System and method for re-condensing boil off gas (BOG) of liquefied natural gas

A technology of liquefied natural gas and evaporated gas, which is applied in liquefaction, refrigeration, liquefaction, solidification, etc., can solve the problems of complex logic control, large equipment investment, and low condensation efficiency, and achieve high economic benefits, high condensation efficiency, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

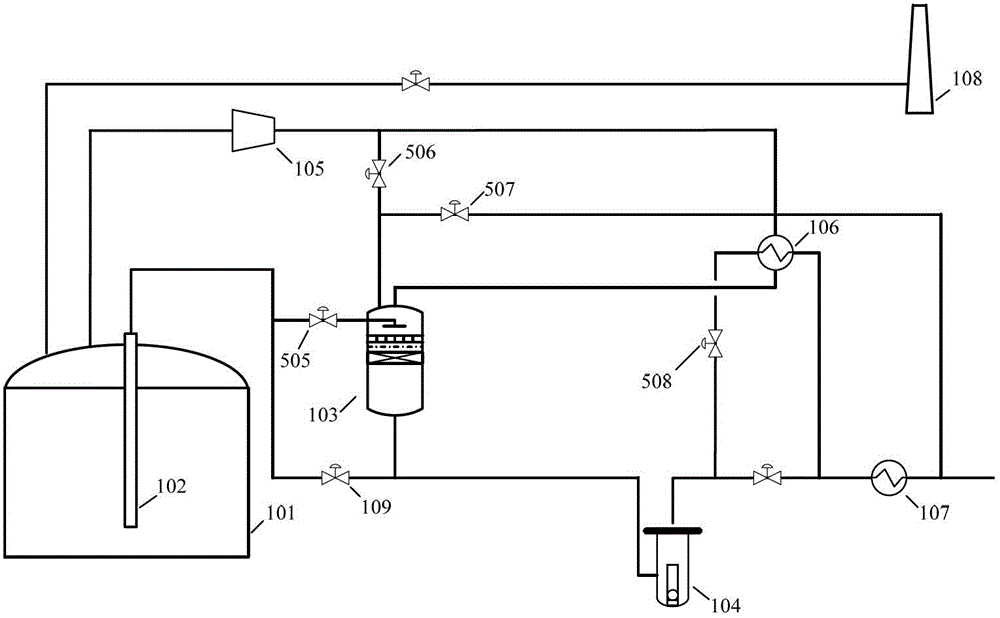

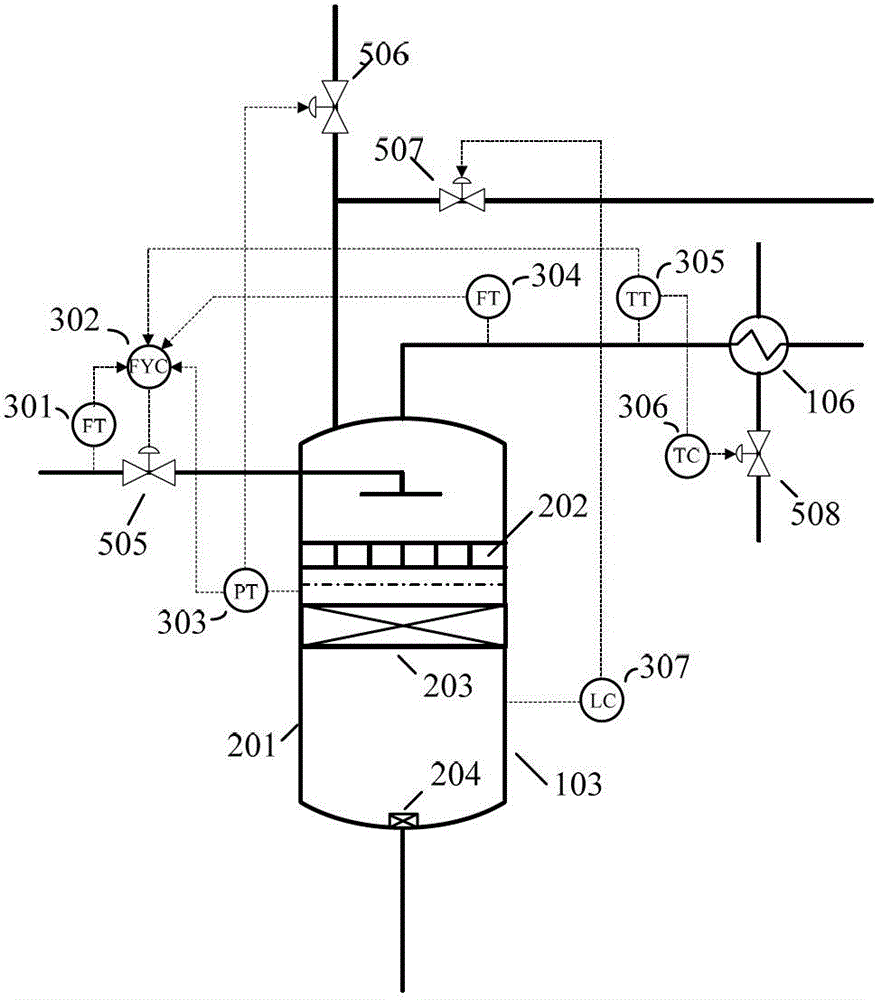

[0070] Such as image 3 As shown, the BOG recondensation system of the LNG receiving station mainly includes an LNG storage tank 101, a low-pressure pump 102 inside the LNG tank, a booster pump 104 outside the LNG tank, a BOG compressor 105, a BOG compressor outlet heat exchanger 106, a gasification Device 107, torch 108, static mixer 109, gas-liquid separator 110. The BOG produced in the storage tank enters the BOG compressor 105 for pressurization through the evaporating gas main pipe, and then enters the static mixer 109 after heat exchange by the heat exchanger 106 . The LNG in the storage tank has a certain degree of subcooling after being pressurized by the low-pressure pump 102 in the tank, and a part of the LNG enters the static mixer 109 to exchange heat with the BOG. The mixed heat-exchanged fluid enters the gas-liquid separator 110 for gas-liquid separation, the separated gas returns to the BOG main pipe, and the separated liquid returns to the LNG low-pressure exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com