Method for producing light aromatic hydrocarbons and high-quality oil products from catalytically cracked diesel

A technology for catalytic cracking of diesel oil and light aromatics, which is applied in the fields of chemical instruments and methods, hydrocarbon cracking to produce hydrocarbons, and treatment of hydrocarbon oils. , improve the effect of pertinence and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

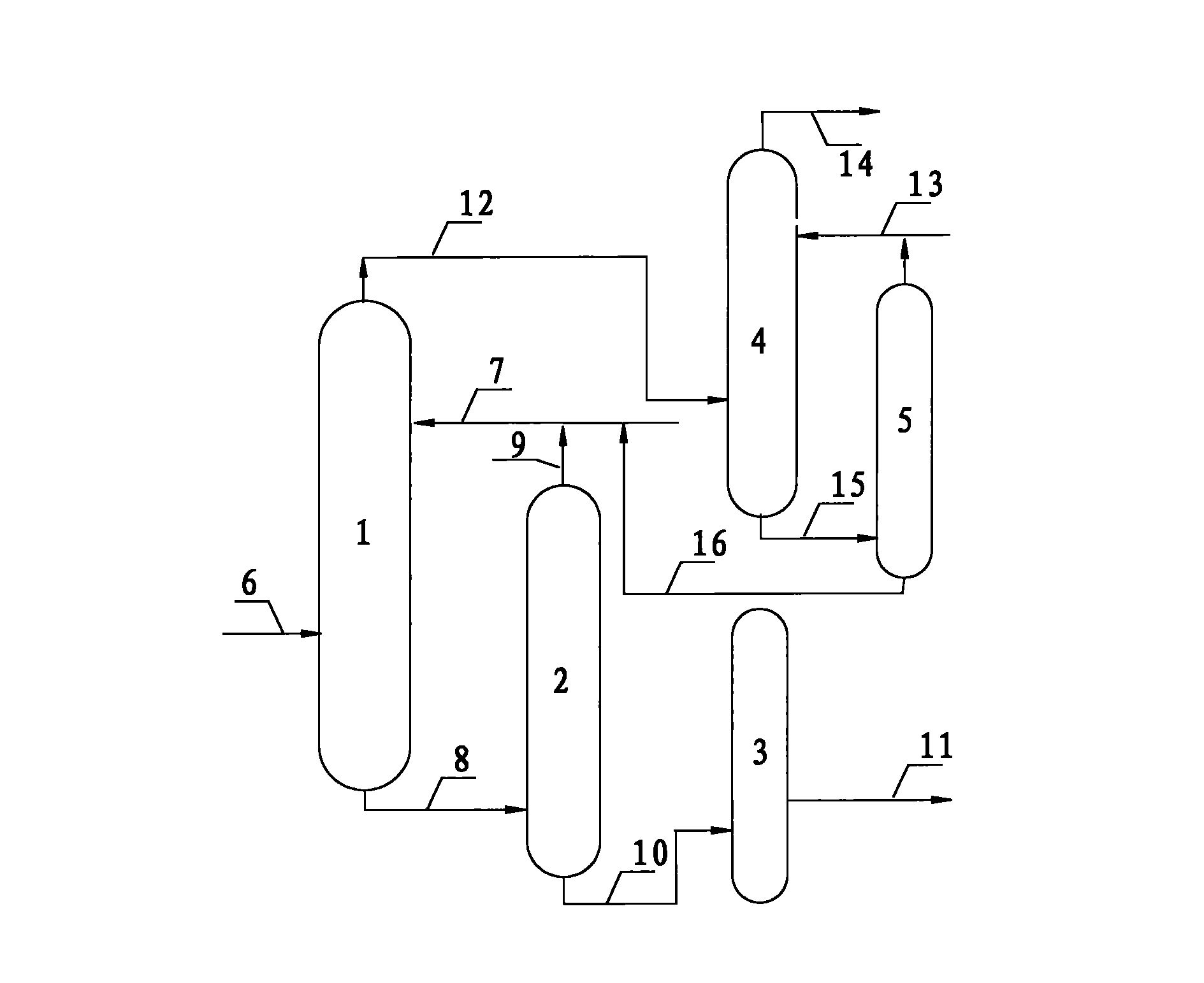

Method used

Image

Examples

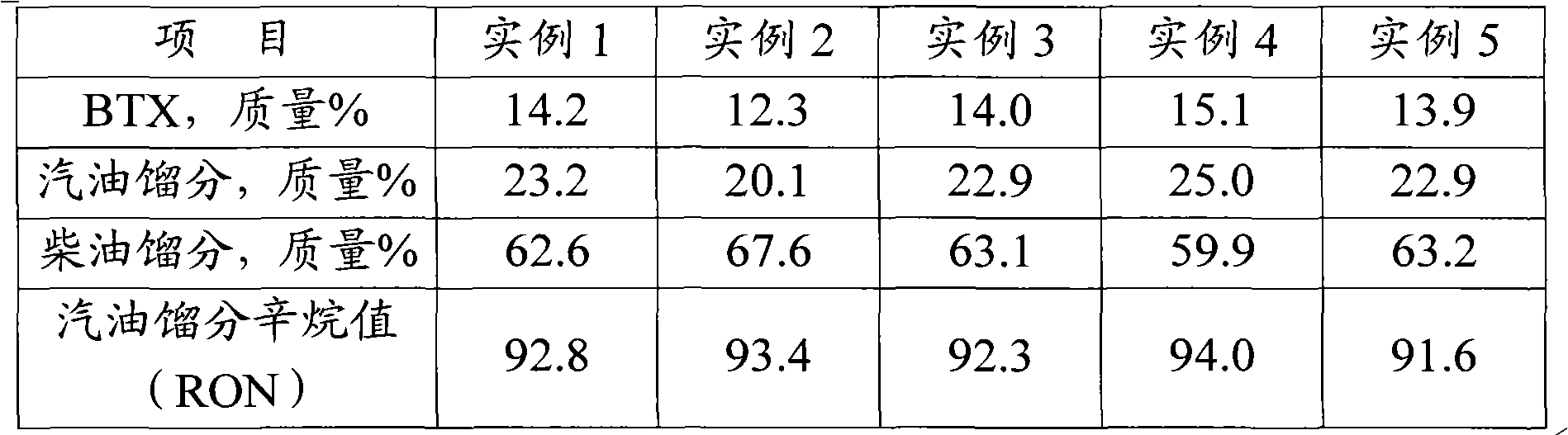

example 1

[0031] According to the method of the invention, FCC diesel is processed to produce BTX and high-quality oil products.

[0032] FCC diesel oil A is used as the extraction material, and its composition is shown in Table 1. Take 100g of FCC diesel oil A and 100g of N,N-dimethylformamide (DMF) into the separatory funnel, oscillate fully to make it evenly mixed, and let stand to separate layers. Take the raffinate of the upper layer, its quality is 55g, add 30g of water therein, fully oscillate and mix evenly, after standing for stratification, separate the oil-water phase to obtain 51g of raffinate, its composition is shown in Table 2.

[0033] The quality of the extracted phase obtained after separating the raffinate phase was 145g, which was subjected to vacuum distillation, and a total of 108g of the extraction solvent and some light components were distilled off to obtain 37g of extracted oil, the composition of which is shown in Table 3.

[0034]Pass the extracted oil into ...

example 2

[0036] According to the method of example 1, FCC diesel oil B is extracted and separated, and the composition of FCC diesel oil B is shown in Table 1. Finally, 47g of raffinate oil was obtained, and its composition was shown in Table 2; 43g of extracted oil was obtained, and its composition was shown in Table 3. The extracted oil is subjected to hydrofining and hydrocracking reactions. The hydrofining catalyst is the catalyst with the brand name RS-1000 produced by Changling Catalyst Factory, and the hydrocracking catalyst is the catalyst with the brand name RHC-2 produced by Changling Catalyst Factory. . The hydrogenation reaction temperature is 380°C, the hydrogen partial pressure is 5.5MPa, and the raw material volume space velocity is 0.8h -1 , The hydrogen / oil volume ratio is 800, and the composition of the extracted oil after hydrogenation reaction is shown in Table 4.

example 3

[0038] FCC diesel oil A is extracted and separated by the method of example 1 and the extracted oil is carried out to hydrotreating. The difference is that the extraction solvent is dimethyl sulfoxide, and 49g of raffinate is obtained, and its composition is shown in Table 2; 39g of extracted oil , its composition is shown in Table 3; the composition of the extracted oil after hydrofining and hydrocracking reactions is shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com