Filamentous arc plasma exciter based on swirl holes

An arc plasma and plasma technology, applied in the direction of plasma, electrical components, machines/engines, etc., can solve the problems of low combustion efficiency and inability to discharge, and achieve the effect of improving combustion efficiency, obvious effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

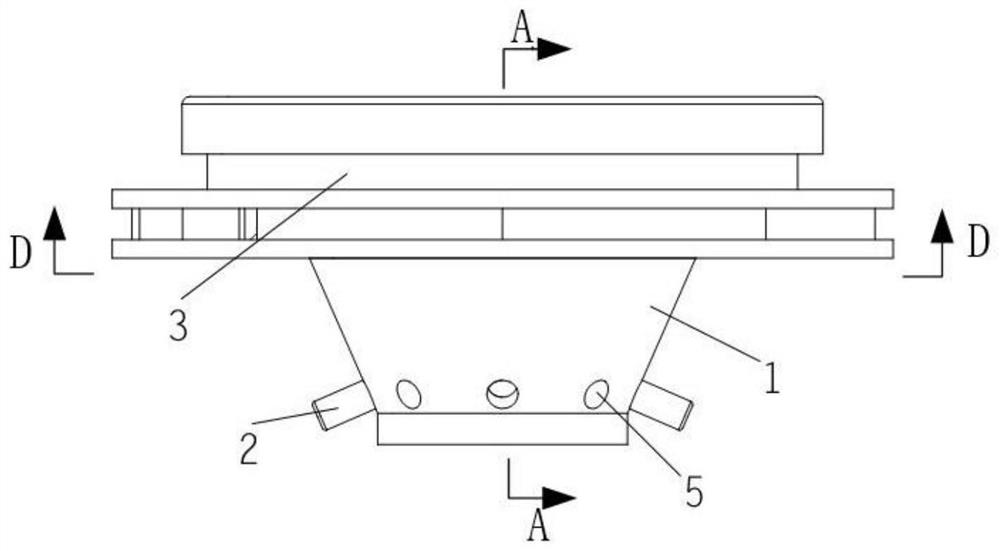

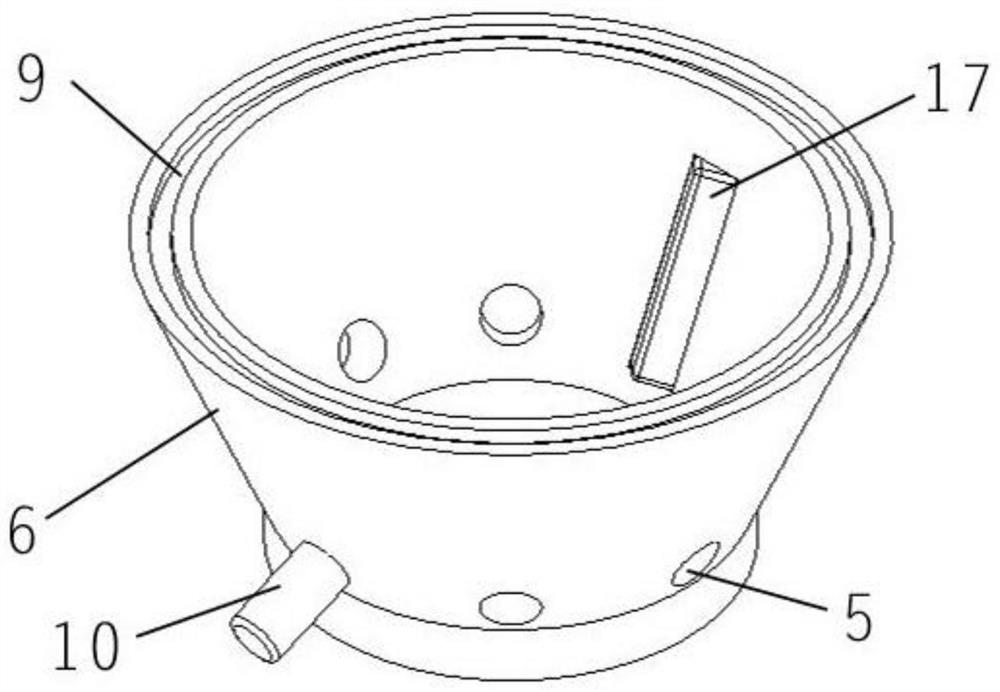

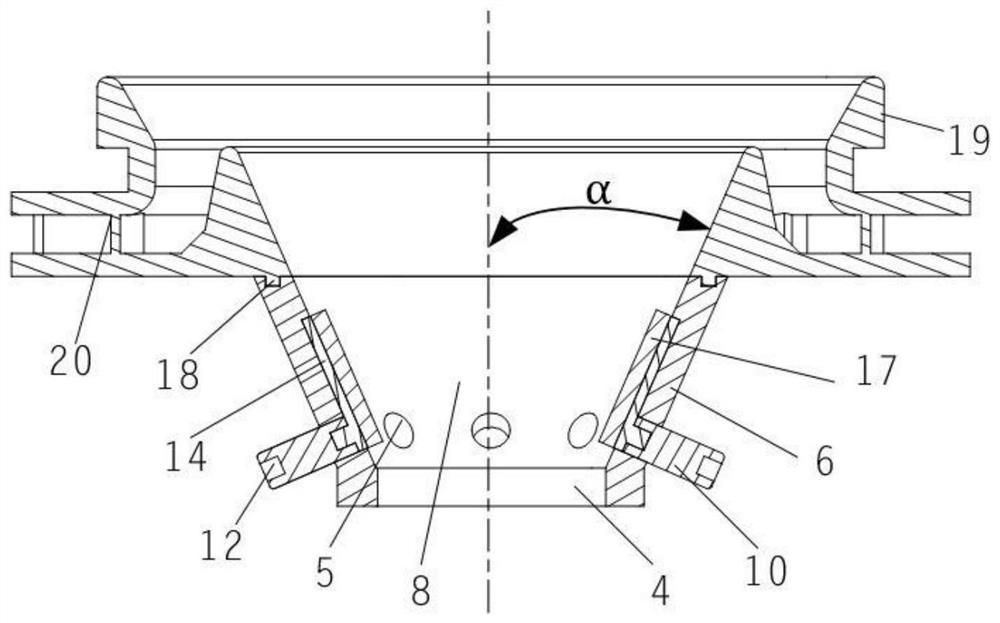

[0043] This embodiment is a filamentary arc plasma exciter based on swirl holes, which includes an inner plasma cyclone 1, an electrode 2 for generating an arc, and an outer cyclone 3 made of ceramics. The inner plasma cyclone 1 and the outer cyclone 3 adopt a split structure.

[0044] The number of the electrodes 2 is a; a=2-5. The electrodes are evenly distributed on the shell, and the electrodes are respectively installed in the swirl holes evenly distributed on the shell. Each electrode divides the circumference of the shell into n arc segments of equal length, and makes the number of swirl holes distributed on the n arc segments equal. The number of the swirl holes 5 is a multiple of m from 6 to 15; m=2,3,4,....

[0045] A plurality of swirl holes 5 are evenly distributed on the casing 6; the vertical distance between the center of each swirl hole and the lower end surface of the casing is 2 mm to 4 mm. The diameter of the swirl hole is 1 mm to 4 mm, and is the same diamete...

Embodiment 2

[0060] This embodiment is a filamentary arc plasma exciter based on swirl holes, which includes an inner plasma cyclone 1, an electrode 2 for generating an arc, and an outer cyclone 3 made of ceramics. The inner plasma cyclone 1 and the outer cyclone 3 adopt a split structure. The number of the electrodes 2 is a; a=2-5. The electrodes are evenly distributed on the shell, and the electrodes are respectively installed in the swirl holes evenly distributed on the shell. Each electrode divides the circumference of the shell into n arc segments of equal length, and equalizes the number of swirl holes distributed on the n arc segments. The number of the swirl holes 5 is a multiple of m selected from 6-15; m=2,3,4....

[0061] A plurality of swirl holes 5 are evenly distributed on the casing 6; the vertical distance between the center of each swirl hole and the lower end surface of the casing is 2 mm to 4 mm. The diameter of the swirl hole is 1 mm to 4 mm, and is the same diameter as...

Embodiment 3

[0075] This embodiment is a filamentary arc plasma exciter based on swirl holes, which includes an inner plasma cyclone 1, an electrode 2 for generating an arc, and an outer cyclone 3 made of ceramics. The inner plasma cyclone 1 and the outer cyclone 3 adopt a split structure.

[0076] The number of the electrodes 2 is a; a=2-5. The electrodes are evenly distributed on the shell, and the electrodes are respectively installed in the swirl holes evenly distributed on the shell. Each electrode divides the circumference of the shell into n arc segments of equal length, and equalizes the number of swirl holes distributed on the n arc segments. The number of the swirl holes 5 is a multiple of m from 6 to 15; m=2,3,4,....

[0077] A plurality of swirl holes 5 are evenly distributed on the casing 6; the vertical distance between the center of each swirl hole and the lower end surface of the casing is 2 mm to 4 mm. The diameter of the swirl hole is 1 mm to 4 mm, and is the same diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com