the powder box shell, and an annular through hole in the right end of the powder box shell is closed; the open end of the combustion chamber shell abuts against the end surface of the end, where an annular boss is located, of the powder box shell; the solid propulsion of the tubular structure is coaxially mounted in the combustion chamber shell, and a gap is reserved between the end surface of the solid propulsion and the end surface of the powder box shell; and the inner circumferential surface of the solid propulsion is located outsidethe annular boss of the powder box shell. The gas generating device increases the length of ignition flame conduction, shortens the ignition delay time, and can achieve quick starting.

Owner:BEIJING POWER MACHINERY INST

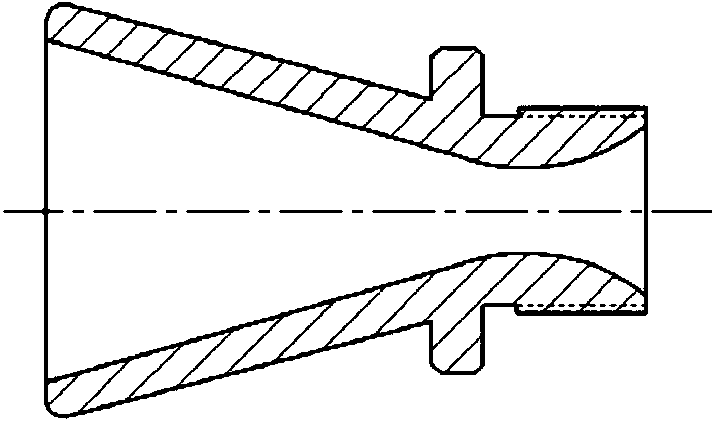

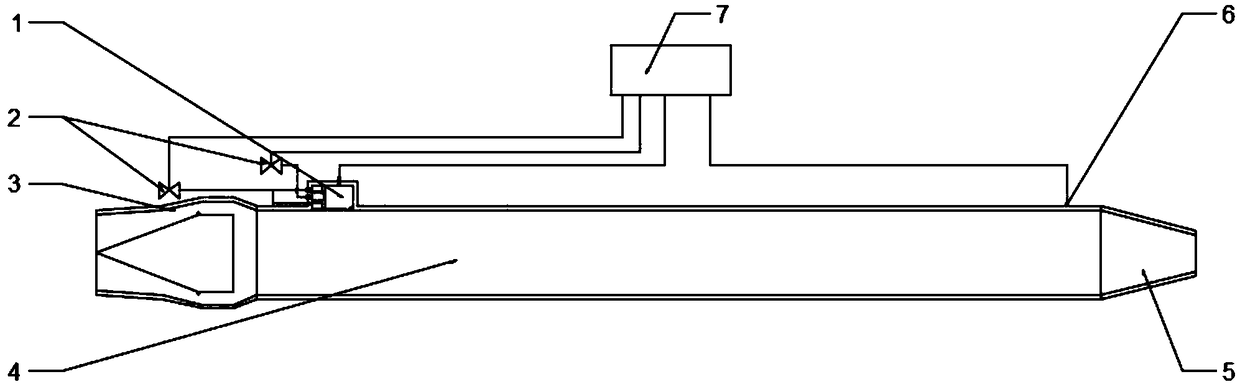

Ramjet with function of high-speed pre-atomization of liquid aviation kerosene

ActiveCN108999726ATake advantage ofSimple configurationContinuous combustion chamberRam jet enginesRamjetCombustion chamber

The invention discloses a ramjet with a function of high-speed pre-atomization of liquid aviation kerosene. The ramjet comprises a shunt cone, a gas inlet channel wall surface, a combustion chamber wall surface, an exhaust nozzle wall surface, an oil storage tank and an oil delivering pipe, wherein the shunt cone is connected with the oil storage tank through the oil delivering pipe; the gas inletchannel wall surface, the combustion chamber wall surface and the exhaust nozzle wall surface are connected in sequence; the shunt cone and the oil storage tank which serve as one part are arranged in a cavity formed by the gas inlet channel wall surface, the combustion chamber wall surface and the exhaust nozzle wall surface; a gas inlet channel is formed between the shunt cone and the gas inletchannel wall surface, a combustion chamber flow channel is formed between the shunt cone and the combustion chamber wall surface, an exhaust nozzle flow channel is formed between the shunt cone and the exhaust nozzle wall surface, and the gas inlet channel, the combustion chamber flow channel and the exhaust nozzle flow channel communicate in sequence; and a gas inlet hole is formed in the top ofthe shunt cone. The economy and safety of the ramjet are improved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Aviation alternative fuel blending method for improving ignition performance of heavy oil piston engine

ActiveCN112812861AImprove ignition performanceBalanced cetane numberLiquid carbonaceous fuelsFuel additivesAlkaneIgnition delay

The invention relates to an aviation alternative fuel blending method for improving ignition performance of a heavy oil piston engine, which comprises the following steps: adding a component (1), a component (2), a component (3) or a combination thereof into an aviation fuel, the component (1) being selected from one or more of methylcyclopentane, methylcyclohexane and ethylcyclohexane; the component (2) is selected from one or more of propyl cyclopentane and propyl cyclohexane; and the component (3) is selected from one or more of C7-C10 paraffins. The invention also discloses an aviation fuel additive. The ignition performance of the aviation piston engine is remarkably improved, atomization, volatility, cetane number, ignition delay, ignition energy, heat value and ignition-extinguishing boundary are balanced, and meanwhile the working condition operation range is expanded.

Owner:BEIHANG UNIV

A clean heat-generating and gas-generating agent

ActiveCN106608775BIncrease gas production rateClean gas componentsExplosivesGeneration rateChemical reaction

The invention provides a clean heat and gas generation agent which comprises 30-50% of fuel, 50-70% of an oxidizing agent, 0-2% of a catalyst and 0-2% of a process additive. The fuel is guanidine nitrate, the oxidizing agent is ammonium nitrate or modified ammonium nitrate, the catalyst is one or combination of copper oxide, or copper chromite or potassium perchlorate, and the process additive is one or combination of kaolin, or clay or silicon nitride. The clean heat and gas generation agent has extremely high safety, it is extremely difficult to generate a chemical reaction under normal pressure, the clean heat and gas generation agent can be triggered through electrical signals under high pressure, and the clean heat and gas generation agent has the advantages of being safe, stable, high in heat generation, high in gas generation rate, clean in gas ingredient, few in residues, free of toxin and harm, high in cost performance and the like.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Method for coating micro/nano-metal powder by chemical vapor deposition

ActiveCN102581274BLow ignition temperatureExcellent hydrophobic propertiesChemical vapor deposition coatingThermal chemical vapor depositionIgnition delay

The invention discloses a method for coating micro / nano-metal powder by chemical vapor deposition, including: decomposing difluorocarbene precursor gas via a cracking pipe to generate difluorocarbene free radicals; contacting the generated difluorocarbene free radicals with micro / nano-metal powder, and due to polymerization between difluorocarbene free radicals, a compact polytetrafluoroethylene coating film is generated on the surface of micro / nano-metal powder. In allusion to disadvantages and defects of the application of micro / nano-metal powder in energy-containing materials, polytetrafluoroethylene is polymerized on the surface of metal powder by chemical vapor deposition in order to coat micro / nano-metal powder. In the invention, the ignition temperature of metal powder is effectively decreased, the ignition delay time is shortened, and the combustion speed of metal powder is improved; the surface of metal powder coated with polytetrafluoroethylene is highly hydrophobic, so that reactive metal powder can be effectively prevented from absorption of moisture and oxidation.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

A kind of organic small molecule gel and its preparation method and application

ActiveCN113461657BImprove combustion effectGood gelOrganic chemistrySolid fuelsIgnition delayEngineering

The invention provides a small organic molecule gelling agent and its preparation method and application, belonging to the technical field of gel fuel. The organic small molecule gelling agent provided by the present invention contains a cyclopropane structure, and the cyclopropane structure belongs to a high-tension structure, which endows the gelling agent with excellent gel performance, and the high-tension cyclopropane structure can also greatly improve the combustion performance of the gelling agent. It can shorten the ignition delay of fuel and play a role in promoting combustion. Moreover, the multiple hydroxyl groups contained in the organic small molecule gel provided by the present invention can effectively form a gel through hydrogen bonding, so it has excellent gel performance for high energy density fuels and energetic nanofluid fuels and has shear Thinning properties, the minimum gelling agent is not higher than 1% when forming a stable gel.

Owner:TIANJIN UNIV

sliding arc ignition

ActiveCN103925116BShorter ignition delay timePromote combustionGas turbine plantsRocket engine plantsRadial positionIgnition delay

The invention discloses a sliding arc ignition device. The sliding arc ignition device comprises a contract-expansion type Laval nozzle, an outer shell, an air flow baffle, an electrode installation seat, a high-voltage anode and a locknut, wherein the contract-expansion type Laval nozzle and the electrode installation seat are fixed to the outer shell through threads, a hole is formed in a radial position of the outer shell, an air inlet connector is installed in the hole, the air flow baffle is clamped between the outer shell and the electrode installation seat, and the high-voltage anode is inserted into a central hole of the electrode installation seat, is stuck through sealants, is fixed through the locknut and is locked on the electrode installation seat. The sliding arc ignition device adopts an independent fuel inlet, the fuel supply can be increased after ignition succeeds, the fuel is catalyzed in a plasma region, and the functions of shortening ignition delay time and intensifying combustion are achieved. According to the design concept, a shell body serves as the installation base, machining difficulty is lowered, and when air flow baffles with different purposes are used, the air flow baffles can be placed in the outer shell without constraints, and assembling efficiency is improved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Plasma Duty Flame Igniter Based on Aeroengine Afterburner

ActiveCN110439691BImprove reliabilitySimple structureGas turbine plantsJet propulsion plantsCombustion chamberEngineering

Owner:AIR FORCE UNIV PLA

Non-nitrine gas generating agent and production thereof

ActiveCN1331827CReduce dosageReduce generationExplosivesPressure gas generationParaffin waxPtru catalyst

A non-laminated gas producing agent and its production are disclosed. The non-laminated gas producing agent consists of oxygen-enriched carbamidine nitrate 40-60% with granularity 0.5-6mu, basic copper nitrate 10-28% as oxidant with granularity 0.5-6mu, copperon oxide of catalyst with primary oxidant 15-30% with granularity 0.1-6mu, and clay or paraffin wax 0.1-3% as process assistant with granularity 1-20mu. The production is carried out by: breaking the materials, adding into mixer by proportioning, mixing, sieving by screen, adding water 10-30%, agitating, drying, sieving the dried materials by screen with 20-80 mesh to obtain medicine particles, pressing into tablets, and drying the tablets under 100-120deg.C for 1.5-2.5hrs with water content <0.4%. It achieves wide regulating range, high gas output efficiency, and clean gas composition.

Owner:HUBEI HANGPENG CHEM POWER TECH

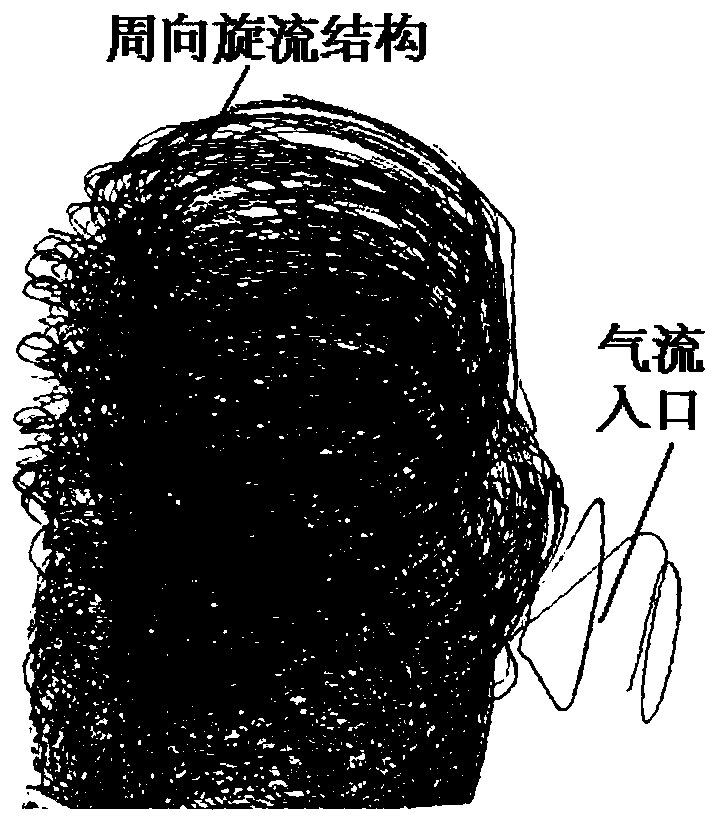

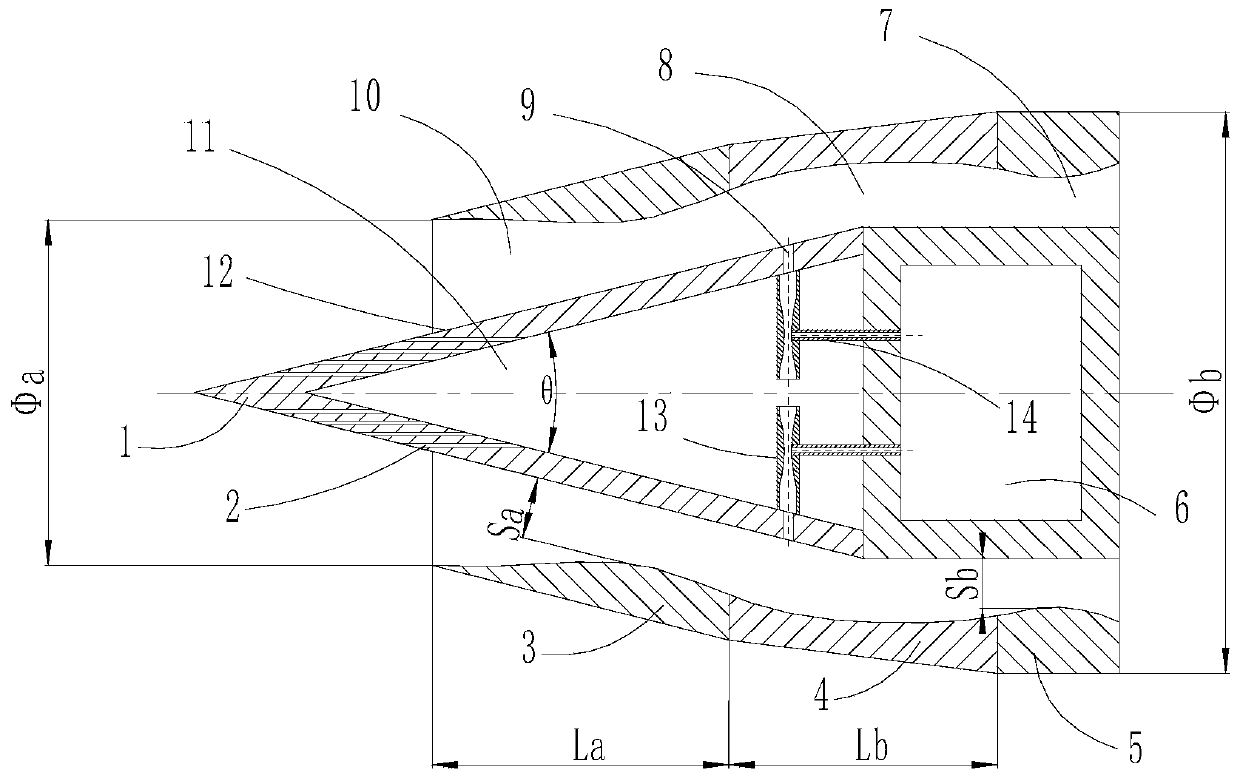

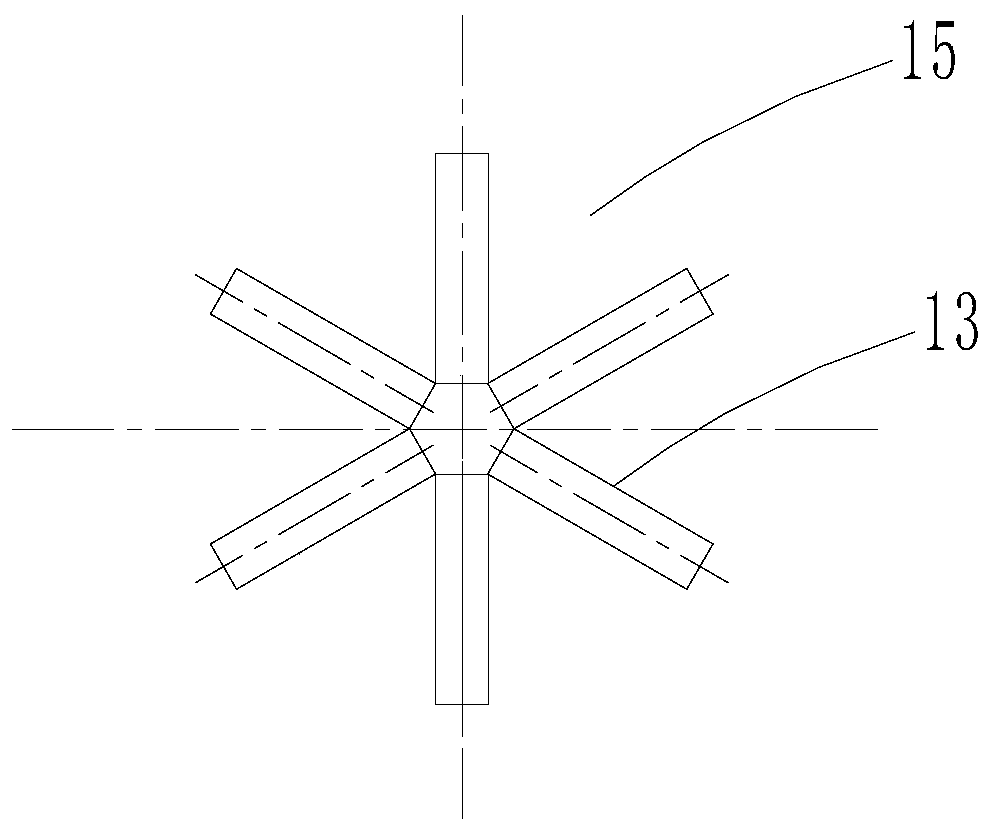

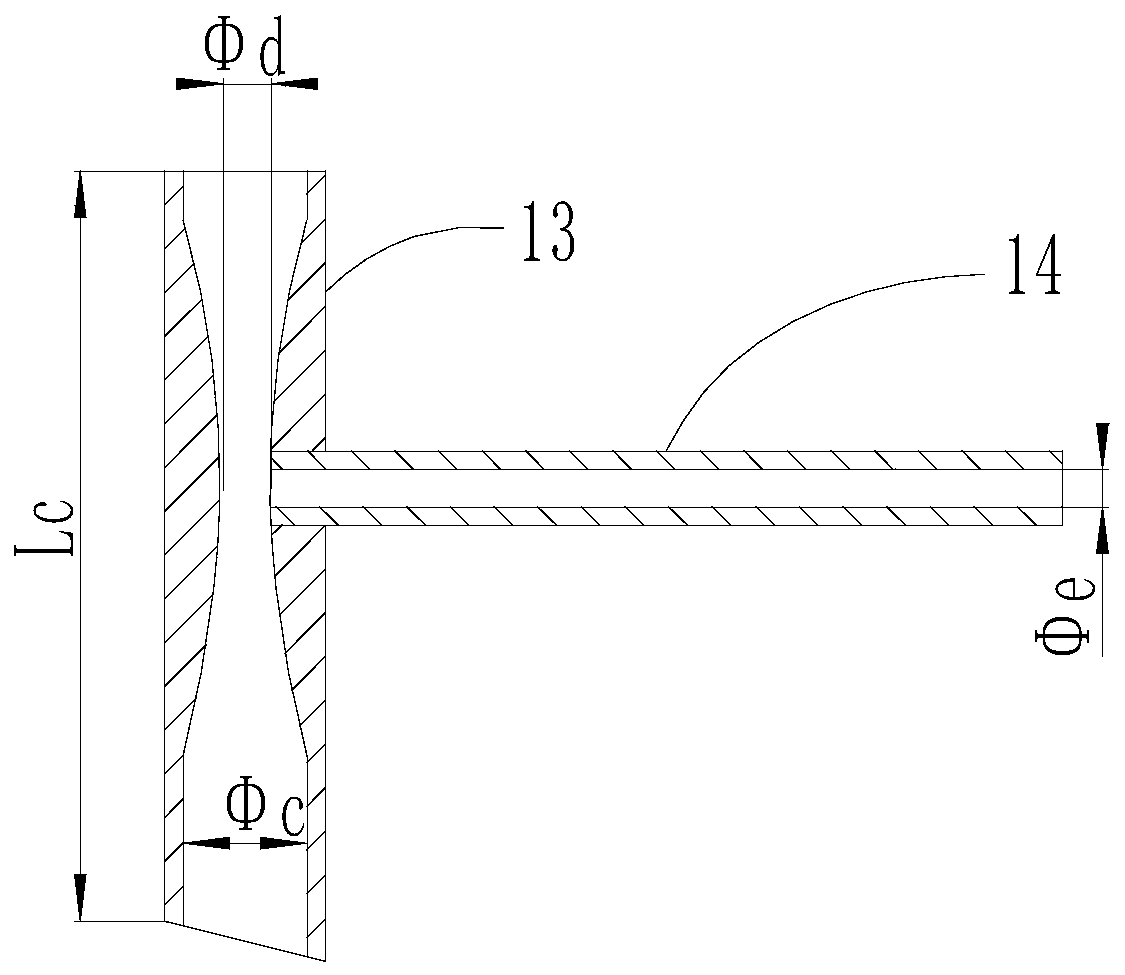

Miniature gas-liquid dual-purpose high-energy igniter

ActiveCN109322750BSmall geometryExtended dwell timeGas turbine plantsJet propulsion plantsStone wallOil retention

The invention relates to a micro gas-liquid dual-purpose high energy igniter, and relates to the technical field of engines. The micro gas-liquid dual-purpose high energy igniter has the advantages that 1) the success rate is increased, and the ignition lag time is shortened under the condition of relatively low ignition energy of a single igniter plug; 2) an efficient circumferential rotational flow structure can be formed in the igniter, the flue gas and flue oil retention time is prolonged, and mixing is enhanced, so that the formation of a stable flame structure is facilitated; 3) a circumferential vortex system structure is formed in a flow field, wherein the vortex system structure comprises a vortex system structure body clinging to the inside wall surface of an inner wall and a circumferential vortex system flow structure formed by entraining inner fluid by the vortex system structure body; 4) the ignition lag is reduced, the ignition success rate is increased, and the flue gasand flue oil retention time is prolonged on the premise of the smallest size of the igniter; and 5) the atomization effect can be ensured, and the fogdrop collision with a stone wall can be avoided.

Owner:BEIJING POWER MACHINERY INST

A ramjet engine with liquid aviation kerosene pre-atomized at high speed

ActiveCN108999726BTake advantage ofSimple configurationContinuous combustion chamberRam jet enginesRamjetCombustion chamber

The invention discloses a ramjet with a function of high-speed pre-atomization of liquid aviation kerosene. The ramjet comprises a shunt cone, a gas inlet channel wall surface, a combustion chamber wall surface, an exhaust nozzle wall surface, an oil storage tank and an oil delivering pipe, wherein the shunt cone is connected with the oil storage tank through the oil delivering pipe; the gas inletchannel wall surface, the combustion chamber wall surface and the exhaust nozzle wall surface are connected in sequence; the shunt cone and the oil storage tank which serve as one part are arranged in a cavity formed by the gas inlet channel wall surface, the combustion chamber wall surface and the exhaust nozzle wall surface; a gas inlet channel is formed between the shunt cone and the gas inletchannel wall surface, a combustion chamber flow channel is formed between the shunt cone and the combustion chamber wall surface, an exhaust nozzle flow channel is formed between the shunt cone and the exhaust nozzle wall surface, and the gas inlet channel, the combustion chamber flow channel and the exhaust nozzle flow channel communicate in sequence; and a gas inlet hole is formed in the top ofthe shunt cone. The economy and safety of the ramjet are improved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Periodic alternating current drive low-temperature plasma ignition method and system

InactiveCN102705108BImprove performanceRealize large volume ignitionIntermittent jet plantsRocket engine plantsCombustion chamberLow voltage

The invention discloses a periodic alternating current system low-temperature plasma ignition method and a periodic alternating current drive low-temperature plasma ignition device, an relates to the technical field of aerospace engine ignition, combustion and propulsion. The method comprises the following steps of: arranging an ignitor at a proper position of a combustion chamber, wherein a high voltage electrode and a low voltage electrode of the ignitor are connected with a high voltage end and a low voltage end of a low-temperature plasma power source, and a frequency controller is connected with the low-temperature plasma power source; triggering the low-temperature plasma power source and a frequency controller switch and adjusting power output parameters; adjusting control discharge frequency of the frequency controller and discharge time of each period; and providing a trigger signal to the low-temperature plasma power source by the frequency controller, discharging by the power source, and discharging to ignite according to certain frequency by the ignitor. The invention also discloses the corresponding periodic alternating current drive low-temperature plasma ignition device. The method and the device have the advantages of large-size ignition, capabilities of shortening ignition delay time, realizing high-efficiency reliable ignition in the aspects of high-altitude low-voltage supersonic speed combustion, lean burn and the like and improving the performance of an engine, industrial energy conservation and emission reduction.

Owner:PEKING UNIV

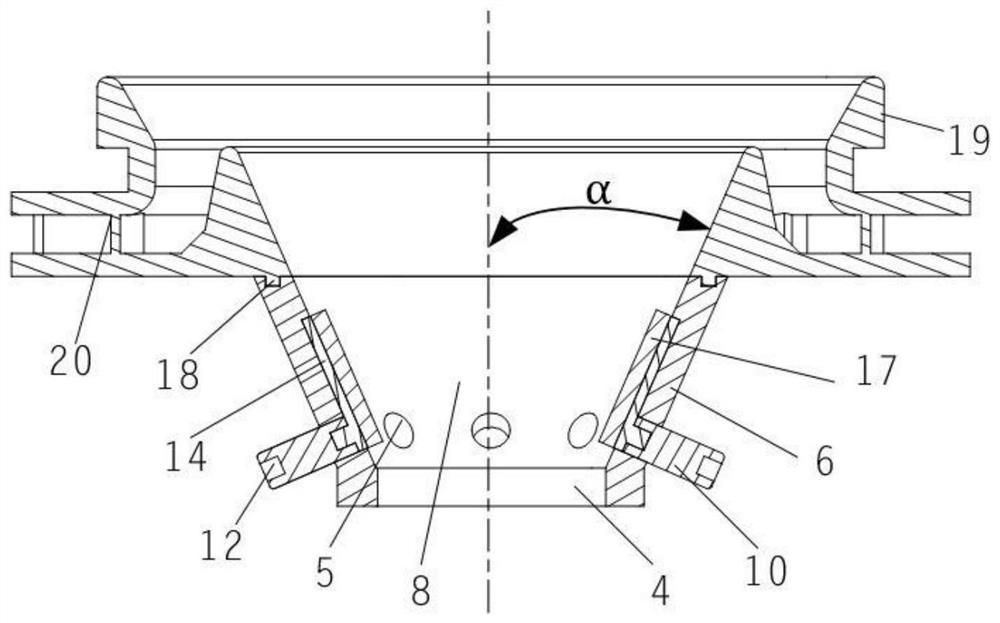

A Plasma-Based Orbital Sliding Arc Actuator

ActiveCN110486172BImprove ignition performanceSimple structureGas turbine plantsJet propulsion plantsEngineeringMechanical engineering

The invention discloses a rail type sliding arc exciter based on plasma. The rail type sliding arc exciter based on the plasma comprises an exciter body and electrodes, wherein the number of the electrodes is at least two, and the electrodes are used for generating electric arcs; the exciter body comprises a first contact, a rotational flow section and a second connect, wherein the shape of the first contact and the shape of the second contact both are cylindrical, the shape of the rotational flow section is in a circular truncated cone shape, the first connect, the second connect and the rotational flow section are of an integrated forming structure, the axes of the first connect, the second connect and the rotational flow section are positioned on the same straight line, the small end ofthe rotational flow section is arranged at one end of the first connect, and the large end of the rotational flow section is arranged at one end of the second connect. According to the rail type sliding arc exciter, the structure is simple, the plasma is used for reinforcing combustion, the ignition boundary of an engine is expanded, the ignition success rate and the combustion efficiency of theengine are improved, and the rail type sliding arc exciter can be popularized and used.

Owner:AIR FORCE UNIV PLA

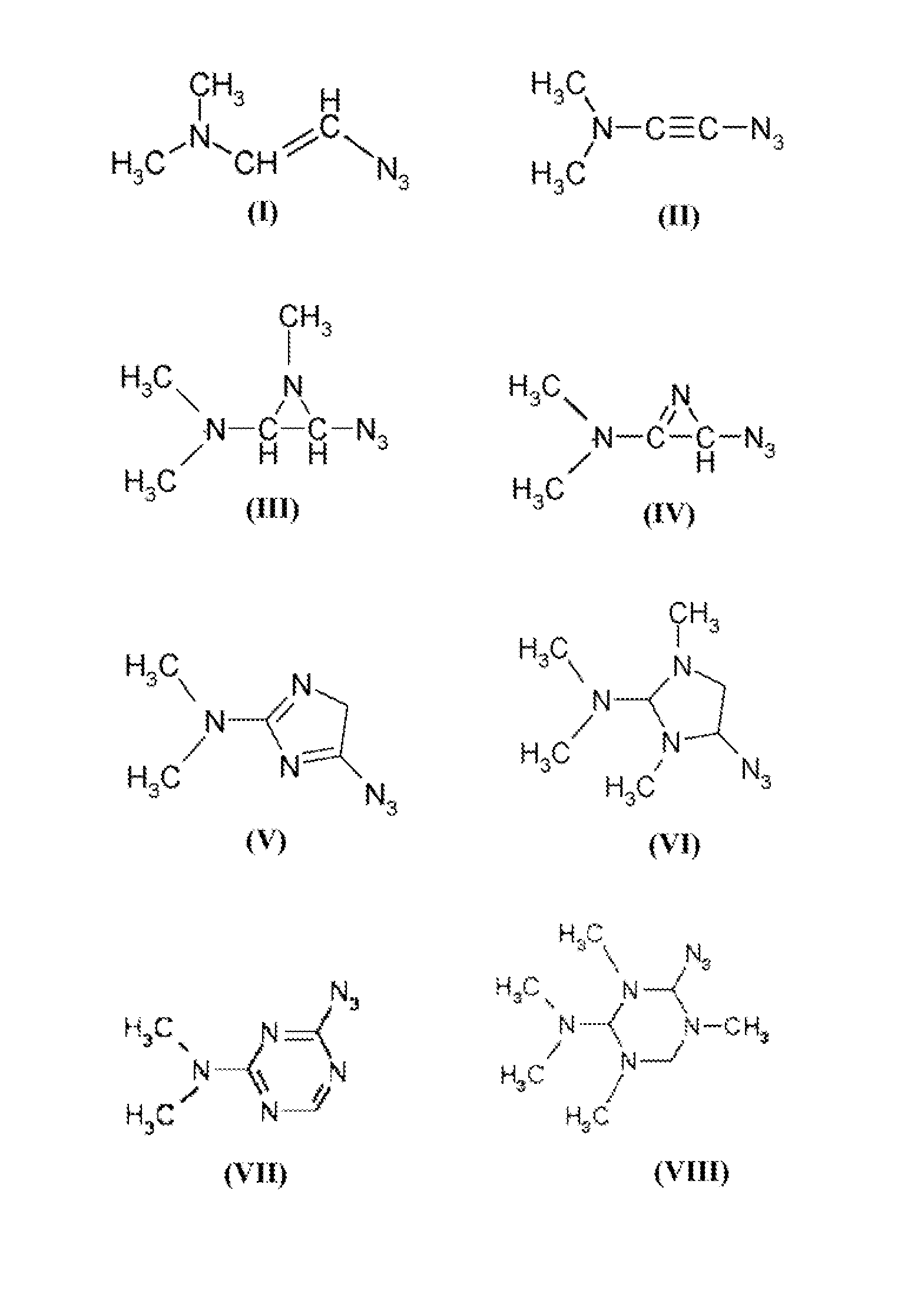

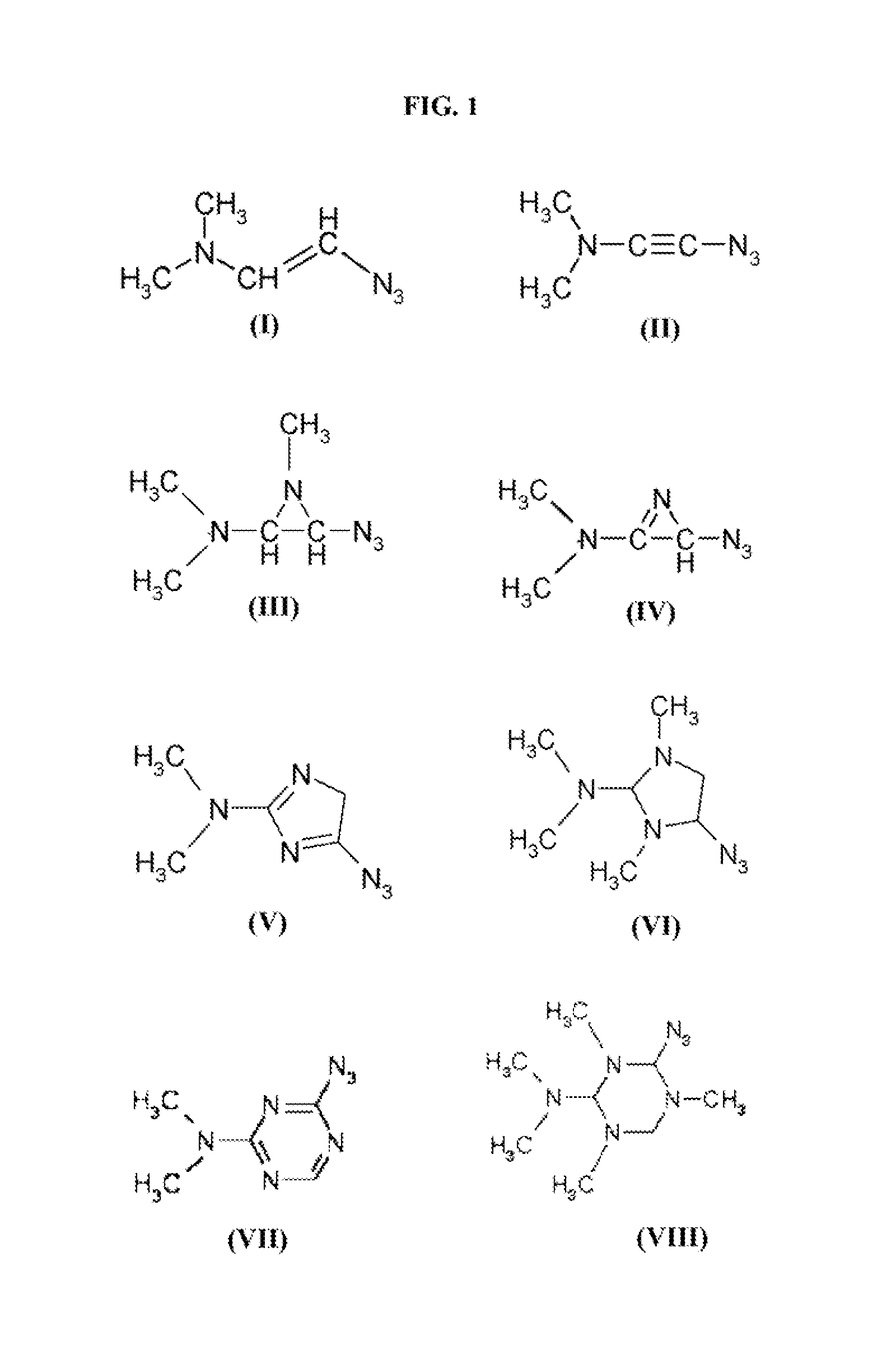

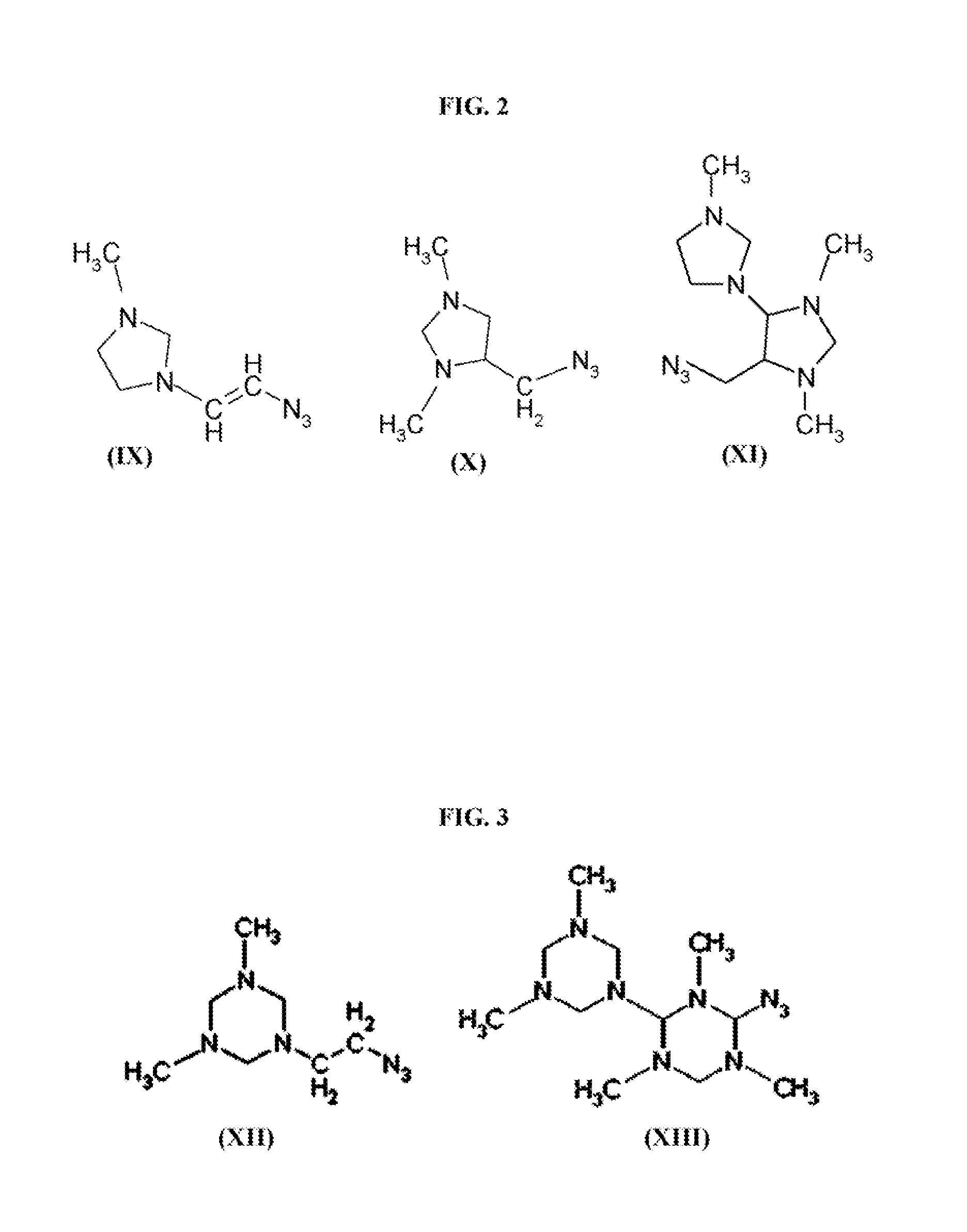

High Performance, Low Toxicity Hypergolic Fuel

ActiveUS20080202655A1High density impulseToxic reductionCigarette manufactureLoomsMonomethyl hydrazineHigh density

Disclosed is a group of tertiary amine azides useful as hypergolic fuels for hypergolic bipropellant mixtures. The fuels provide higher density impulses than monomethyl hydrazine (MMH) but are less toxic and have lower vapor pressures that MMH. In addition, the fuels have shorter ignition delay times than dimethylaminoethylazide (DMAZ) and other potential reduced toxicity replacements for MMH.

Owner:CFD RES CORP

A fast-starting gas generating device

ActiveCN109611215BIncrease space dwell timeIncrease startGas turbine plantsJet propulsion plantsCombustion chamberIgnition delay

The invention discloses a gas generating device capable of being started quickly, and belongs to the technical field of gas generating devices. The gas generating device comprises a powder box shell,ignition powder, a powder blocking sheet, a sealing sheet, a combustion chamber shell and a solid propellant; the ignition powder is installed in an annular cavity of the powder box shell to be used for igniting the solid propellant; the powder blocking sheet is installed in the annular cavity of the powder box shell, and an annular through hole in the left end of the powder box shell is closed; the sealing sheet is mounted on the right end surface of the powder box shell, and an annular through hole in the right end of the powder box shell is closed; the open end of the combustion chamber shell abuts against the end surface of the end, where an annular boss is located, of the powder box shell; the solid propulsion of the tubular structure is coaxially mounted in the combustion chamber shell, and a gap is reserved between the end surface of the solid propulsion and the end surface of the powder box shell; and the inner circumferential surface of the solid propulsion is located outsidethe annular boss of the powder box shell. The gas generating device increases the length of ignition flame conduction, shortens the ignition delay time, and can achieve quick starting.

Owner:BEIJING POWER MACHINERY INST

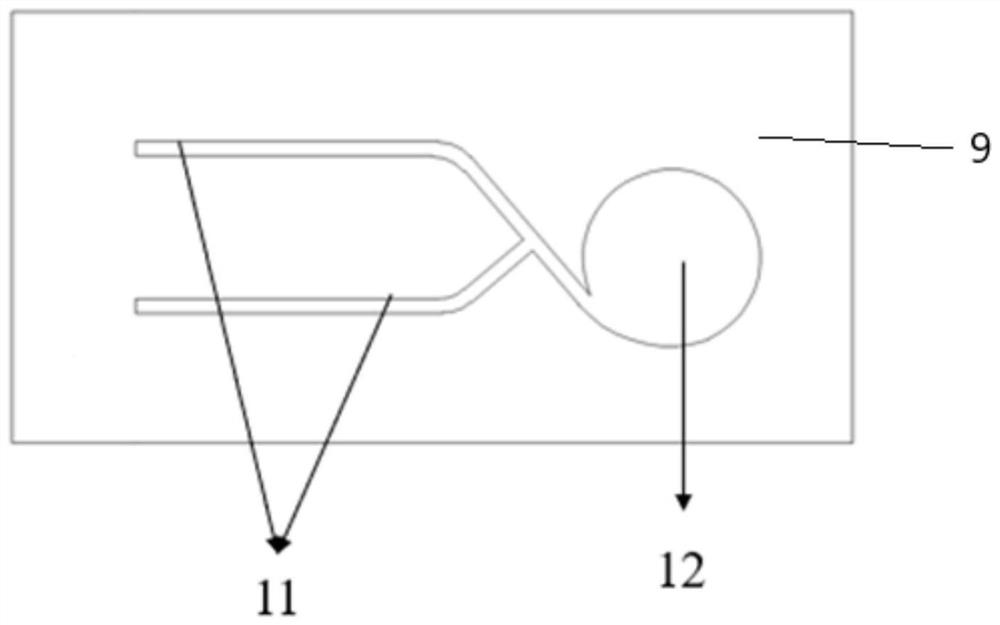

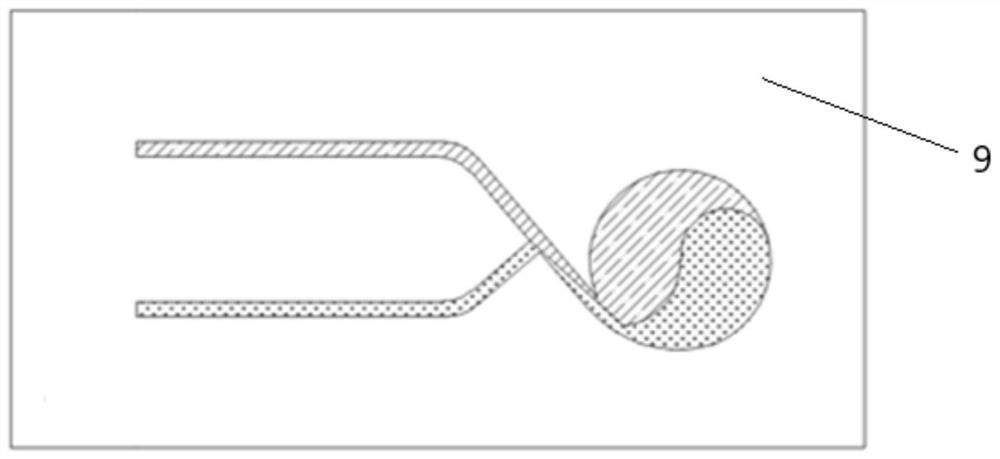

Energetic liquid laser-enhanced propulsion device based on microfluidic technology

ActiveCN111120146BIncrease reaction rateFast ignitionRocket engine plantsCombustion chamberEngineering

The invention belongs to the field of laser propulsion, and in particular relates to an energy-containing liquid laser-enhanced propulsion device based on microfluidic technology. Including a microfluidic supply system, a microreaction mixed chip system and a laser ablation system; the microfluidic supply system and the microreaction mixed chip system are connected through a microtube, and the propellant is transmitted to the microreaction mixed chip system; the microreaction mixed chip system includes There are two micro-channels and a mixing combustion chamber. There is a nozzle at the outlet of the fluid, and the direction of the axis of the nozzle is the incident direction of the laser pulse; energetic propellants. The propulsion device of the present application can realize fast ignition, controllable thrust and flow, and can provide micro-satellites with high specific impulse and thrust-to-impulse ratio at the same time.

Owner:NANJING UNIV OF SCI & TECH

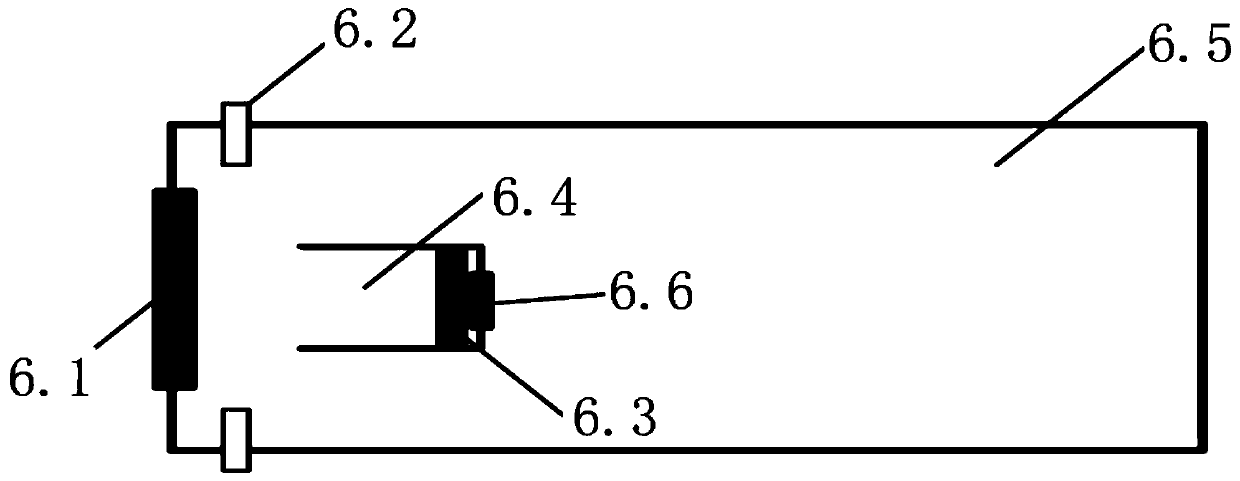

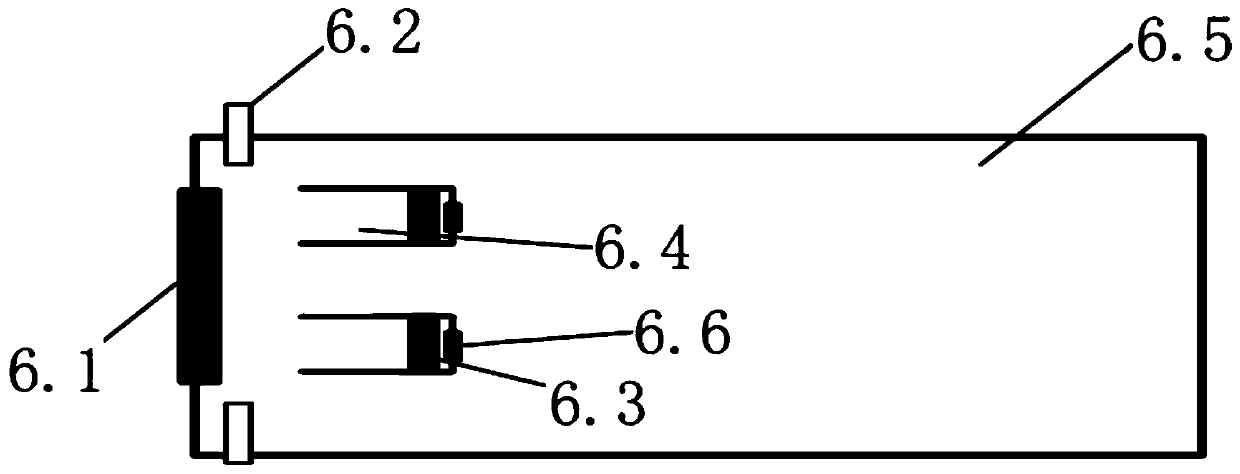

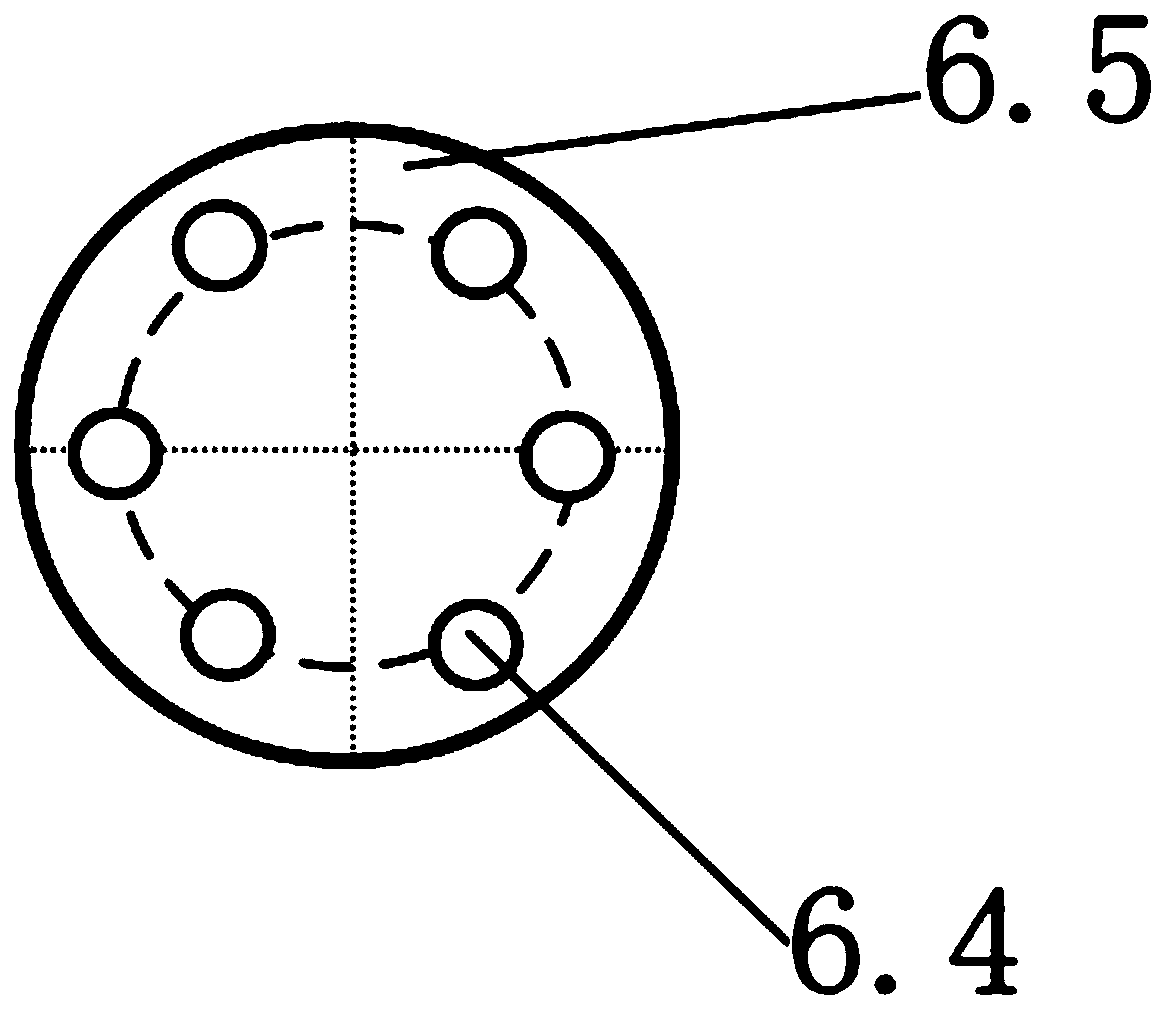

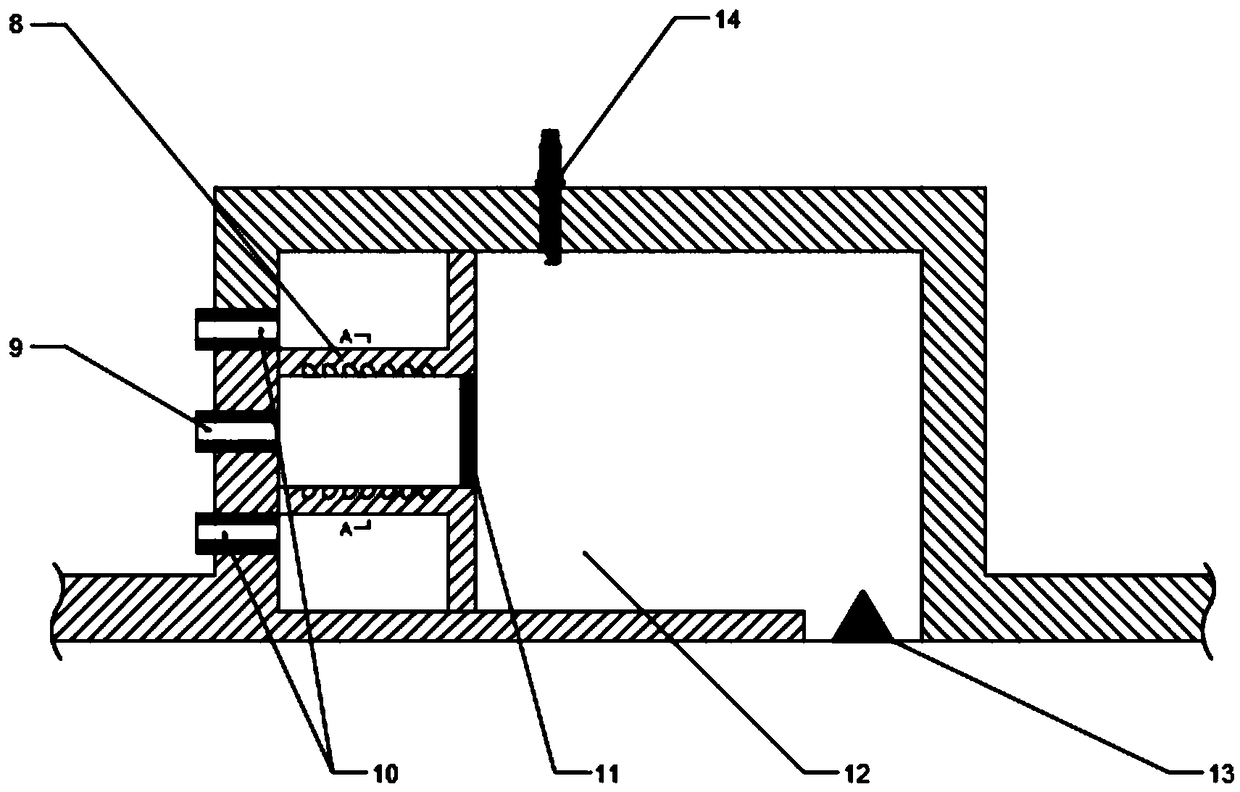

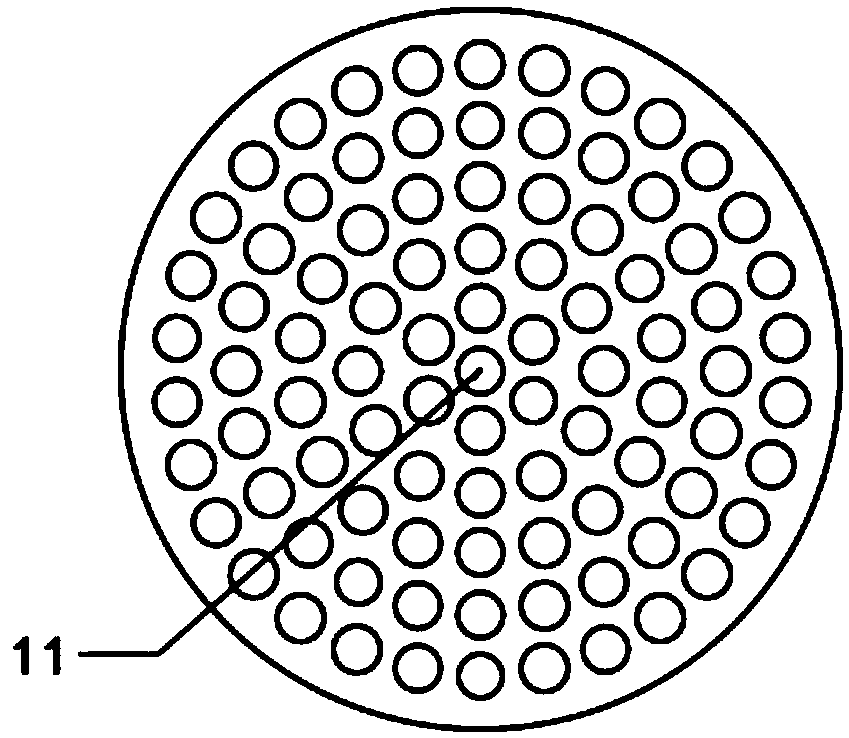

An ignition system for pulse detonation engine

ActiveCN107605603BControl ignition timingControl ignition intensityGas turbine plantsJet propulsion plantsControl systemWork cycle

The invention provides an ignition system for a pulse detonation engine. The ignition system comprises a jet flow generator, the pulse detonation engine and a control system. The pulse detonation engine comprises a detonation chamber, an air inlet chamber and a tail spray chamber. The tail spray chamber is internally provided with a fuel gas detector, the jet flow generator comprises a jet flow cavity and a fuel chamber, and a sealing plate is arranged between the jet flow cavity and the fuel chamber. A swirler is mounted between the fuel chamber and the sealing plate, a first fuel gas chamberis internally provided with at least two fuel gas inlets, and a second fuel gas chamber is internally provided with an oxidant inlet. The swirler is a rotation body, a plurality of swirling holes areformed in the swirler, and a through hole is formed in the connecting position of the swirler and the sealing plate. The jet flow cavity is provided with an outlet, and the control system is connected with a sparking plug and the fuel gas detector. According to the ignition system for the pulse detonation engine, ignition energy of a detonation pipe can be increased, the DDT time and distance canbe effectively shortened, the time of the engine for completing one work cycle is shortened accordingly, and the work frequency and reliability of the engine are improved.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com