Pulse detonating combustion chamber and air turbine rocket engine based on pulse detonating

A rocket engine and pulse detonation technology, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc., to achieve the effects of weight reduction, high thermal efficiency, and small entropy increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

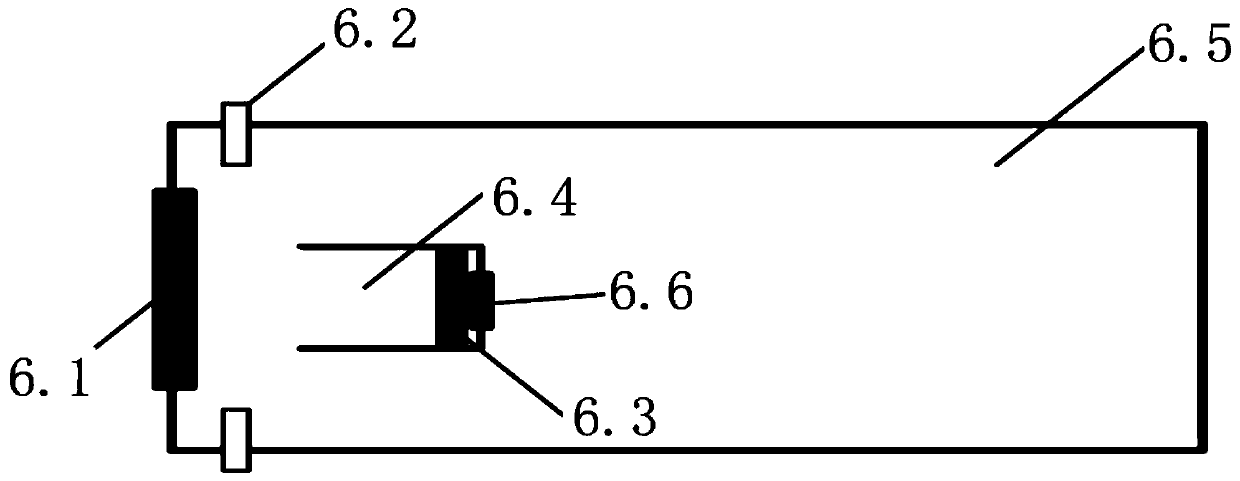

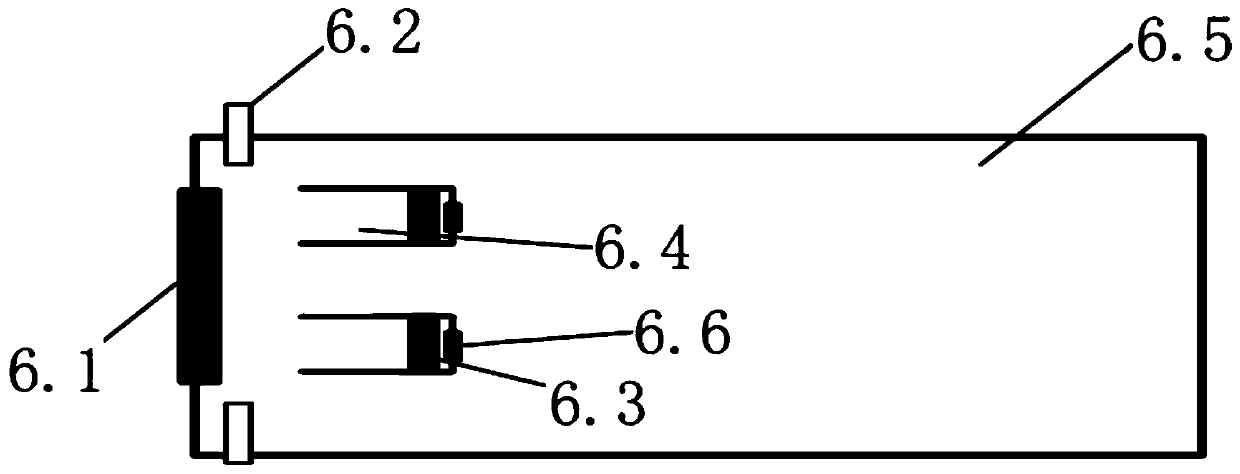

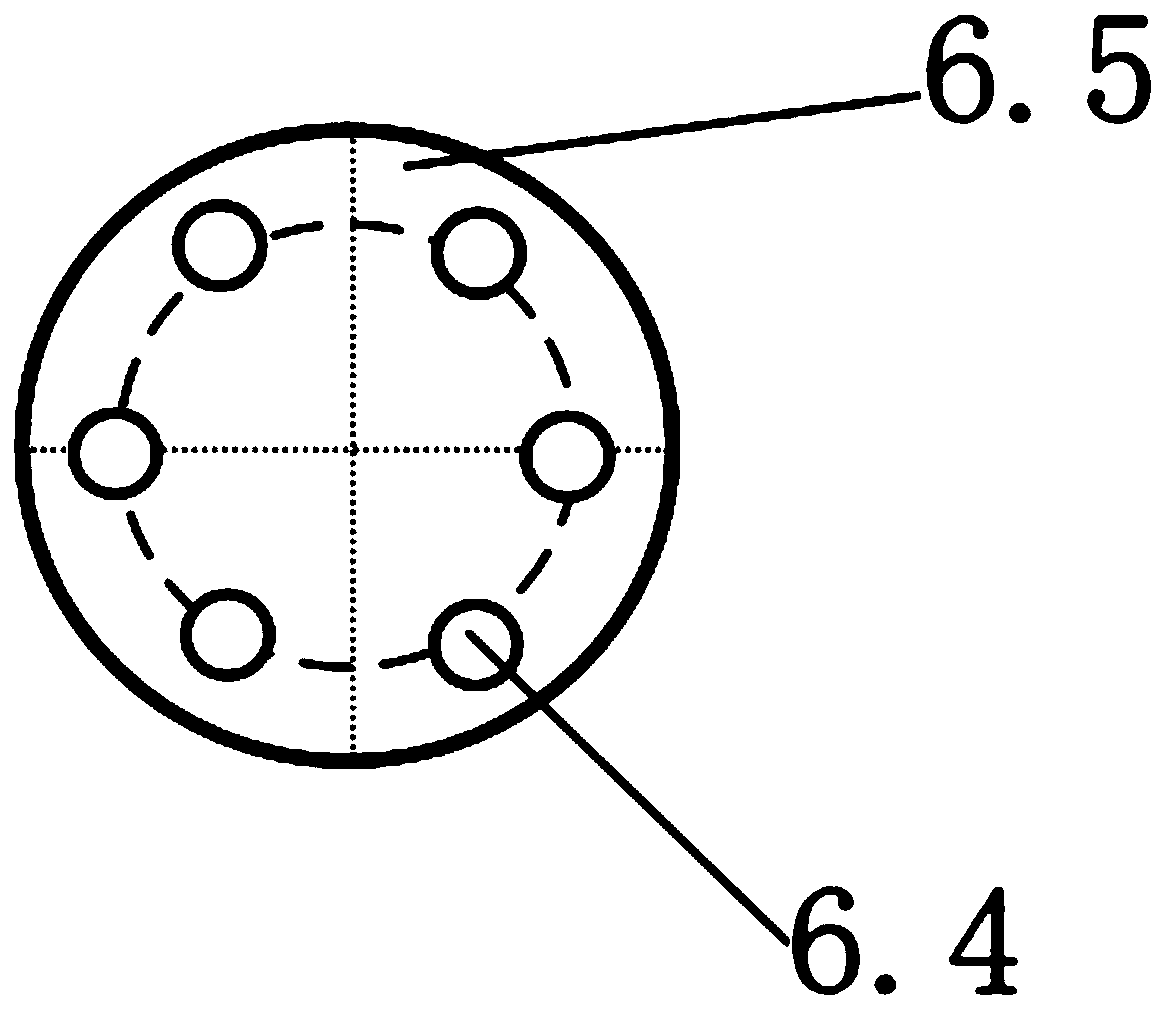

[0038] The present invention combines ATR with pulse detonation engine (Pulse Detonation Engine, PDE for short), utilizes the respective advantages and characteristics of PDE and ATR engine, and utilizes pulse detonation combustion chamber (PDC) to replace the ram combustion chamber in the ATR engine , proposed a new concept based pulse detonation air turbine rocket engine (PD-ATR).

[0039] Due to the special structure and working mode of the PD-ATR engine, what enters the detonation combustion chamber is the mixture of the rich combustion gas flowing through the turbine expansion and the compressed air flowing through the compressor, that is, the mixture entering the detonation combustion chamber It is not composed of pure fuel and air according to a certain equivalent ratio, but impure fuel doped with a certain amount of primary combustion products, and has a certain temperature and pressure. It is difficult to use the traditional pulse detonation engine combustion chamber. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com