BOG (Boil Off Gas)-zero emission LNG (Liquefied Natural Gas) storage method and device

A storage device and zero-emission technology, which is applied in the field of LNG storage without BOG (flash steam), can solve the problems of high equipment investment costs and large floor space, and achieve small floor space, low cost, and high condensation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

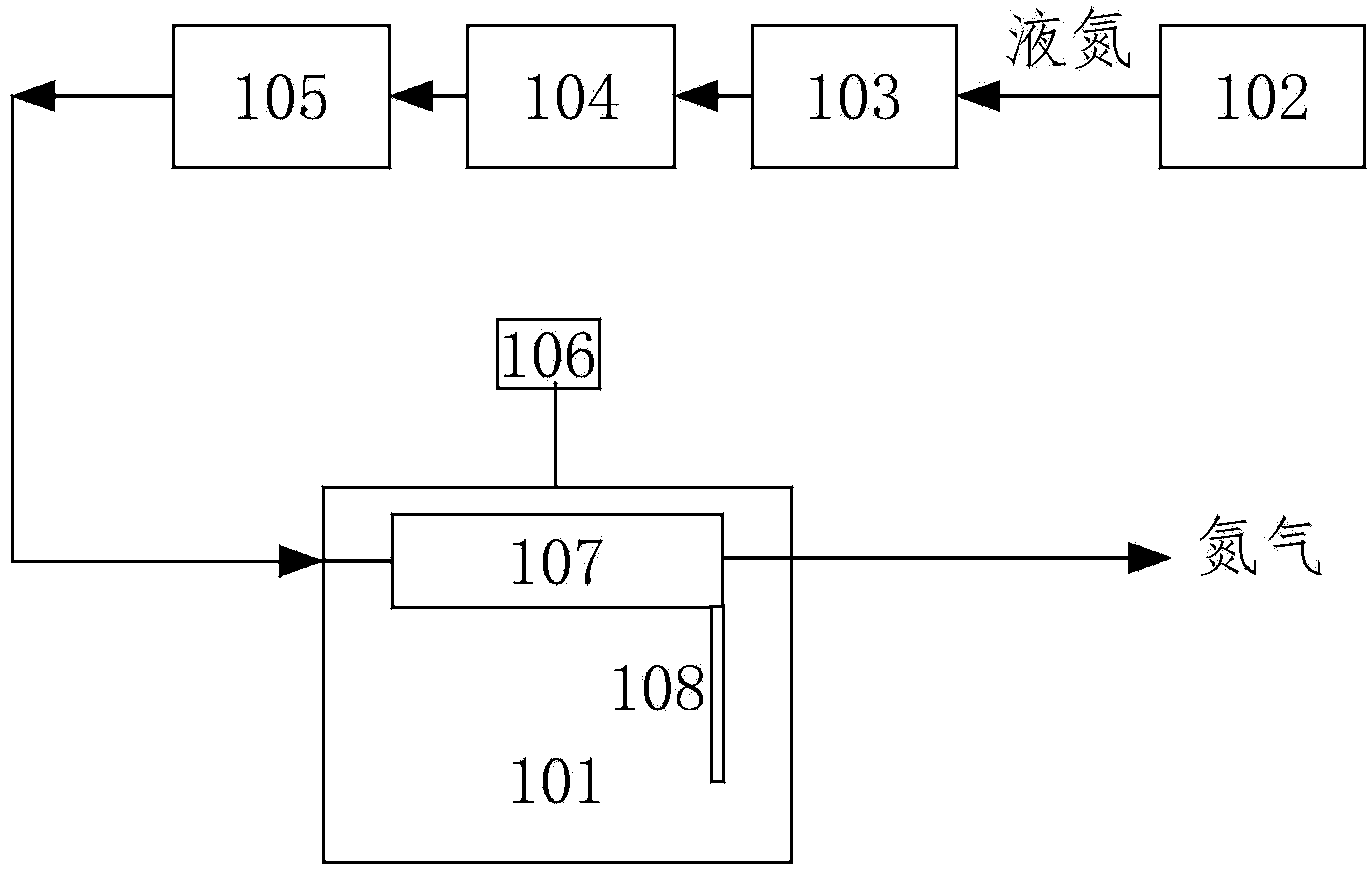

[0030] A BOG zero-emission LNG storage method and device in an LNG receiving station. The parameters of the LNG storage tank are as follows: the capacity is 160,000 m3, the maximum design pressure is 29kpa, the diameters of the outer tank and the inner tank are 82000mm and 80000mm respectively, and the temperature inside the tank is ‐162°C, the total amount of LNG is 7680t, the daily evaporation rate is 0.05%, and the working pressure value of the BOG condenser is specified as 15-20kpa.

[0031] Determination of liquid nitrogen flow rate: -162°C BOG production q B It is 7680×0.05%=3.84t / d, which is 0.16t / h. The chemical process simulation software Aspen is used for simulation calculations, and the required liquid nitrogen flow rate q is calculated according to the fact that BOG is condensed at -162°C to a saturated liquid at -162°C, and liquid nitrogen is vaporized from -196°C to -170°C N , the result q N =0.365t / h, then the ratio of recovered BOG mass to consumed liquid nit...

Embodiment 2

[0041] A BOG zero-discharge LNG storage method and device in an LNG satellite station. The parameters of the LNG storage tank are as follows: the capacity is 350 cubic meters, the maximum design pressure is 10Mpa, the diameters of the outer tank and inner tank are 4500mm and 4000mm respectively, and the temperature in the tank- 140°C, the total amount of LNG is 477t, the daily evaporation rate is 0.1%, and the working pressure value of the BOG condenser is specified as 6Mpa.

[0042] Determination of liquid nitrogen flow rate: -140°C BOG production q B It is 477×0.1%=0.477t / d, which is 19.8kg / h. The chemical process simulation software Aspen is used for simulation calculations, and the required liquid nitrogen flow rate q is calculated according to the fact that BOG is condensed at -140°C to a saturated liquid at -140°C, and liquid nitrogen is vaporized from -196°C to -170°C N , the result q N =40kg / h, then the ratio of recovered BOG mass to consumed liquid nitrogen mass, q ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com