Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

614 results about "Electric arc discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electric arc is a visible plasma discharge between two electrodes that is caused by electrical current ionizing gasses in the air.

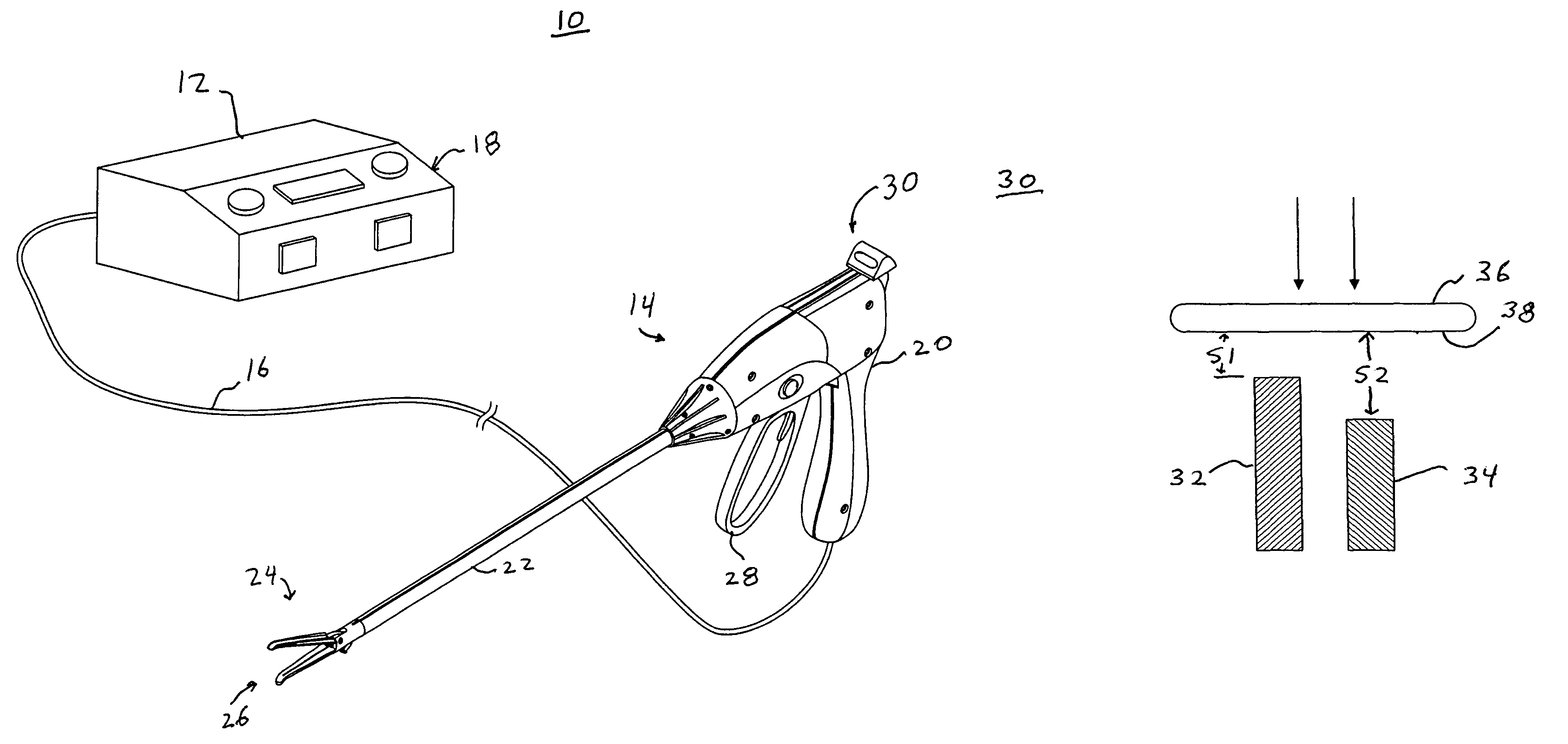

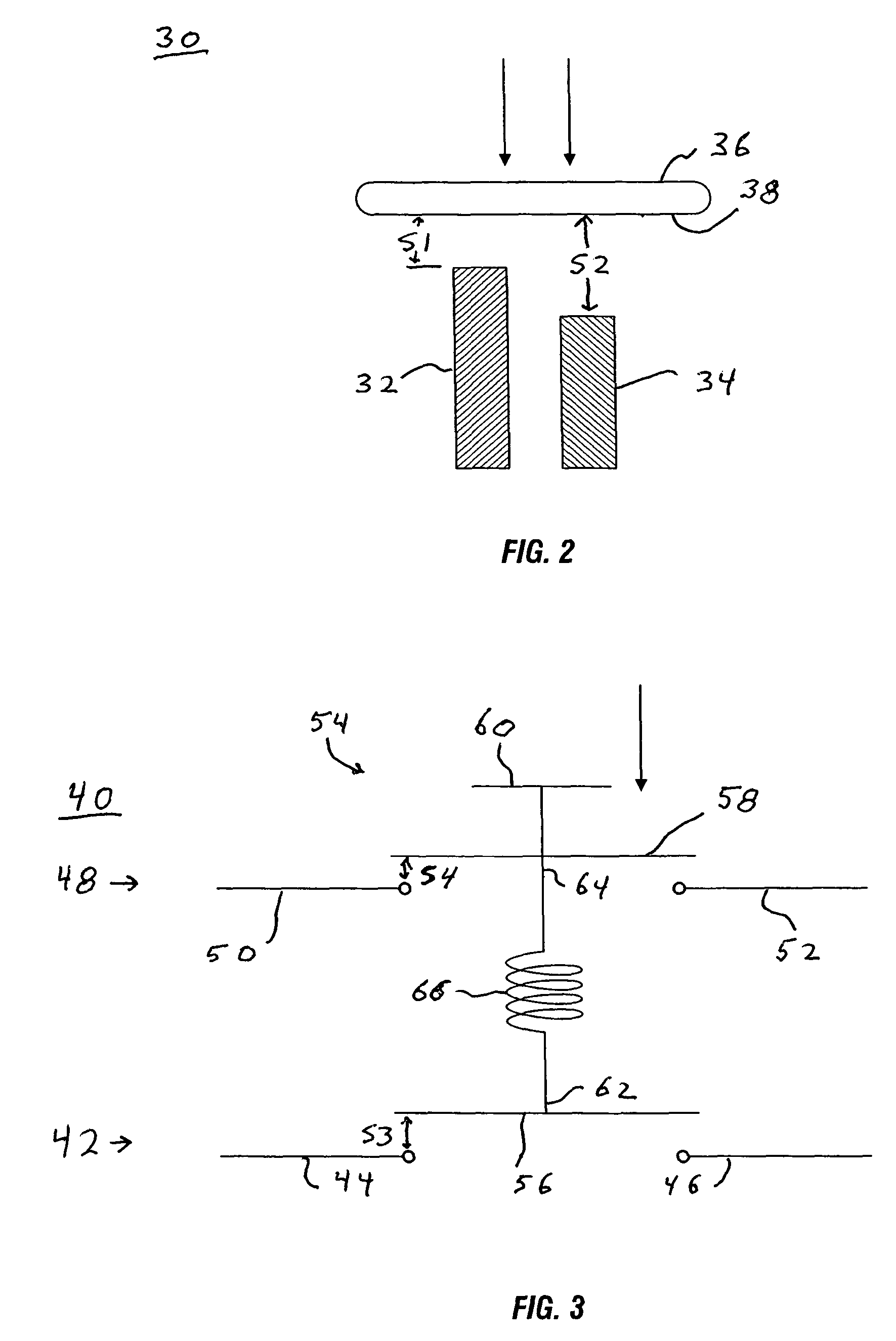

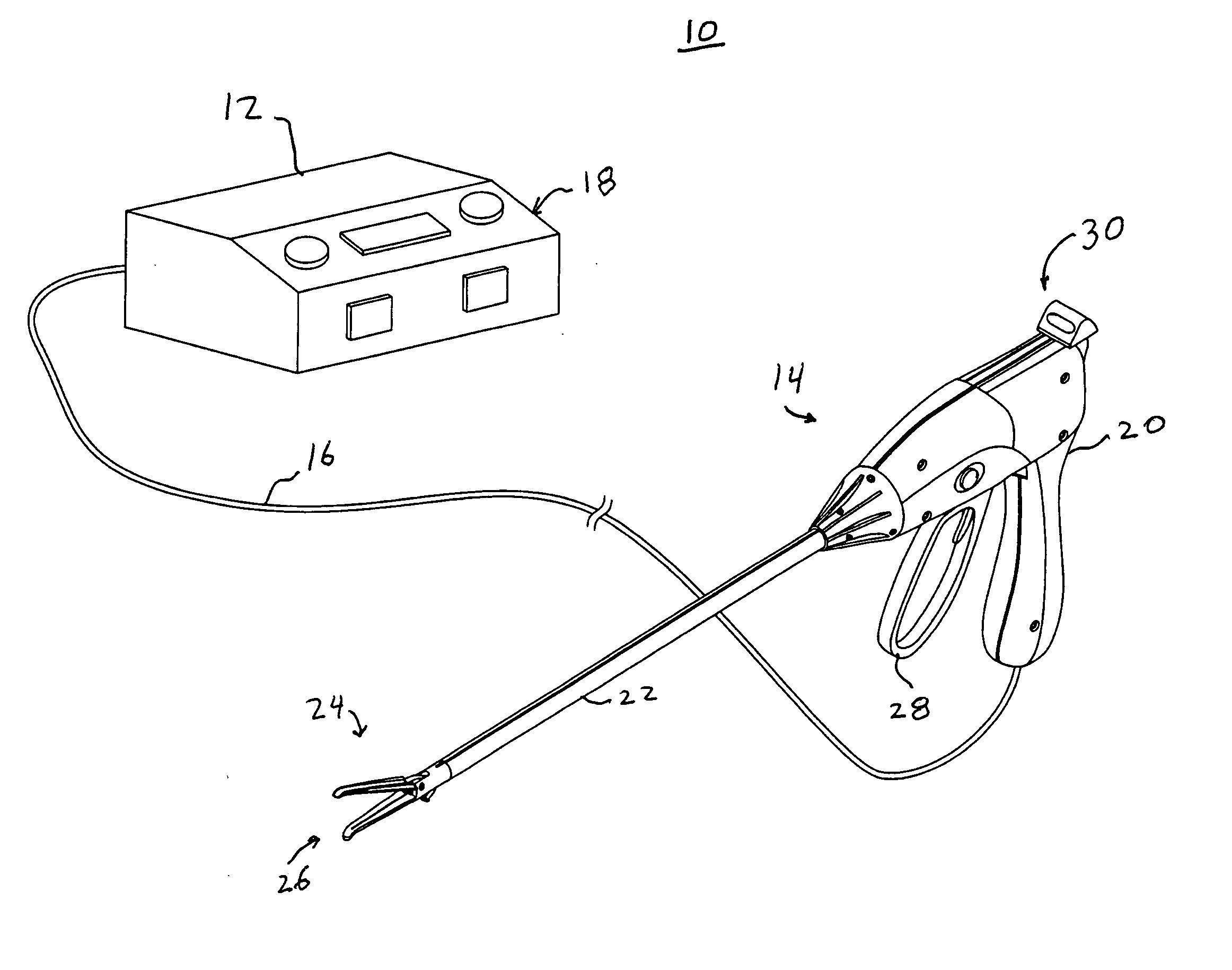

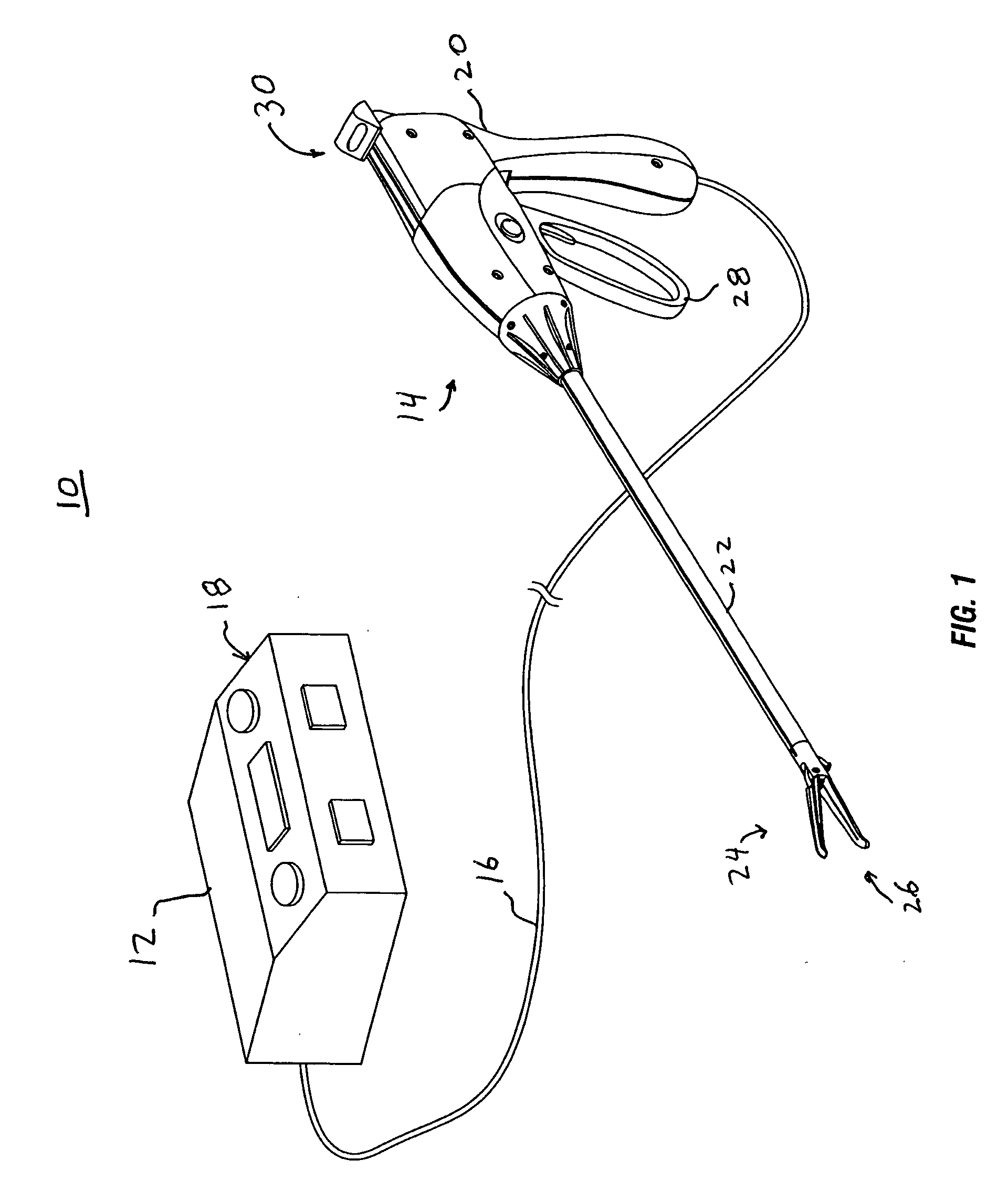

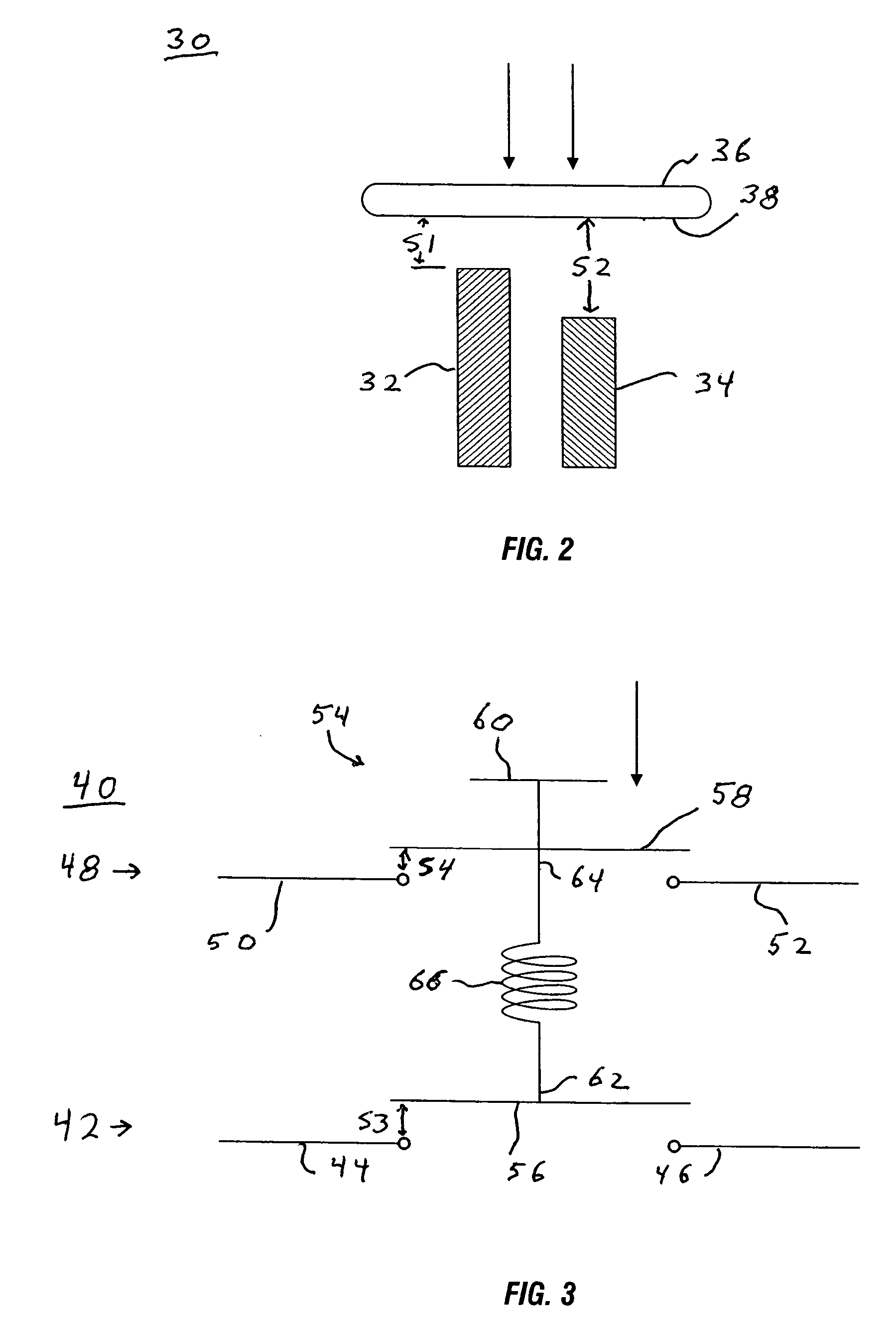

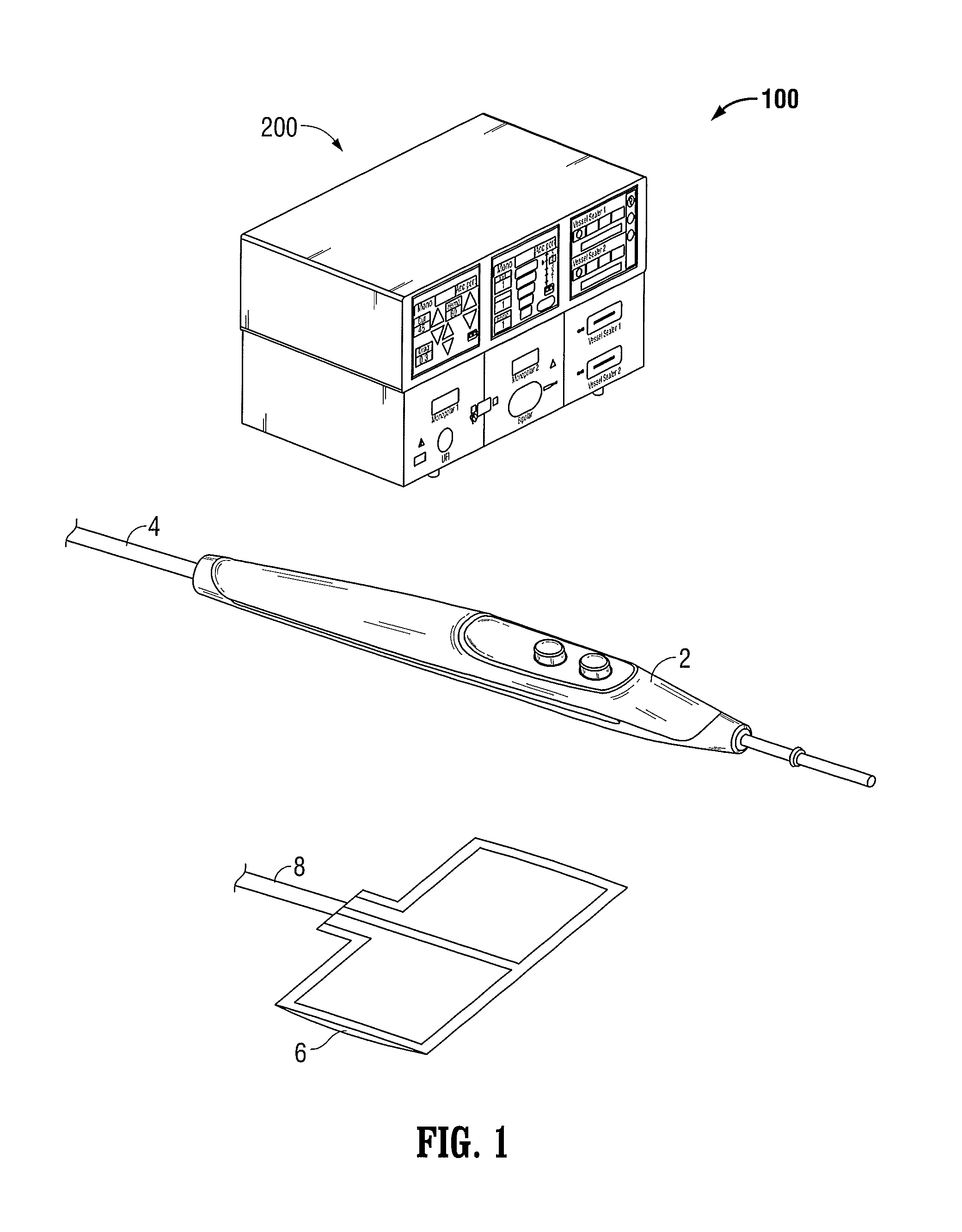

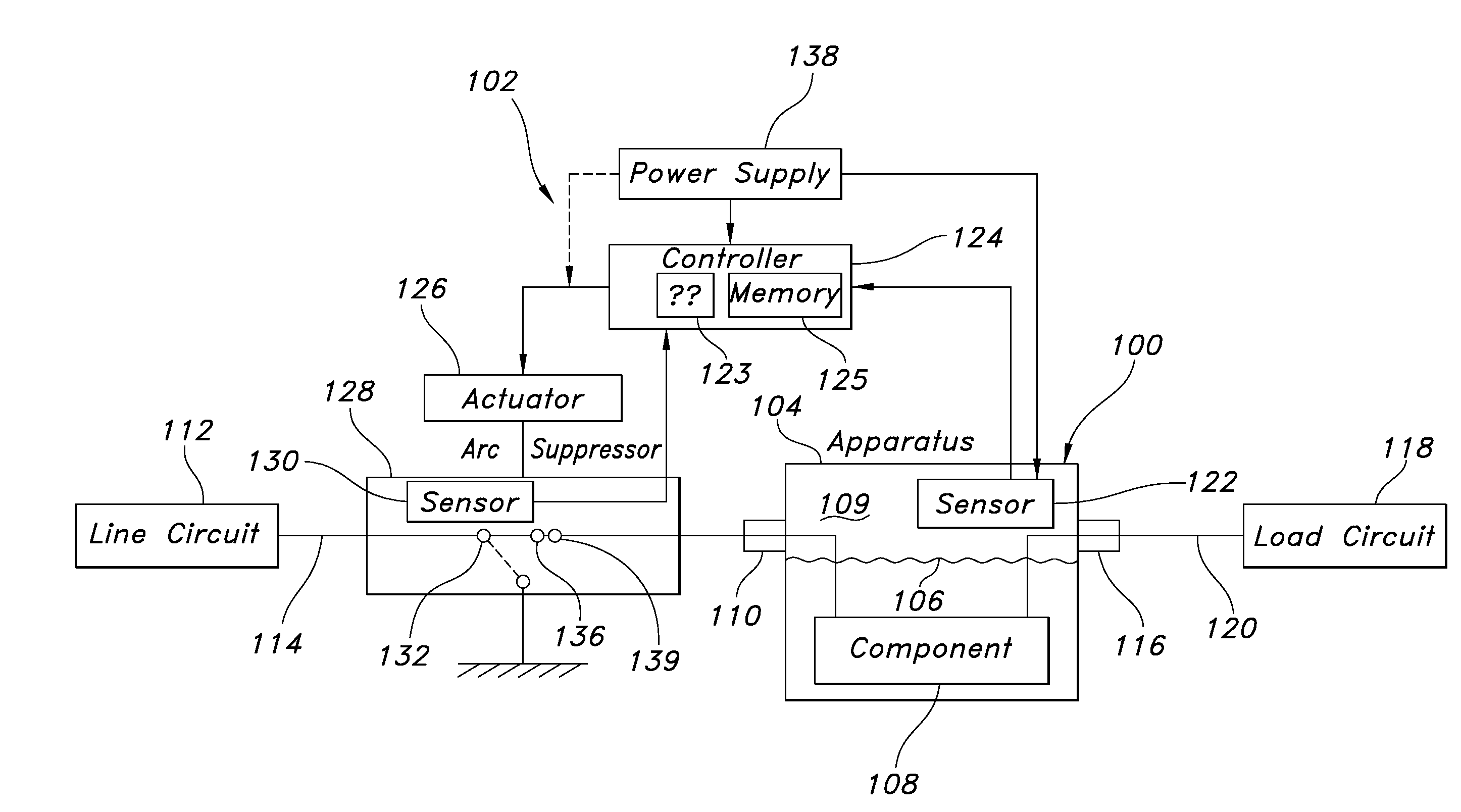

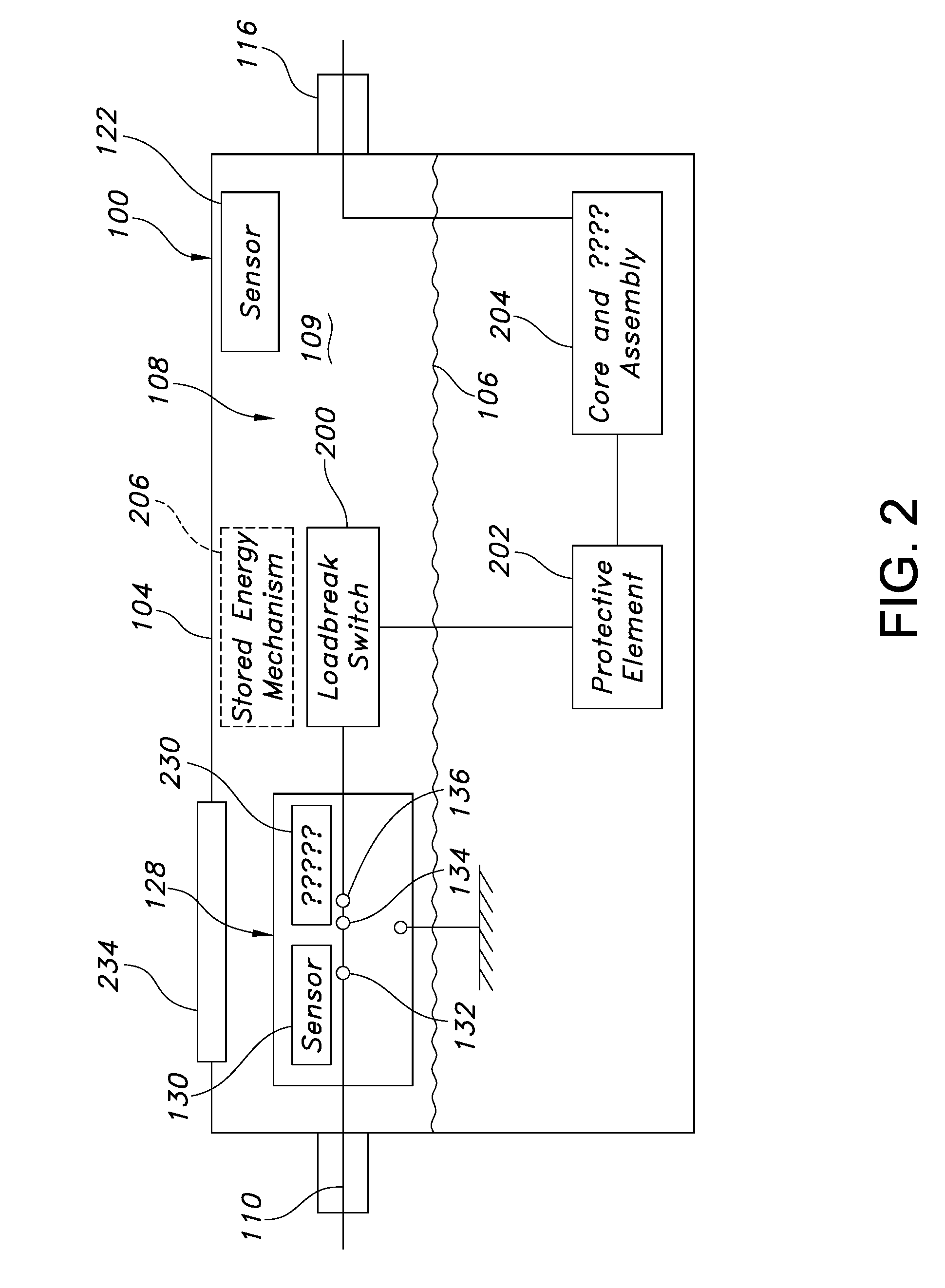

Switch mechanisms for safe activation of energy on an electrosurgical instrument

ActiveUS7837685B2Secure bootElectric switchesSurgical instruments for heatingHigh energyBiological activation

Various safe switching mechanisms are provided for use with electrosurgical instruments which prevent arcing between the high-energy contacts as the high-energy source is activated. The switching mechanisms generally include a pair of high-energy contacts and a pair of activation contacts. An actuator is provided which initially engages the high-energy contacts in advance of engagement of the activation contacts to prevent arcing and subsequently disengages the activation contacts in advance of the high-energy contacts as the energy source is deactivated. A method of switching power to an electrosurgical instrument while avoiding damage to high-energy contacts is also disclosed.

Owner:COVIDIEN AG

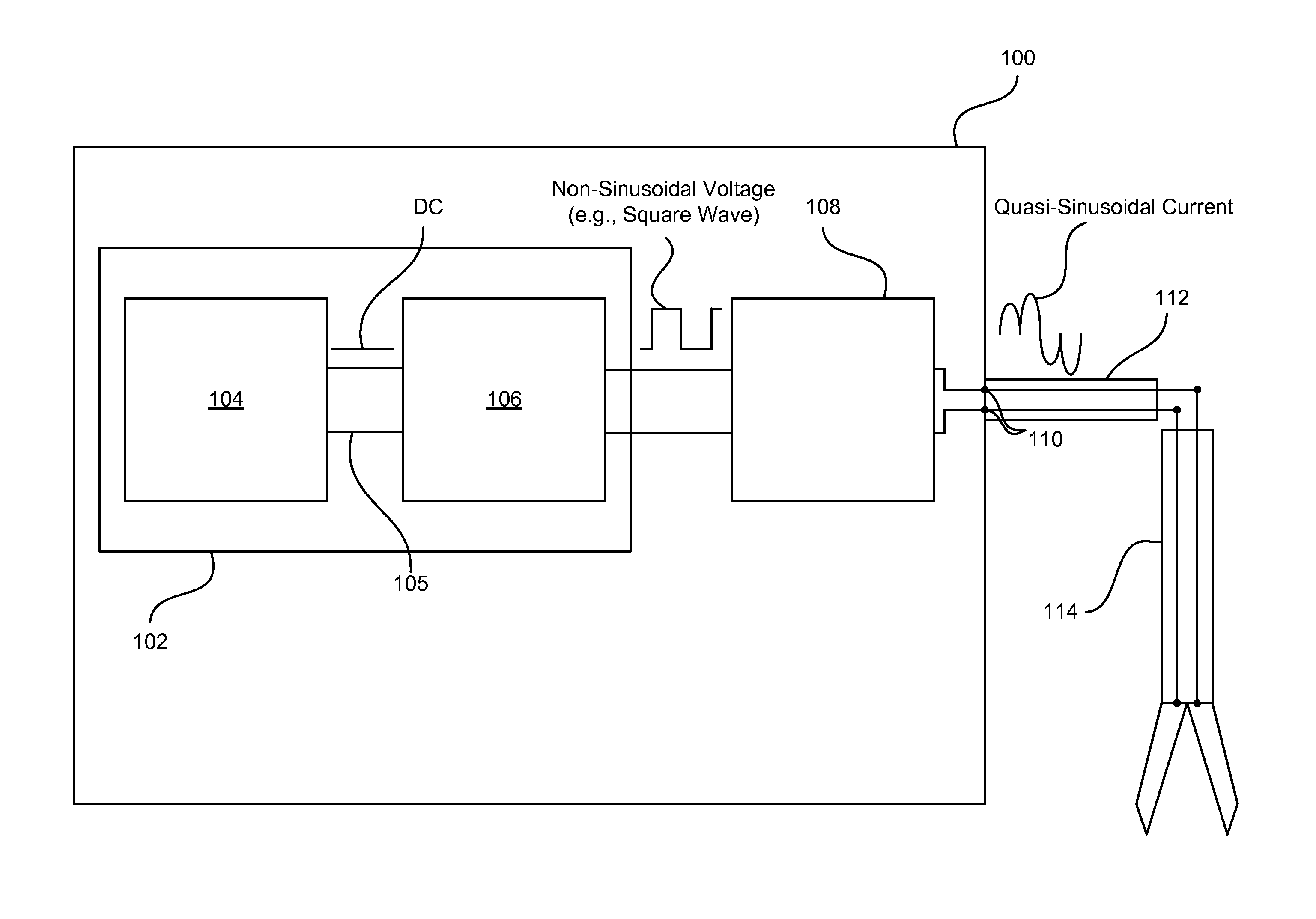

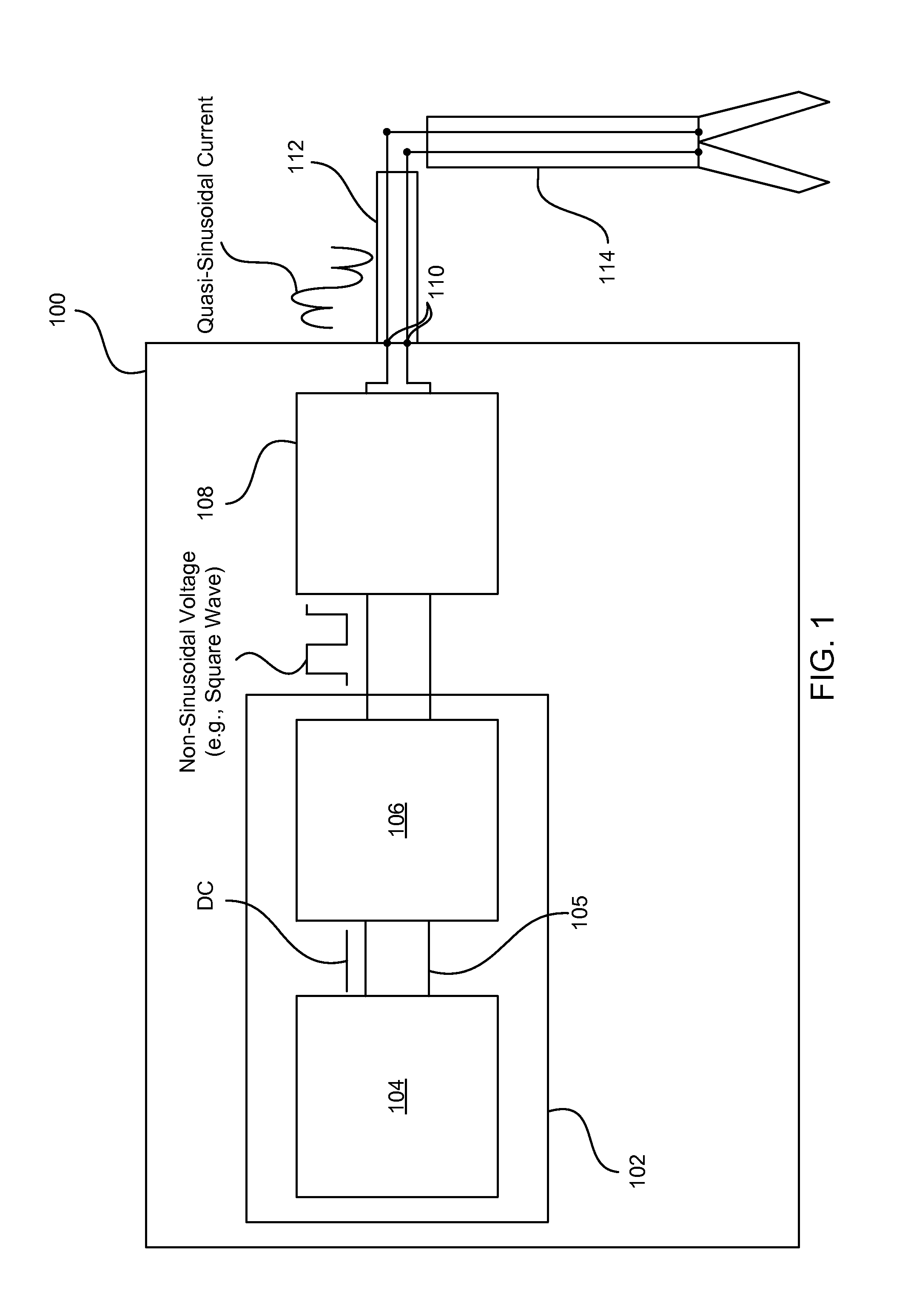

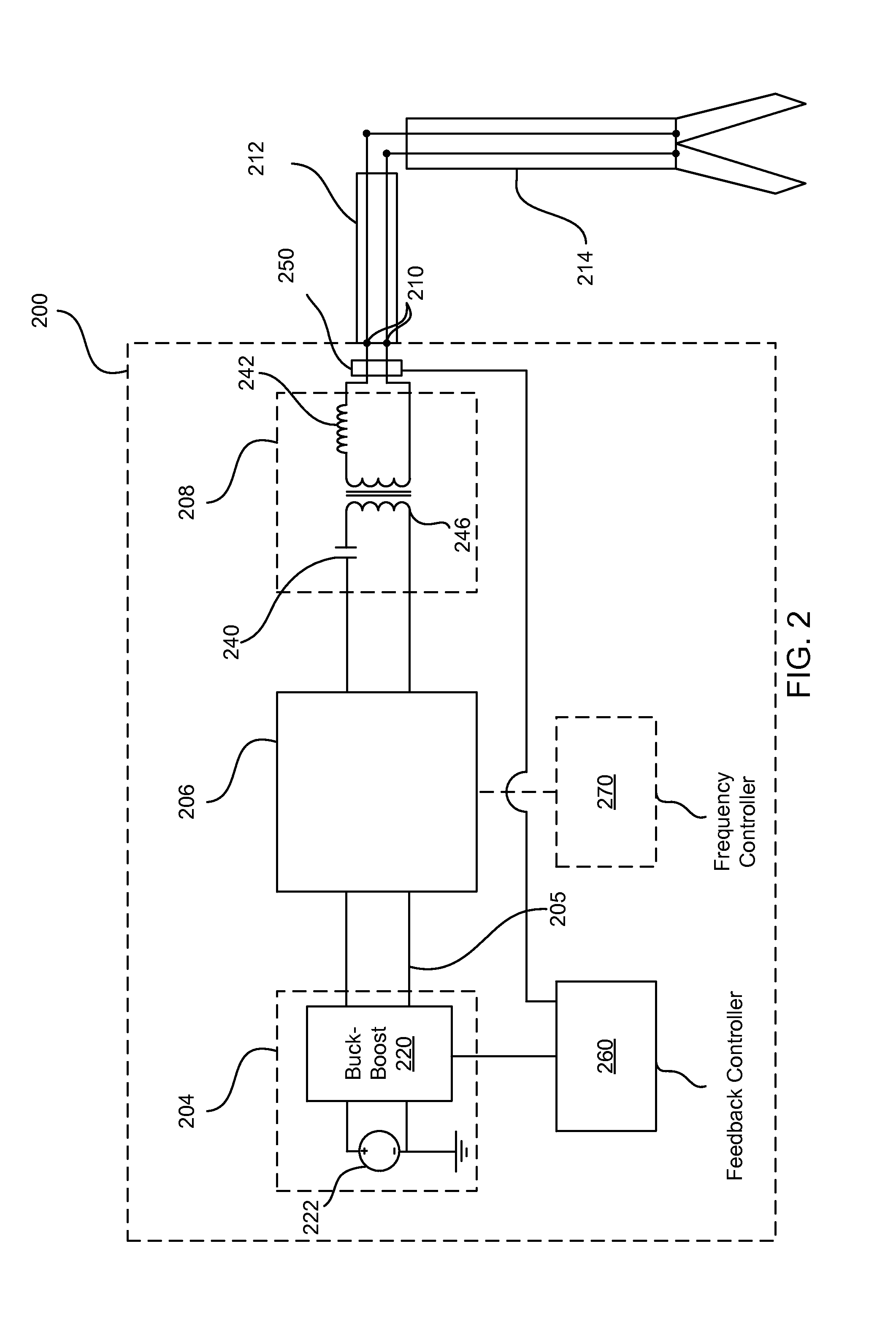

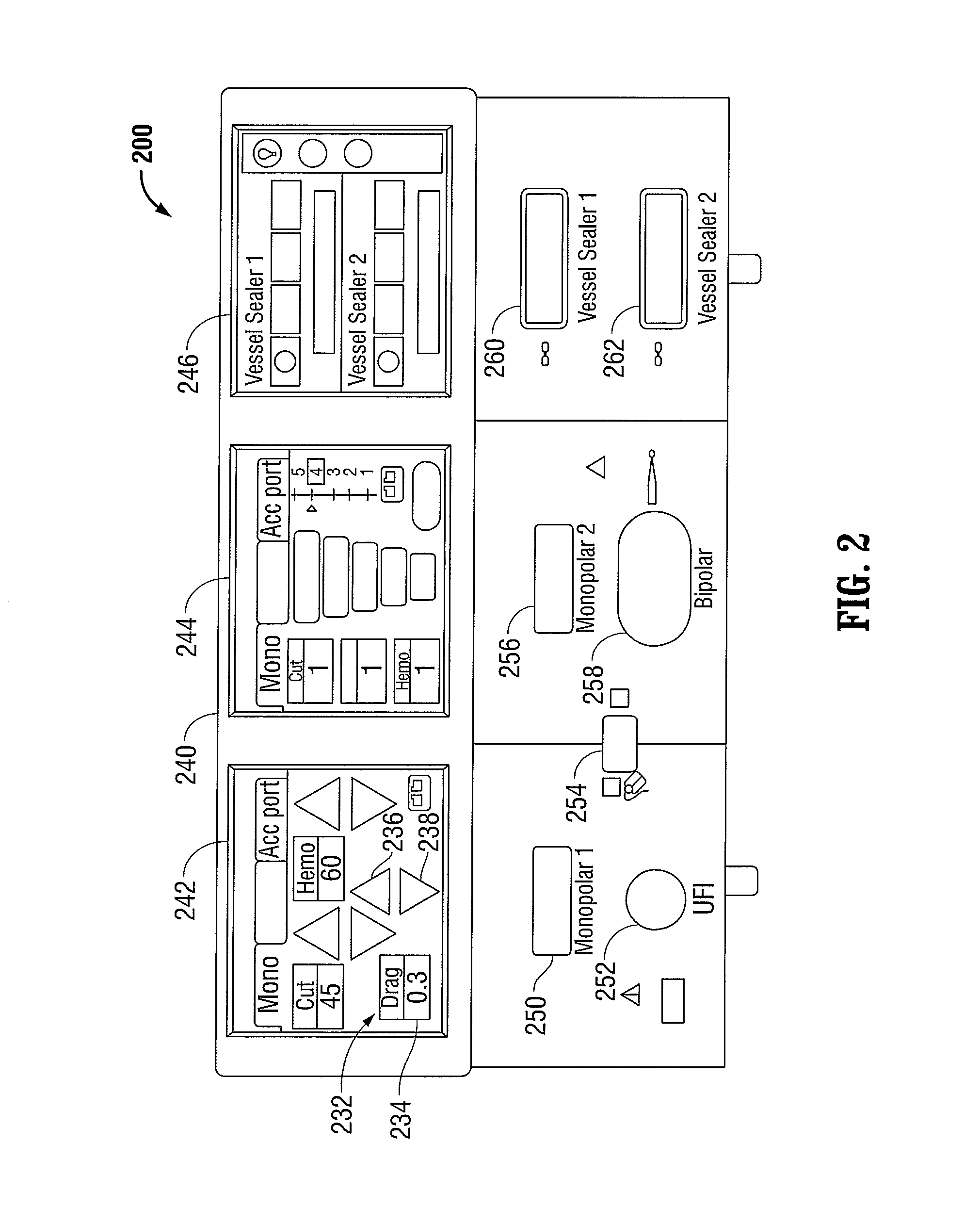

RF generator system for surgical vessel sealing

ActiveUS9039694B2Efficient power electronics conversionSurgical instruments for heatingConstant frequencyVessel sealing

Systems, methods, and apparatus for providing power to an electrosurgical instrument. In particular, a power supply is disclosed in which non-sinusoidal (e.g., pulsed) constant frequency voltage having a variable amplitude is passed to an LC circuit to produce a quasi-sinusoidal current in the LC circuit. The constant driving frequency can be one half the resonant frequency of the LC circuit allowing the LC circuit to operate as an impedance, and thus limit current spikes and arcing. The frequency and phasing of the driving voltage also enables the LC circuit to discharge energy back into a power provider of the power supply so that energy does not build up in the LC circuit. These features result in less severe current spikes and arcing, as well as reduced cutoff times.

Owner:JUST RIGHT SURGICAL

Electrosurgical instrument and method

InactiveUS7517349B2Lower base resistanceRule out the possibilityDiagnosticsSurgical instruments for heatingElectrical resistance and conductanceVaricose veins

Owner:TYCO HEALTHCARE GRP LP

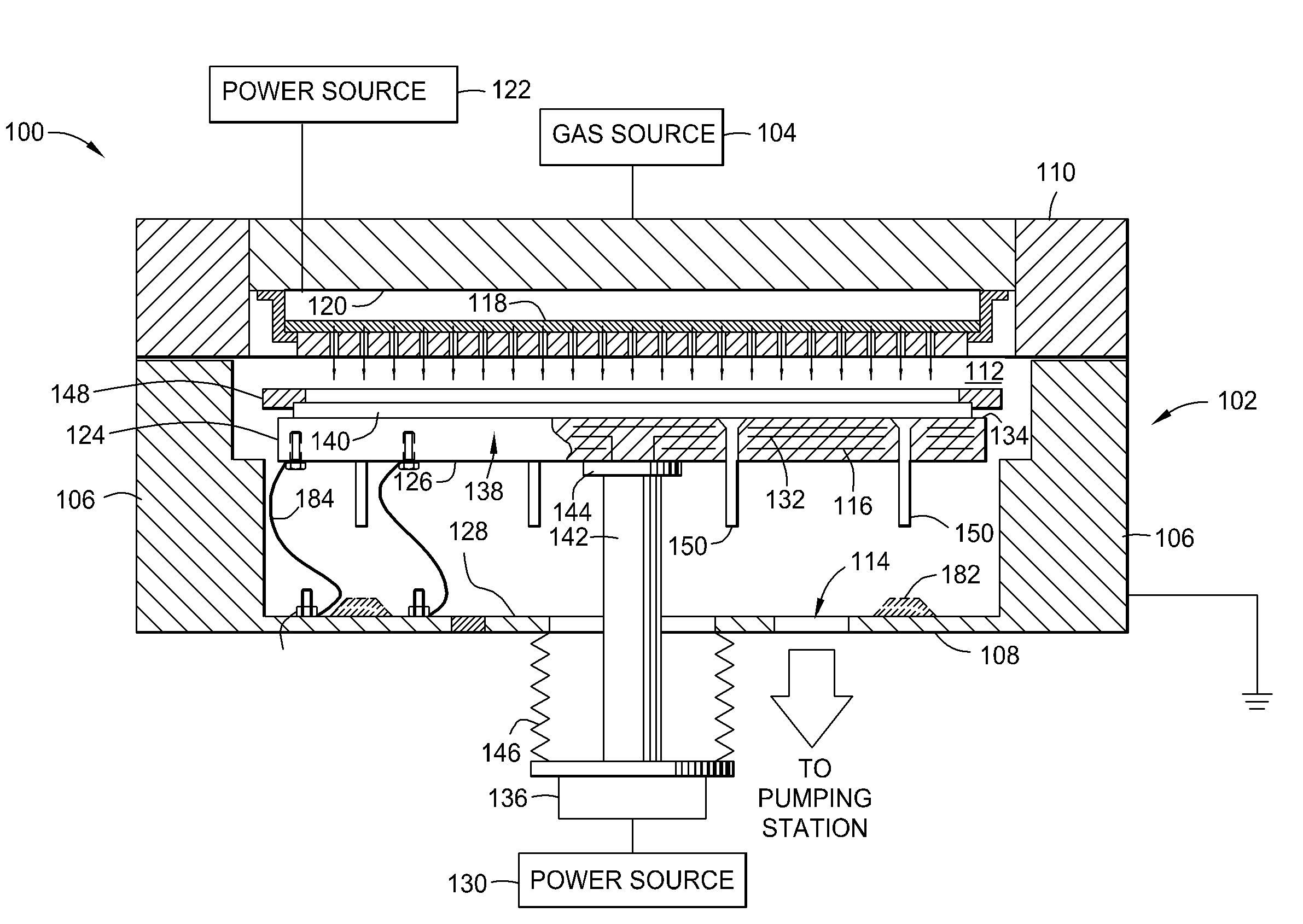

Susceptor with insulative inserts

InactiveUS20080194169A1Reduce arcingElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorMechanical engineering

A method and apparatus for reducing arcing in a plasma processing system when processing large area substrates which contain one or more holes. In one embodiment of the invention, a substrate support member includes an electrically insulating insert located beneath a hole in an insulating, large area substrate. The insulating insert is made of aluminum oxide, and is located within a hole in the support member such that the insert is disposed beneath a hole in a glass substrate. The substrate support member is made of aluminum with an anodized surface.

Owner:APPLIED MATERIALS INC

Switch mechanisms for safe activation of energy on an electrosurgical instrument

ActiveUS20070016187A1Secure bootElectric switchesSurgical instruments for heatingHigh energyActuator

Various safe switching mechanisms are provided for use with electrosurgical instruments which prevent arcing between the high-energy contacts as the high-energy source is activated. The switching mechanisms generally include a pair of high-energy contacts and a pair of activation contacts. An actuator is provided which initially engages the high-energy contacts in advance of engagement of the activation contacts to prevent arcing and subsequently disengages the activation contacts in advance of the high-energy contacts as the energy source is deactivated. A method of switching power to an electrosurgical instrument while avoiding damage to high-energy contacts is also disclosed.

Owner:COVIDIEN AG

Detection and suppression of electrical arcing

ActiveUS20060049831A1Eliminate exceptionsGuaranteed uptimeTesting dielectric strengthMaterial analysis by electric/magnetic meansElectrical resistance and conductanceDisplay device

Method and apparatus for detecting or suppressing electrical arcing or other abnormal change in the electrical impedance of a load connected to a power source. Preferably the load is a plasma chamber used for manufacturing electronic components such as semiconductors and flat panel displays. Arcing is detected by monitoring one or more sensors. Each sensor either responds to a characteristic of the electrical power being supplied by an electrical power source to the plasma or is coupled to the plasma chamber so as to respond to an electromagnetic condition within the chamber. Arcing is suppressed by reducing the power output for a brief period. Then the power source increases its power output, preferably to its original value. If the arcing resumes, the power source repeats the steps of reducing and then restoring the power output.

Owner:APPLIED MATERIALS INC

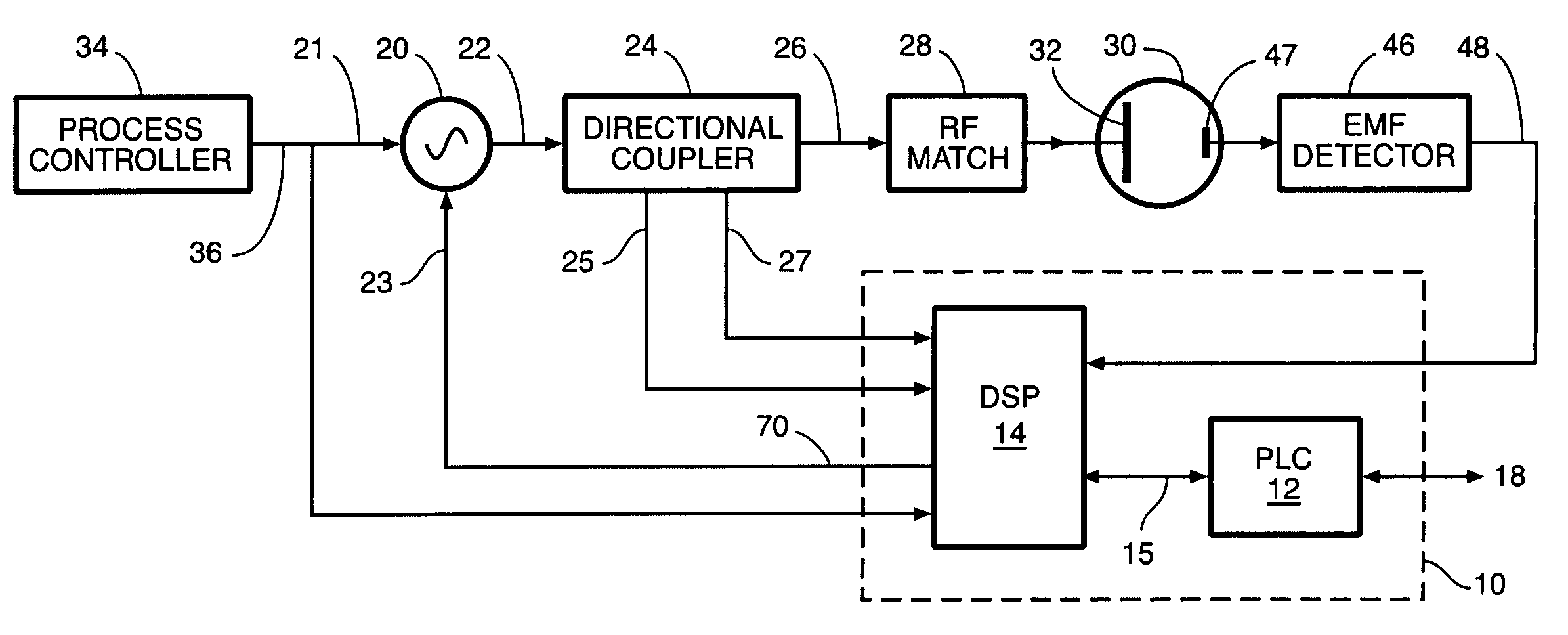

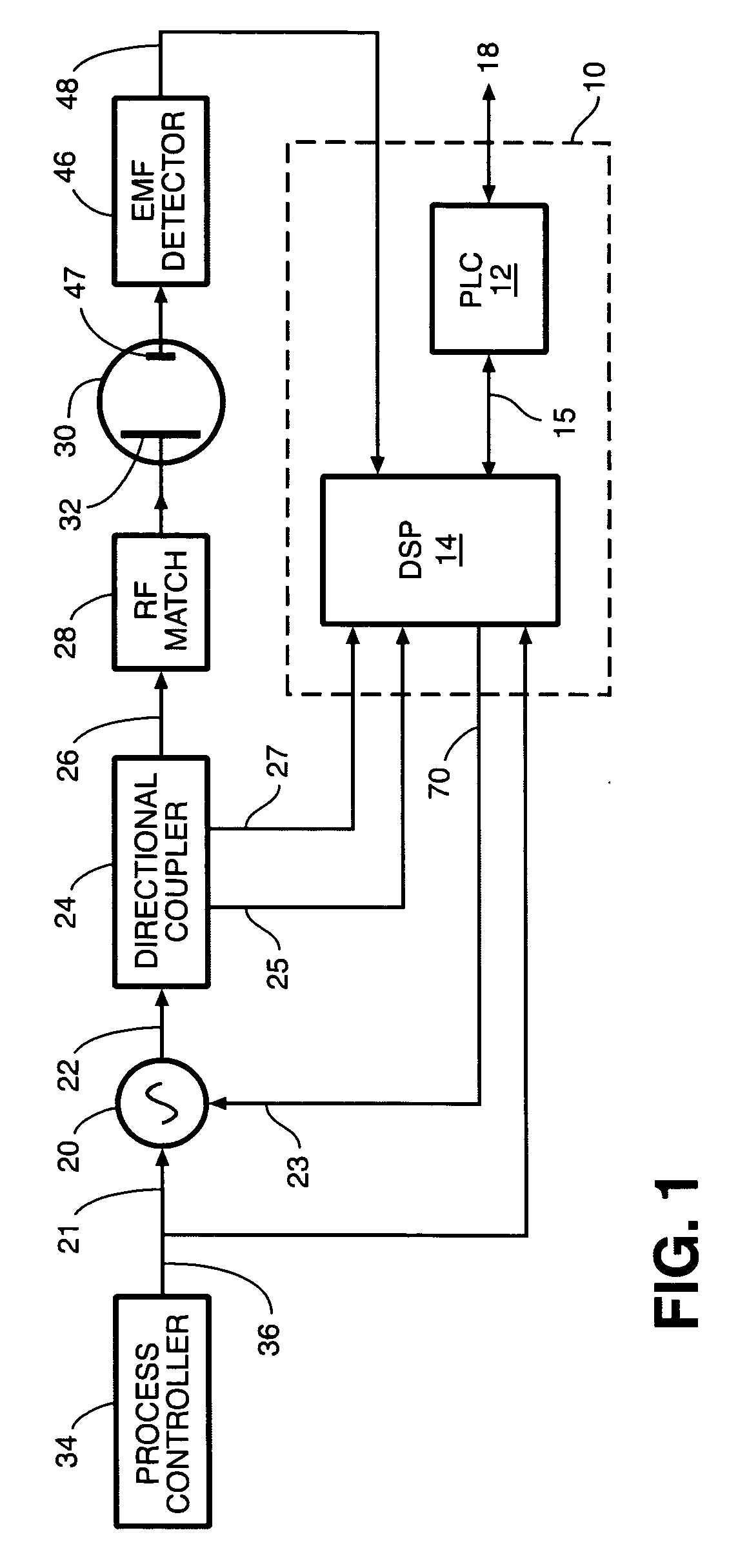

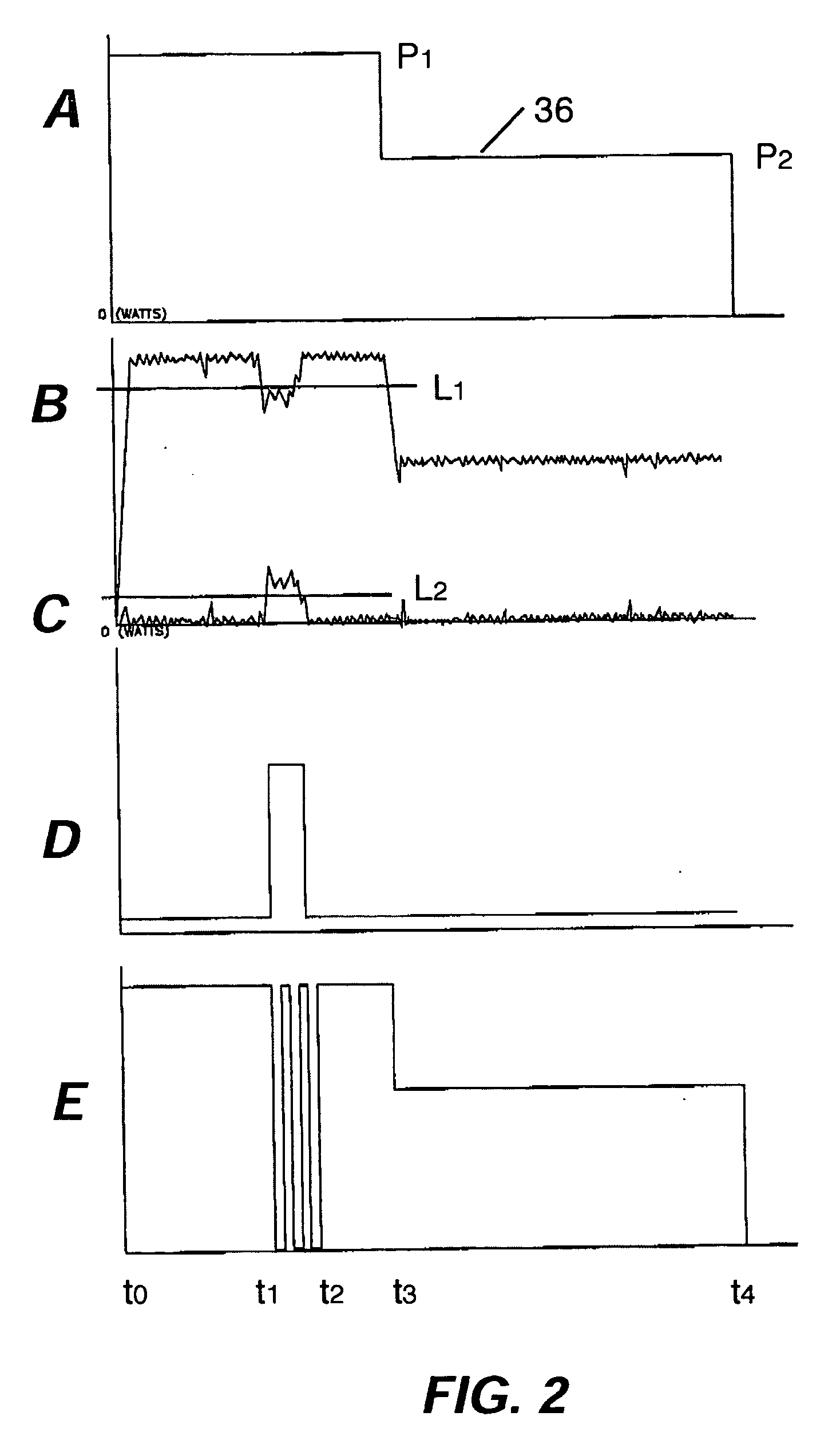

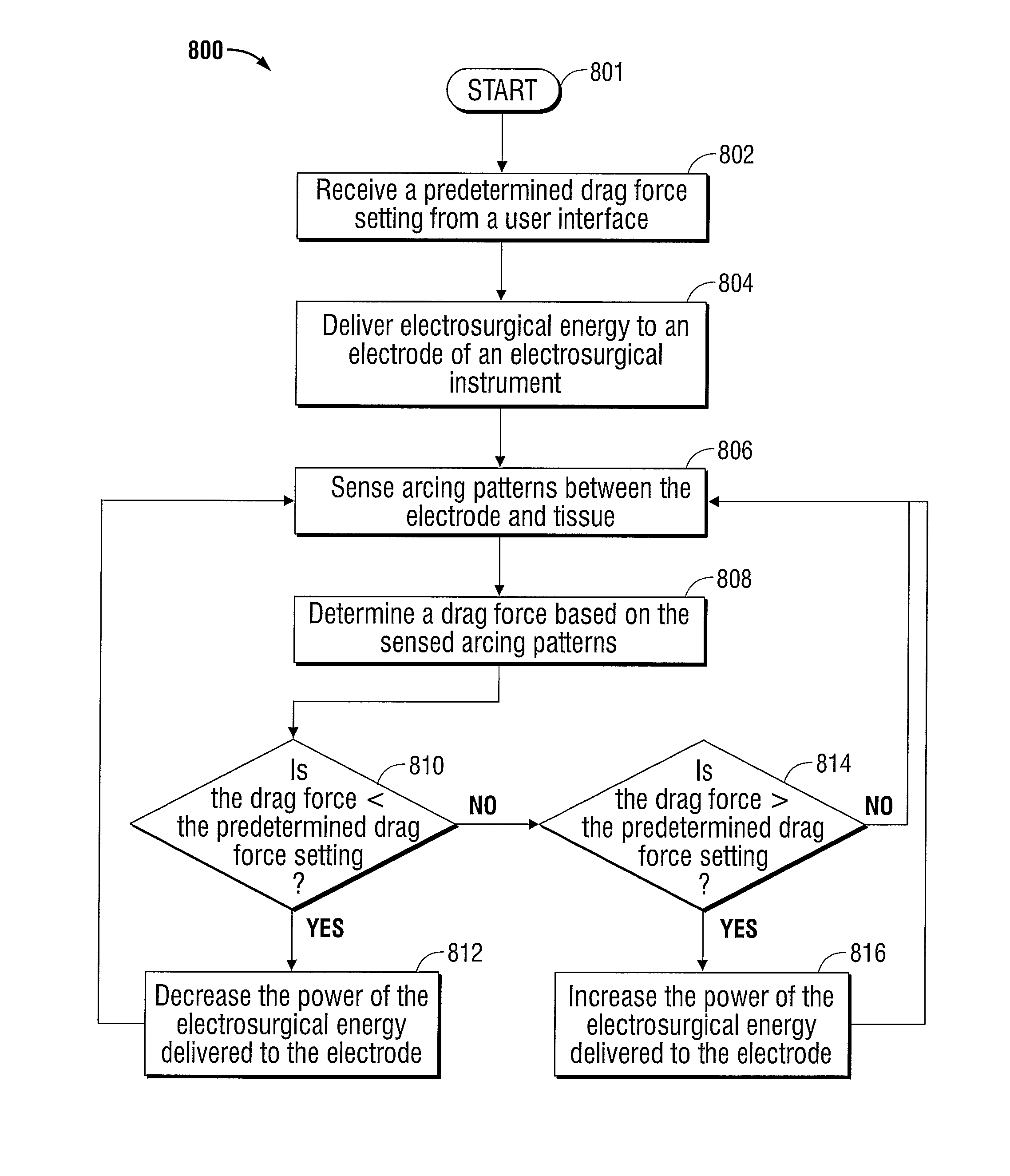

Systems and methods for arc detection and drag adjustment

ActiveUS9498275B2Increase powerReduce the required powerSurgical instruments for heatingBandpass filteringWaveform analysis

Controlling a level of electrosurgical energy provided to tissue based on detected arcing patterns or impedance changes. The drag force imposed on an electrode or blade of an electrosurgical instrument may be controlled by adjusting the level of electrosurgical energy based on the arcing patterns or impedance changes. The arcing patterns or impedance changes may be detected by sensing and analyzing voltage and / or current waveforms of the electrosurgical energy The current and / or voltage waveform analysis may involve calculating impedance based on the voltage and current waveforms and calculating changes in impedance over time. The waveform analysis may involve detecting harmonic distortion using FFTs, DFTs, Goertzel filters, polyphase demodulation techniques, and / or bandpass filters. The waveform analysis may involve determining a normalized difference or the average phase difference between the voltage and current waveforms.

Owner:TYCO HEALTHCARE GRP LP

Electrodynamic field generator

This device is a brushless high-voltage electrical generator, requiring suitable means of input rotary torque, for purposes of producing a very-high-energy external electrodynamic field or continuous quasi-coherent DC corona or arc discharge of uniform current density which completely encloses the machine's conductive housing. This housing is divided into distinct electrical sections and contains a flat conductive rotor which electrically links separate negative and positive housing sections and upon which a plurality of toroidal generating coils are rotatably mounted. Circular arrays of stationary permanent magnets are affixed within the housing which induce a constant DC voltage within said coils upon their rotation. The primary voltage so-generated is electrostatically impressed across the rotor such that great quantities of electronic charge may be transported between the opposite polarity sections of the housing, in such a manner that a much higher secondary voltage is caused to appear across interposed neutral sections thereof, and the resulting external breakdown current once initiated is independent of the generating coils' ampacity. Ancillary mechanical, electrical, an / or electronic features may be attached upon or within the housing to aid in harnessing and controlling the useful effects associated with the external dynamic electric field produced by the device.

Owner:LV DYNAMICS

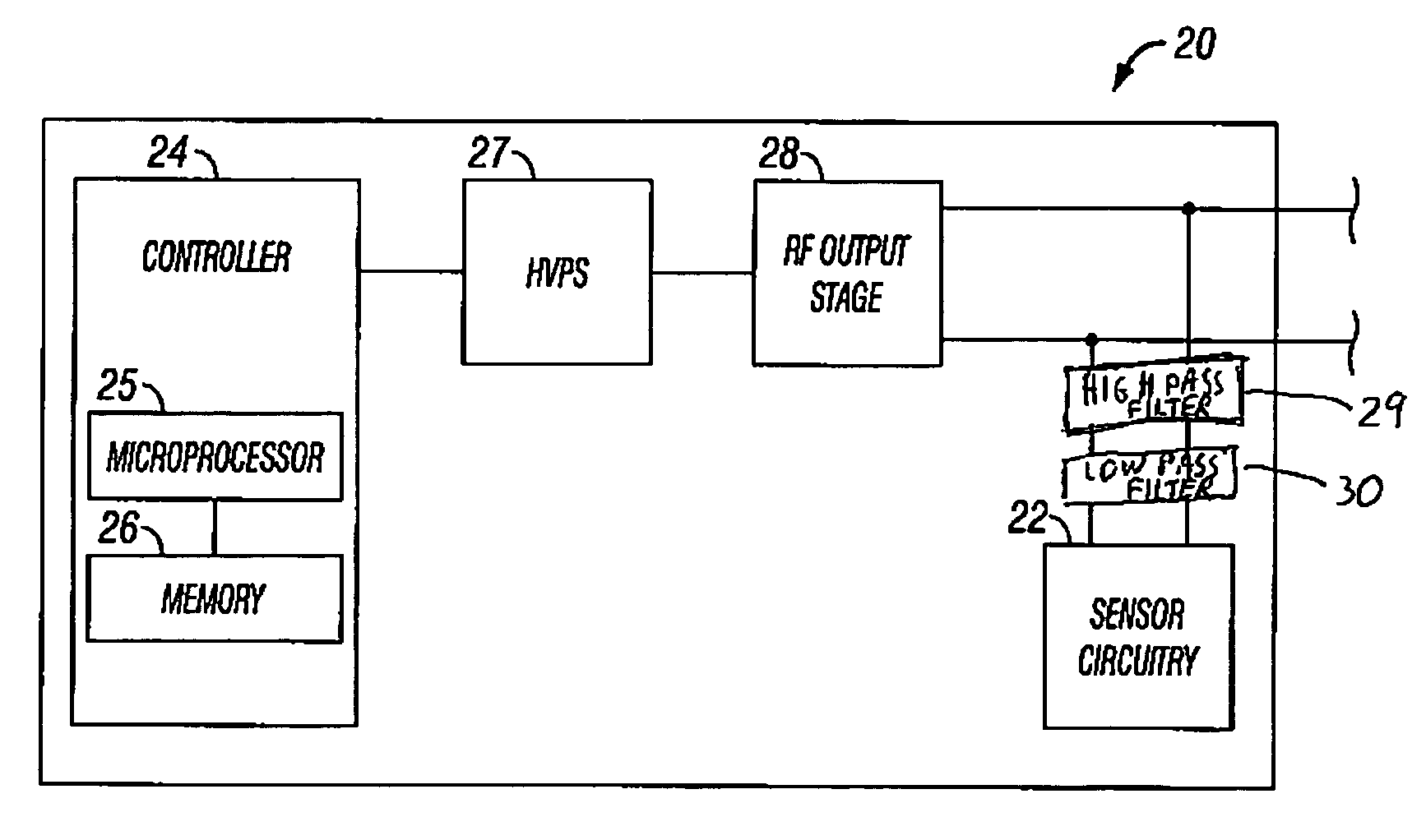

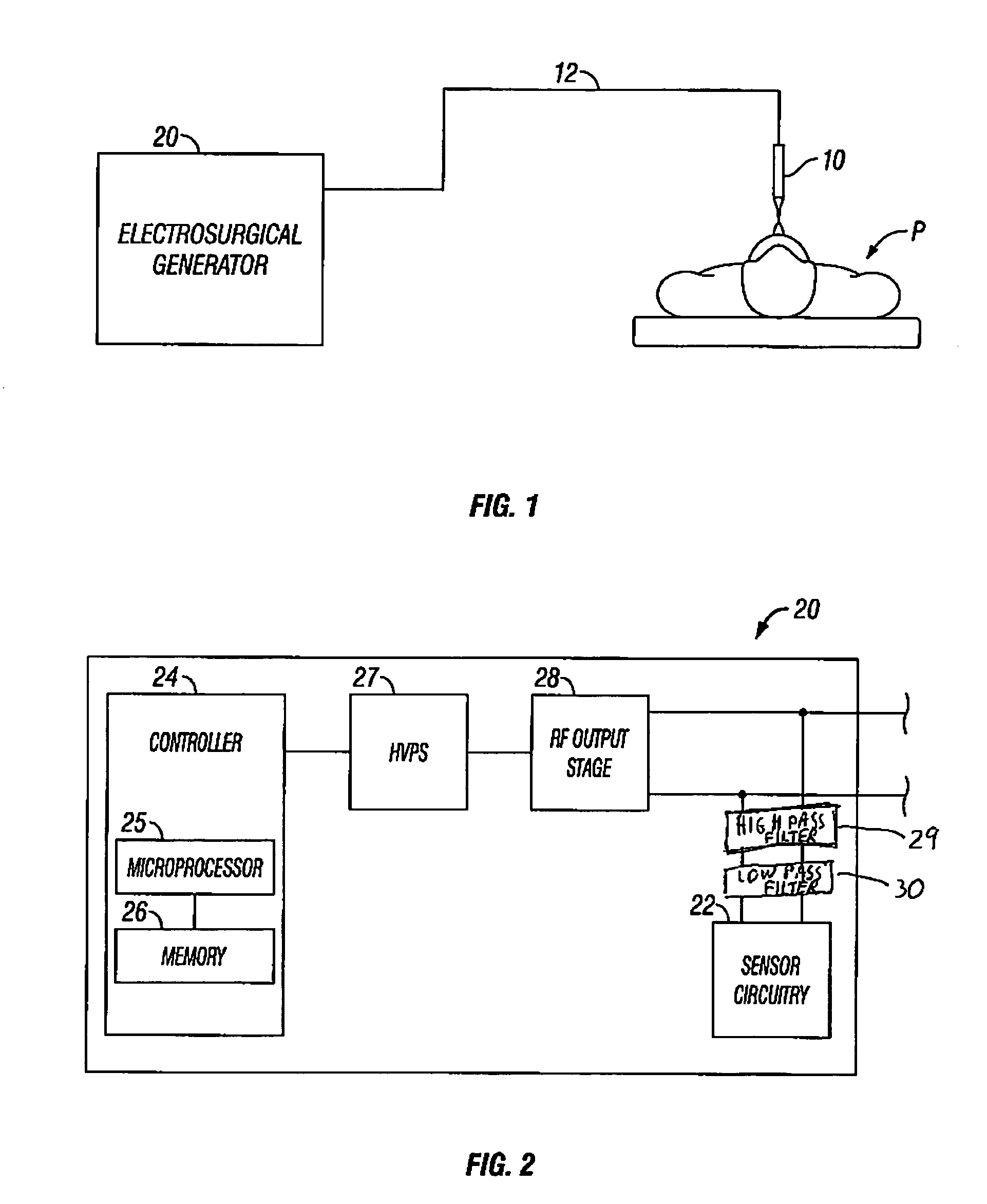

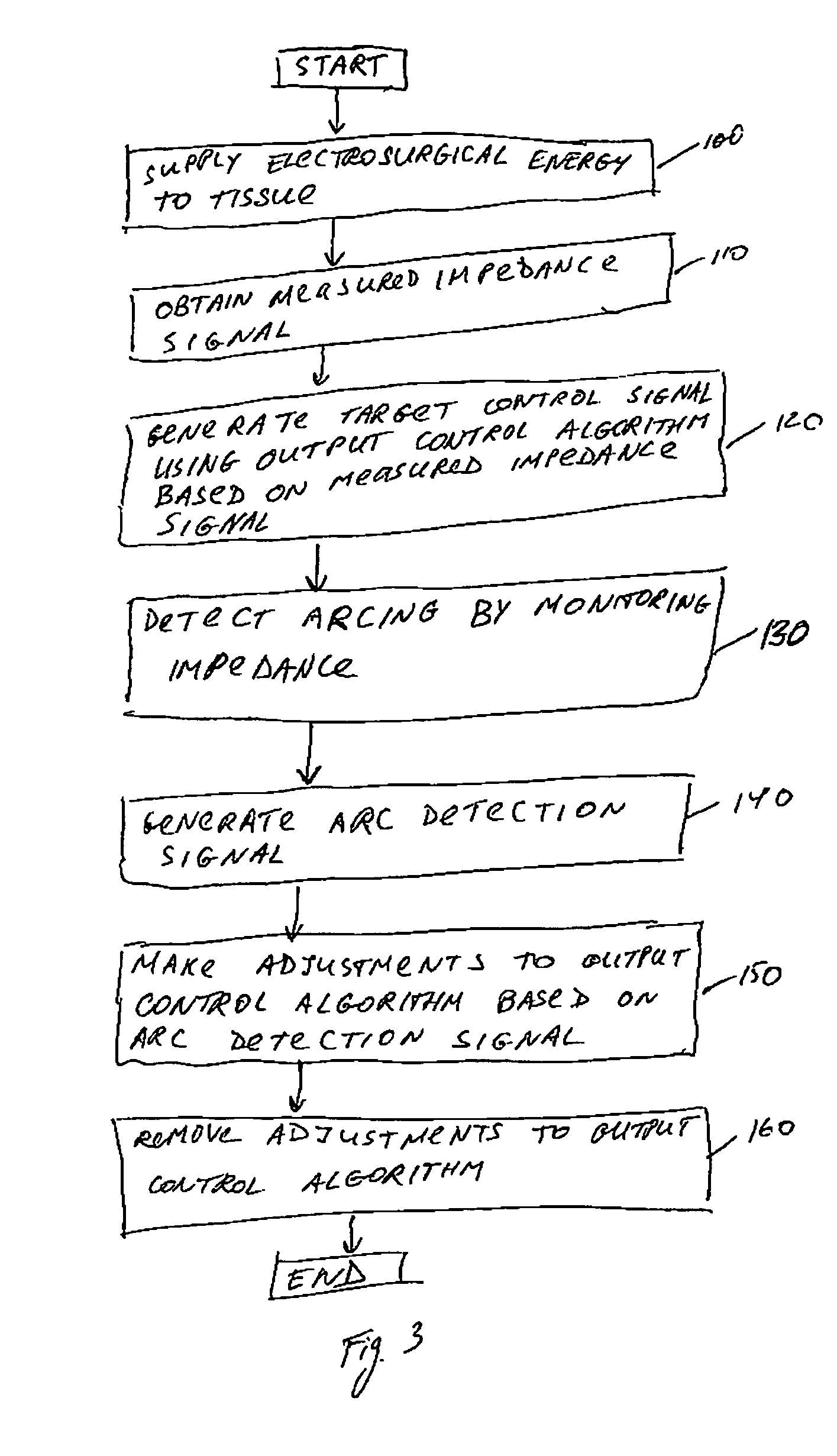

Arc based adaptive control system for an electrosurgical unit

A system and method for performing electrosurgical procedures are disclosed. The system includes an electrosurgical generator adapted to supply electrosurgical energy to tissue in form of one or more electrosurgical waveforms having a crest factor and a duty cycle. The system also includes sensor circuitry adapted to measure impedance and to obtain one or more measured impedance signals. The sensor circuitry is further adapted to generate one or more arc detection signals upon detecting an arcing condition§. The system further includes a controller adapted to generate one or more target control signals as a function of the measured impedance signals and to adjust output of the electrosurgical generator based on the arc detection signal. An electrosurgical instrument is also included having one or more active electrodes adapted to apply electrosurgical energy to tissue.

Owner:COVIDIEN AG

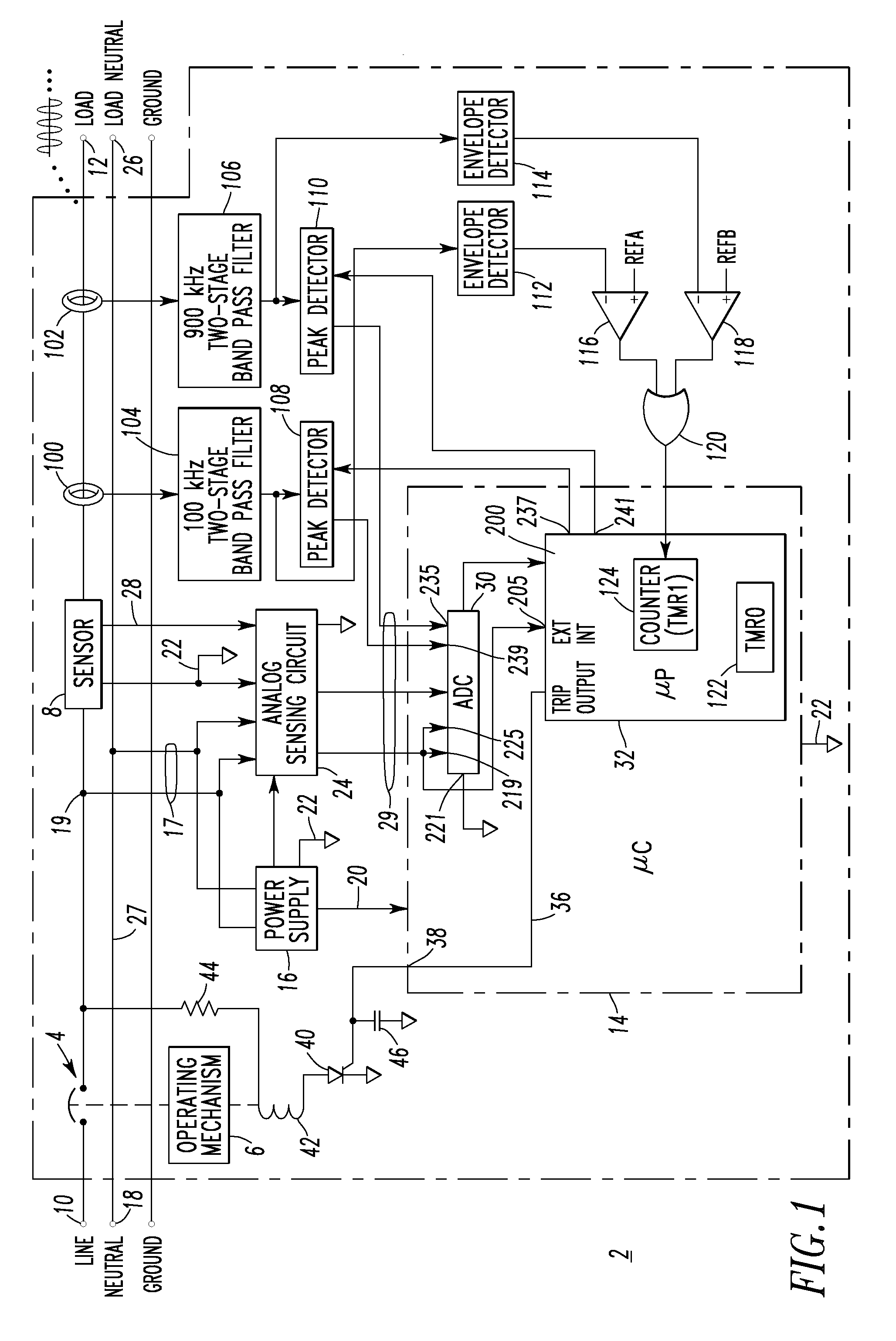

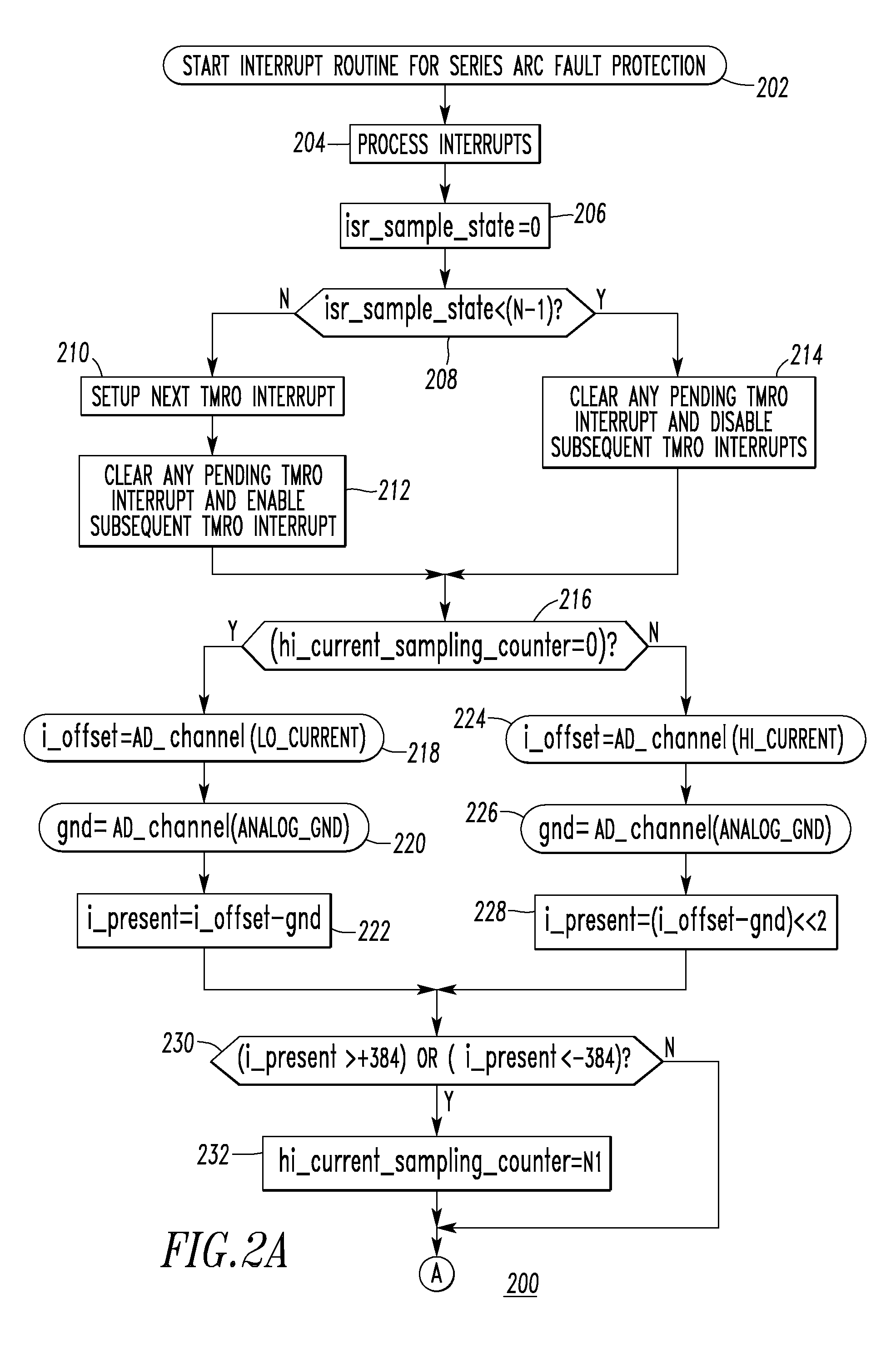

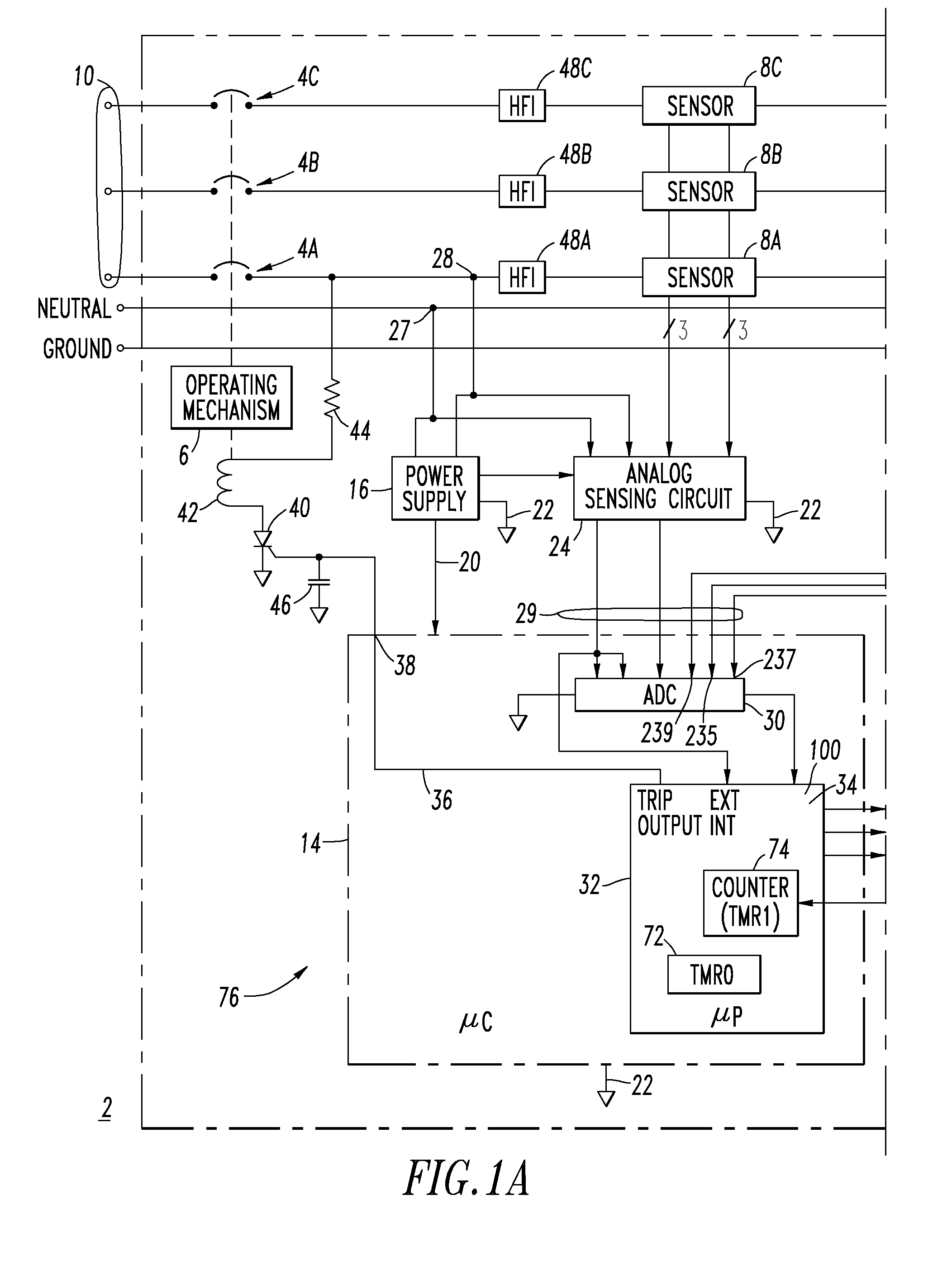

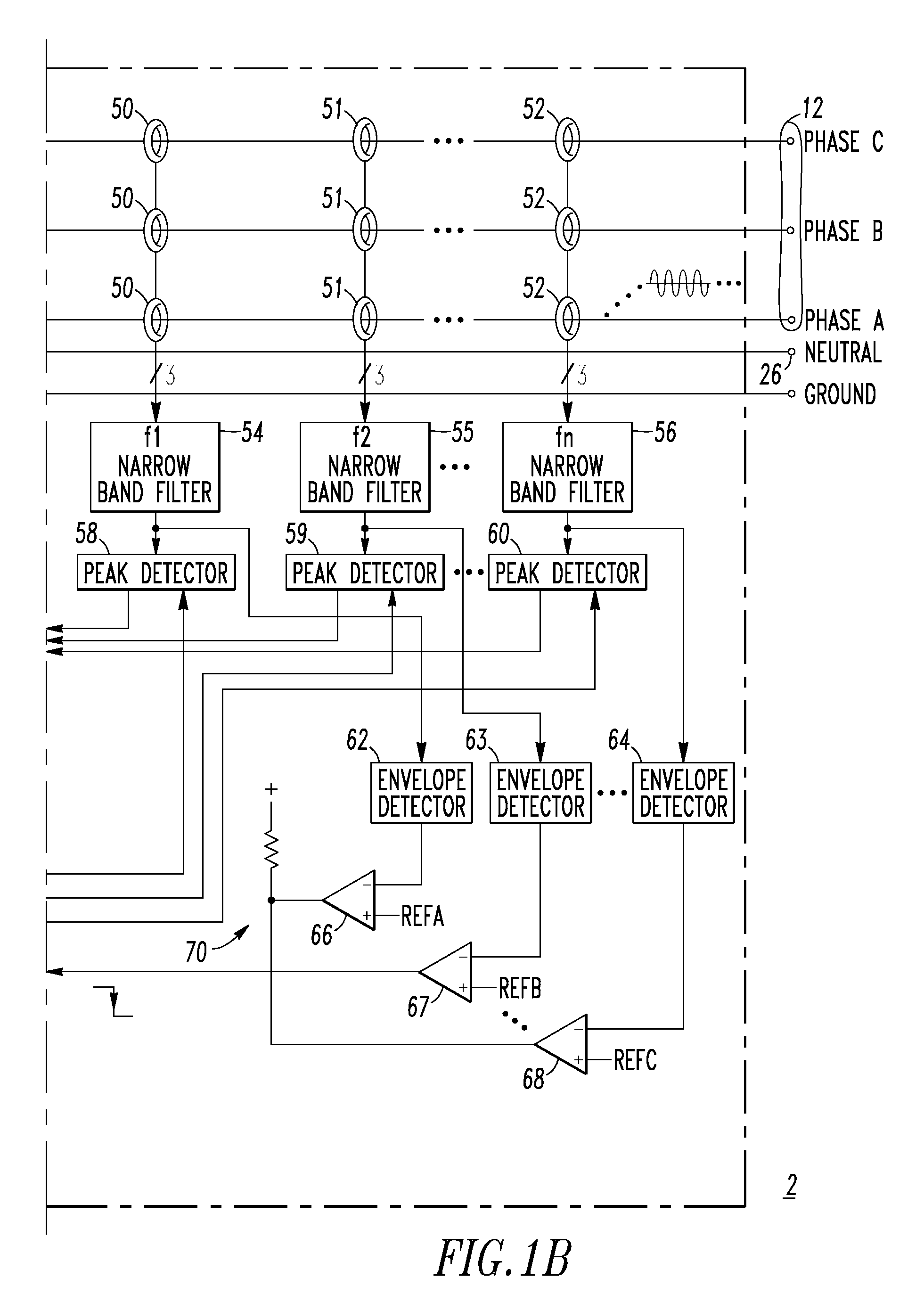

Arc fault circuit interrupter and series arc fault detection method using plural high frequency bands

ActiveUS20080204950A1Remove baseline shiftingRotary current collectorEmergency protective arrangement detailsBand-pass filterCurrent sensor

A circuit interrupter includes band pass filters cooperating with a current sensor to output bands having different, non-overlapping ranges of frequencies, peak detectors cooperating with the filters to detect corresponding peak current values, envelope detectors cooperating with the filters to detect corresponding occurrences from the bands being within corresponding predetermined magnitude ranges, a counter counting the occurrences, and a processor providing and disabling series arc detection when sensed current is greater than a first predetermined value. The processor determines tallies responsive to peak current values exceeding corresponding thresholds, determines series arcing from sensed current being less than the first predetermined value for a predetermined time, the tally for a current half-cycle being nonzero, and a count for the current half-cycle being different than the count for an immediately previous half-cycle of like polarity by at least a second predetermined value. A series chaos accumulator is increased responsive to series arcing.

Owner:EATON INTELLIGENT POWER LTD

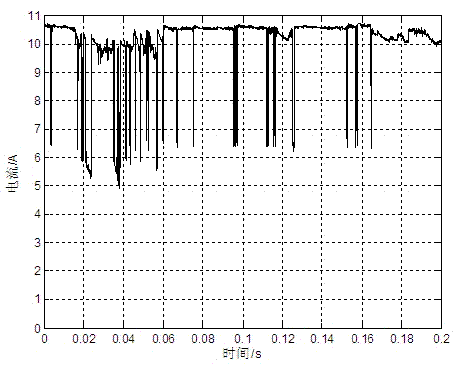

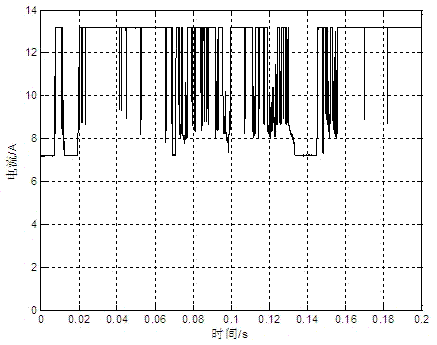

Detection method and device of direct current arc faults

The invention discloses a detection method of direct current arc faults. The method is characterized by acquiring and computing a plurality of arc phenomena detection periods, confirming the arc phenomena, namely spark discharge phenomenon and arc discharge phenomenon by two feature extraction methods including a time domain standard deviation method and a Mahalanobis distance method based on time and frequency domains and counting the two phenomena respectively, and in the primary arc fault diagnosis period, judging that the arc faults exist if the total count of the two phenomena exceeds the given threshold and needing to judge whether suspected arcs appear if the total count of the two phenomena still fails to exceed the given threshold beyond the time. By the detection method, the arc faults in an electrified loop can be detected and protected. In a detection device, the current flowing through a sampling resistor is sampled, and when occurrence of the arc faults is judged, the trip signal is sent to a drive circuit of a power switch. The invention also discloses the detection device of the direct current arc faults, which can implement the detection method.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

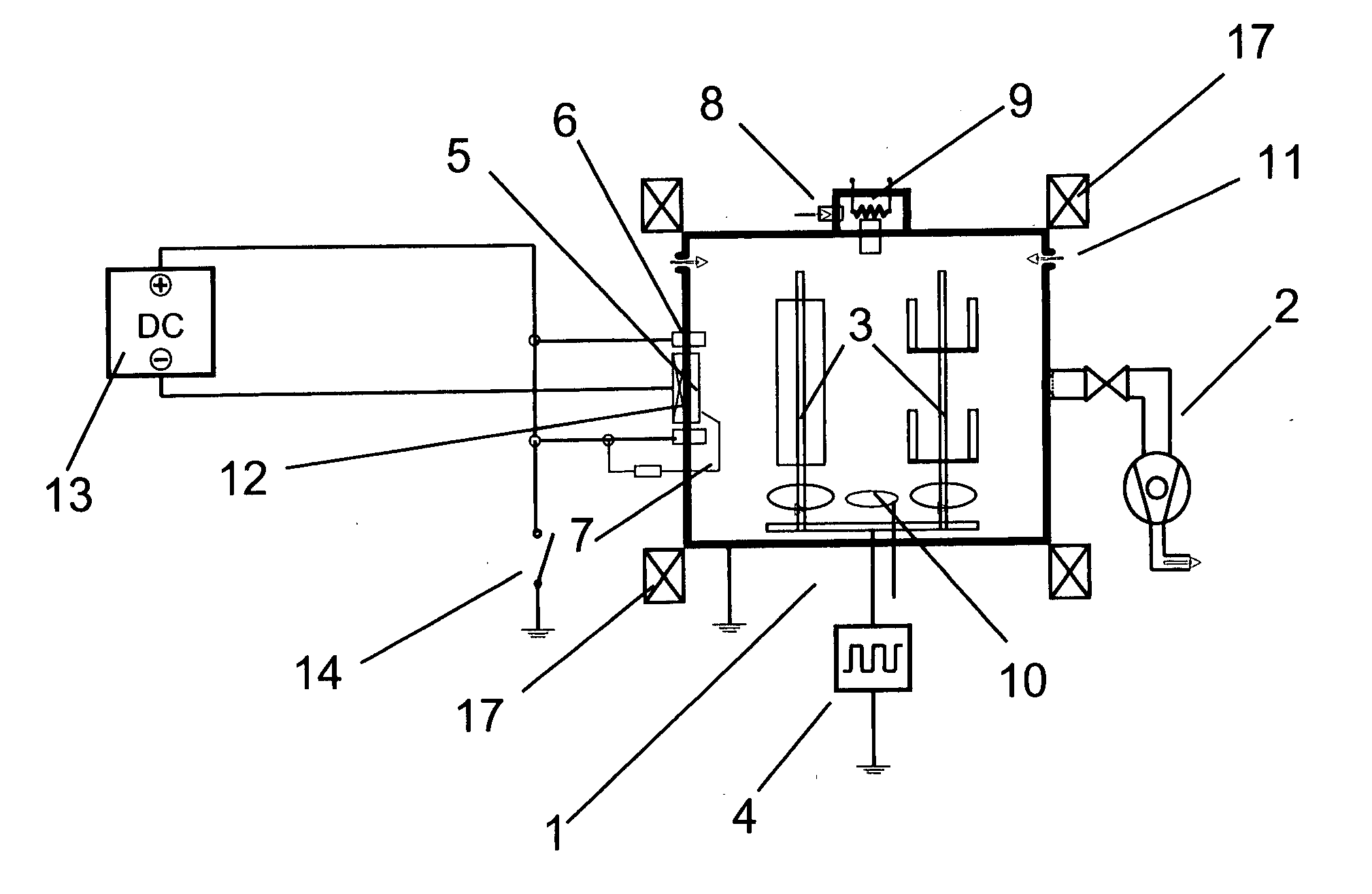

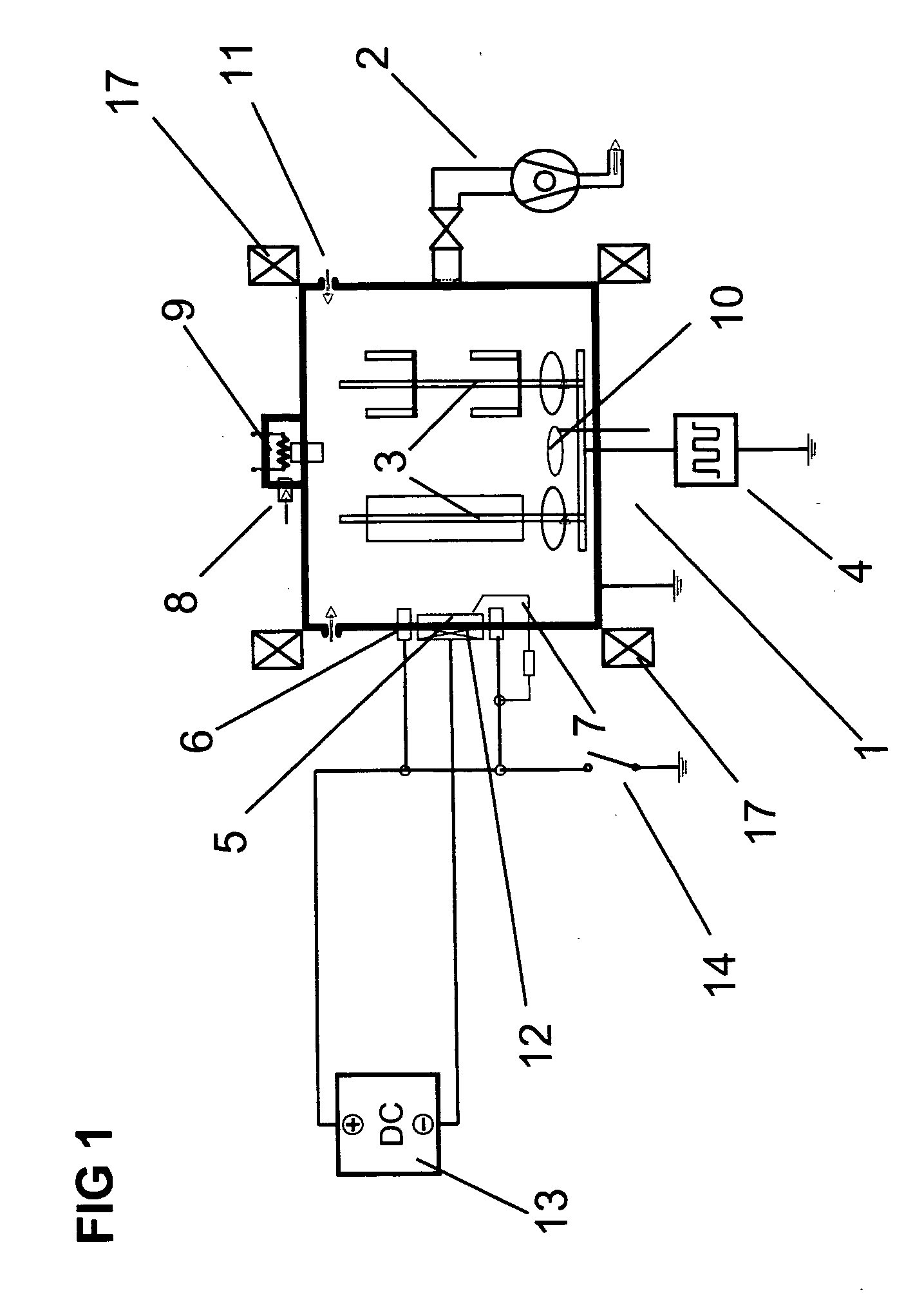

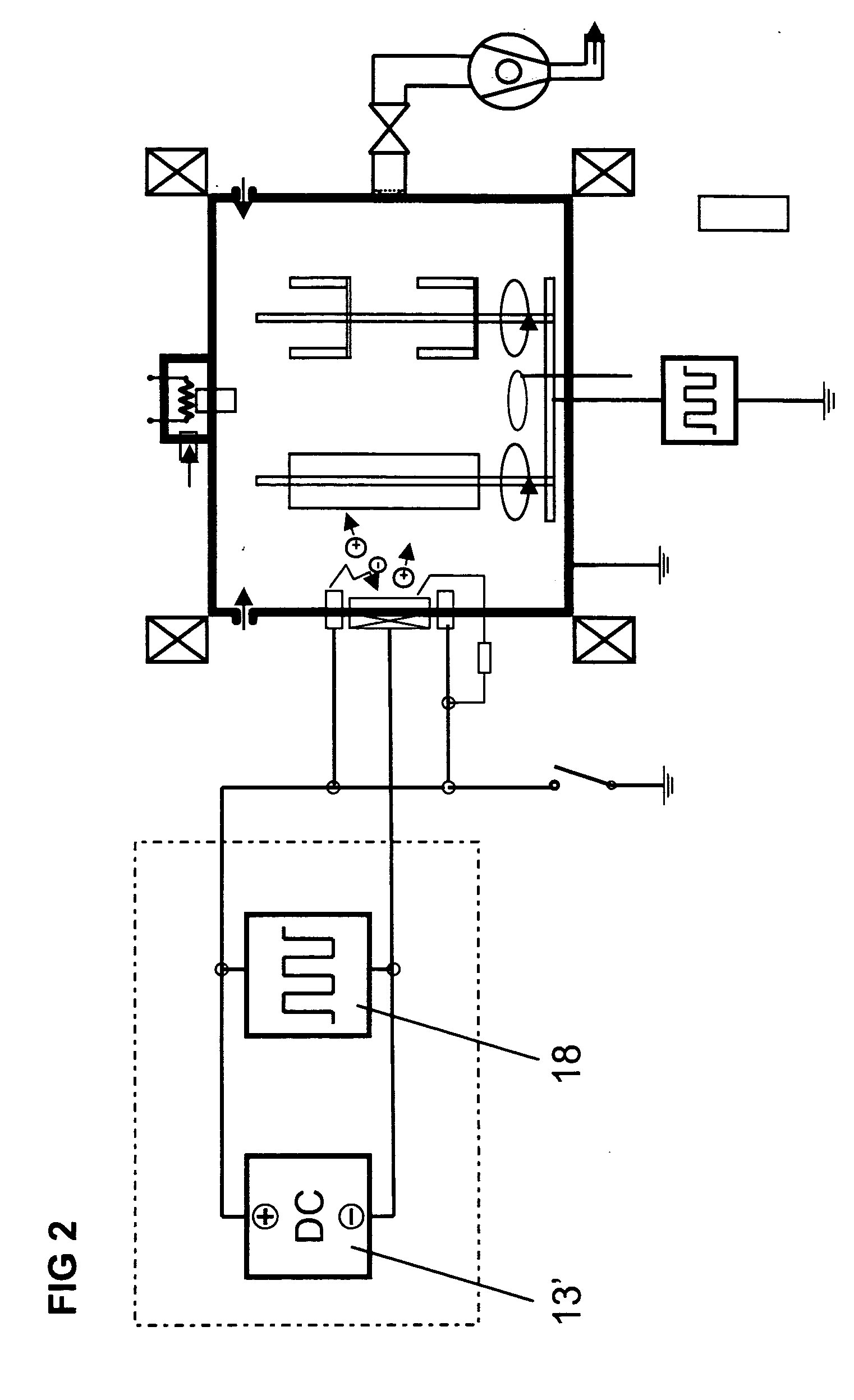

Method for operating a pulsed arc source

This invention relates to an arc-based method for the deposition of insulating layers and to an arc-based method for low-temperature coating processes, in which an electric arc discharge, ignited and applied on the surface of a target in an arc source, is simultaneously fed a direct current and a pulsed or alternating current. The invention further relates to an arc source in which the target is connected to a power supply unit that encompasses either a minimum of one pulsed high-current power supply 18, 18′ and an additional power supply 13′, 18″, or a power supply 21, 21′, 22 designed with switchable combinatorial circuitry.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

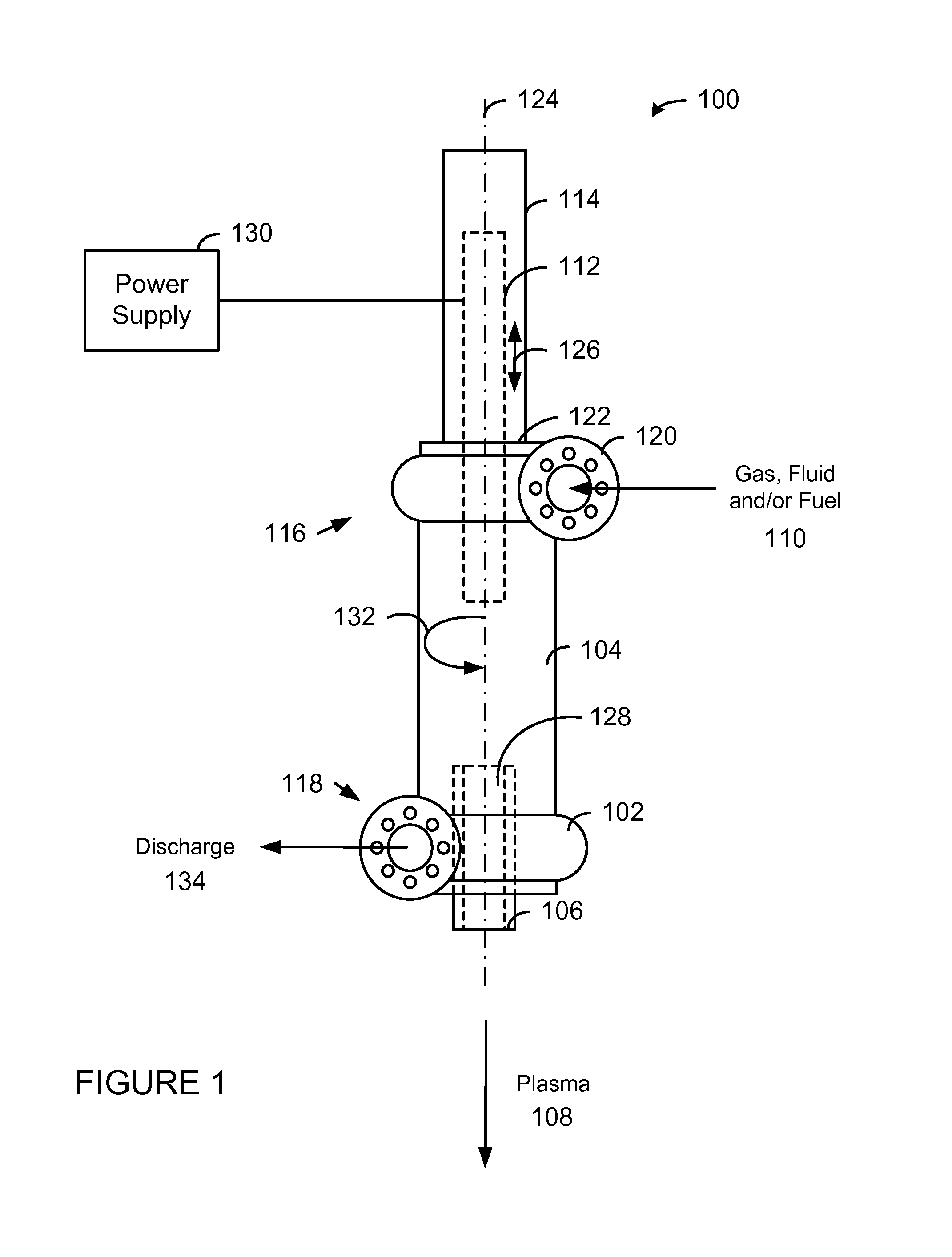

Method and apparatus for plasma generation

ActiveUS20050092596A1Improved plasma confinement propertyIncrease currentElectric discharge tubesVacuum evaporation coatingElectric dischargePlasma flow

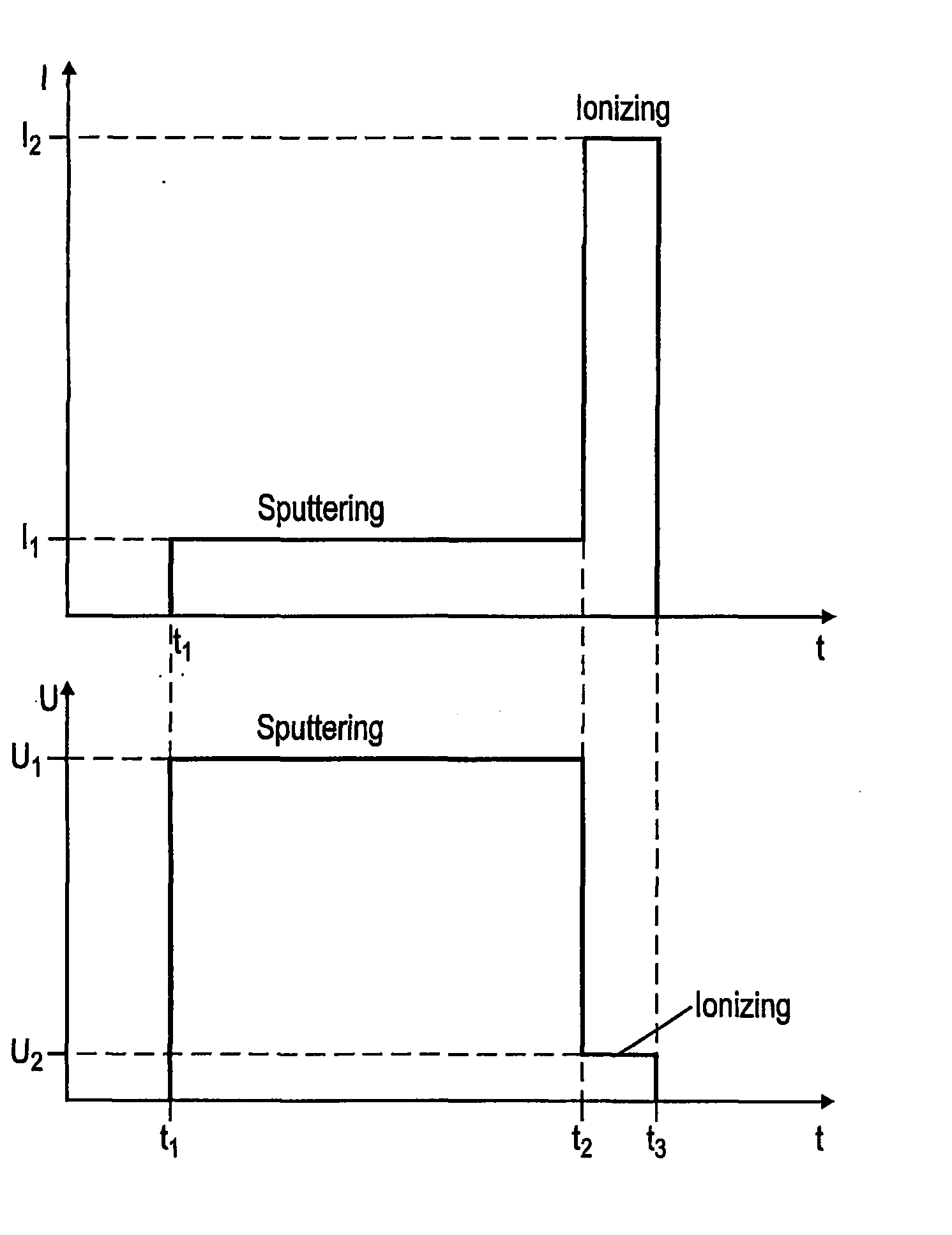

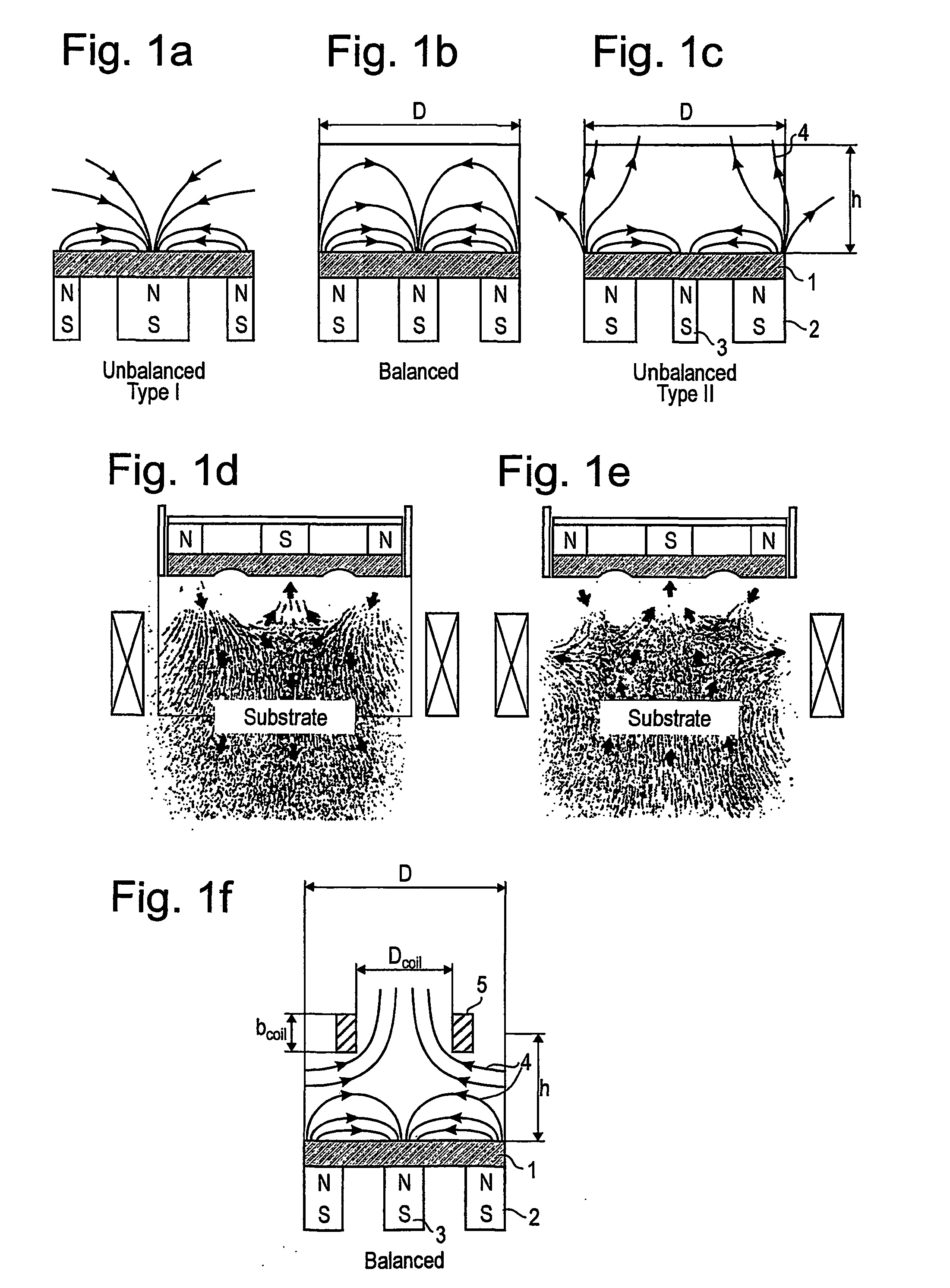

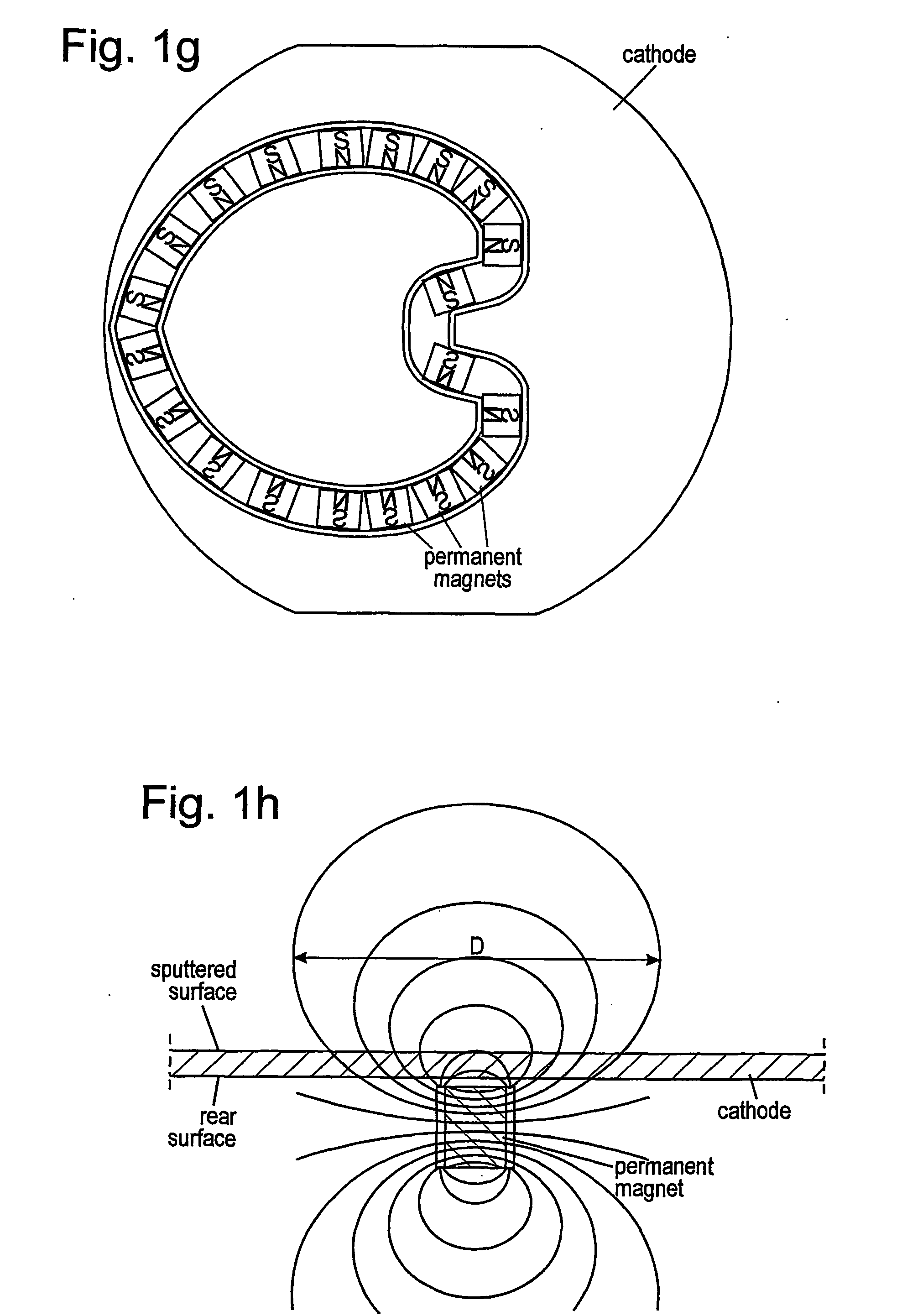

In a simple method and device for producing plasma flows of a metal and / or a gas electric discharges are periodically produced between the anode and a metal magnetron sputtering cathode in crossed electric and magnetic fields in a chamber having a low pressure of a gas. The discharges are produced so that each discharge comprises a first period with a low electrical current passing between the anode and cathode for producing a metal vapor by magnetron sputtering, and a second period with a high electrical current passing between the anode and cathode for producing an ionization of gas and the produced metal vapor. Instead of the first period a constant current discharge can be used. Intensive gas or metal plasma flows can be produced without forming contracted arc discharges. The selfsputtering phenomenon can be used.

Owner:CEMECON +1

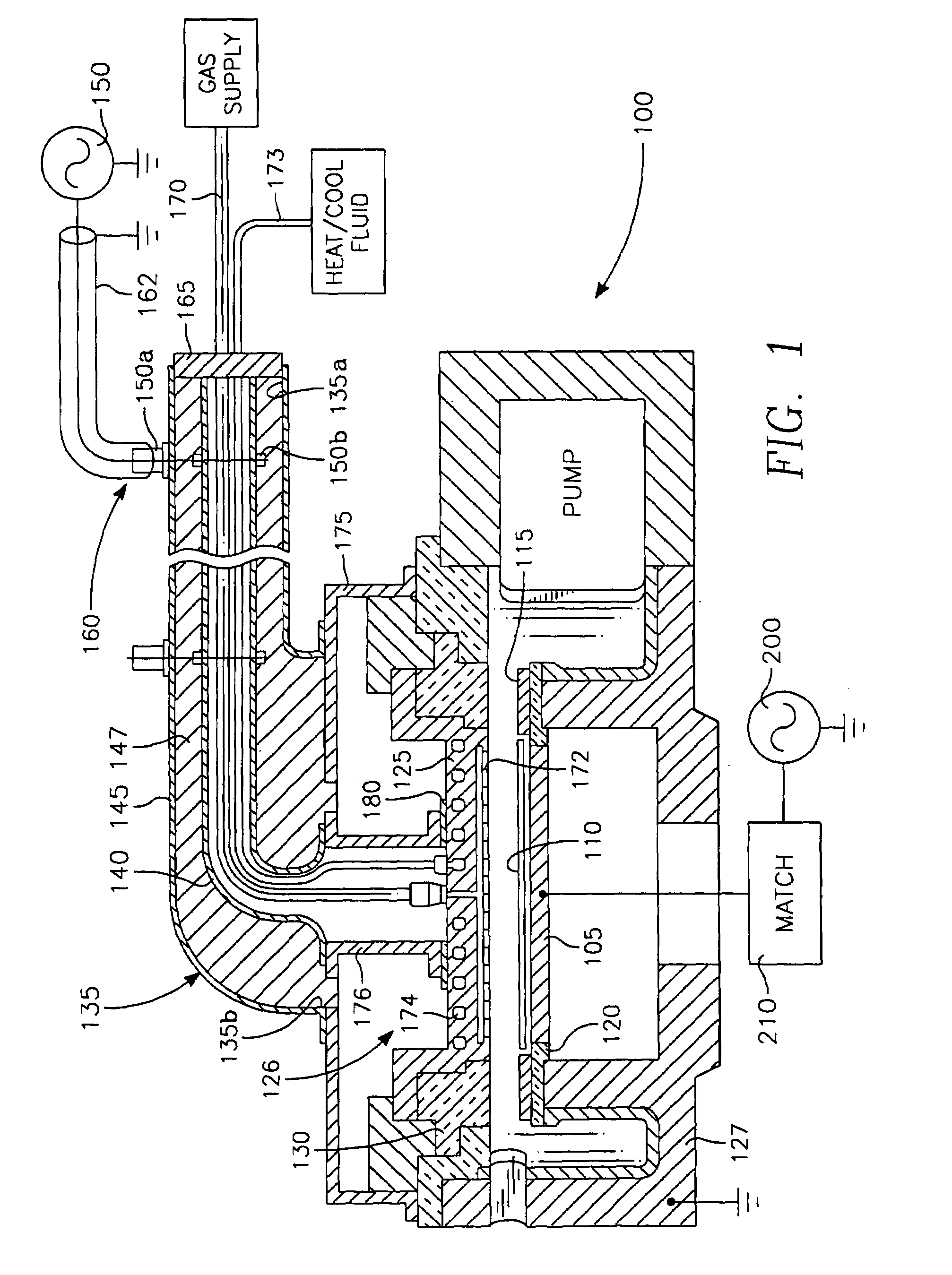

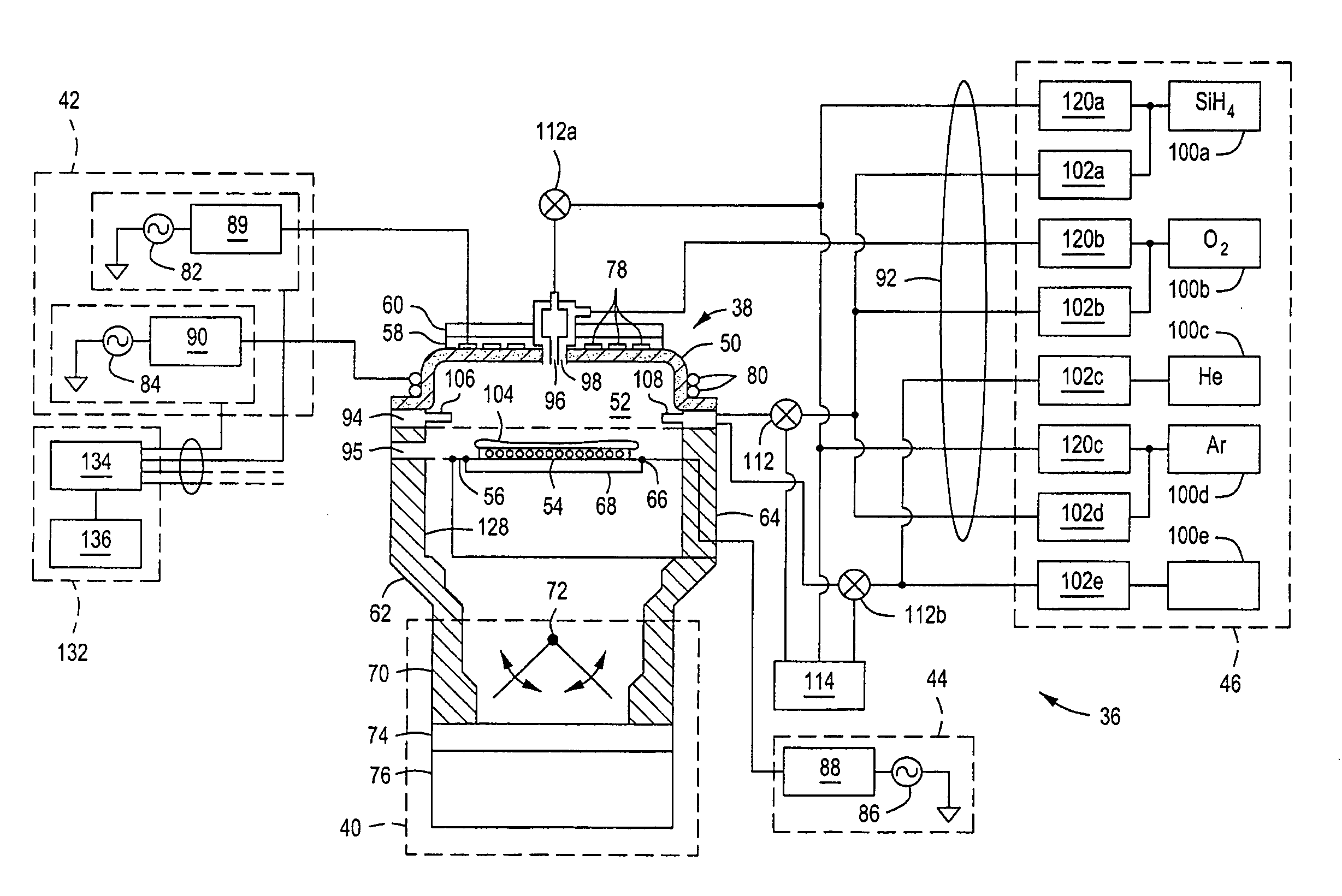

Plasma reactor with overhead RF source power electrode with low loss, low arcing tendency and low contamination

A gas distribution ceiling electrode for use as a capacitive source power applicator and gas distribution showerhead in a plasma reactor includes a metal base and a process-compatible protective layer on the interior surface of he electrode having a dopant impurity concentration within a range corresponding to a minimal change in RF power absorption in the protective layer at an RF source power frequency with changes in coating temperature and or thickness. The metal base may have a set of first arcuately slotted gas passages and a set of pressure-dropping orifices coinciding axially with the top ends of the gas passages. The protective coating a set of arcuately slotted gas passages in registration gas passages of the metal base. The pressure drop in the orifices and the electric field drop in the slotted gas passages are both sufficient to maintain the pressure and electric field within the gas passages within a range that prevents arcing.

Owner:APPLIED MATERIALS INC

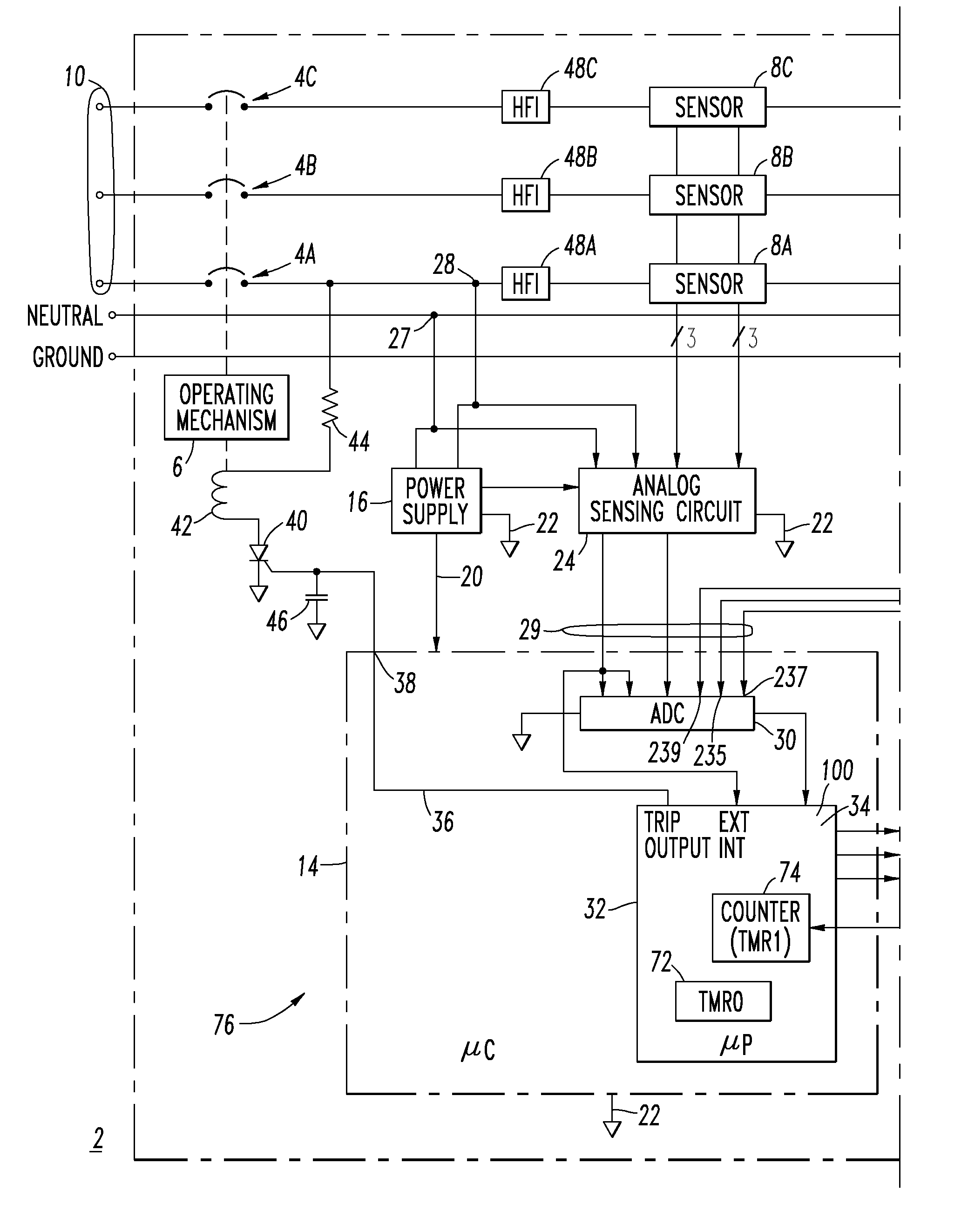

Industrial arc fault circuit interrupter and method of detecting arcing conditions

ActiveUS20090161270A1Emergency protective arrangement detailsEmergency protective arrangements for limiting excess voltage/currentBandpass filteringElectrical polarity

A method of detecting arcing conditions includes sensing current and HF signals therefrom; bandpass filtering the HF signals and providing filtered signals; detecting peak signals and envelopes from the filtered signals; counting occurrences of the envelopes exceeding a first value; maintaining temporary values corresponding to the peak signals; determining a trip time as a function of the current; determining if any peak signal is greater than a second value, and responsively increasing a temporary value and, otherwise, decreasing the temporary value; determining if a predetermined function of the temporary values is greater than a fifth value, and adding the temporary values to an accumulator, and otherwise, decreasing the accumulator; and tripping open the power circuit if: a difference between the occurrences of current and immediately previous half cycle having the same polarity is at least two, the accumulator is greater than a seventh value, and the trip time is reached.

Owner:EATON INTELLIGENT POWER LIMITED

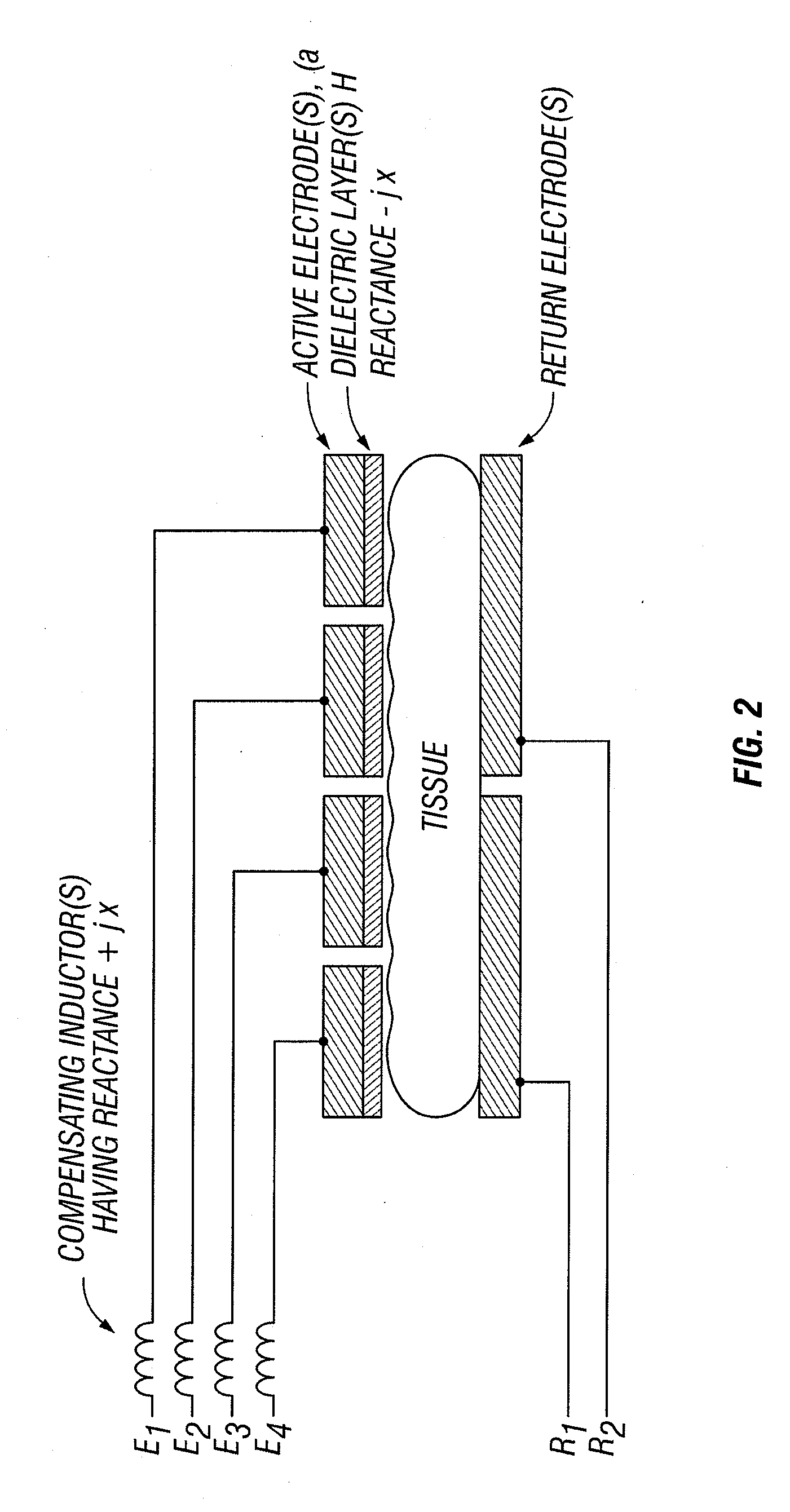

Electrocautery method and apparatus

InactiveUS20080228179A1Avoid arcingSurgical instruments for heatingSurgical forcepsBiomedical engineeringElectrode

An electrode structure and a mechanism for automated or user-selected operation or compensation of the electrodes, for example to determine tissue coverage and / or prevent arcing between bottom electrodes during electrocautery is disclosed.

Owner:AESCULAP AG

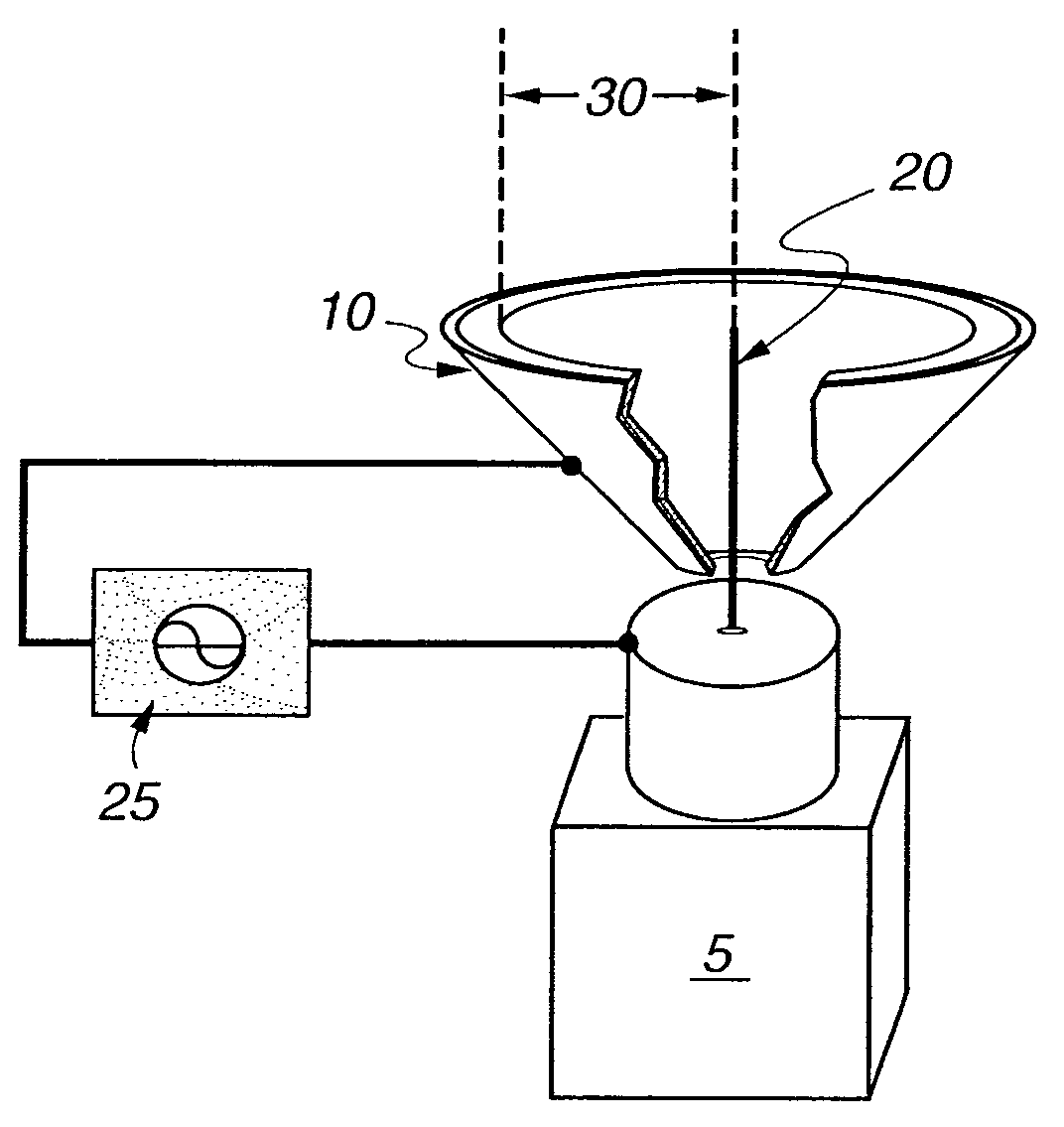

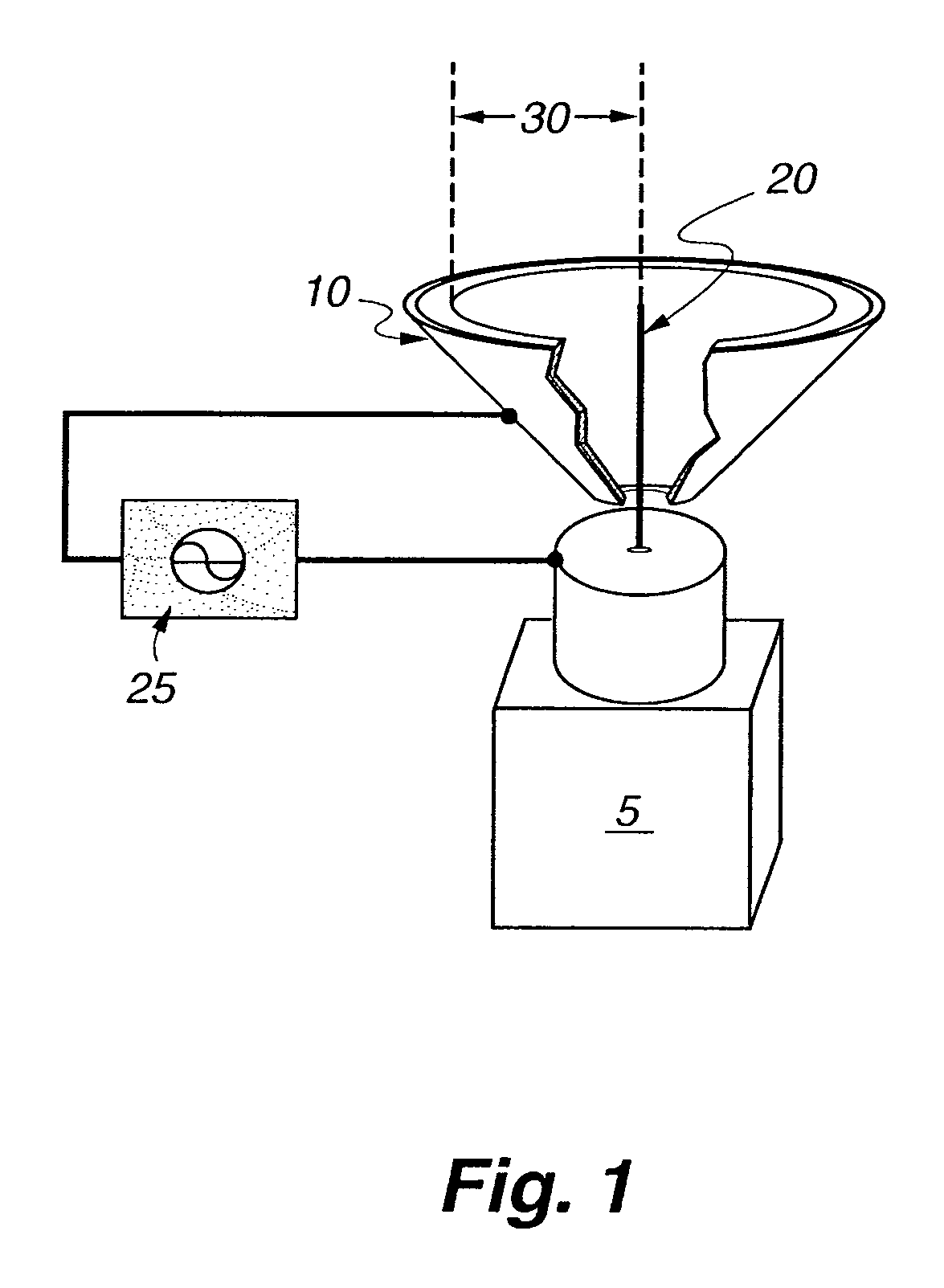

Fuel injector utilizing non-thermal plasma activation

A non-thermal plasma assisted combustion fuel injector that uses an inner and outer electrode to create an electric field from a high voltage power supply. A dielectric material is operatively disposed between the two electrodes to prevent arcing and to promote the formation of a non-thermal plasma. A fuel injector, which converts a liquid fuel into a dispersed mist, vapor, or aerosolized fuel, injects into the non-thermal plasma generating energetic electrons and other highly reactive chemical species.

Owner:LOS ALAMOS NATIONAL SECURITY

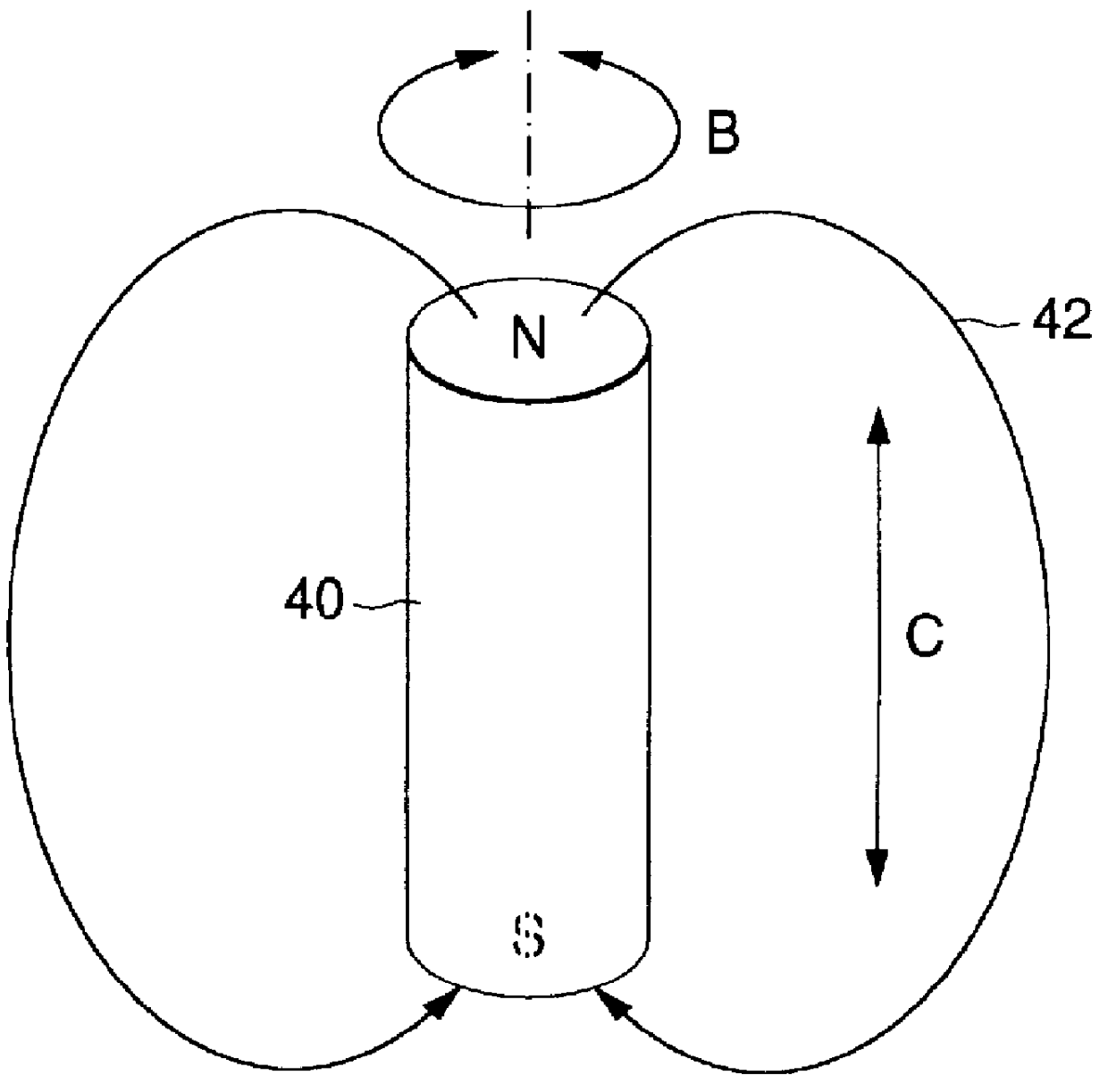

Low Pressure Arc Plasma Immersion Coating Vapor Deposition And Ion Treatment

A vacuum coating and plasma treatment system includes a magnetron cathode with a long edge and a short edge. The magnetic pole of the magnetron results in an electromagnetic barrier. At least one remote arc discharge is generated separate from the magnetron cathode and in close proximity to the cathode so that it is confined within a volume adjacent to the magnetron target. The remote arc discharge extends parallel to the long edge of the magnetron target and is defined by the surface of the target on one side and the electromagnetic barrier on all other sides. There is a remote arc discharge cathode hood and anode hood extending over the arc discharge and across the short edge of the magnetron cathode. Outside of the plasma assembly is a magnetic system creating magnetic field lines which extend into and confine the plasma in front of the substrate.

Owner:VAPOR TECH

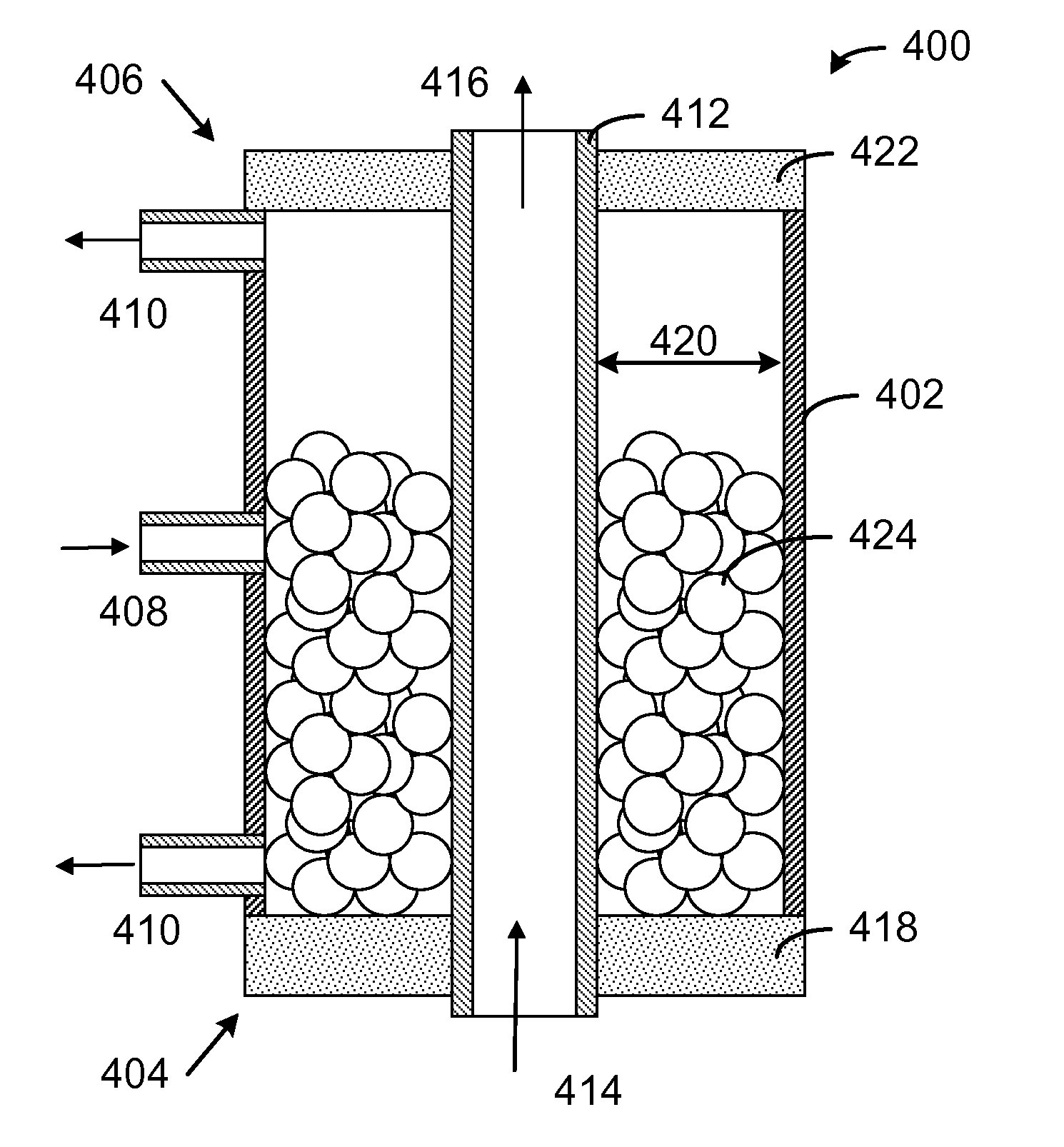

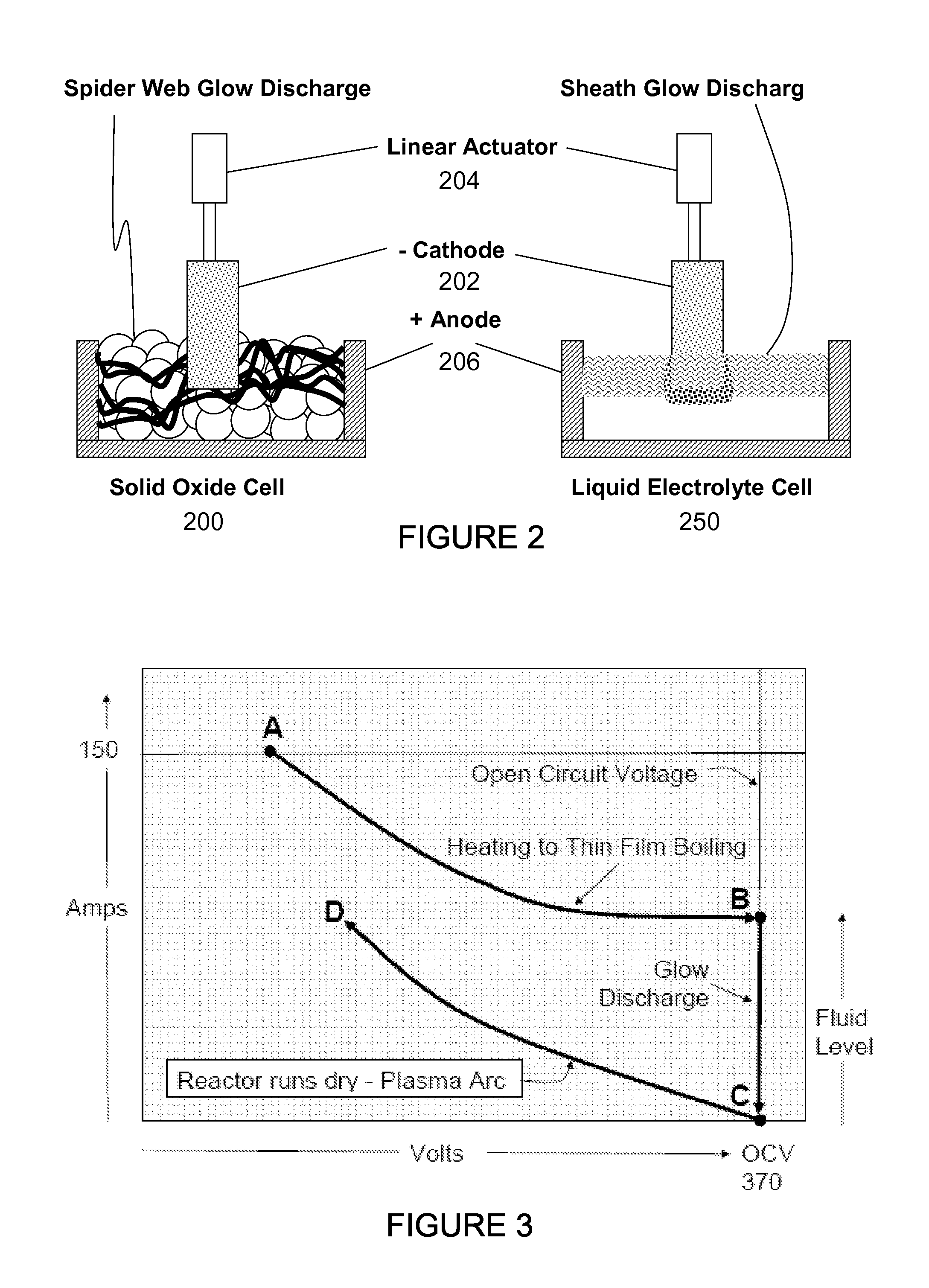

Solid oxide high temperature electrolysis glow discharge cell

The present invention provides a glow discharge cell comprising an electrically conductive cylindrical vessel having a first end and a second end, and at least one inlet and one outlet; a hollow electrode aligned with a longitudinal axis of the cylindrical vessel and extending at least from the first end to the second end of the cylindrical vessel, wherein the hollow electrode has an inlet and an outlet; a first insulator that seals the first end of the cylindrical vessel around the hollow electrode and maintains a substantially equidistant gap between the cylindrical vessel and the hollow electrode; a second insulator that seals the second end of the cylindrical vessel around the hollow electrode and maintains the substantially equidistant gap between the cylindrical vessel and the hollow electrode; a non-conductive granular material disposed within the gap, wherein the non-conductive granular material (a) allows an electrically conductive fluid to flow between the cylindrical vessel and the hollow electrode, and (b) prevents electrical arcing between the cylindrical vessel and the hollow electrode during a electric glow discharge; and wherein the electric glow discharge is created whenever: (a) the glow discharge cell is connected to an electrical power source such that the cylindrical vessel is an anode and the hollow electrode is a cathode, and (b) the electrically conductive fluid is introduced into the gap.

Owner:FORET PLASMA LABS

Method and apparatus for providing an electrostatic chuck with reduced plasma penetration and arcing

ActiveUS20090034147A1Reducing plasma formationSleeve/socket jointsSemiconductor/solid-state device manufacturingEngineeringHeat transfer fluid

A method and apparatus for providing a fluid distribution element for an electrostatic chuck that reduces plasma formation and arcing within heat transfer fluid passages. One embodiment comprises a plate and a dielectric component, where the dielectric component is inserted into the plate. The plate is adapted to be positioned within a channel to define a plenum, wherein the dielectric component provides at least a portion of a fluid passage coupled to the plenum. A porous dielectric layer, formed upon the dielectric component, provides at least another portion of a fluid passage coupled to the plenum. In other embodiments, the fluid distribution element comprises various arrangements of components to define a fluid passage that does not provide a line-of-sight path from the support surface for a substrate to a plenum.

Owner:APPLIED MATERIALS INC

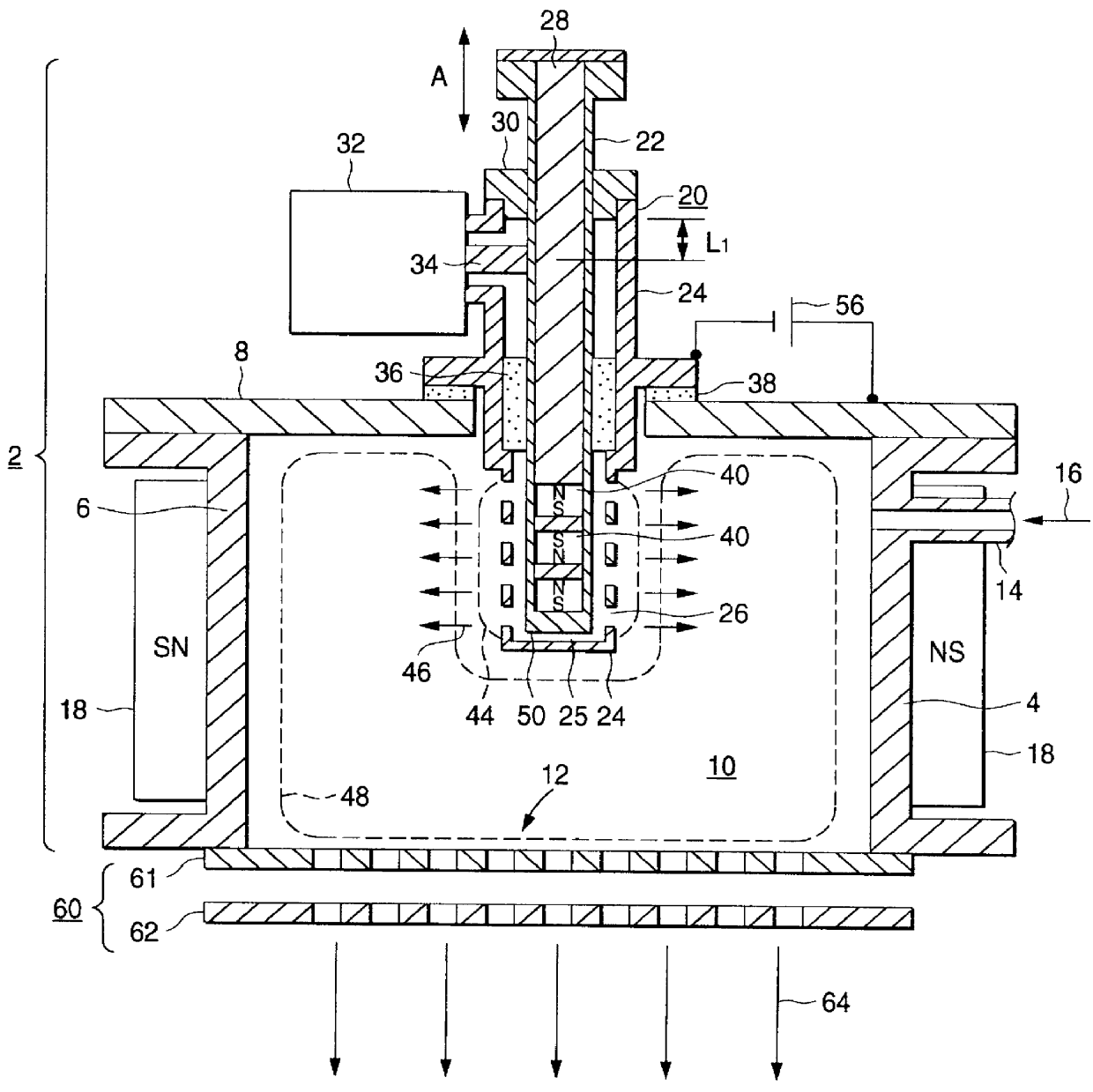

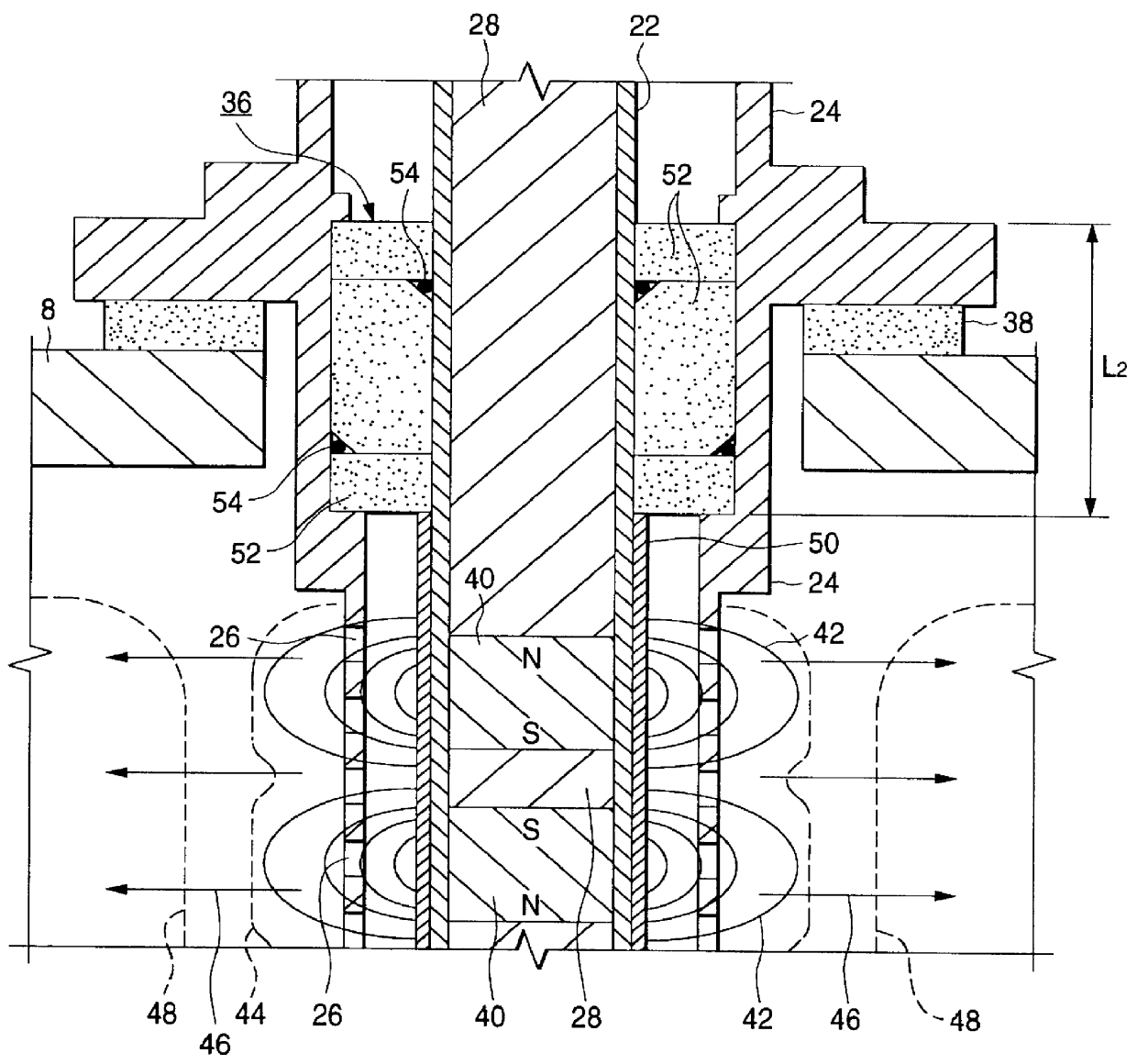

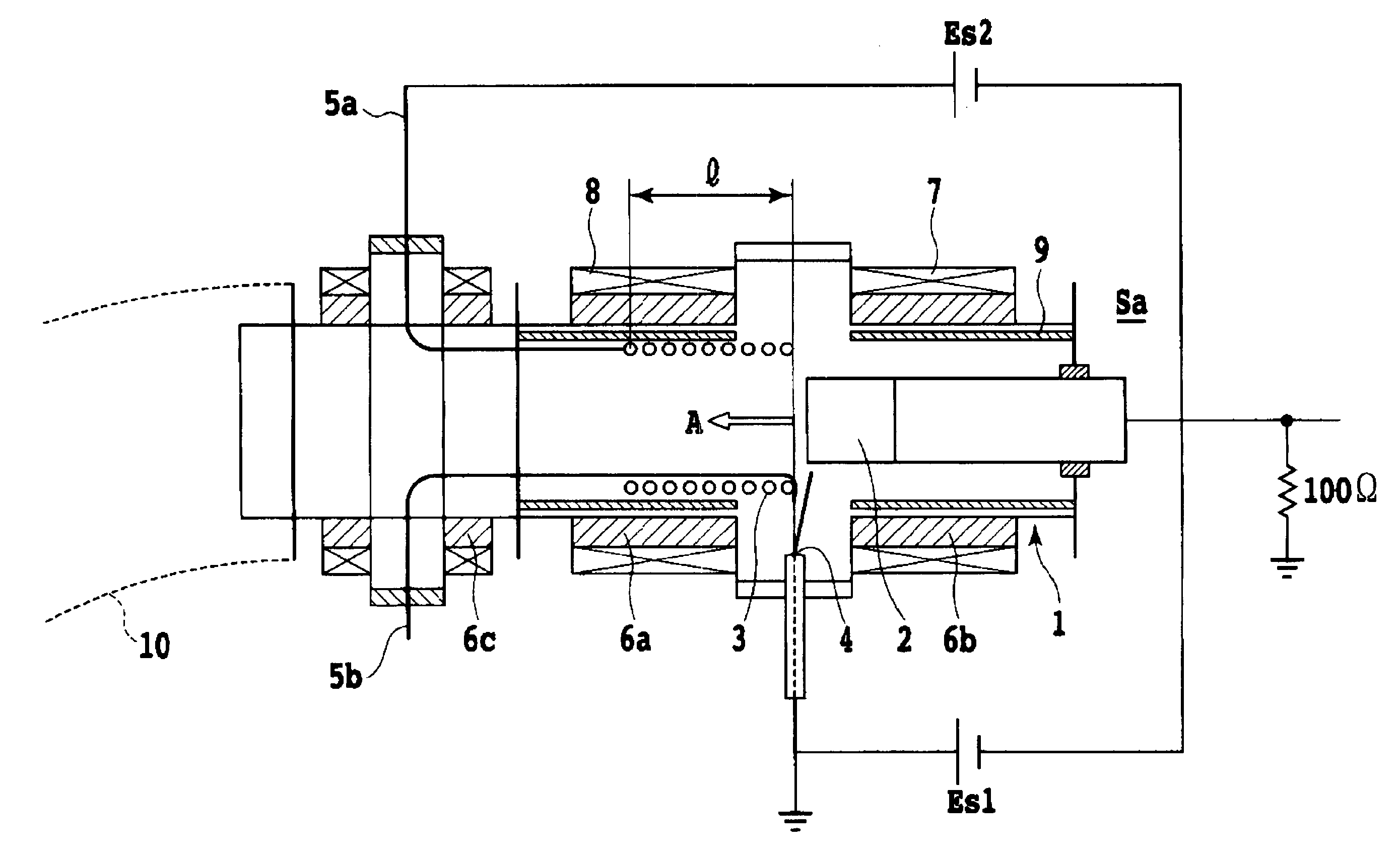

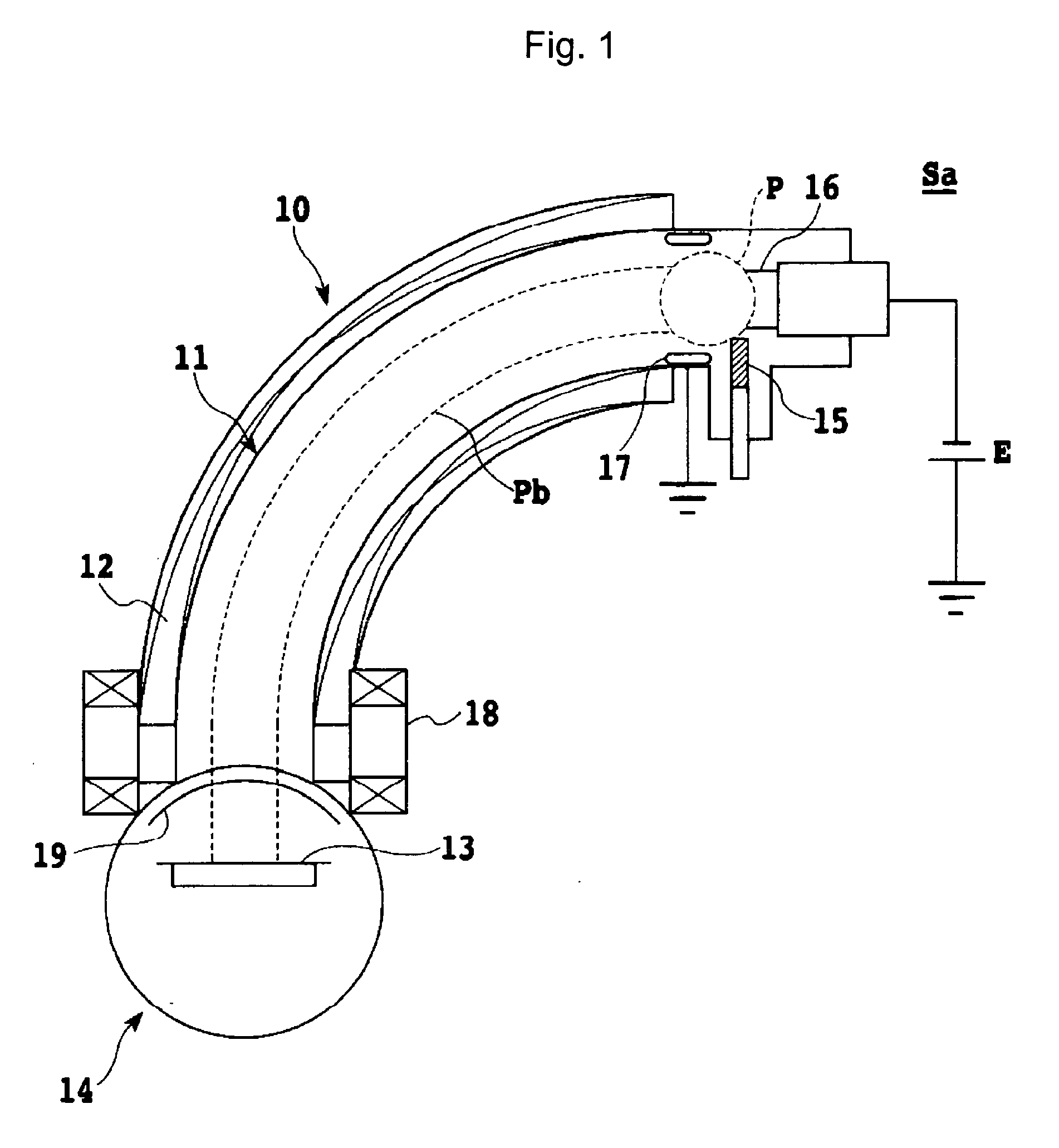

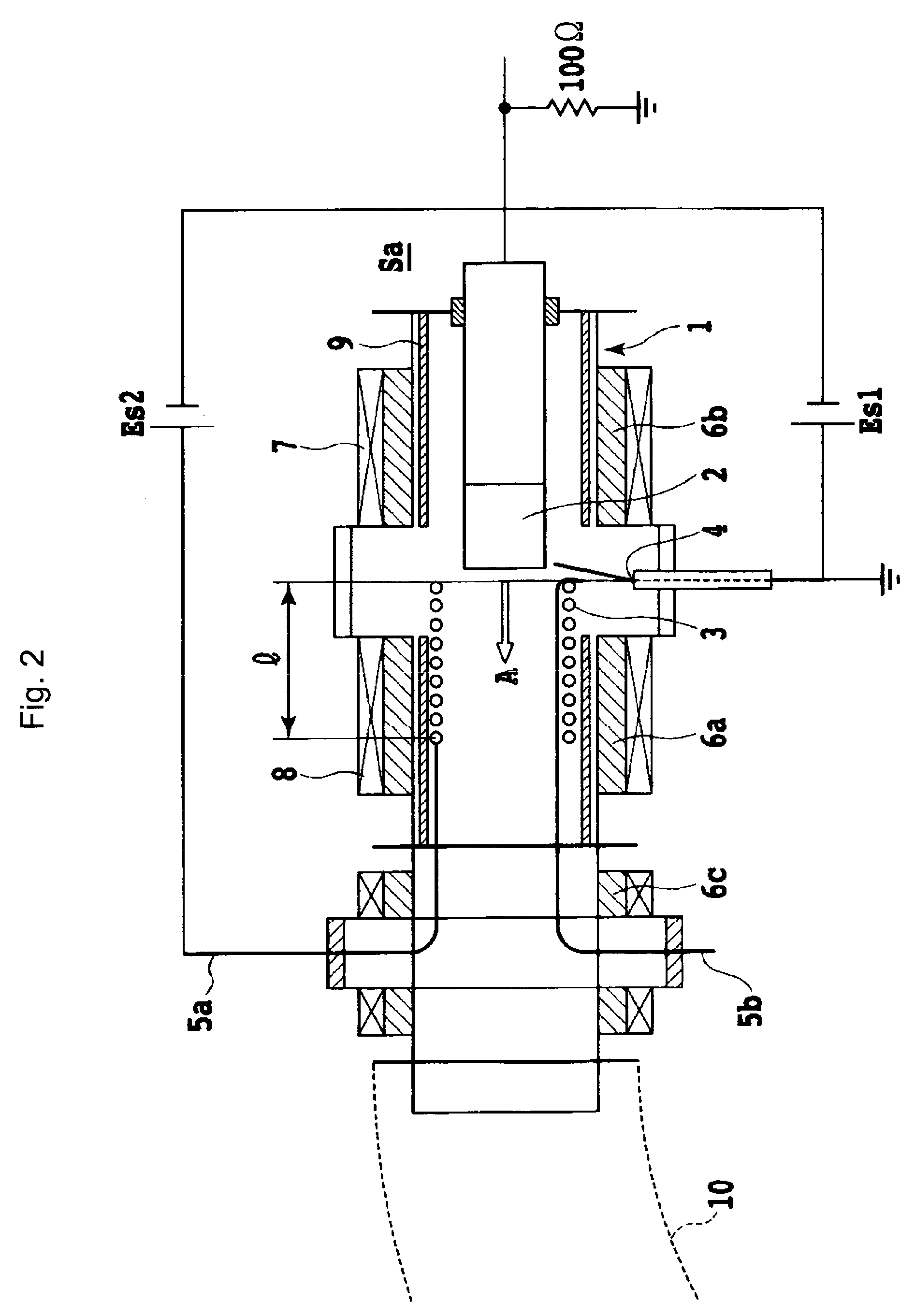

Plasma generating apparatus and ion source using the same

InactiveUS6060836AEfficient yieldFacilitate initiationVacuum evaporation coatingSputtering coatingElectrical conductorMicrowave

A plasma generating apparatus has a plasma-generating vessel into which a gas is introduced. A coaxial line is inserted into the plasma-generating vessel. The coaxial line is insulated from the vessel with an insulator. The coaxial line has a central conductor and an outer conductor, to both of which microwave is supplied from a magnetron. That part of the central conductor which is located inside the plasma-generating vessel has, disposed therein, permanent magnets which form a cusp field. A seed plasma is formed around the permanent magnets by microwave discharge. A direct-current voltage is applied from a direct-voltage source between the outer conductor 24 and the plasma-generating vessel. Upon this application, electrons in the seed plasma move toward the inner wall of the plasma-generating vessel and are accelerated to ionize the gas. The ionized gas serves as seeds to cause arc discharge between the outer conductor and the plasma-generating vessel to generate a main plasma. By disposing an extracting electrode at the opening of the plasma-generating vessel, ion beams can be extracted from the main plasma.

Owner:NISSIN ELECTRIC CO LTD

Vacuum arc evaporation apparatus and method, and magnetic recording medium formed thereby

In a vacuum arc evaporation apparatus, to stably maintain vacuum arc discharge at an arc source when depositing a cathode material on a substrate, namely a magnetic recording medium, an ungrounded anode of a coil-type tube is placed inside an arc source discharge vacuum chamber. A DC arc power supply is connected between the cathode and the anode to cause an arc current to flow in the anode to generate a first magnetic field in one direction, from the cathode toward the anode. A second magnetic field is generated in the opposite direction, from the anode to the cathode by feeding a specified current to an external coil positioned around the discharge chamber. The external coil includes an around-cathode coil and an around-anode coil. The arc discharge can be started by operating a striker to carry out the deposition.

Owner:FUJI ELECTRIC DEVICE TECH CO

Arc suppression device, system and methods for liquid insulated electrical apparatus

InactiveUS20080192389A1Current/voltage measurementEmergency protective arrangement detailsElectrical devicesEngineering

Arc suppression systems, devices and methods for avoiding undesirable arcing conditions inside a liquid-filled tank of a high-voltage electrical apparatus.

Owner:COOPER TECH CO

Method for manufacturing poorly conductive layers

ActiveUS20080020138A1High levelAvoid disadvantagesCellsElectric discharge tubesTarget surfaceElectricity

Method for producing poorly conductive and in particular nonconductive layers on at least one work piece by means of a vacuum-coating process in which an electric arc discharge is activated between at least one anode and the cathode of an arc source in a reactive-gas atmosphere, whereby on the surface of a target that is electrically connected to the cathode either none or only a small outer magnetic field is generated that extends essentially perpendicular to the target surface for assisting the evaporation process, the degree of recoating of the target surface by other coating sources is less than 10%, and the magnetic field is generated with a magnet system that encompasses at least one axially polarized coil with a geometry similar to the circumference of the target.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

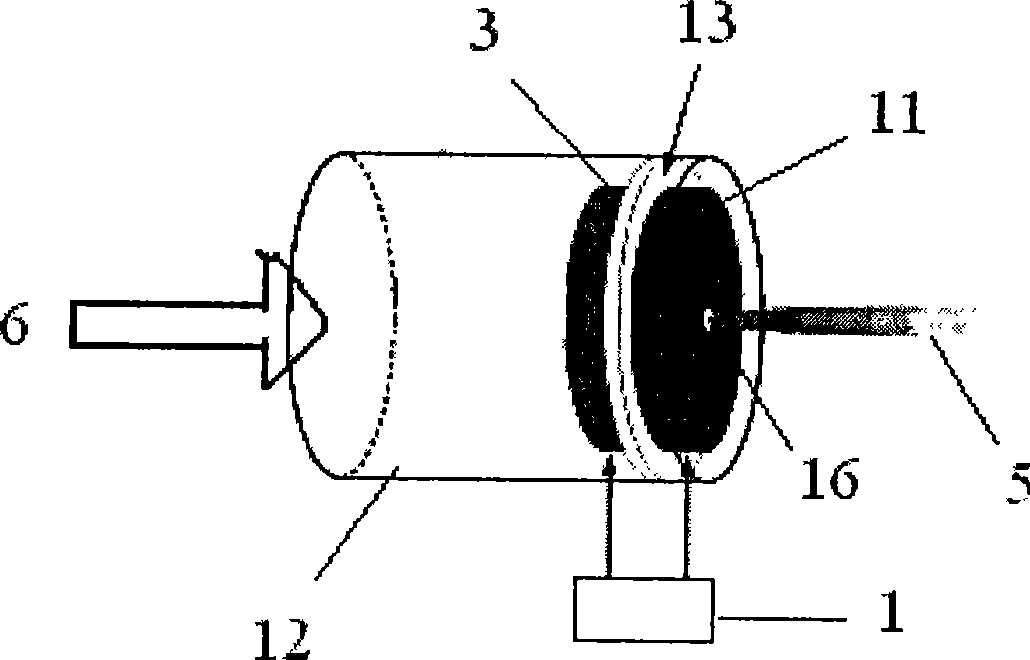

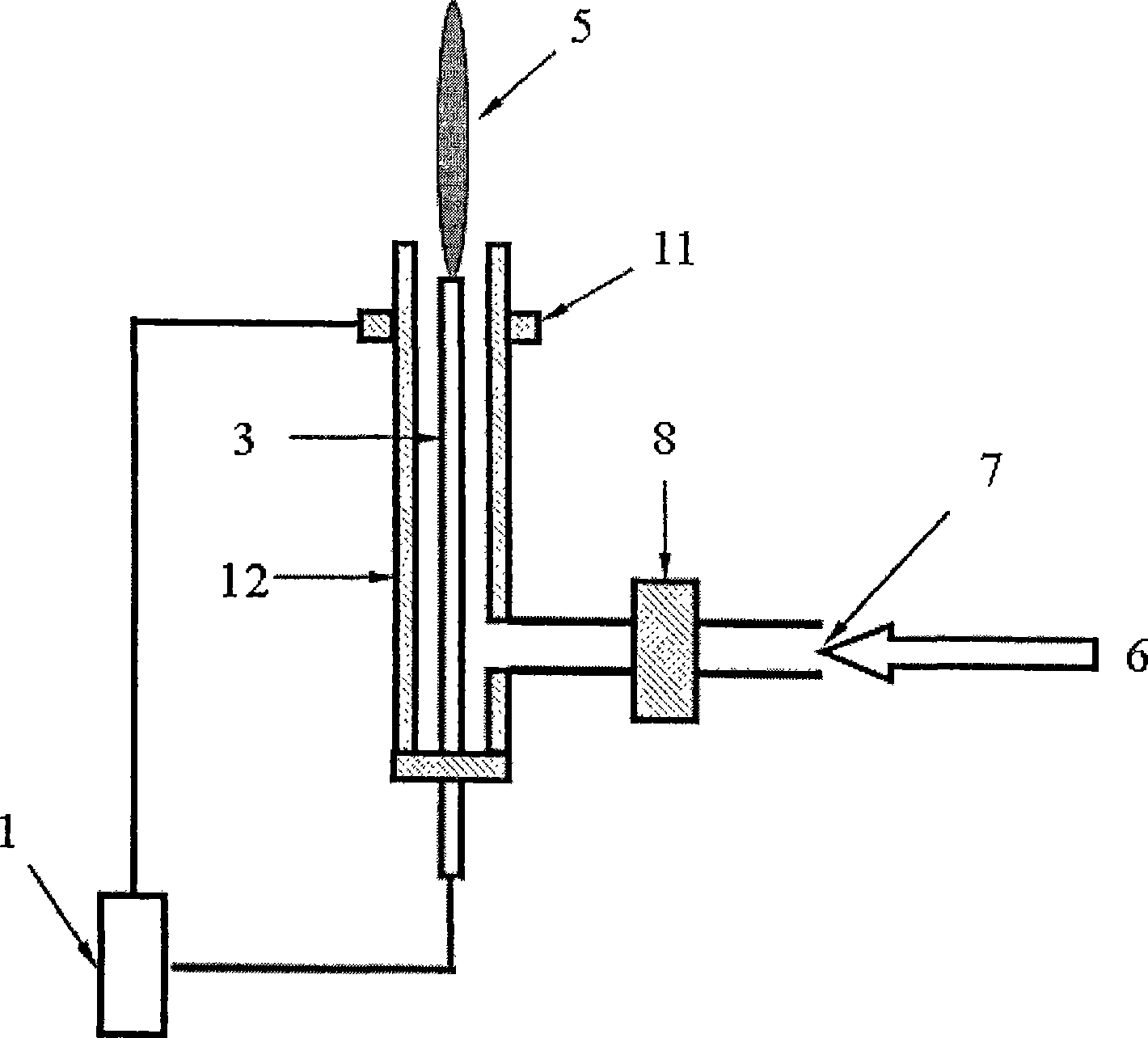

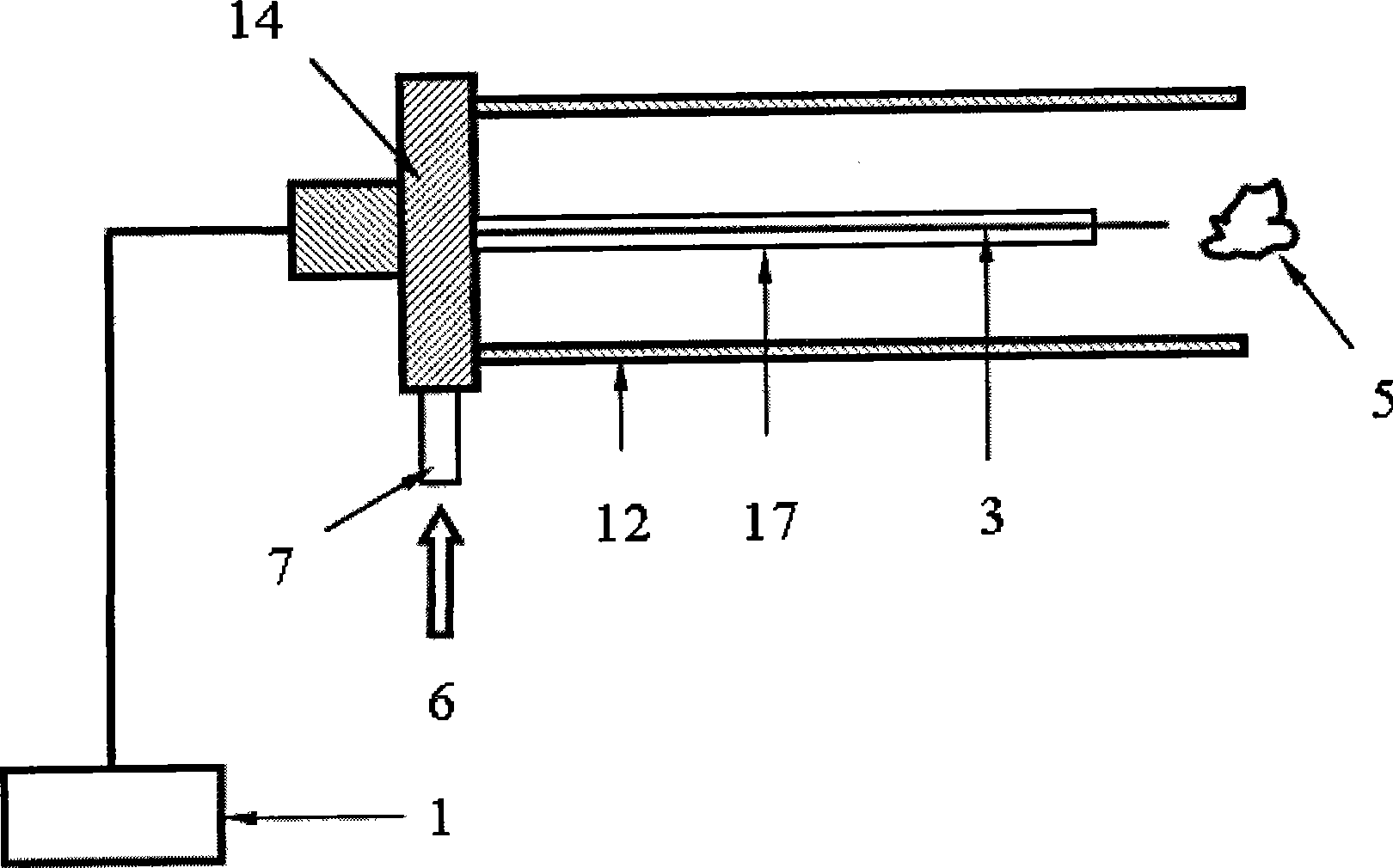

Plasma jet device

ActiveCN101426327AIncrease varietyIncrease the number ofElectric discharge tubesPlasma techniqueCapacitancePlasma jet

A plasma jet device belongs to a plasma generator and settles the problem the unsafe electrode and the likely generation of arc discharging between the electrode and the grounding existing in the prior plasma jet device. The plasma jet device according to the invention comprises a power supply, a working gas source and an electrode. The working gas of the working gas source enters the electrode from the gas input port of the electrode. The electrode is in the shape of empty tube, is provided with a gas input port at one end and is provided with a gas output port at the other end. The electrode is connected with the power supply through a resistor and a capacitor. The plasma jet device according to the invention has the advantages of easy manufacture, easy maintenance, convenient use, low cost and easy carrying. The temperature of the generated plasma jet can be different when resistor with different resistance, capacitor with different capacitance, different driving power supply and different working gas are selected. The human body can touch with the plasma jet safely when the temperature of the plasma jet is approximate to the room temperature. At the same time the plasma jet can be provided with different shapes and can diffuse to different directions simultaneously. The specific application with large scale and large area in normal temperature and normal pressure can be realized.

Owner:武汉海思普莱生命科技有限公司

Device for indoor air purification and sterilization

ActiveUS20120207647A1Improve purification effectImprove the bactericidal effectLighting and heating apparatusExhaust apparatusExcited stateContact time

The present invention relates to a device for indoor air purification and sterilization which excites indoor air by arc discharge to decompose bad odor and sterilize air, wherein an excited state is maintained by applying a magnetic field and the contact time between molecules activated by arc and pollutants is extended, thereby improving air purification and sterilization effects, and the noise generated by arc discharge is reduced by a silencer and ozone and static electricity are removed by a filter which removes ozone and a metal filter for removing static electricity, respectively, thereby enabling very suitable configuration for indoor air purification and sterilization.

Owner:KIM BU YEOL

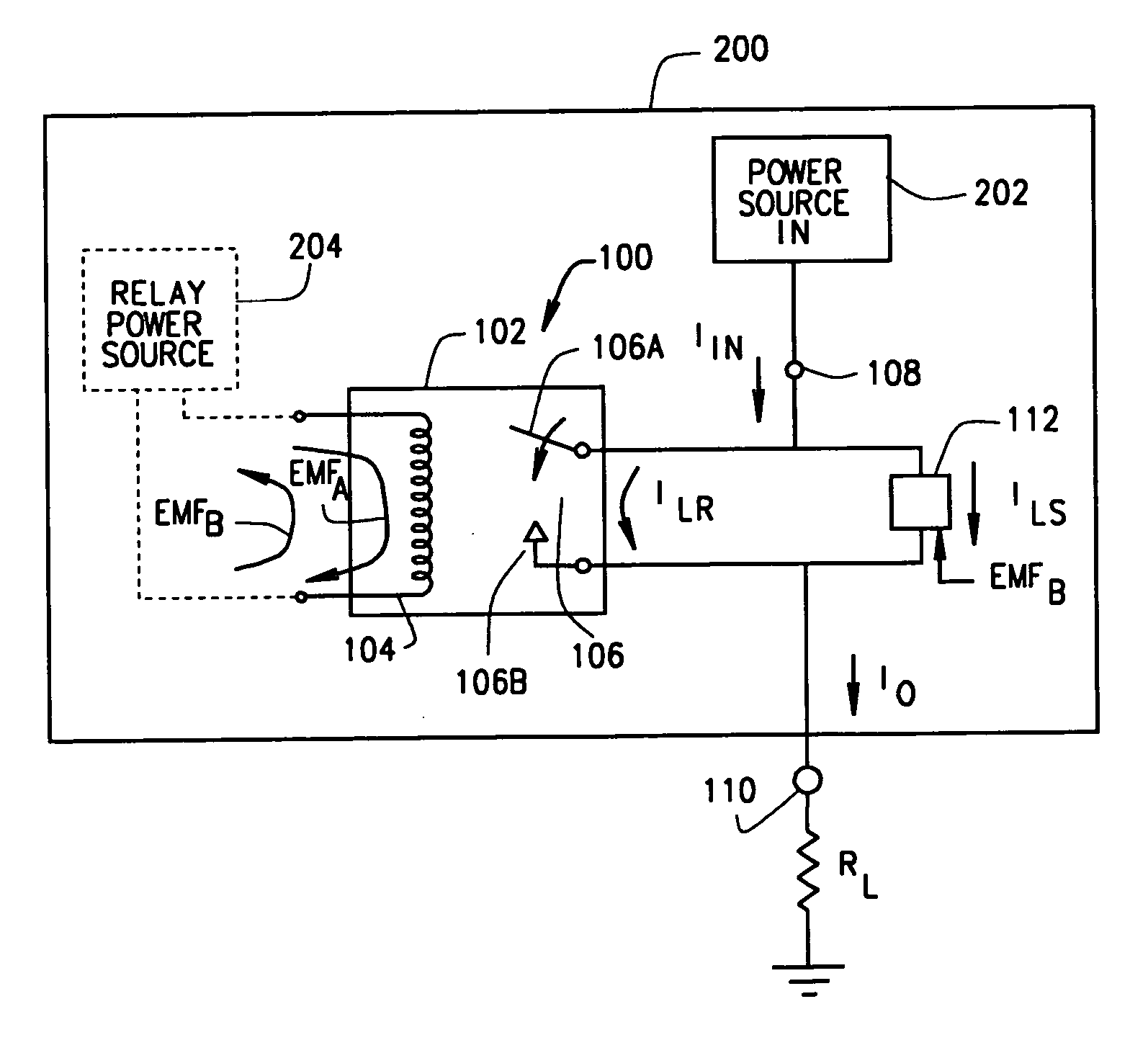

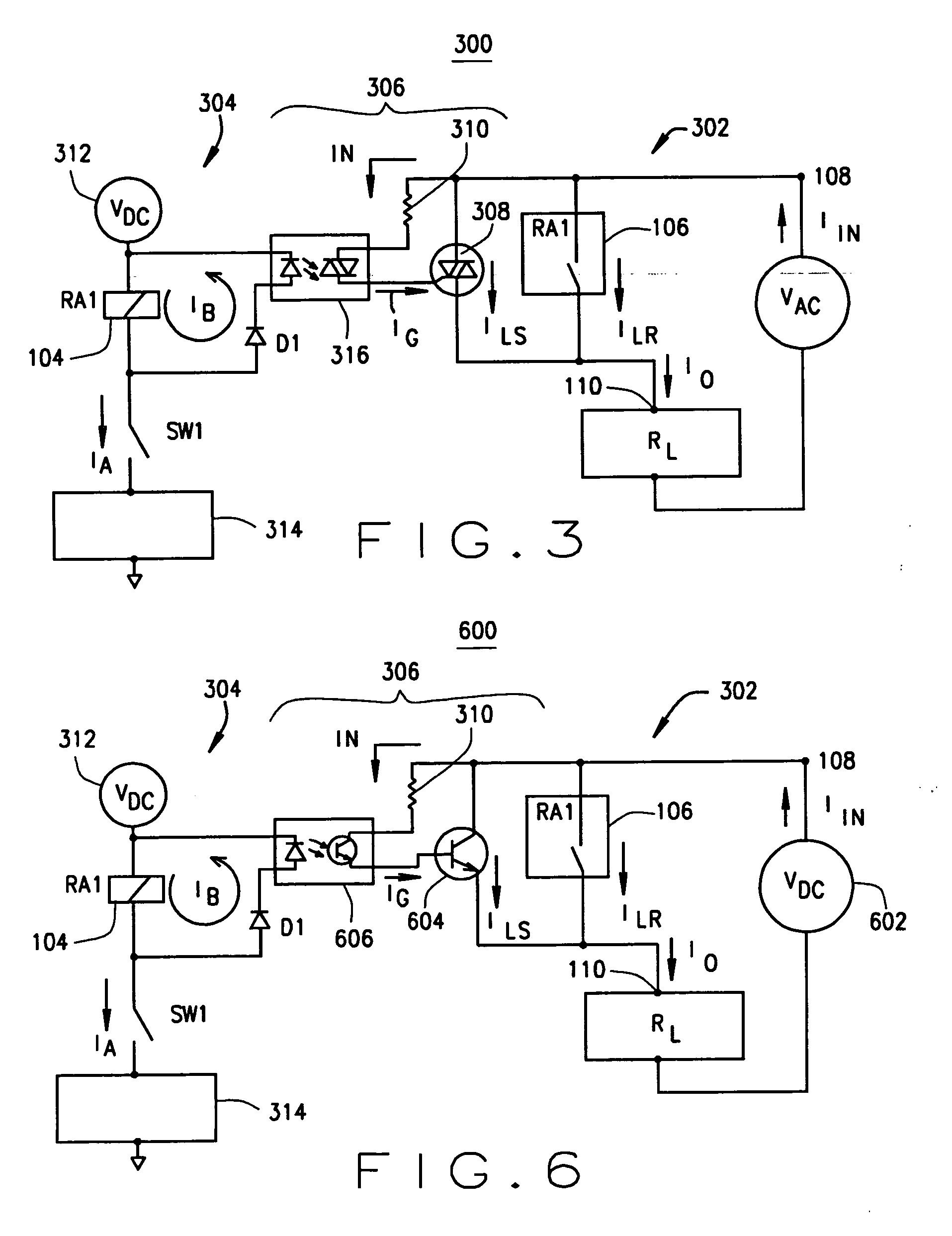

Apparatus and method for relay contact arc suppression

ActiveUS20070014055A1Low costAvoid damageElectric switchesEmergency protective arrangements for automatic disconnectionPower switchingCounter-electromotive force

An arc suppression circuit for a power switch or power supply with a relay having a coil and a set of contacts for providing a portion of an input power as load power to an output. The relay coil is configured for closing the relay contacts in response to receiving relay activating energy and for generating back EMF energy following termination of the receiving of the relay activating energy. A switch is connected in parallel to the relay contacts and is configured for providing a portion of the input power as supplemental load power to the output as a function of back EMF energy. Also, a method of suppressing damaging arcing across relay contacts in a power switch or power supply includes receiving back EMF energy generated by the relay coil following termination of the relay coil receiving activating energy and connecting supplemental load power to the output in parallel with the relay contacts in response to the receiving of the back EMF energy.

Owner:WATLOW ELECTRIC MFG

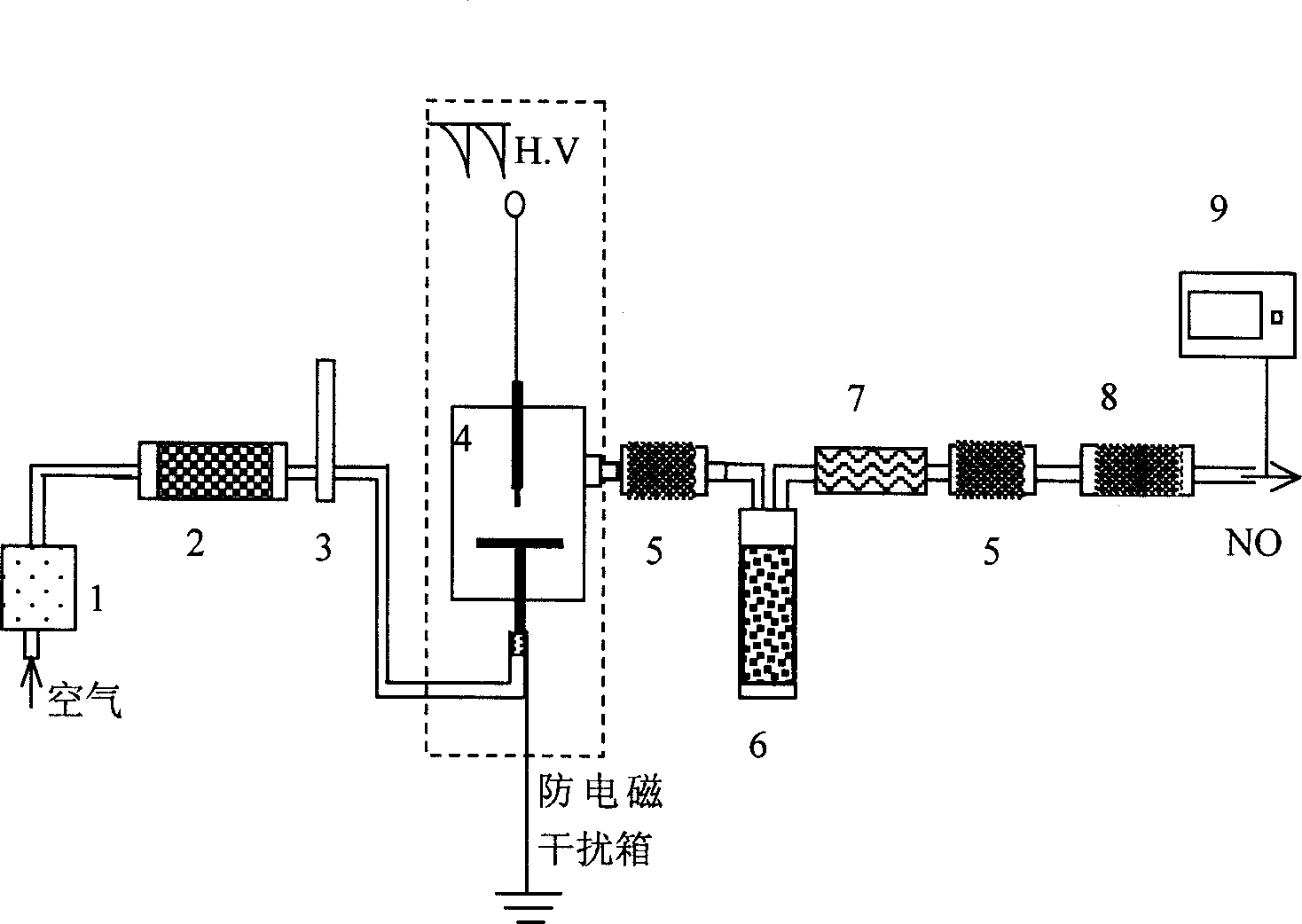

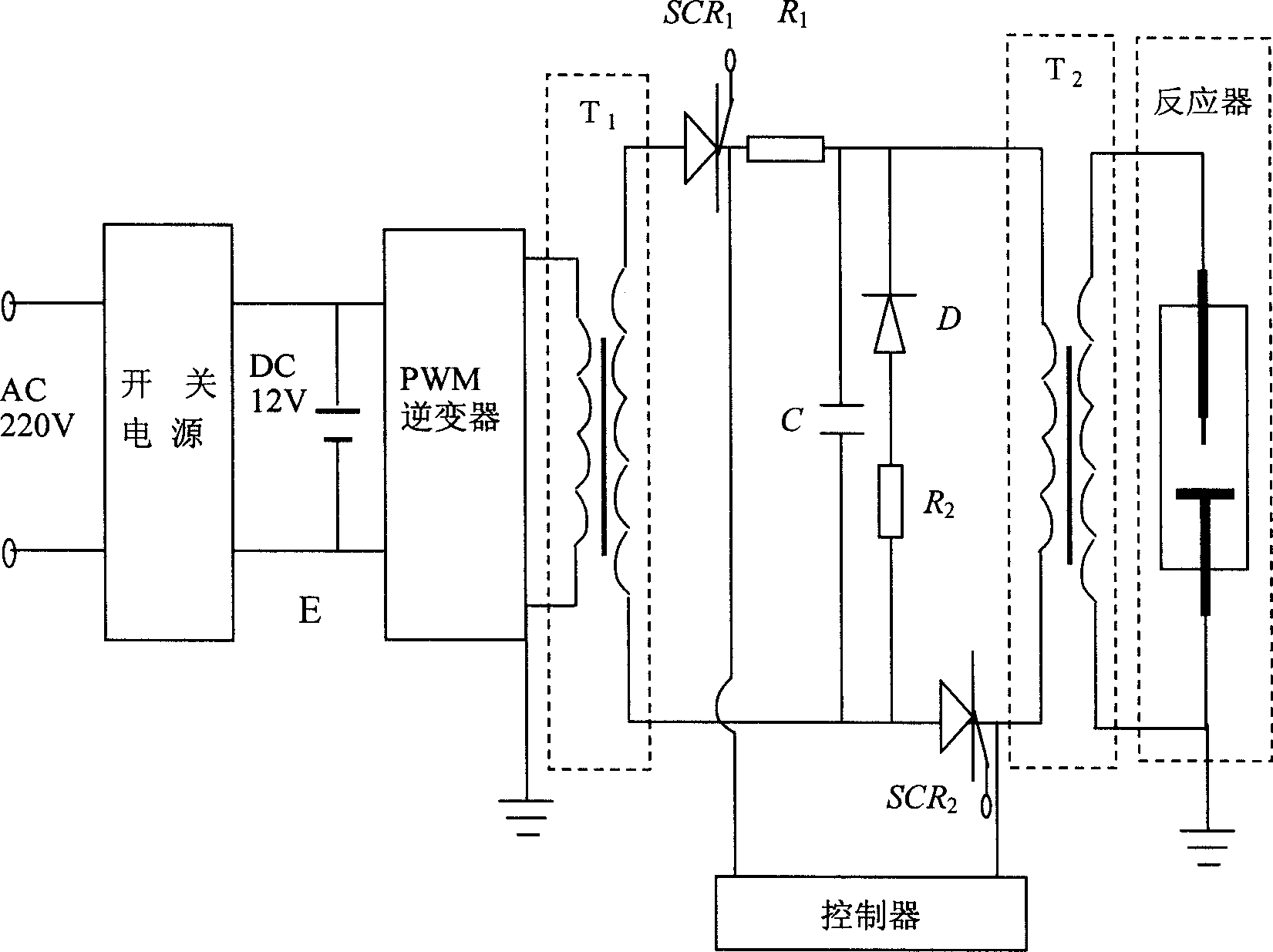

Nitric oxide gas supply system of respiratory failure salvage instrument

InactiveCN1730115AExtend your lifeEasy to operateRespiratorsNitric oxideHigh concentrationElectric discharge

Disclosed a nitric oxide supply system of respiratory failure rescue device belongs to the disease therapy apparatus, which avoids the high concentration NO gas cylinder, the high concentration dry gas cylinder and the nitrogen-oxygen mixed gas cylinder. The invention uses the air as raw material for attaining the NO at any time without the storage and via controlling the electric discharge condition, generates NO gas at most with least NO2 harmful gas to attain the low ratio of NO2 / NO. While the concentration of NO ranges from 0-200 ppm in the pulse frequency of 1-90 Hz. The invention comprises an air pump connected in series to the gas passage, a clean-dry air generating device, a flow counter, a pulse generate and control circuit, a arc discharge reactor, a particle filter film, a NO2 catalytic reduction conversion apparatus, a cooler, a particle filter film, a selective absorber and a gas monitor.

Owner:HUAZHONG UNIV OF SCI & TECH

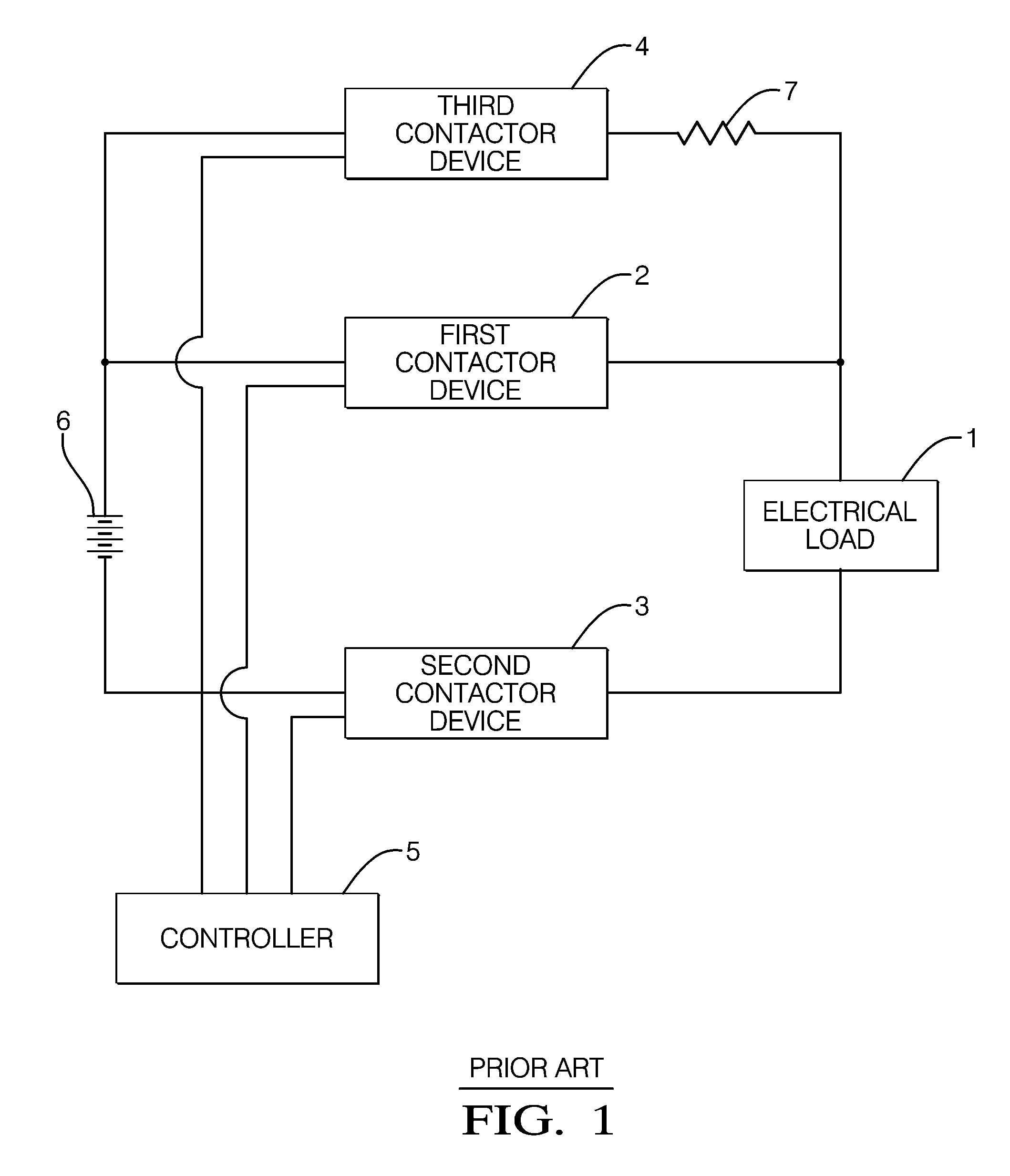

Power charging assembly and method that includes a low voltage electrical device operable with pulse width modulation (PWM) control

A power charging assembly and methods are provided to provide a pre-charge low-current state, a steady-state, high-current charging state, and an unconnect state for an electrical load of an electrical propulsion system in a hybrid electrical vehicle (HEV). The power charging assembly includes a positive contactor device, a negative contactor device, and a non-contactor device means. The rate at which that electrical load is pre-charged may be effectively controlled by using a pulse-width modulated (PWM) signal received by the non-contactor device means. A current-only carrying positive or negative contactor may be configured with the non-contactor device means to further prevent electrical arcing of the contacts of the positive and the negative contactor during power charging assembly operation.

Owner:APTIV TECH LTD

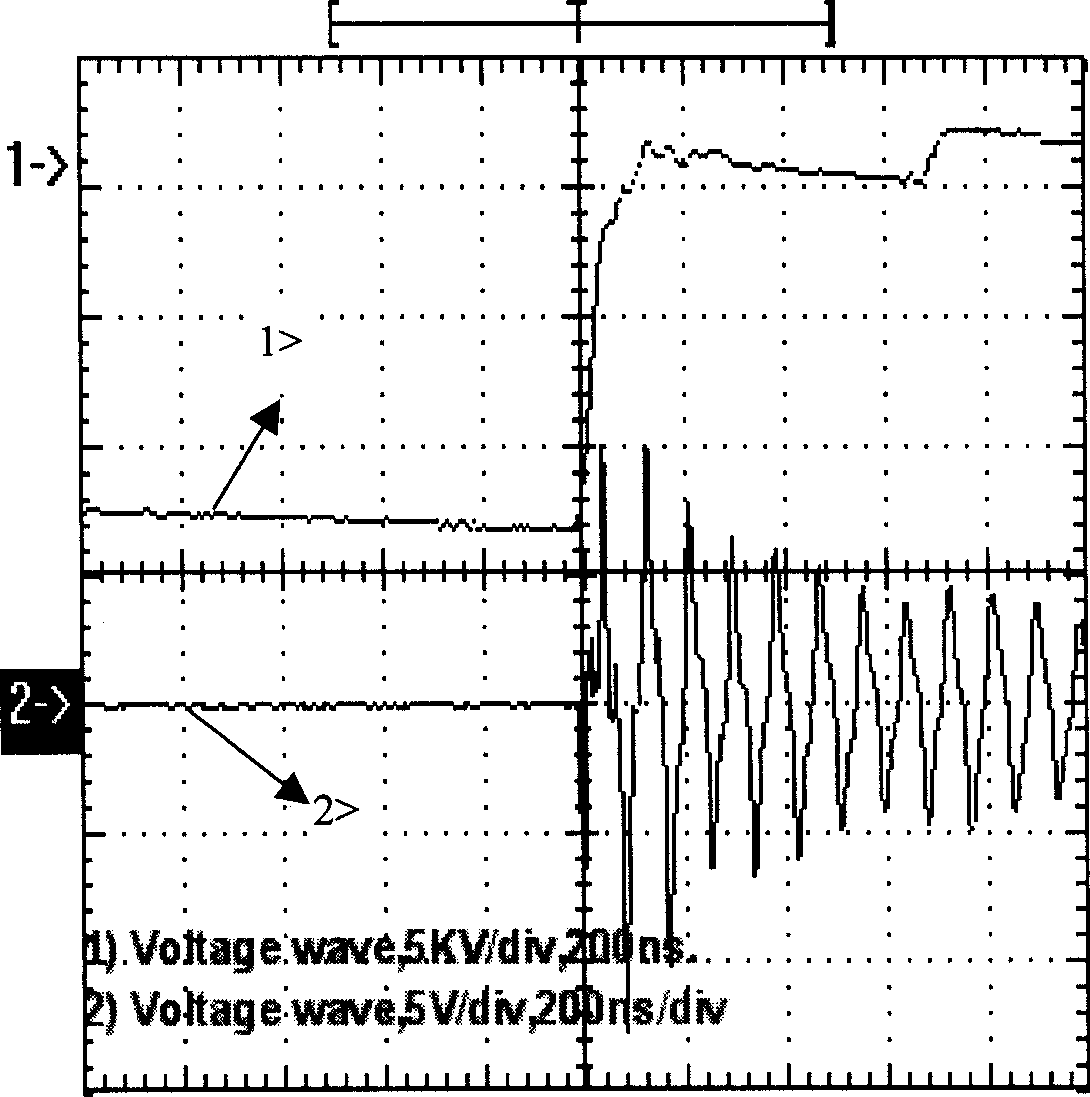

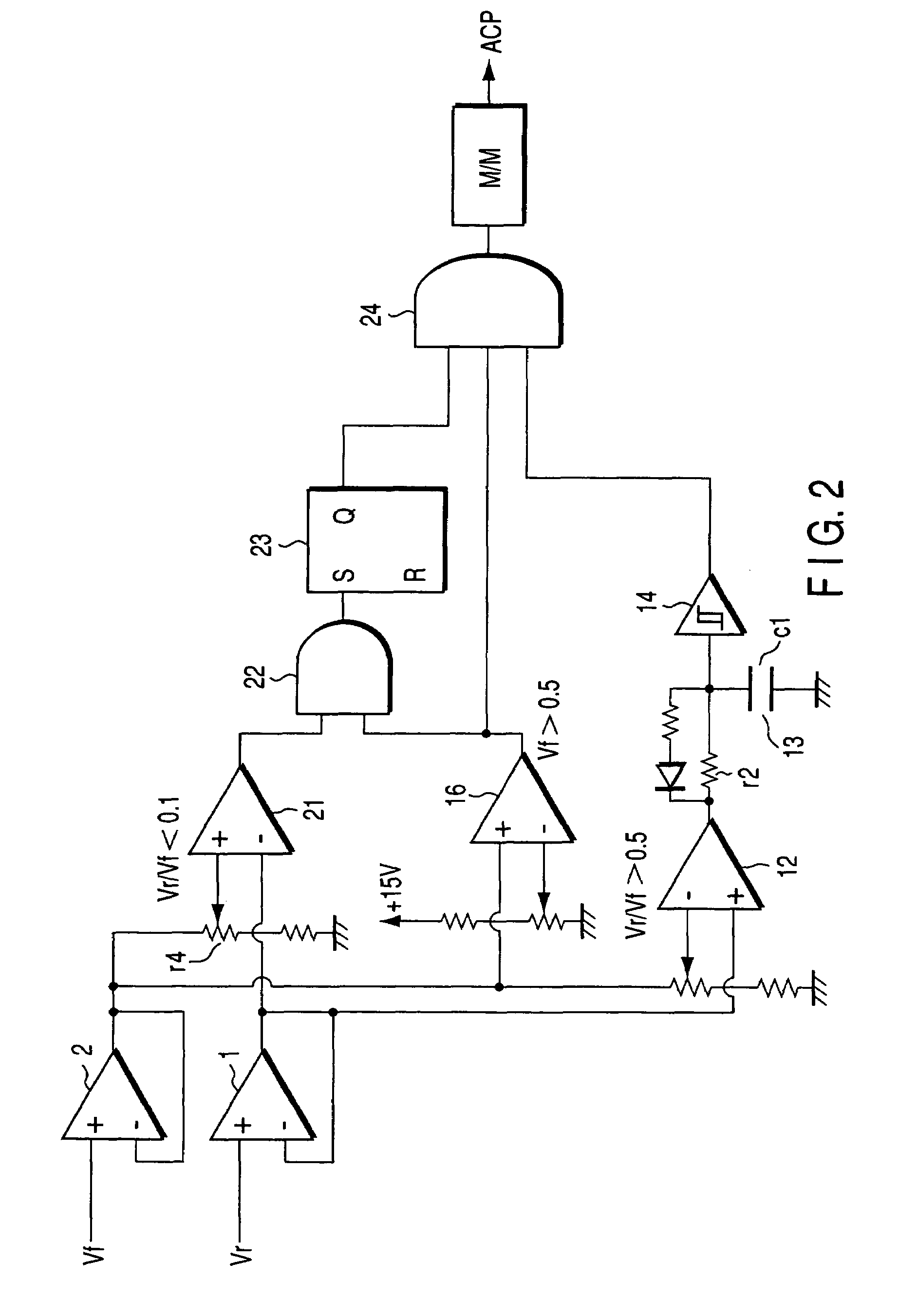

Method of detecting an arc in a glow-discharge device and apparatus for controlling a high-frequency arc discharge

In a method of detecting arc discharge in a glow-discharge apparatus GD that has a high-frequency power source PS, a cutting pulse is output for time T1 to the high-frequency power source PS to stop a supply of power to the glow-discharge apparatus GD, when dVr / dt−dVf / dt increases over a first level, where Vf and Vr are a traveling-wave voltage and a reflected-wave voltage applied to the glow-discharge apparatus GD, respectively. Arc discharge is determined to have developed in the glow-discharge apparatus, when Vr / Vf increases to a second level or a higher level within a preset time To after the supply of power to the glow-discharge apparatus is stopped.

Owner:SHIBAURA MECHATRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com