Heat-gaining combined heat and power system

A heat-electricity-cooling combined supply and heat-increasing technology is applied in the application field of energy technology, which can solve the problems of not fully utilizing the heat of flue gas in the high-temperature section to work, and achieve the effects of improving efficiency, reducing exhaust gas temperature, and reducing emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

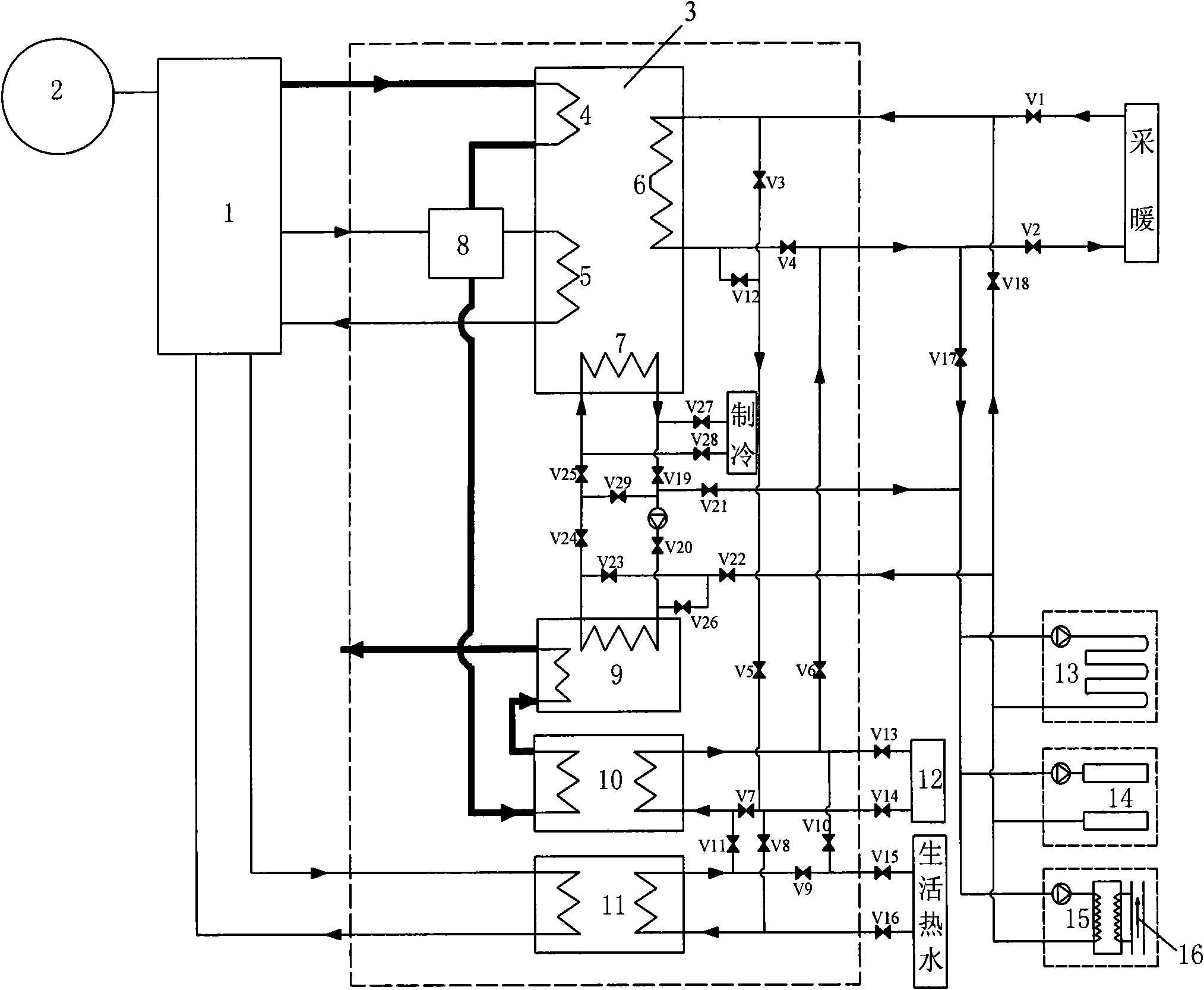

[0022] Example 1 as figure 2 As shown, the type of gas engine 1 is a gas internal combustion engine, and the high-temperature flue gas at 500 °C first enters the first generator 4 of the absorption heat pump 3 as a driving heat source and cools down to 170 °C to be discharged, and then enters the high-temperature flue gas-water heat exchanger 8 releases heat and cools down to 120°C, then enters medium-temperature flue gas-water heat exchanger 10 releases heat and cools to 60°C, and finally enters low-temperature flue gas-water heat exchanger 9 releases heat and cools to 25°C, and discharges to the atmosphere. After the high-temperature jacket water enters the high-temperature flue gas-water heat exchanger 8 to exchange heat with the flue gas, it enters the second generator 5 of the absorption heat pump 3 and then flows back to the gas internal combustion engine. The low-temperature intercooled water enters the water-water heat exchanger 11 and then flows back to the gas inter...

Embodiment 2

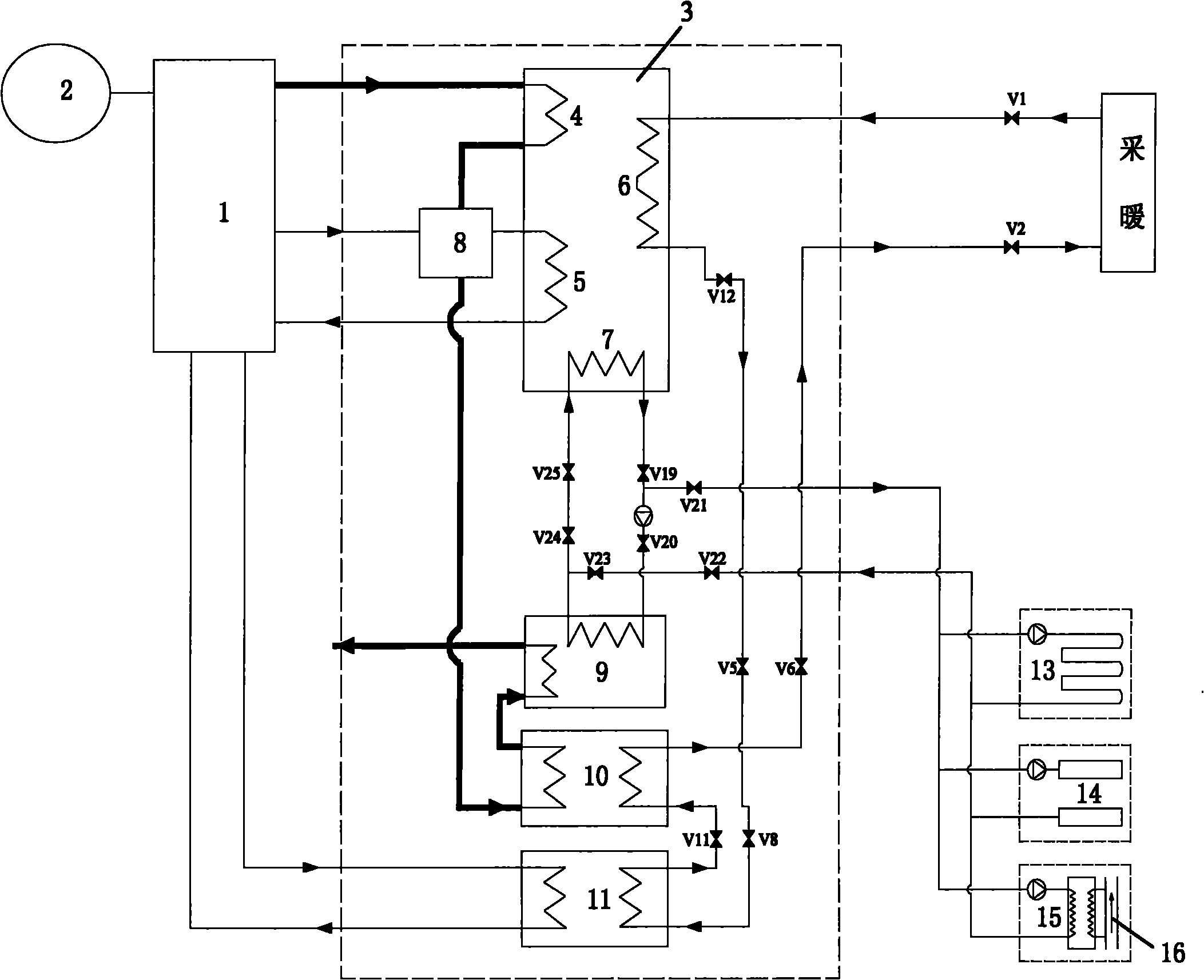

[0024] Example 2 as image 3 As shown, the type of gas engine 1 is a gas internal combustion engine, and the processes of flue gas, high-temperature jacket water, and low-temperature intercooling water are the same as in embodiment 1.

[0025] Embodiment 2 On the basis of Embodiment 1, a pipeline from the buried pipe 13 or the shallow groundwater well 14 or the sewage heat exchanger 15 to the water inlet of the low-temperature flue gas-water heat exchanger 9 and the pipeline located in the pipe are added. The valve on the road is the twenty-sixth valve V26. Under this heating condition, the first valve V1, the second valve V2, the fifth valve V5, the sixth valve V6, the eighth valve V8, the eleventh valve V11, the Twelfth valve V12, nineteenth valve V19, twenty-first valve V21, twenty-second valve V22, twenty-fourth valve V24, twenty-fifth valve V25, twenty-sixth valve V26 open, and other valves closed , the heating return water enters the condensation and absorber 6 of the a...

Embodiment 3

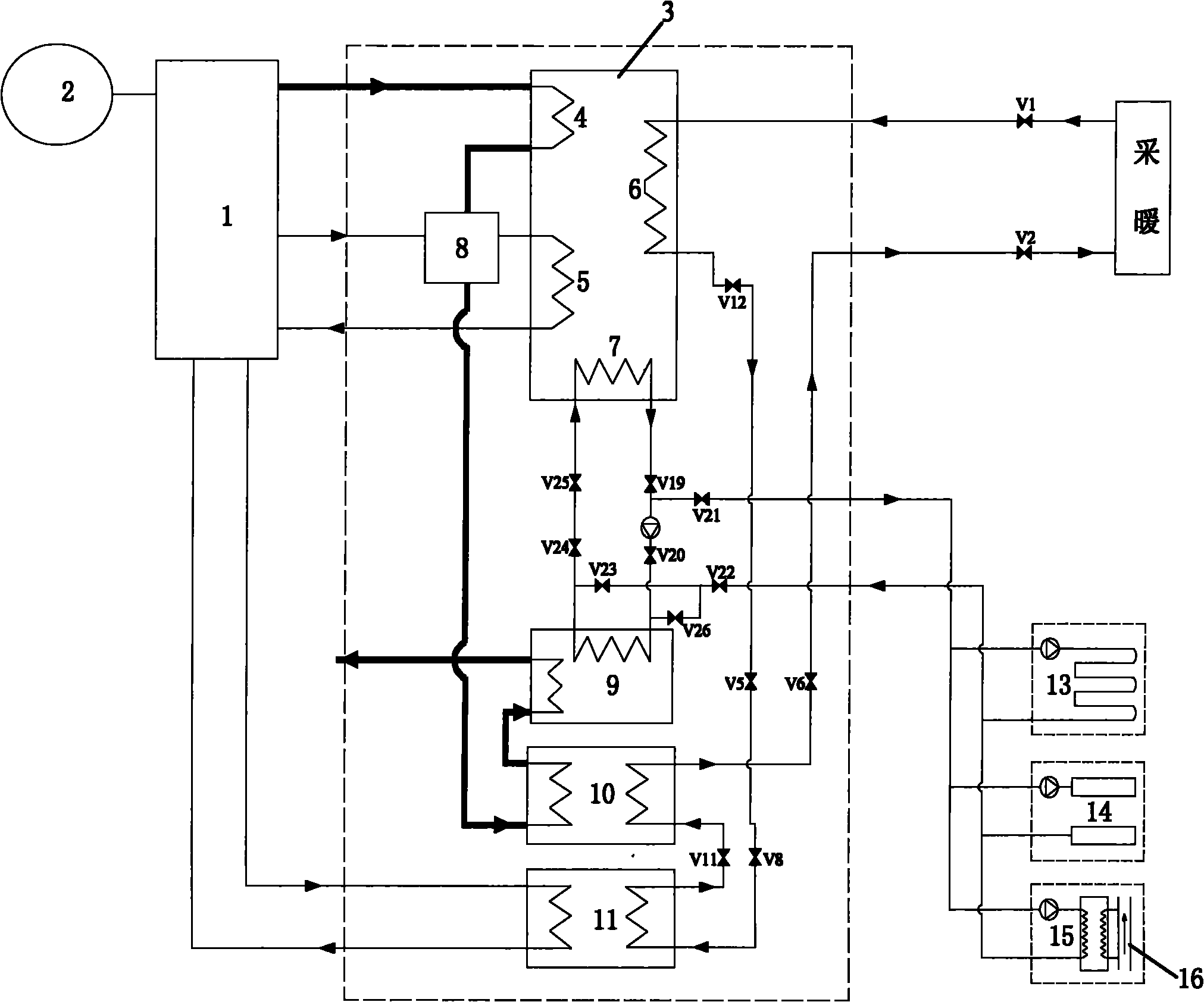

[0027] Example 3 as Figure 4 As shown, the type of gas engine 1 is a gas internal combustion engine, and the processes of flue gas, high-temperature jacket water, and low-temperature intercooled water are the same as those in Embodiment 1. Embodiment 3 On the basis of Embodiment 1, a pipeline from the heating return water to the water outlet of the condensation and absorber 6 of the absorption heat pump 3 and a third valve V3 located on the pipeline are added, and a pipeline from the water outlet of the condensation and absorber 6 to the water outlet of the absorption heat pump 3 is added. For the heating water supply pipeline and the fourth valve V4 on the pipeline, a pipeline from the heating return water to the water inlet of the medium-temperature flue gas-water heat exchanger 10 and the seventh valve V7 on the pipeline are added. - The pipeline from the water outlet at the low temperature side of the water heat exchanger 11 to the heating water inlet, and the ninth valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com