Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Reduce steam usage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

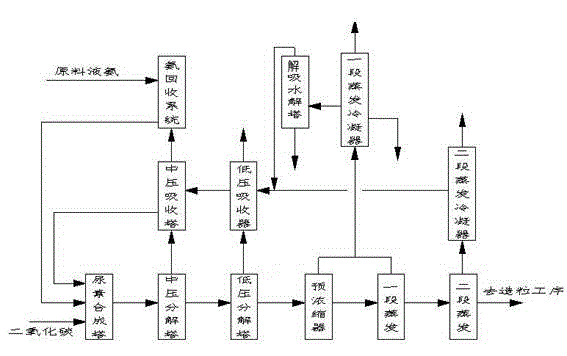

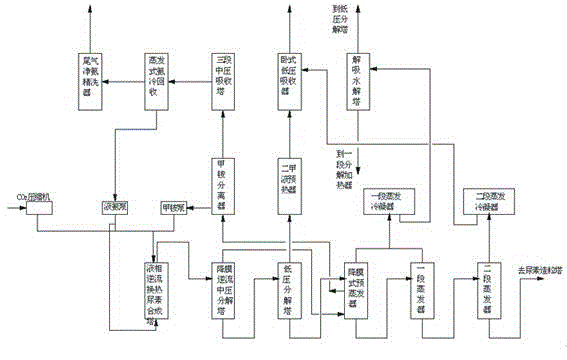

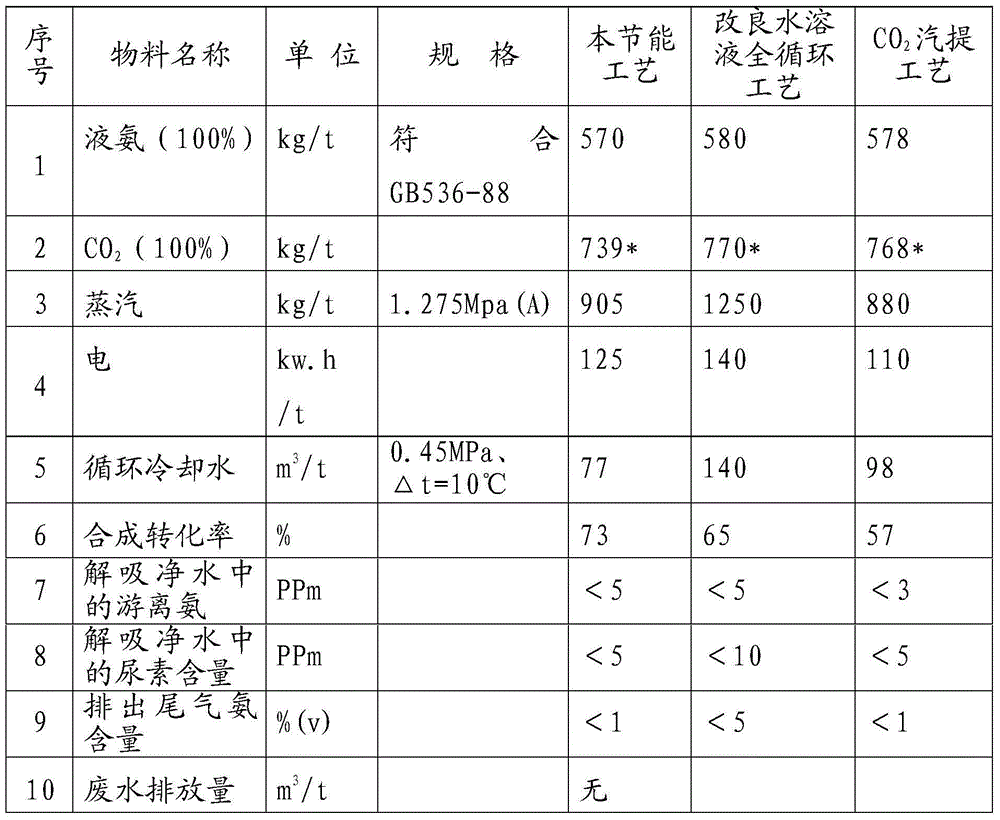

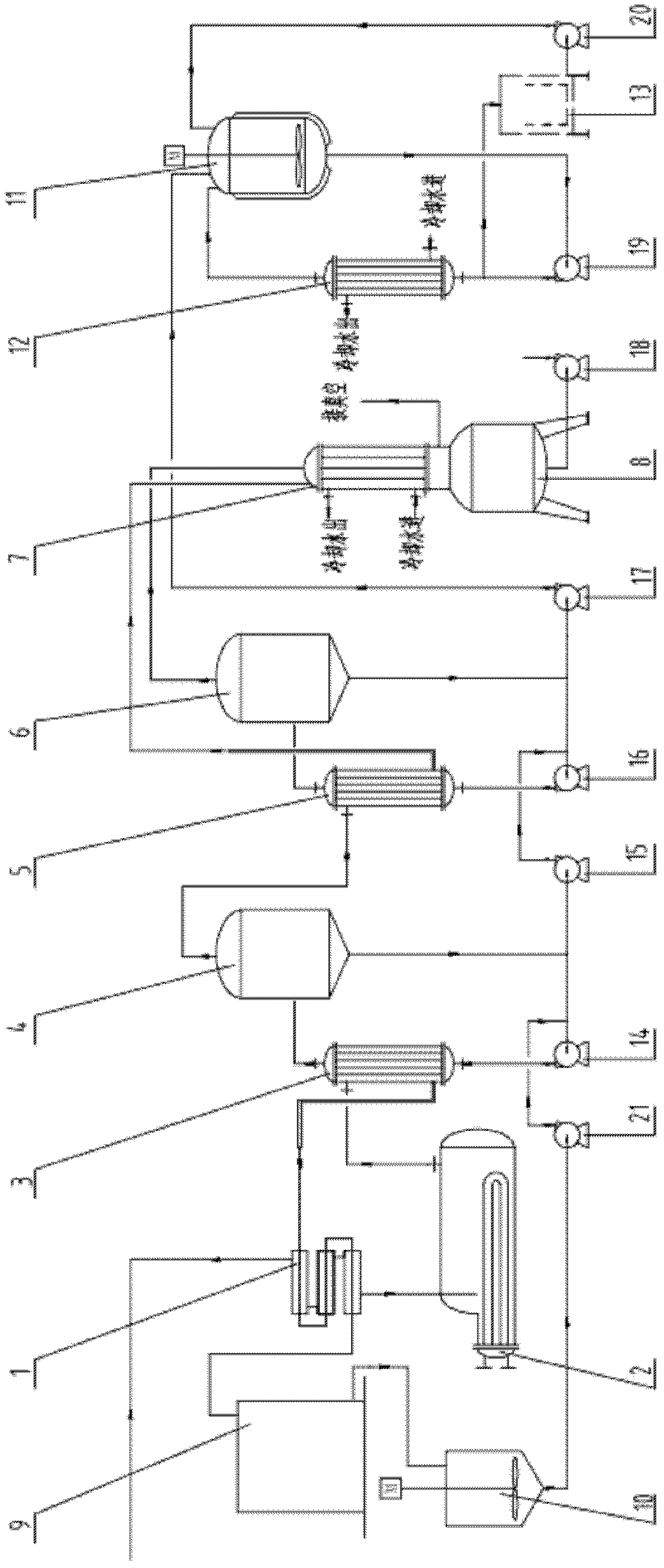

Energy-saving urea production system and production process thereof

ActiveCN104829494AReduce energy consumptionEasy to operateUrea derivatives preparationOrganic compound preparationDesorptionAmmonium carbamate

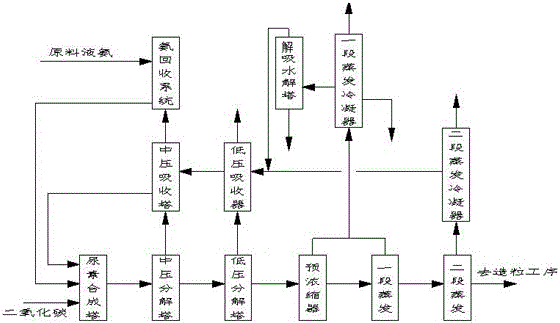

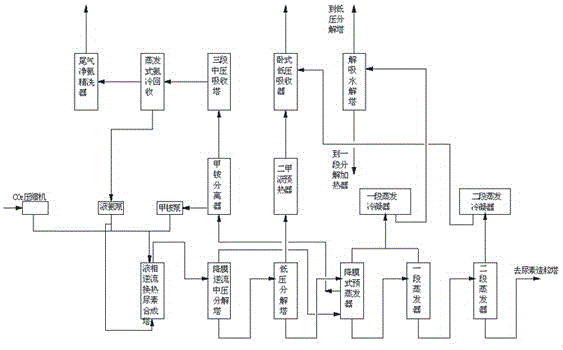

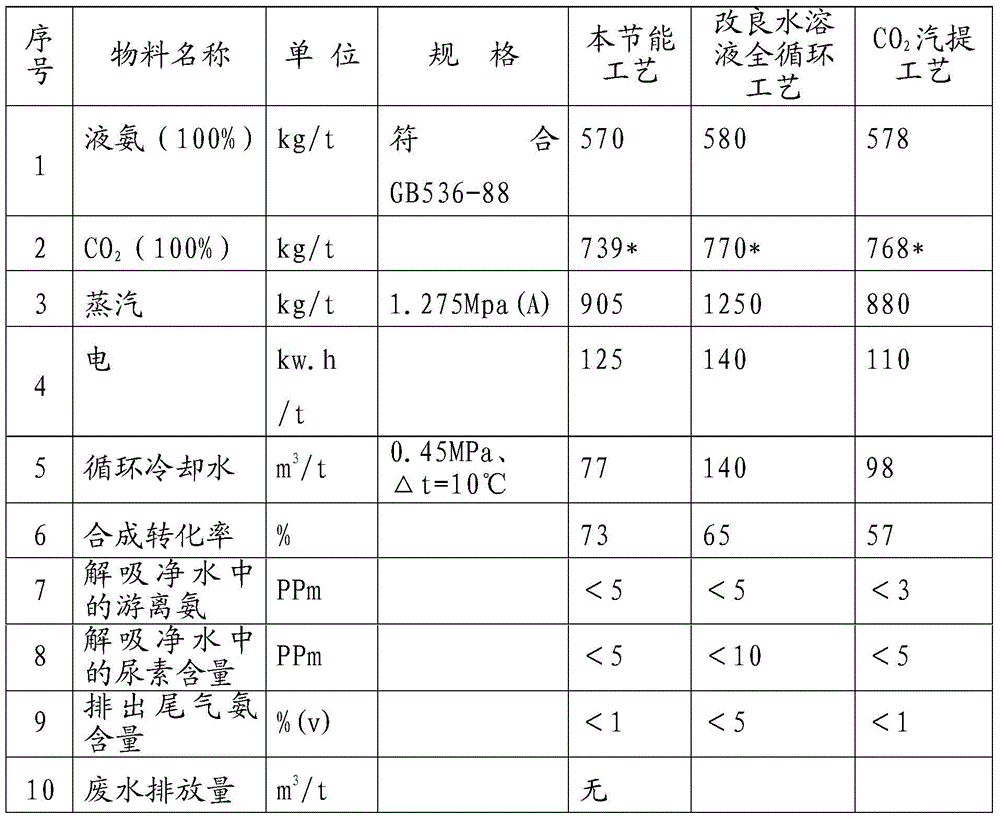

The invention belongs to the field of urea preparation, and particularly relates to an energy-saving urea production system and a production process thereof. The system comprises a CO2 compressor, an ammonium carbamate pump, a liquid ammonia pump and a urea synthesizer. The system is characterized in that the CO2 compressor is connected with the ammonium carbamate pump and the liquid ammonia pump, the liquid ammonia pump is connected with the urea synthesizer, a falling-film countercurrent medium-pressure decomposing tower and a heater, an ammonium carbamate condenser, an ammonium carbamate separator, a three-stage medium-pressure absorption tower and an evaporative ammonia refrigeration recoverer, a liquid ammonia buffer tank, an inert gas scrubber, a tail-gas ammonia cleaning fine purifier, a low-pressure decomposing tower and a heater, a dimethyl liquid preheater, a horizontal low-pressure absorber, a falling film type pre-evaporator, a one-stage evaporator and a one-stage evaporative condenser, a two-stage evaporator and a two-stage evaporative condenser, and a process wastewater desorption and hydrolysis tower are sequentially connected behind the urea synthesizer in sequence. The energy-saving urea production system has the advantages of low investment, low energy consumption, simple operation, high elasticity and the like, thereby the process technology has considerable economic benefit and social benefit.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

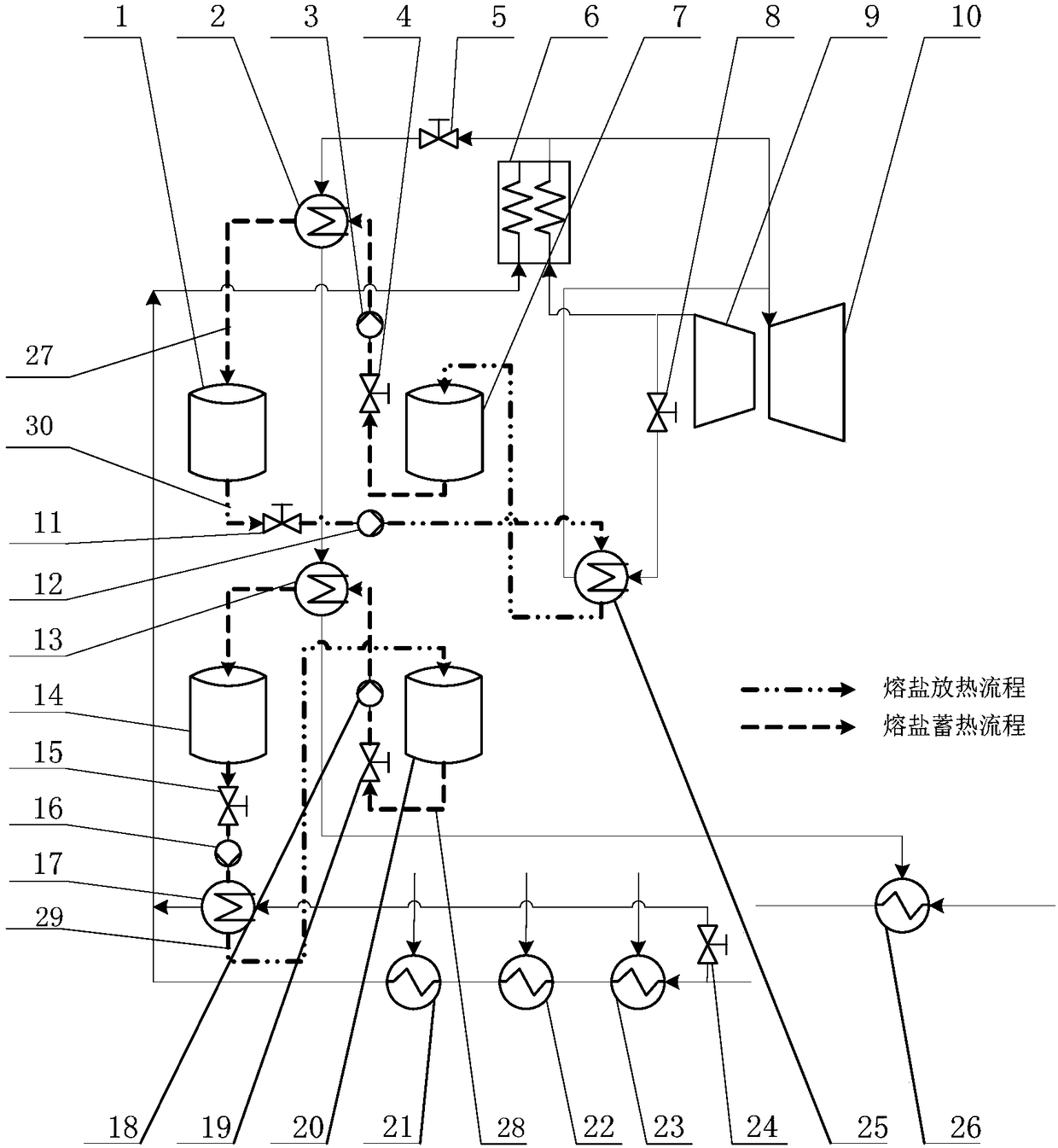

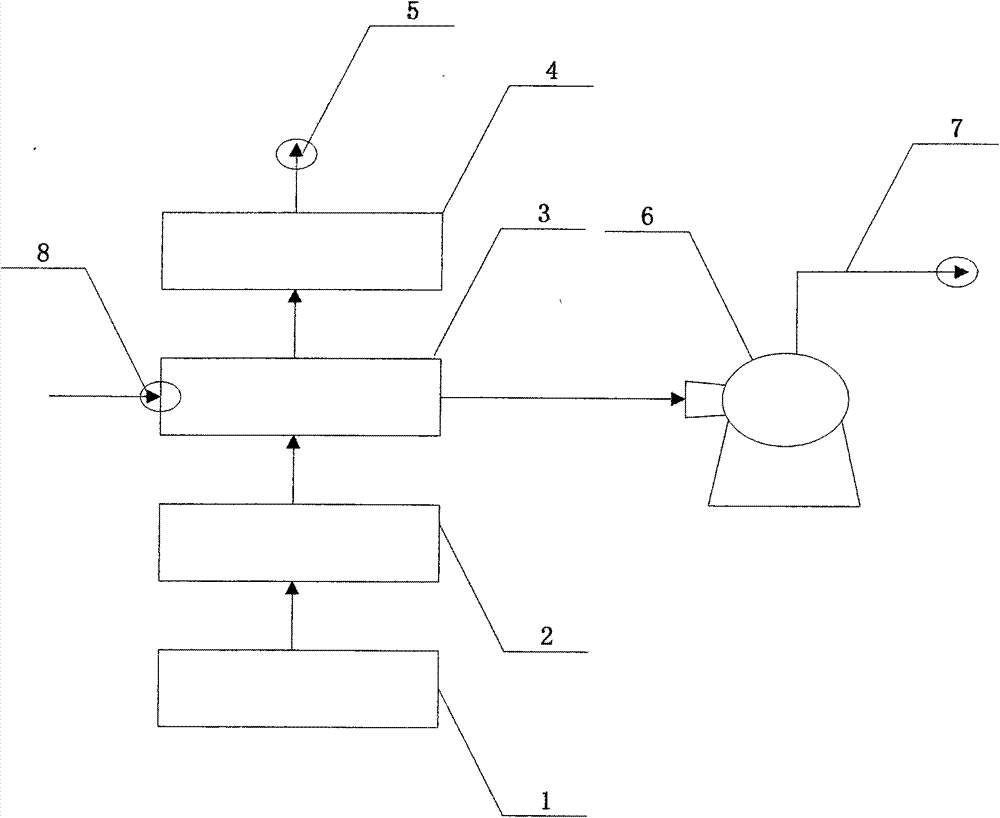

Fused salt heat storage and heat release peak load regulating system for thermal power generating unit

The invention discloses a fused salt heat storage and heat release peak load regulating system for a thermal power generating unit. According to the fused salt heat storage and heat release peak loadregulating system, a fused salt heat storage system, an I-stage fused salt low-temperature heat release system and a II-stage fused salt high-temperature heat release system are additionally arrangedon the basis of the original thermal power generating unit, and therefore peak load regulating of a power grid is realized through heat storage and heat release of fused salt; when the dispatching load of the power grid is decreased, part of high-temperature reheat steam is extracted from an outlet of a boiler reheater and exchanges heat with the fused salt in the fused salt heat storage system, and therefore consumption and utilization of the reheat steam in the electricity utilization off-peak season are completed; when the dispatching load of the power grid is increased, a part of high-pressure feedwater flowing to a high-pressure heater is divided into the I-stage fused salt low-temperature heat release system to exchange heat with the fused salt; and meanwhile, the steam discharge amount of a high-pressure cylinder is increased, part of increased exhaust steam of the high-pressure cylinder is fed into the II-stage fused salt high-temperature heat release system to exchange heat with the high-temperature fused salt, the heated steam enters an intermediate-pressure cylinder to apply work, the amount of the steam entering the intermediate-pressure cylinder and the output of a steam turbine can be increased, and the electric power of the thermal power generating unit can be rapidly increased.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

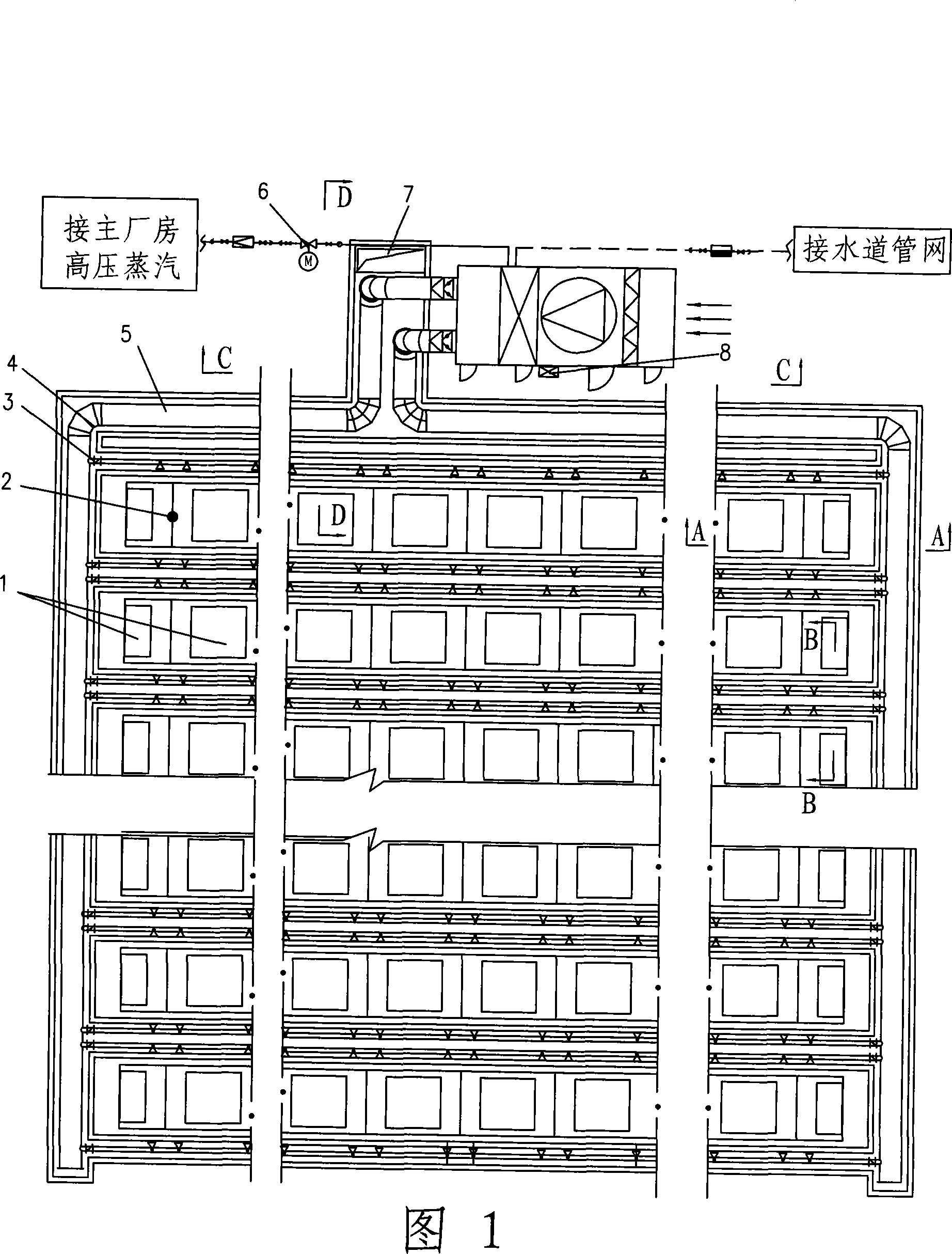

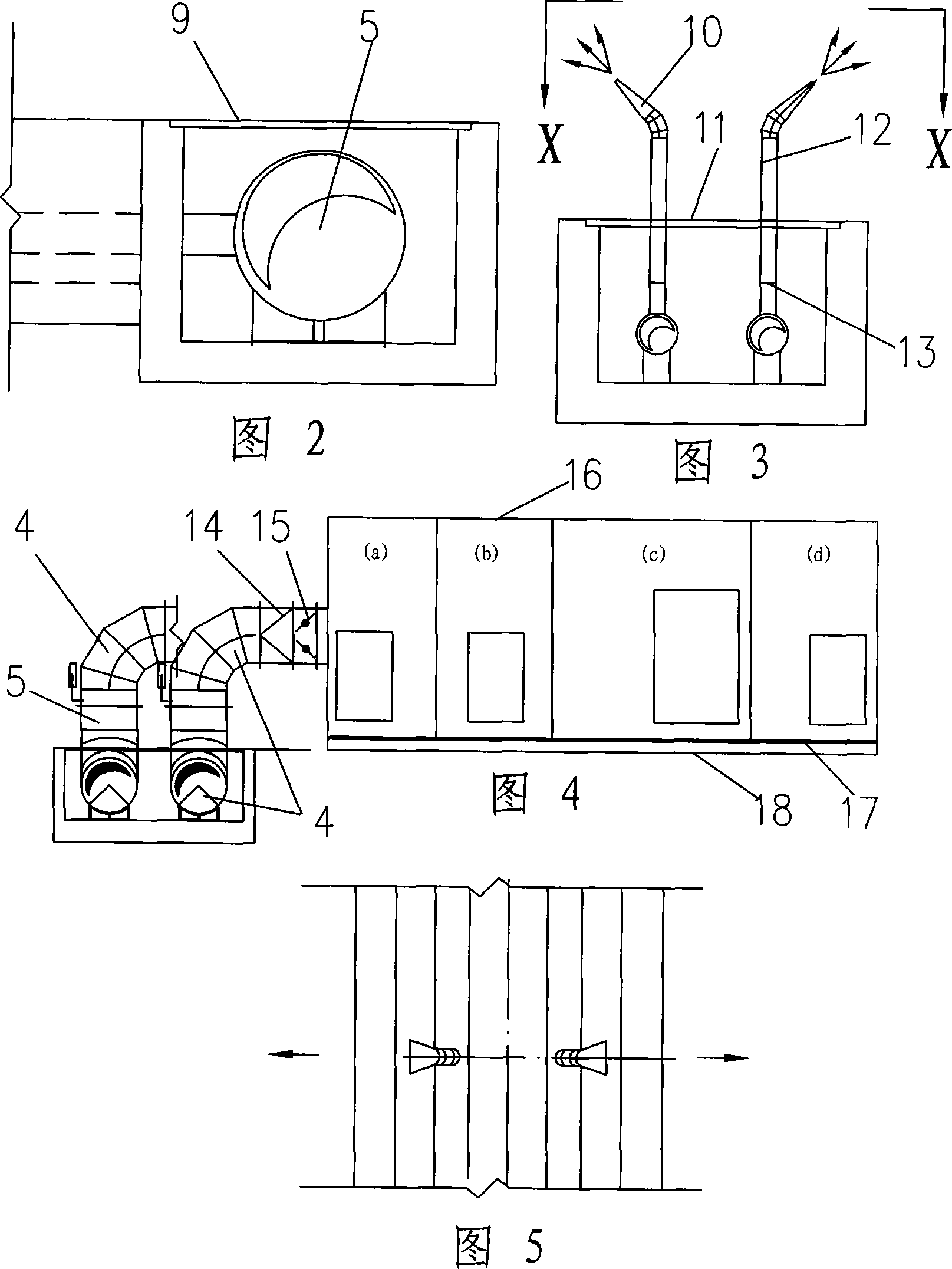

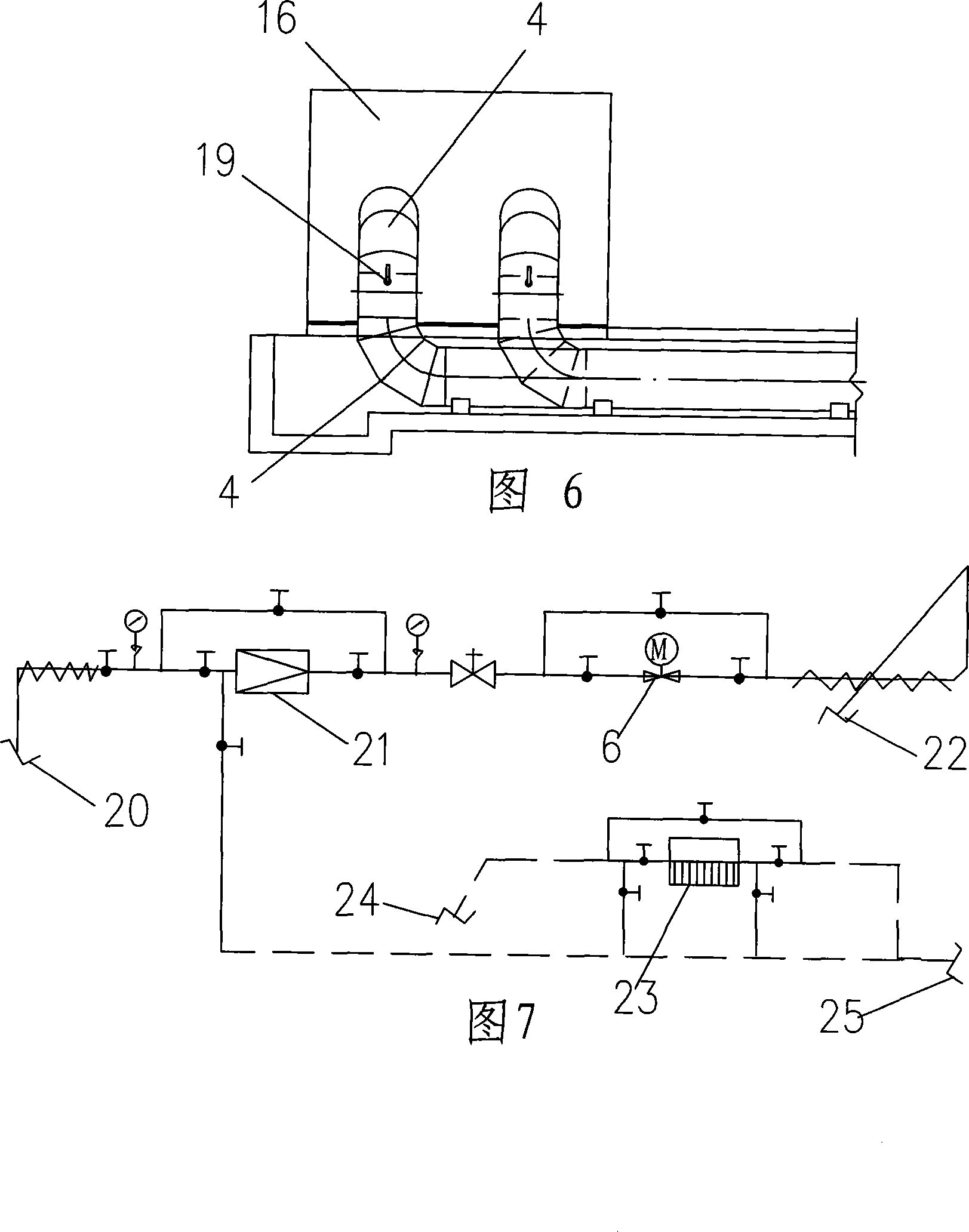

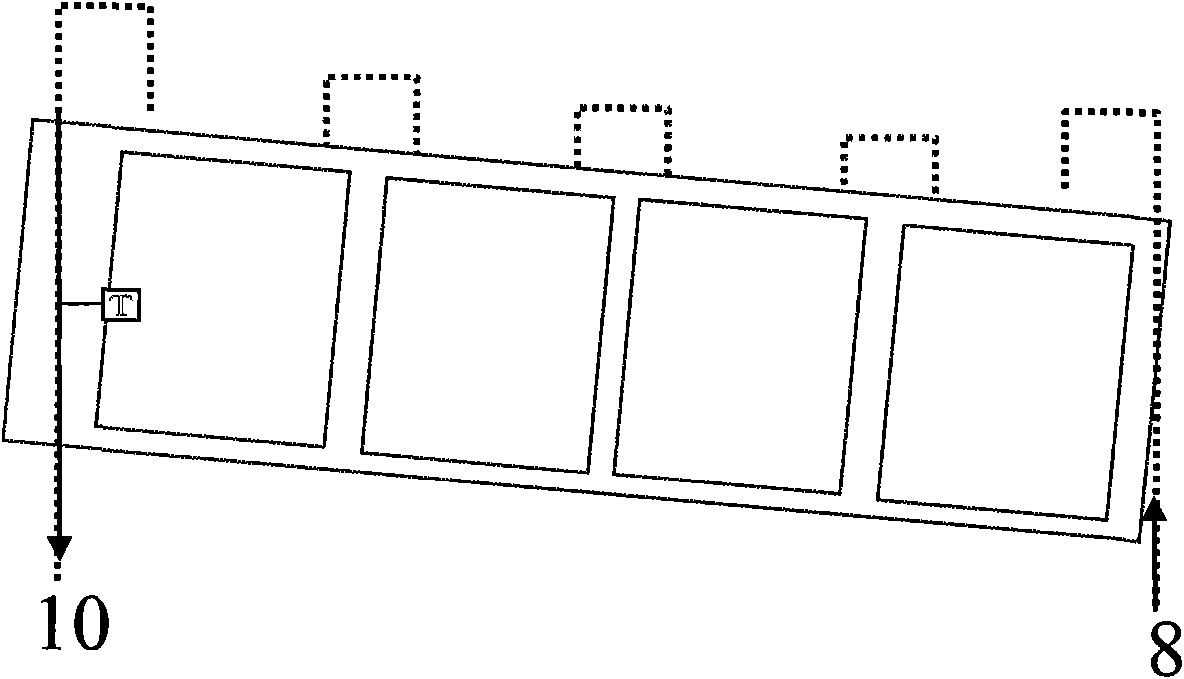

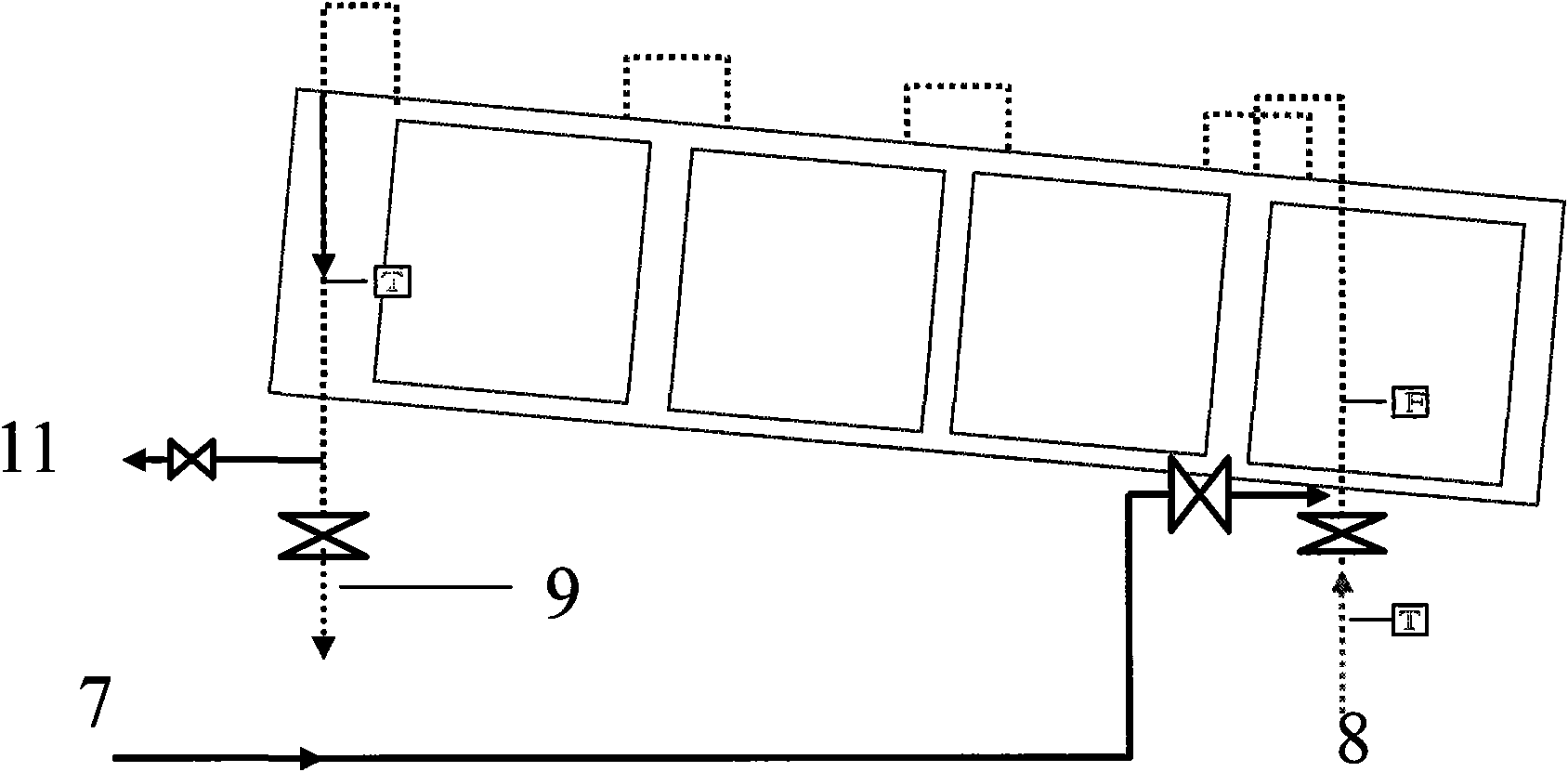

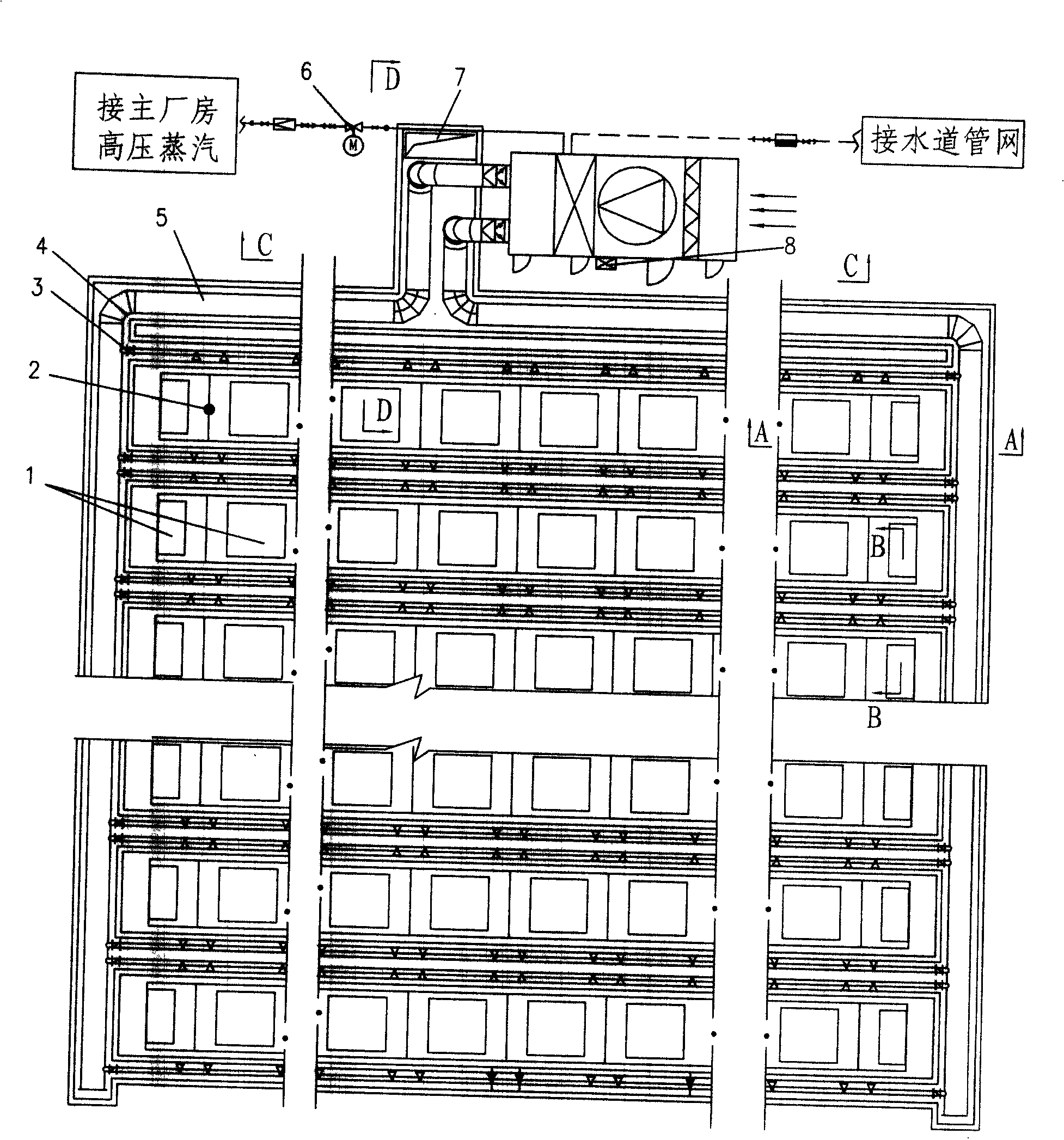

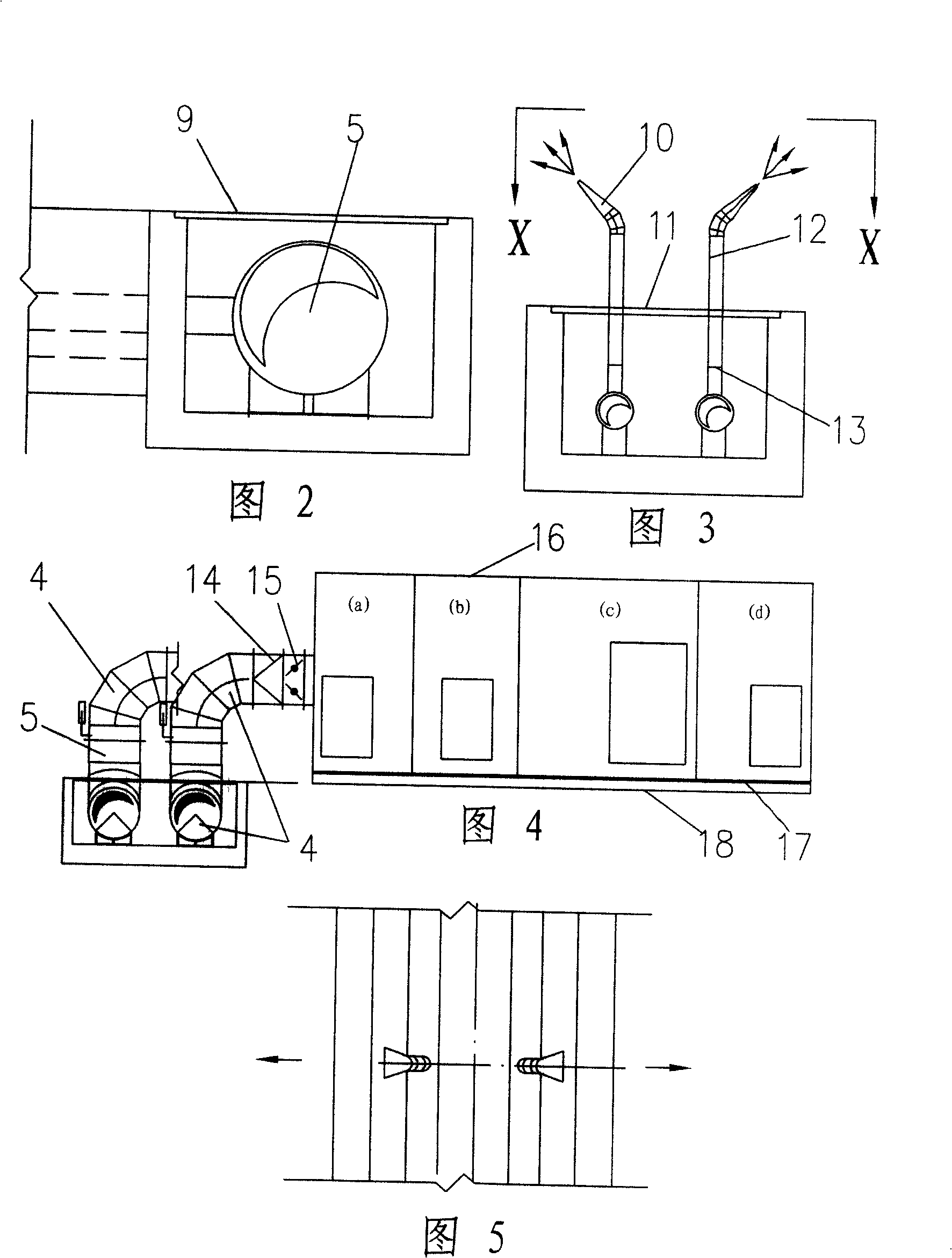

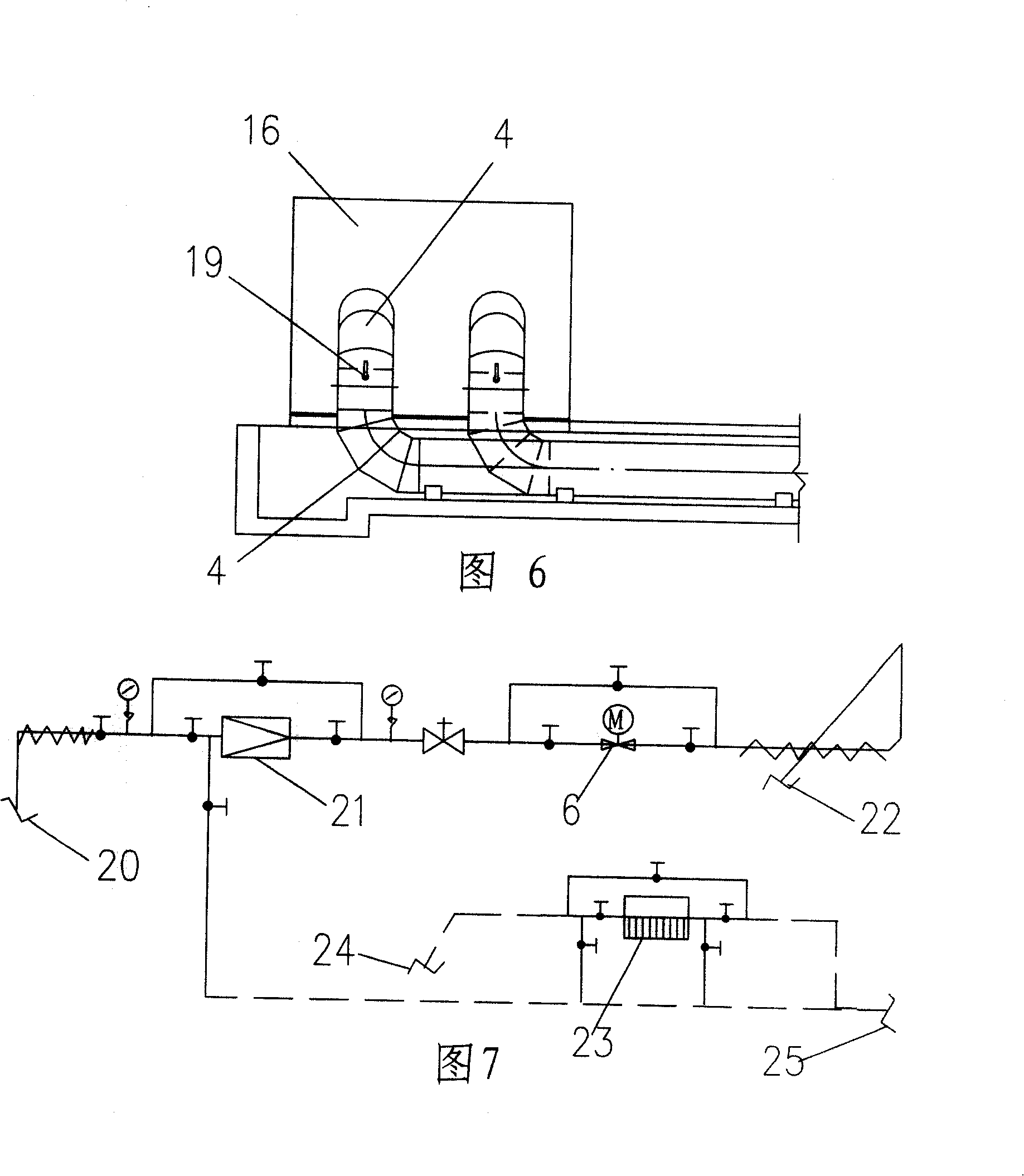

Anti-dew ventilation method and facilities for main factory building of cold rolling factory

InactiveCN101196333ALower investmentLess equipmentMechanical apparatusSpace heating and ventilation safety systemsDewPeripheral

The invention relates to a dew prevention and ventilation method and facility for main workshop of cold rolling plant, which comprises the delivery of hot air. The invention gushes high speed hot air via an air blowing port on the pipe network laid on the ground at the peripheral of a steel coil; a hot air screen that isolates with other zones of the plant is formed in the steel coil piling zone, so that the ambient temperature in the steel coil piling zone is higher than the dewing temperature. The invention also comprises a monitoring system and delivers hot air to the ventilation system according to the monitoring signal fed back by the steel coil piling zone, so as to prevent the dewing of steel coil. The facility in the invention comprises: a dew point monitoring system, a monitoring point is positioned at a testing coil pre-arranged at the steel coil piling zone, an equipment for the monitoring and early warning of the dewing temperature of steel coil is positioned in the monitoring point; a hot air delivery system, the hot air delivery pipe network is laid collectively on the ground next to the steel coil and a blowing port (10) is positioned on the pipeline of the pipe network. Therefore, the invention, which can prevent the discard of a great number of steel coil due to dewing, reduces the consumption of energy resources, assures low equipment operation cost, realizes little work load for maintenance and overhaul as well as ensures low investment cost in each time.

Owner:WISDRI ENG & RES INC LTD

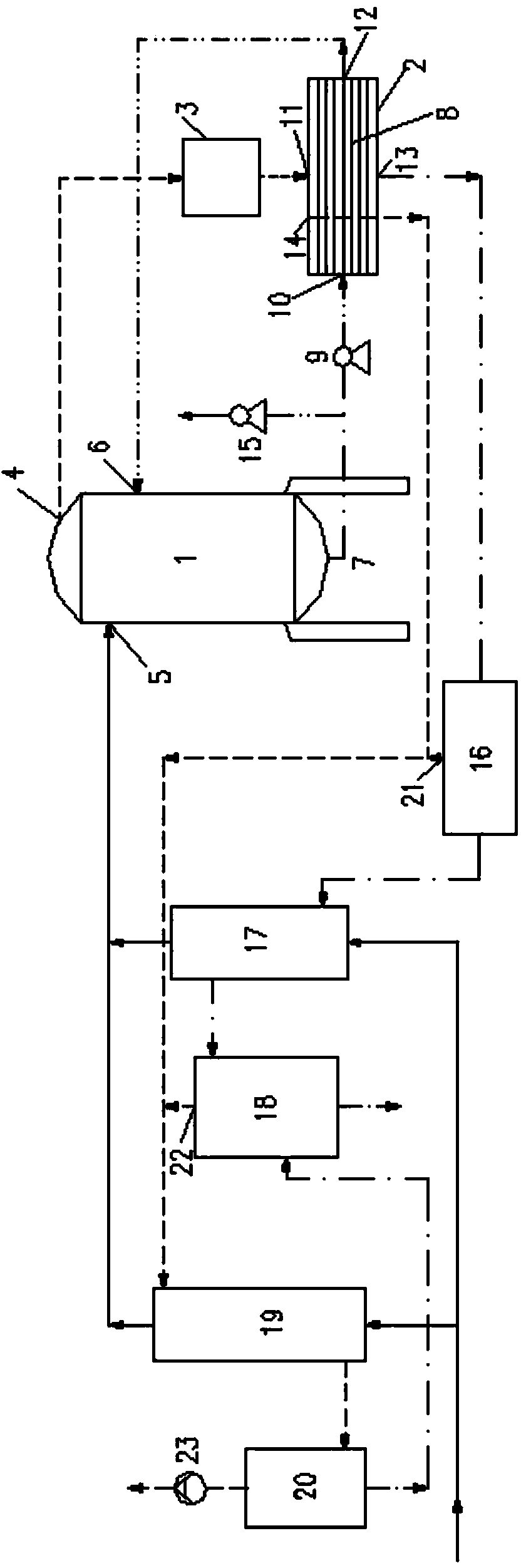

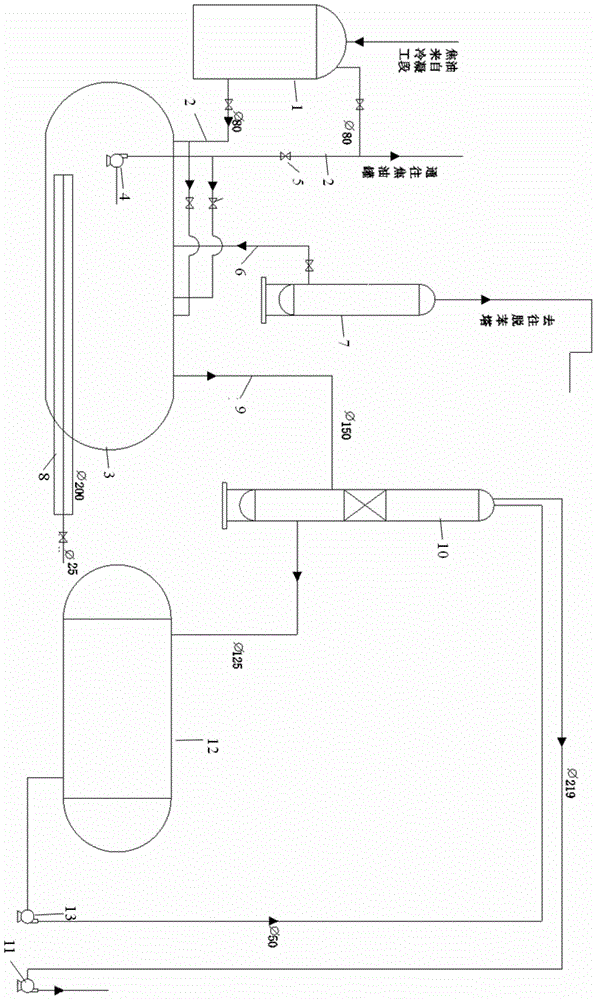

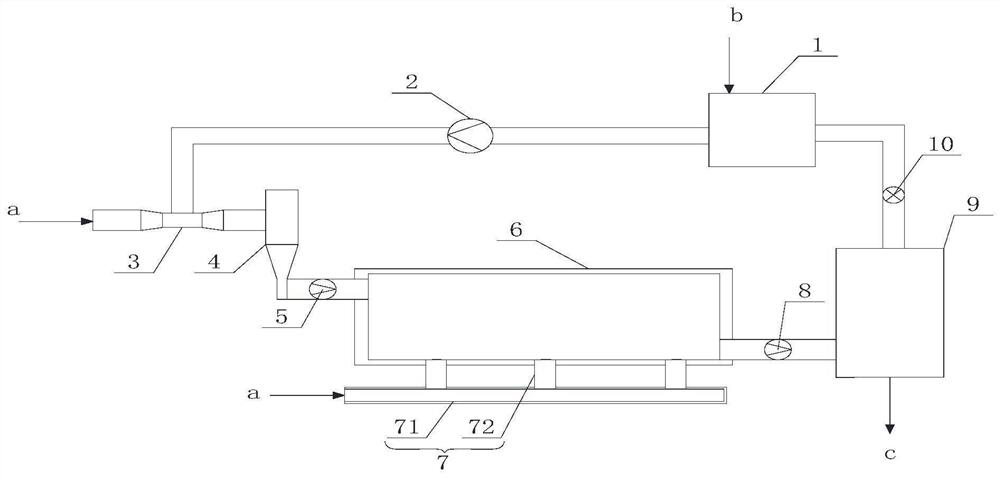

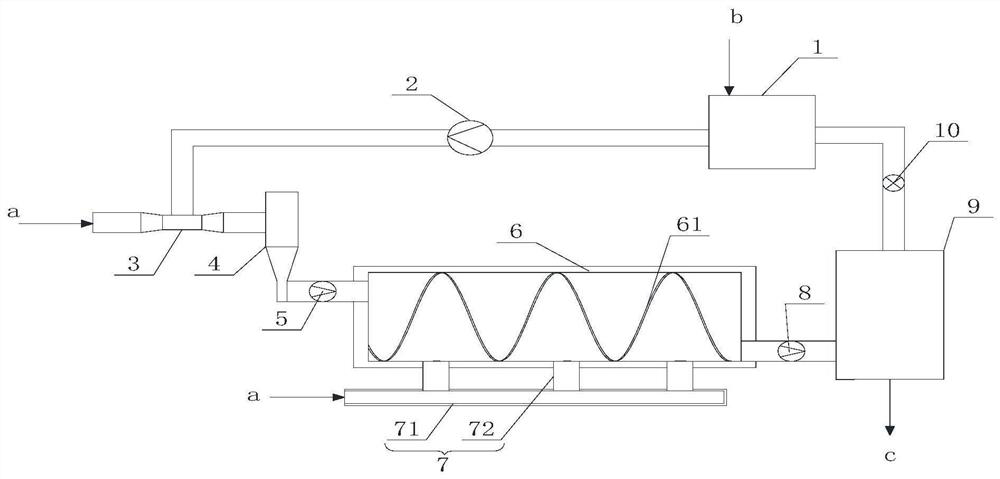

Garbage leachate treatment system

ActiveCN103910399AReduce energy consumptionReduce steam usageWater/sewage treatmentCondensed waterEvaporator

The invention discloses a garbage leachate treatment system, which comprises an evaporator, a heater and a steam compressor, wherein the evaporator is provided with a steam outlet, a garbage leachate feeding pipe, a concentrated solution reflow pipe and a concentrated solution outlet; a concentrated solution inlet, a heater steam inlet, a concentrated solution outlet, a condensed water outlet and a non-condensed steam outlet are formed in the heater; the steam outlet of the evaporator is connected to the steam compressor; an outlet of the steam compressor is communicated with the heater steam inlet of the heater; the concentrated solution outlet of the evaporator is partitioned into two paths, wherein one path is communicated to a concentrated solution discharging pump, and the other path is communicated to a forced circulation pump; the forced circulation pump is communicated to the concentrated solution inlet of the heater; the concentrated solution outlet of the heater is communicated to the concentrated solution reflow pipe of the evaporator. Secondary steam generated by an evaporation system is mainly taken as a heat source of the evaporation system. Secondary steam is recycled as a heat source.

Owner:SOUTHEAST UNIV +2

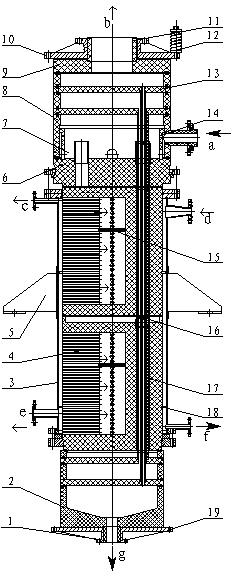

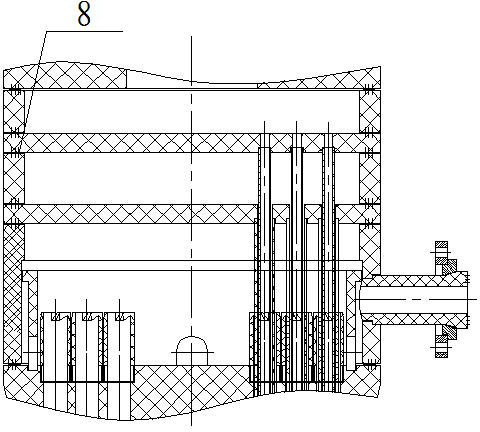

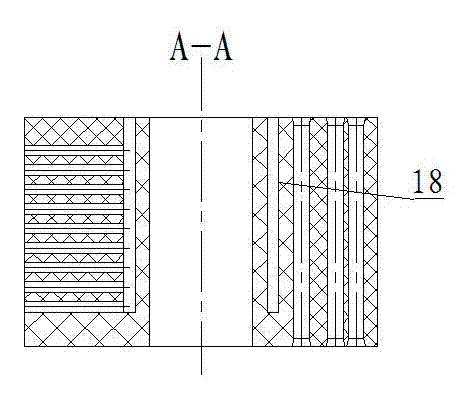

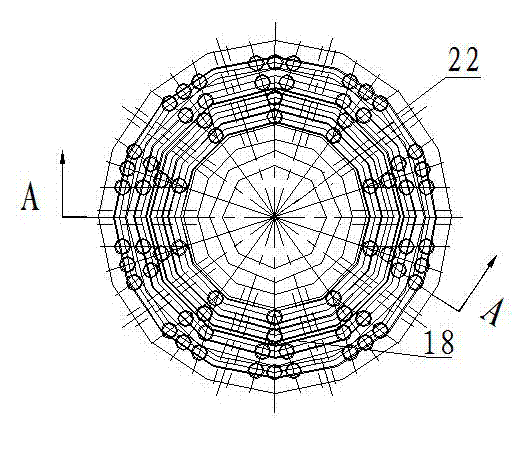

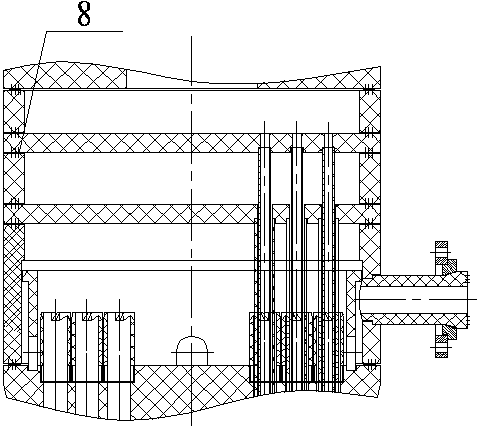

High-efficiency falling film type rectifier

InactiveCN102527068AGuaranteed evaporation residence timeHeat up and evaporate quicklyChlorine/hydrogen-chloride purificationOrganic compound preparationEngineeringGraphite

The invention relates to a high-efficiency falling film type rectifier. According to the high-efficiency falling film type rectifier, the lower end of a barrel body is fixedly connected with a lower cover board; a lower separator is placed on the lower cover board; a plurality of falling film type graphite blocks are accumulated and arranged in the barrel body sequentially; a gas liquid mixing chamber is arranged above a gas liquid distribution disc; at least one distribution weir fixedly connected with the gas liquid distribution disc is communicated with the gas liquid mixing chamber; the top end of the gas liquid mixing chamber is fixedly connected with an upper cover board through a graphite cover board; a graphite connecting pipe is fixedly connected to the inside of the upper cover board; a mixed liquid material inlet is formed on the gas liquid mixing chamber; a steam inlet is formed on the upper part of the barrel body; a steam outlet is formed on the lower part of the barrel body; a purified material outlet is formed at the lower end of a lower connecting pipe; and a separated gas outlet is formed at the upper end of the graphite connecting pipe. The high-efficiency falling film type rectifier is characterized in that: at least one rectification weir is arranged on one falling film type graphite block on the middle section of the falling film type graphite blocks accumulated and arranged sequentially; and pipe hole type graphite regular fillers are arranged in vertical holes of the falling film type graphite blocks. The high-efficiency falling film type rectifier has the advantages of reasonable structure, good separation effect, high product purity and the like.

Owner:JILIN SHUANGNING TECH

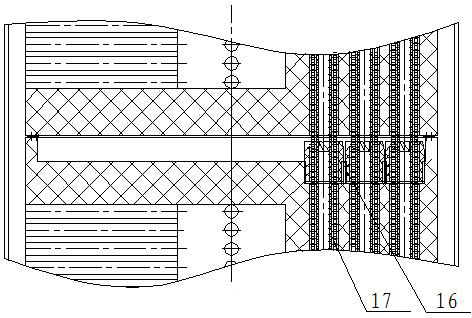

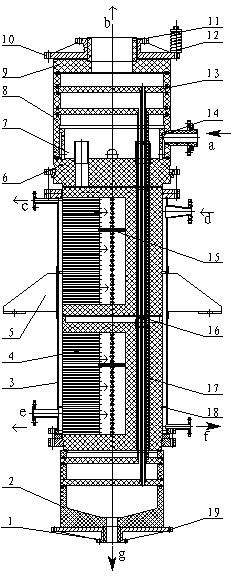

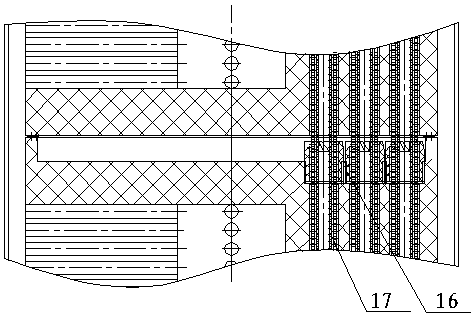

High-efficiency falling film evaporation reboiler

InactiveCN102350068AHeat up and evaporate quicklyTemperature control standardEvaporator accessoriesBoiling apparatusReboilerSmall footprint

The invention relates to a high-efficiency falling film evaporation reboiler which is characterized by comprising a cylinder body, wherein at least two porous evaporating and reboiling block bodies, a distributing cone, a thin-film evaporating and absorbing lower single block, at least one thin-film evaporating and absorbing middle single block, a thin-film evaporating and absorbing upper single block, a gas-liquid distributing disk and a gas-liquid mixing chamber are sequentially arranged in the cylinder body from bottom to top in an accumulating way, the gas-liquid distributing disk is fixedly connected with a plurality of absorbing weirs communicated with the gas-liquid mixing chamber, the upper part of the gas-liquid mixing chamber is provided with a defogger, and the top end of the gas-liquid mixing chamber is fixedly connected with an upper cover plate by a graphite cover plate. The Hcl and the C2H5OH of the mixed liquid material of isobutyric acid, the Hcl and triethyl phosphate can be removed by the heat exchange of steam so as to separate out a finished product of the triethyl phosphate. The high-efficiency falling film evaporation reboiler has the advantages of reasonable structure, low height, small floor area, low cost, high separation efficiency, good effect, energy saving, the environmental friendliness, simpleness for operation, low working pressure, high safety performance and the like.

Owner:宁晓初

Slagging device of crude benzene regenerator and slagging method

ActiveCN105132042AOptimize wash oil qualityReduce steam usageCombustible gas purificationAbsorption purification/separationSlagSpray tower

The invention discloses a slagging device of a crude benzene regenerator and a slagging method. Tar is poured into a slag tank and mixed with washing oil from the regenerator, generated waste gas enters a spray tower and makes contact with circulating water to be condensed, condensate water enters a circulation water trough, and the waste gas which is not condensed is recycled; an outer delivery valve is opened, and the tar is delivered into a tar trough. By means of the slagging device of the crude benzene regenerator and the slagging method, the quality of the washing oil can be optimized, the using amount of steam is reduced, a slagging pipeline is prevented from being blocked, the waste gas originally discharged into air is recycled in a sealed container, and harm to the environment is reduced.

Owner:山东恒伟化工科技有限公司 +1

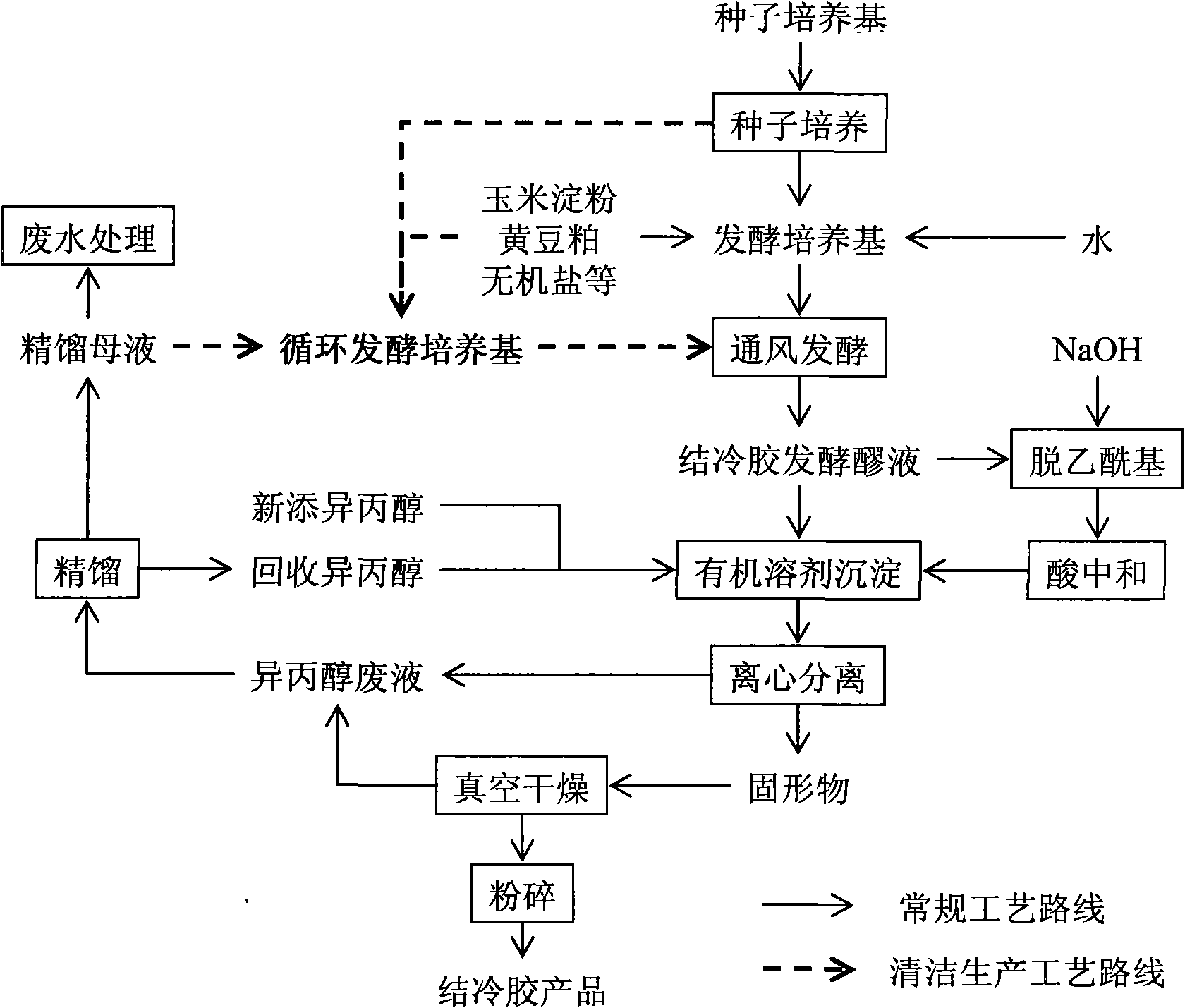

Cleaner production method of gellan gum

InactiveCN101560261AImprove featuresEmission reductionMicroorganism based processesFermentationFermentationPrecipitation

The invention relates to a cleaner production method of gellan gum, belonging to the technical field of biotechnology. In the method, microorganism for producing gellan gum suffers from ventilating and fermenting; isopropanol or ethanol is added into the obtained ferment broth to precipitate and centrifugalize; precipitate is vacuumed, dried and ground; gellan gum product is obtained. Supernatant fluid obtained by centrifugation is rectified to recover isopropanol or ethanol which can be circularly utilized for the next precipitation. Residual distilled water after rectification is analyzed and brought into loop fermentation medium, cornstarch, soyabean expeller and other raw materials are added, gellan gum ferment broth is obtained after ventilation and fermentation to form a closed-circuit cleaner production method. In the invention, under the condition of not increasing investment on equipment and site, cyclic utilization of residual distilled water is realized by adjusting production technique structure of gellan gum, which can not only save raw materials cost, reduce usage amount of water in technique, but also greatly lowers process load of waste water, particularly brings down process load and discharge amount of phosphorus and nitrogen.

Owner:JIANGNAN UNIV

Method for reducing temperature of baked aluminum oxide by boiler desalted water

InactiveCN101624222AReduce steam usageGood economic benefitsWater/sewage treatment by heatingWater/sewage treatment by degassingChillerSalt water

The invention provides a method for reducing temperature of baked aluminum oxide by boiler desalted water, comprising the following steps: before entering a low pressure deaerator, the boiler desalted water enters a cooler of a baking furnace fluidized bed firstly by passing through a pipeline to reduce temperature of baked aluminum oxide, replacing circulation cooling water; and after heat exchange, the desalted water is merged into an original boiler desalted water flow by passing through the pipeline again after going out from the fluidized bed, and enters the low pressure deaerator for a second time. The invention fully utilizes waste heat of the baked aluminum oxide to heat the boiler desalted water, and reduces the steam consumption for heating the desalted water; and meanwhile, circulating water baking equipment stops running, therefore, the consumption of manpower, electric power, spare parts and the like is reduced so that the invention has remarkable economic benefit.

Owner:GUANGXI HUAYIN ALUMINUM

Combined treatment method for two kinds of waste acid water generated in tetraacetylethylenediamine (TAED) production

ActiveCN102583853AAvoid it happening againSave energyMultistage water/sewage treatmentCarboxylic acid salt preparationThermal energyEthylenediamine

The invention discloses a combined treatment method for two kinds of waste acid water generated in tetraacetylethylenediamine (TAED) production. The combined treatment method is characterized by comprising the following steps of: evaporating dark acid water generated after washing TAED crystals by using live steam; carrying out multi-effect concentration on decolored neutralized liquid by using the acid steam generated by evaporation as a heat source; cooling and crystallizing; and separating solid from liquid to obtain sodium acetate trihydrate which is a by-product, wherein the live steam can be generated by burning residues for recycling after the dark acid water is evaporated, The decolored neutralized liquid is generated by the method that after the acid steam is subjected to heat exchange, the acid steam is condensed into colorless acid water; then the colorless acid water is mixed with light acid water generated by high-temperature dewatering after acetic acid and ethanediaminereact in the production of the TAED; alkali is added to the mixed liquid for neutralization; and then the mixed liquid is decolored by using thiourea dioxide. According to the combined treatment method, the acid steam of the dark acid water is used as a primary heat source for carrying out the multi-effect concentration on the mixed liquid of the mixed acid, therefore, energy can be greatly saved, and environment friendliness is facilitated; and the thiourea dioxide is used as a decoloring agent, the complication of solid and liquid separation and the generation of solid waste residues, whichare brought by decoloring solid adsorptive substances such as activated carbon, are also avoided.

Owner:浙江金科日化新材料股份有限公司

Method for producing zinc sulfide by acidic waste gas

InactiveCN110550651AReduce pollutionSimple processDispersed particle separationZinc sulfidesSlurryAtmospheric pollution

The invention provides a method for producing zinc sulfide by acidic waste gas. The method comprises the steps: preparing a zinc sulfate solution with the molar concentration of 1.65-1.75 mol / L; injecting the zinc sulfate solution into a reaction kettle, and heating the solution to 65 DEG C under 0.4 MPa steam heating; introducing hydrogen sulfide gas into the reaction kettle, and stirring to enable zinc sulfate to react with hydrogen sulfide; introducing the reacted material into a front water rinsing tank, discharging a supernatant into a sulfuric acid storage tank through sedimentation, then adding water, and washing with water; heating the water-washed powder slurry at the temperature of 90-93 DEG C, carrying out heat preservation for about 150 min, and curing; introducing the cured slurry into the water rinsing tank, and washing off impurities in crystals; filtering out mechanical impurities, then guiding the powder slurry into a dehydrator, and carrying out dehydration treatment;and drying the dehydrated powder. The device is simple in process, can be directly led out from an original waste gas channel, does not need to modify original facilities, is low in cost and high inpurification efficiency, and reduces atmospheric pollution.

Owner:弘润石化(潍坊)有限责任公司

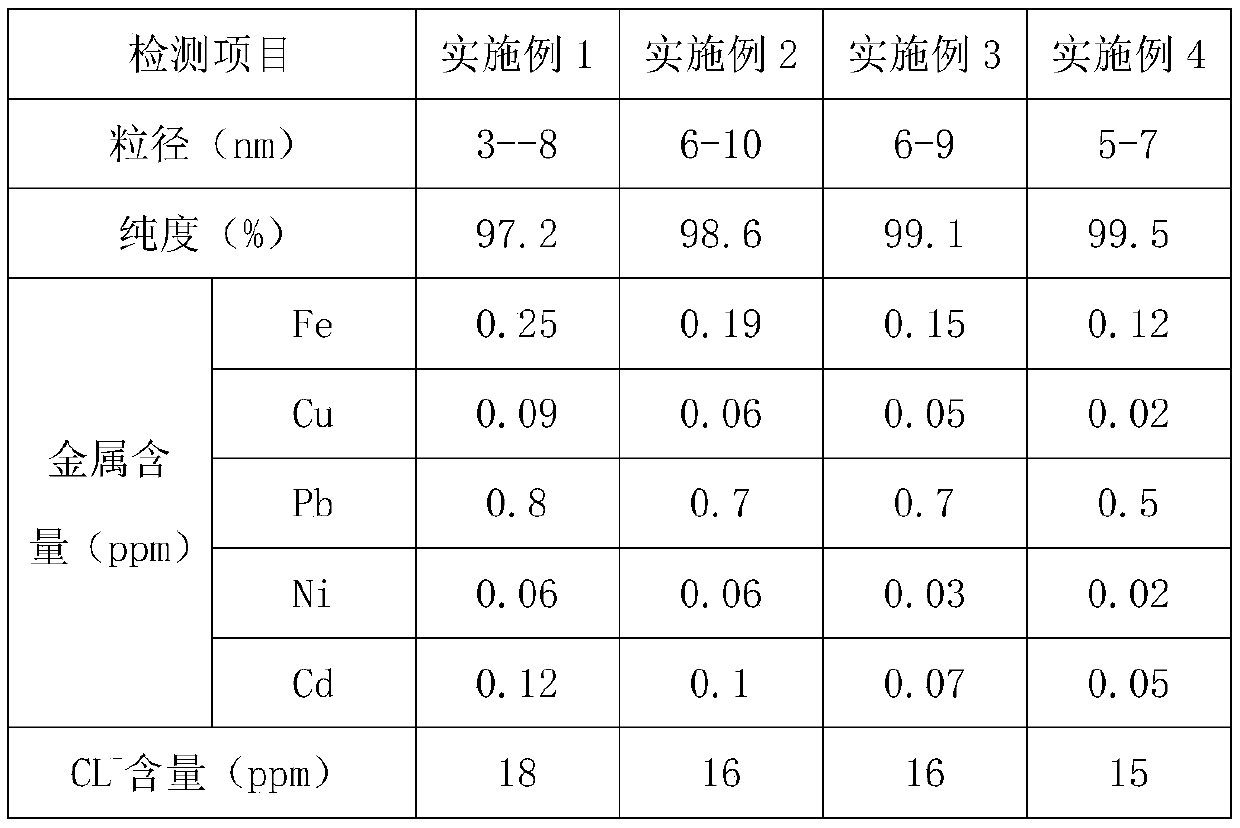

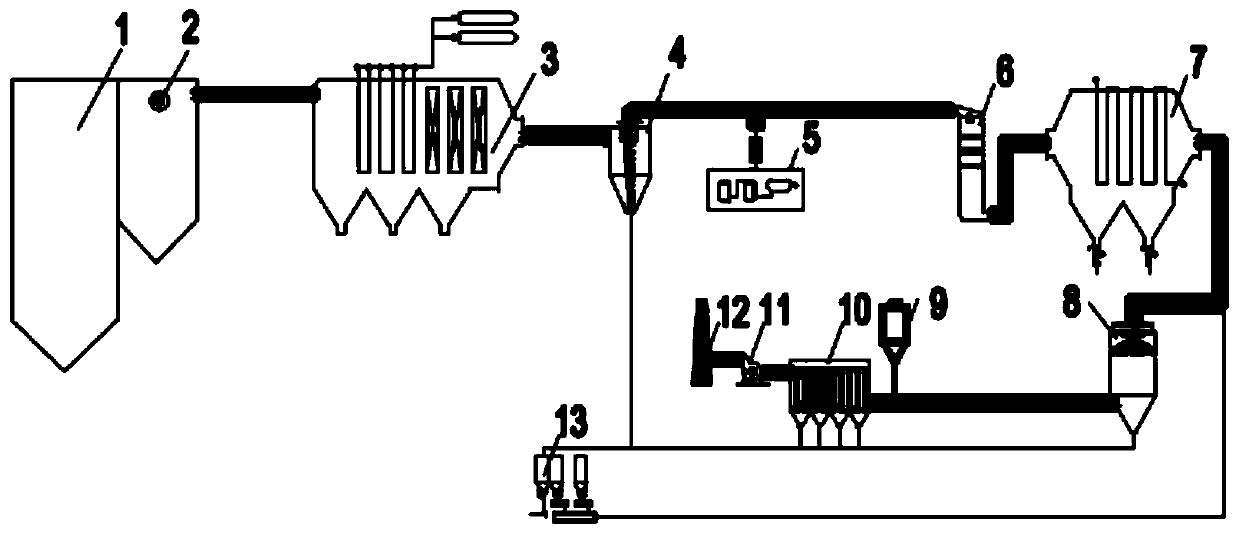

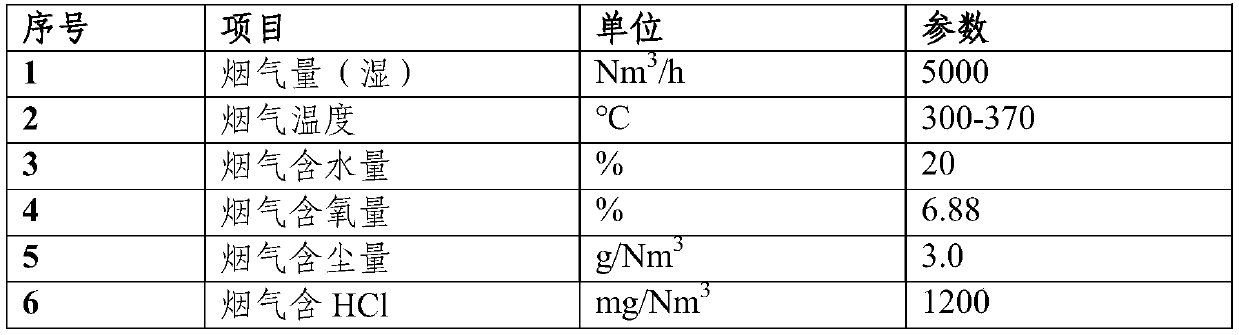

Purification treatment method and purification treatment device for garbage incineration flue gas

PendingCN110624384ASave investment and land occupationReduce steam usageCombination devicesGas treatmentActivated carbonChemistry

The invention belongs to the technical field of garbage incineration flue gas treatment and in particular relates to a purification treatment method and device for garbage incineration flue gas. The purification treatment method for garbage incineration flue gas comprises the following steps: leading out flue gas from an evaporator, performing treatment by using processes of cyclone dust collection-SCR (selective catalytic reduction) denitration-economizer-semidry method deacidification-activated carbon adsorption-bag type dust collection, and performing purification and emission. As SCR denitration is performed on the garbage incineration flue gas at a specific site (between the evaporator and an economizer), not only are investment and floor spaces of two stages of GGHs (gas-gas heaters)and one stage of an SGH (steam-gas heater) in a conventional purification treatment process reduced, but also the amount of vapor for heating the flue gas can be reduced; and in addition, the problems of SCR facility scale increase and investment increase can be avoided, the ammonia escape amount of the whole system can be reduced, and thus the process is energy-saving and environmentally friendly.

Owner:中国环境保护集团有限公司

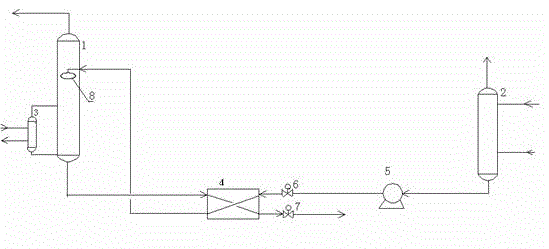

Method for recovering methanol from tail gas washing water in low-temperature methanol washing technology

ActiveCN103524298ARaise the pHReduce steam usageOrganic compound preparationHydroxy compound separation/purificationAcid washingWastewater

The invention provides a method for recovering methanol from tail gas washing water in a low-temperature methanol washing technology. The method comprises the following flows: exchanging heat of washing water from a tail gas washing tower and wastewater at the bottom of a methanol / water separating tower in a heat exchanger, and sending the wastewater out of a boundary region for processing after cooling; heating the washing water to about 100 DEG C, feeding the washing water into the methanol / water separating tower, providing a distributor in the methanol / water separating tower, evenly distributing the heated washing water on a tower tray through the distributer; distilling and separating the washing water in the methanol / water separating tower after quickly releasing the dissolved CO2, and recovering methanol after condensing an overhead component. By adopting the method for recovering methanol from the tail gas washing water in the low-temperature methanol washing technology disclosed by the invention, corrosion of acid washing water on the wall of the methanol / water separating tower is reduced to the lowest extent; the service life of the methanol / water separating tower can be prolonged; meanwhile, the device and operation costs are reduced.

Owner:NANJING CHENGZHI CLEAN ENERGY CO LTD

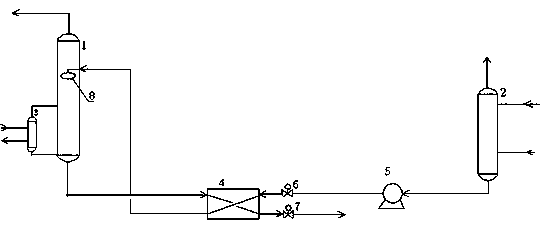

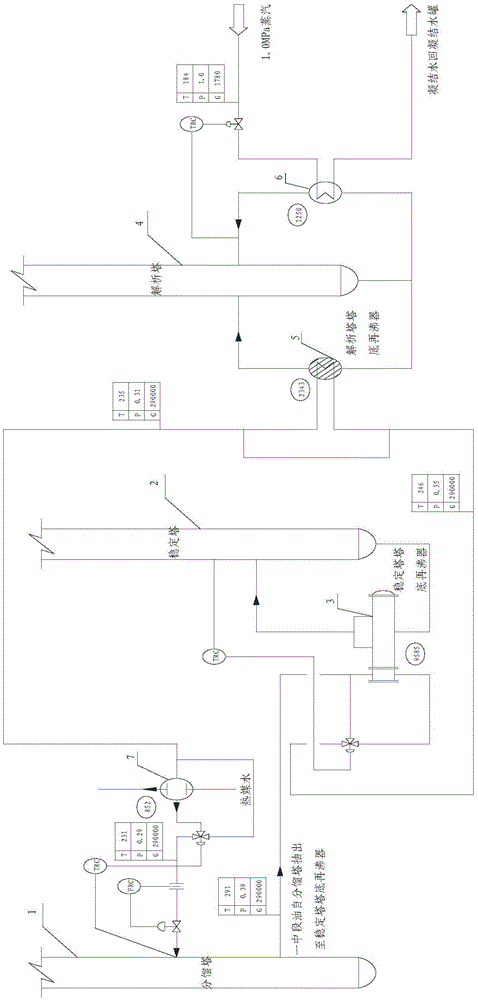

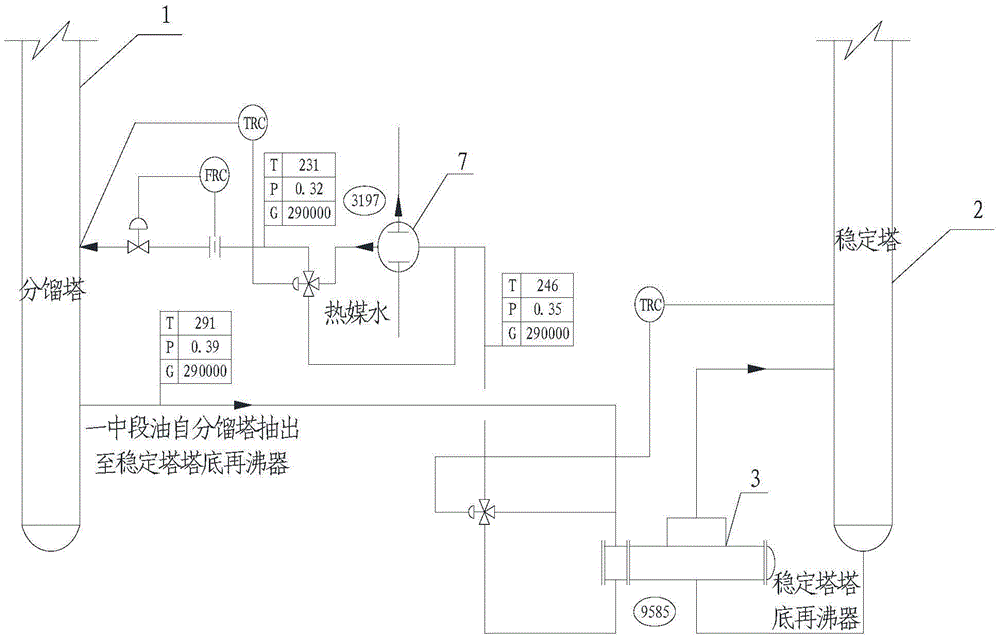

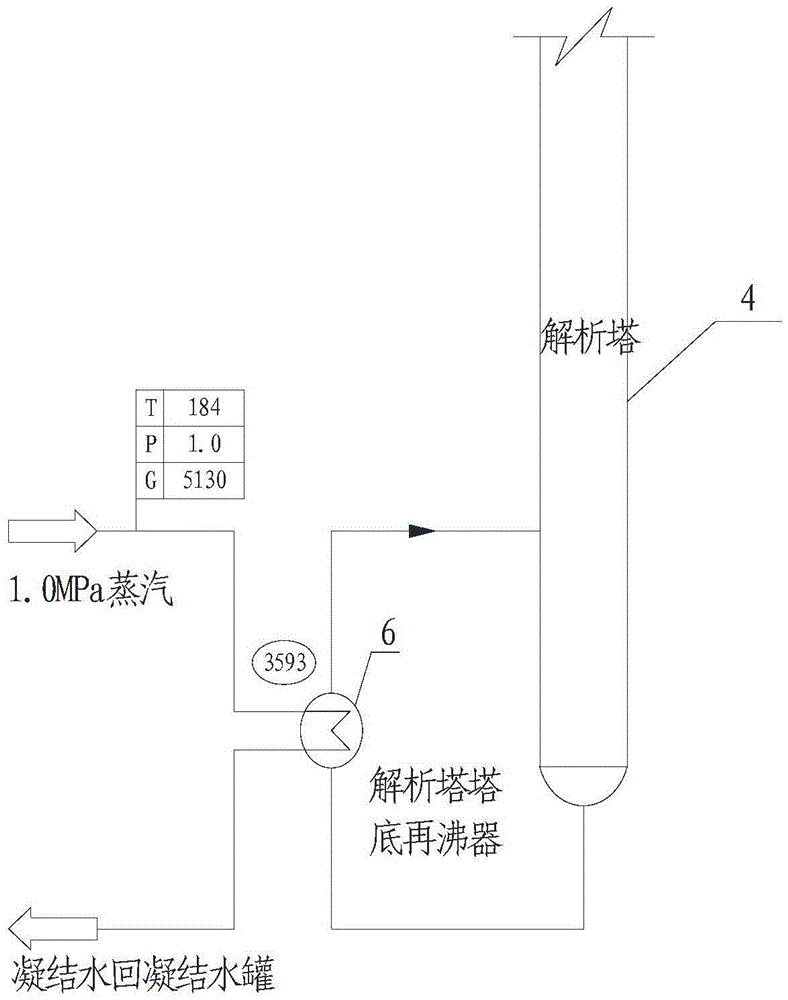

Catalytic cracker primary midsection oil heat utilization system and heat utilization method

ActiveCN105623722AImprove heat utilization gradeReduce steam usageTreatment with plural serial stages onlyReboilerEngineering

The invention provides a catalytic cracker primary midsection oil heat utilization system. The system comprises a fractionating tower, a stabilizing tower system, a resolution tower system and a heat medium water-to-water heat exchanger, wherein the stabilizing tower system comprises a stabilizing tower and a stabilizing tower bottom reboiler; the resolution tower system comprises a resolution tower and a resolution tower bottom reboiler; a primary midsection oil outlet of the fractionating tower is connected with the stabilizing tower bottom reboiler, and the resolution tower bottom reboiler is connected with the heat medium water-to-water heat exchanger; and a primary midsection oil outlet of the heat medium water-to-water heat exchanger is connected with a feed port of the fractionating tower. By regulating the heat exchange process, the system and method fully utilize the heat of the high-temperature position of the primary midsection oil, continuously utilize the primary midsection oil as the heat source of the stabilizing tower bottom reboiler and the resolution tower bottom, and reduce the steam consumption for the resolution tower bottom reboiler, thereby finally achieving the goal of lowering the energy consumption of the catalytic cracker.

Owner:SHANGHAI YOUHUA PROCESS INTEGRATED TECH CO LTD

An energy-saving urea production system and its production process

ActiveCN104829494BReduce energy consumptionEasy to operateUrea derivatives preparationOrganic compound preparationDesorptionAmmonium carbamate

The invention belongs to the field of urea preparation, and particularly relates to an energy-saving urea production system and a production process thereof. The system comprises a CO2 compressor, an ammonium carbamate pump, a liquid ammonia pump and a urea synthesizer. The system is characterized in that the CO2 compressor is connected with the ammonium carbamate pump and the liquid ammonia pump, the liquid ammonia pump is connected with the urea synthesizer, a falling-film countercurrent medium-pressure decomposing tower and a heater, an ammonium carbamate condenser, an ammonium carbamate separator, a three-stage medium-pressure absorption tower and an evaporative ammonia refrigeration recoverer, a liquid ammonia buffer tank, an inert gas scrubber, a tail-gas ammonia cleaning fine purifier, a low-pressure decomposing tower and a heater, a dimethyl liquid preheater, a horizontal low-pressure absorber, a falling film type pre-evaporator, a one-stage evaporator and a one-stage evaporative condenser, a two-stage evaporator and a two-stage evaporative condenser, and a process wastewater desorption and hydrolysis tower are sequentially connected behind the urea synthesizer in sequence. The energy-saving urea production system has the advantages of low investment, low energy consumption, simple operation, high elasticity and the like, thereby the process technology has considerable economic benefit and social benefit.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

Waste heat recovery device

The invention discloses a waste heat recovery device. The waste heat recovery device is composed of a first effect heat exchanger (1), a condensation water tank (2), a tubular water heater (3), a condensation water tank (4) used after temperature is reduced, a desalted water removal station port (5), a drying fan (6), a hot wind conveying pipe (7) and an air conveying pipe (8), wherein the condensation water tank (2), the tubular water heater (3) and the condensation water tank (4) used after the temperature is reduced are sequentially connected with the rear of the first effect heat exchanger (1), one end of the tubular water heater (3) is connected with the air conveying pipe (8), the other end of the tubular water heater (3) is connected with the drying fan (6), the condensation water tank (4) used after the temperature is reduced is connected with the desalted water removal station port (5), and the hot wind conveying pipe (7) is located on the drying fan (6). The waste heat recovery device can effectively reduce energy consumption, reduce pollutant emission, reduce production cost of a product, improve production effectiveness, and achieve double winning of economic effectiveness improvement, and energy conservation and environment protection.

Owner:李英华

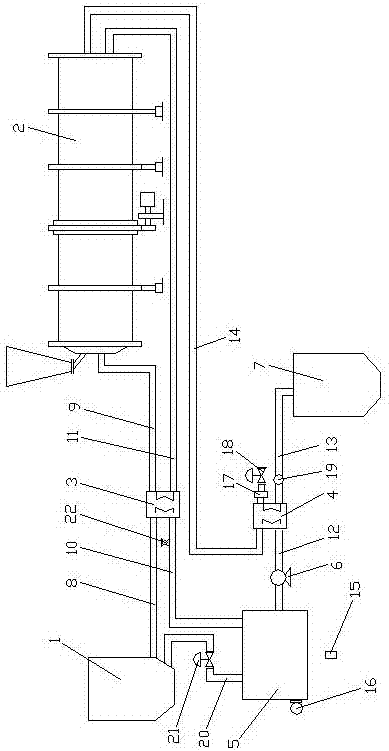

Water circulation equipment for maturation process in production of viscose fiber

PendingCN107383209AReduce steam usageIncrease profitChemical industryArtificial filaments from viscoseMaturation processWater circulation

The invention discloses a piece of water circulation equipment for a maturation process in production of viscose fiber, and belongs to the field of viscose fiber production. The equipment comprises a water storage tank and a maturation drum, and is characterized in that the equipment also comprises a first plate type heat exchanger, a second plate type heat exchanger, a recycling water tank, a centrifugal pump and an alkaline liquor pot; the water storage tank is connected to the first plate type heat exchanger through a first water inlet pipe, the maturation drum is connected to the first plate type heat exchanger through a second water inlet pipe, the recycling water tank is connected to the first plate type heat exchanger through a return pipe, the first plate type heat exchanger is connected to the maturation drum through a water outlet pipe, the second plate type heat exchanger is connected to the recycling water tank through a first circulation pipe, the alkaline liquor pot is connected to a high temperature soft water outlet of the second plate type heat exchanger through a second circulation pipe, and a water return pipe is arranged between the second plate type heat exchanger and the maturation drum. The equipment improves utilization rate of production water and soft water, reduces consumption of steam, realizes gradient utilization of maturation drum jacket water thermal energy, and has good energy saving and environmental protection property.

Owner:YIBIN GRACE GROUP CO LTD

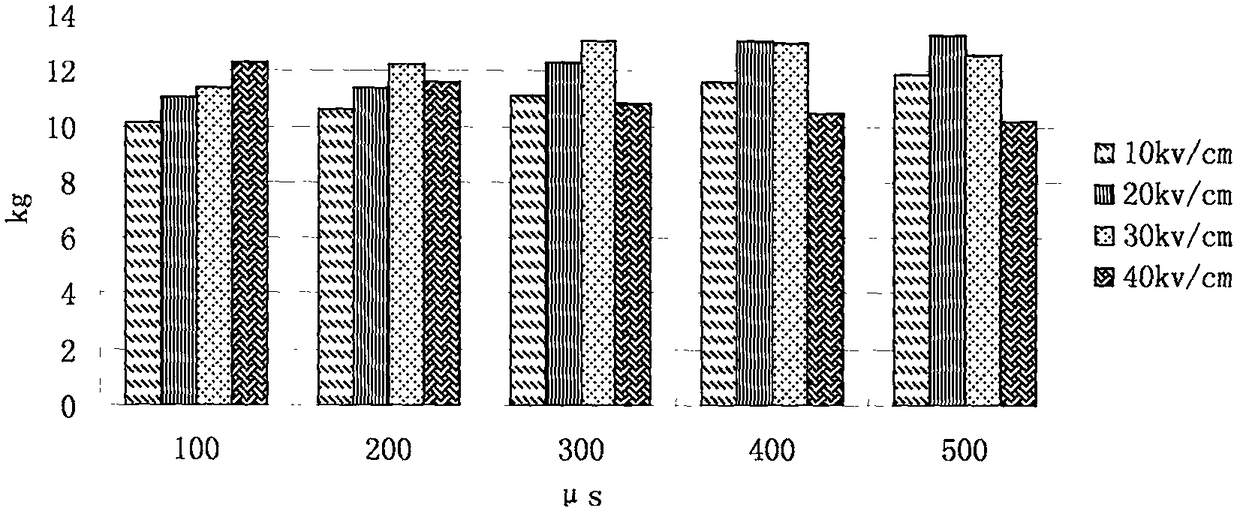

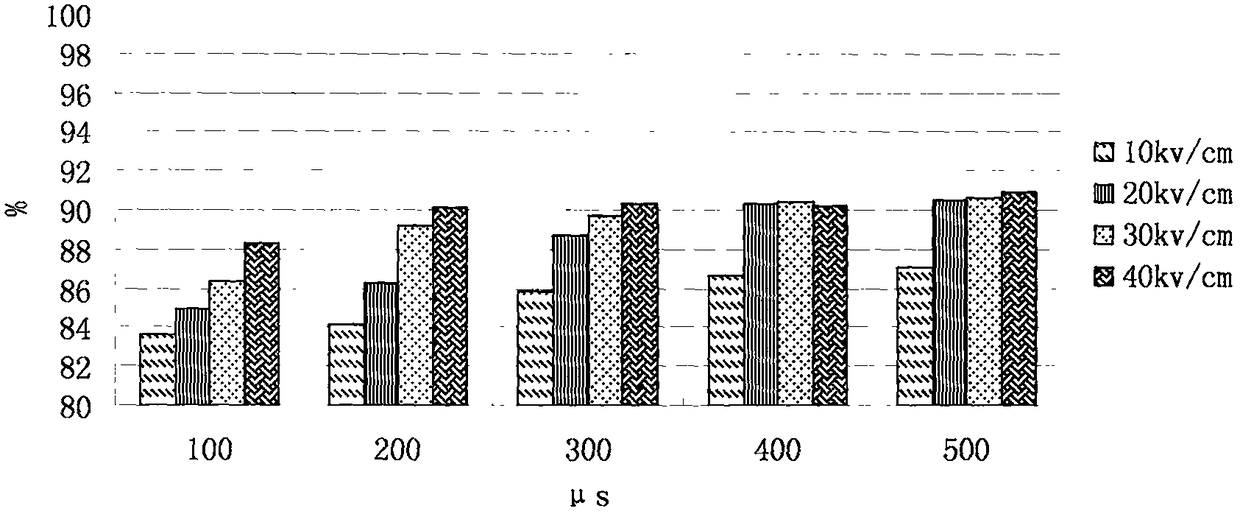

Efficient and energy-saving process for preparing pectin

The invention belongs to the technical field of pectin extraction. An efficient and energy-saving process for preparing pectin comprises the following steps: 1) smashing; 2) cleaning, pH adjustment, electric field treatment and filtration; 3) stirring and pH adjustment; 4) filtration; 5) concentration; 6) alcohol precipitation; 7) repetition of the step 6) once to twice; 8) vacuum freeze drying and smashing.

Owner:XINJIANG FUFENG BIOTECH

Production method of expandable polystyrene with high-foaming-multiplying power

The invention discloses a production method of expandable polystyrene with high-foaming-multiplying power. The method comprises the following steps of (1) metering pure water; then, adding the pure water into a reaction kettle; during stirring, sequentially adding emulsifiers, activated calcium phosphate and sodium hydroxide; then, adding metered styrene into the reaction kettle; then, sequentially adding benzoyl peroxide, tert-butyl peroxybenzoate, a nucleating agent, dioctyl phthalate and white oil; uniformly mixing the materials; (2), introducing steam into a reaction kettle jacket; (3) adding calcium phosphate and emulsifiers; (4) adding mixed pentane; (5) raising the temperature; (6) introducing cooling water for lowering the temperature of the reaction kettle; (7) feeding the material liquid into a centrifugal machine; dewatering the materials; performing drying treatment on the dewatered materials by a hot air flow; (8) adding a coating layer; obtaining a product. The particles produced by the method can be subjected to pre-foaming for a plurality of times; the pre-foamed foam particle unit volume weight is lighter; the foam holes are fine and dense; little steam is used; the combination performance of a product is good.

Owner:安徽裕河新材料有限公司

Fermentation method of straw mushroom culture material

ActiveCN111328632AFast heatingReduce steam usageCultivating equipmentsMushroom cultivationVolvariella volvaceaEngineering

The invention relates to a fermentation method of straw mushroom culture material. The method comprises the following steps: (1) pre-wetting and mixing each component of the straw mushroom culture material, and adjusting the water content to 65-75%; (2) feeding: respectively taking a secondary fermentation culture material and the culture material in (1) with a weight ratio of (1-10):(90-100), conducting mixing evenly, and spreading the mixture on a mobile cultivation bed frame; (3) circulating secondary fermentation: moving the mobile cultivation bed frame to a pasteurization room for secondary fermentation. The fermentation method of straw mushroom culture material of the present invention can be extended backward in turn and recycled, which can save the one-time fermentation process ofthe straw mushroom culture material. The temperature rising speed of the culture material is fast, the steam consumption is greatly reduced, the fermentation time is shortened, and fast and efficientfermentation is realized.

Owner:SHANGHAI ACAD OF AGRI SCI +1

Method and system for pre-atomizing catalytic feed oil

ActiveCN114849592AImprove physical and chemical propertiesReduce steam usageCatalytic crackingBio-feedstockOil processingPtru catalyst

The invention relates to the technical field of heavy oil processing, in particular to a method and system for pre-atomizing catalytic feed oil, and the method comprises the following steps: (1) introducing atomized gas into a middle cavity of a micro-interface treatment tank, and dispersing the atomized gas in a micro-interface guide pipe to obtain microbubbles; (2) catalytic feed oil is introduced into a bottom cavity of a micro-interface treatment tank and enters a micro-interface guide pipe to be mixed with the micro-bubbles to obtain gas-liquid emulsified phase oil, and (3) the gas-liquid emulsified phase oil enters a top cavity of the micro-interface treatment tank and is led out of the micro-interface treatment tank to obtain gas-liquid emulsified phase oil. Introducing the mixture into a molecular rearrangement device for molecular rearrangement to obtain rearrangement gas-liquid emulsified phase oil. The method provided by the invention can reduce the viscosity, density and surface tension of the catalytic feed oil, facilitates full contact vaporization of the catalytic feed oil and a high-temperature catalyst, and improves the efficiency of a catalytic cracking reaction.

Owner:湖南长科诚享石化科技有限公司

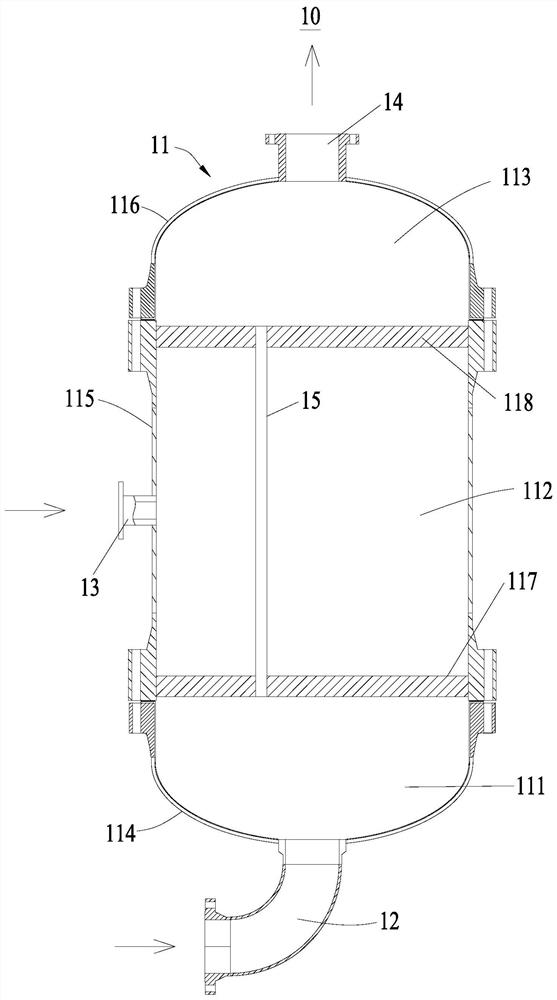

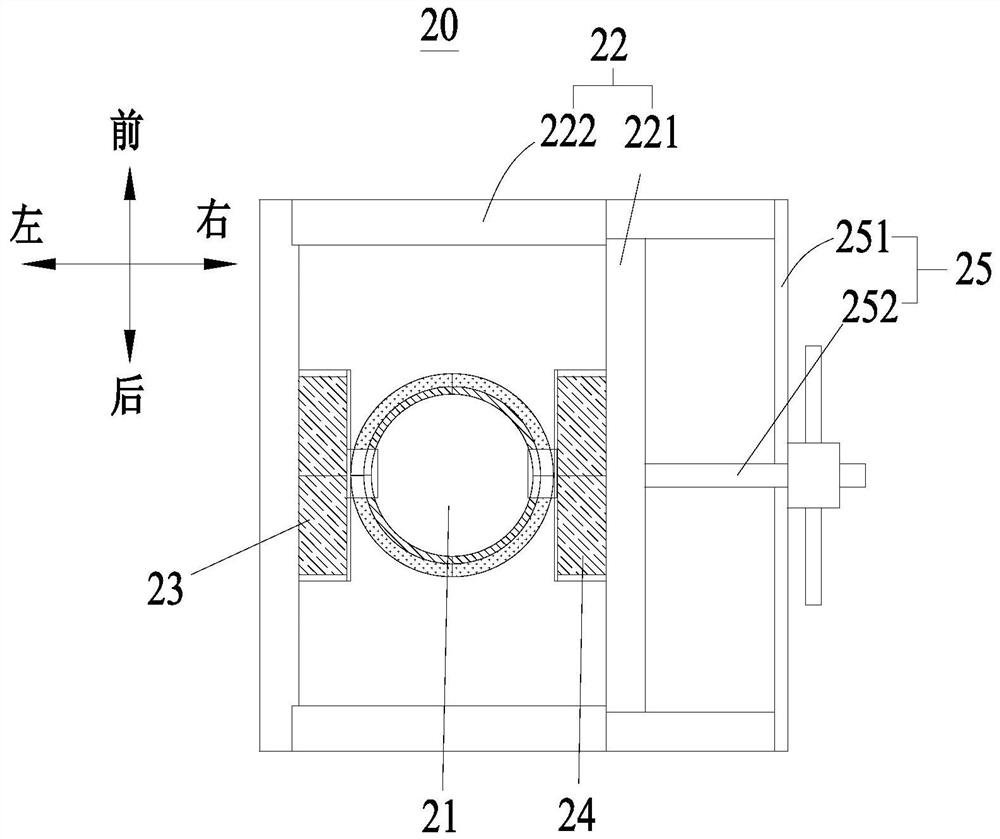

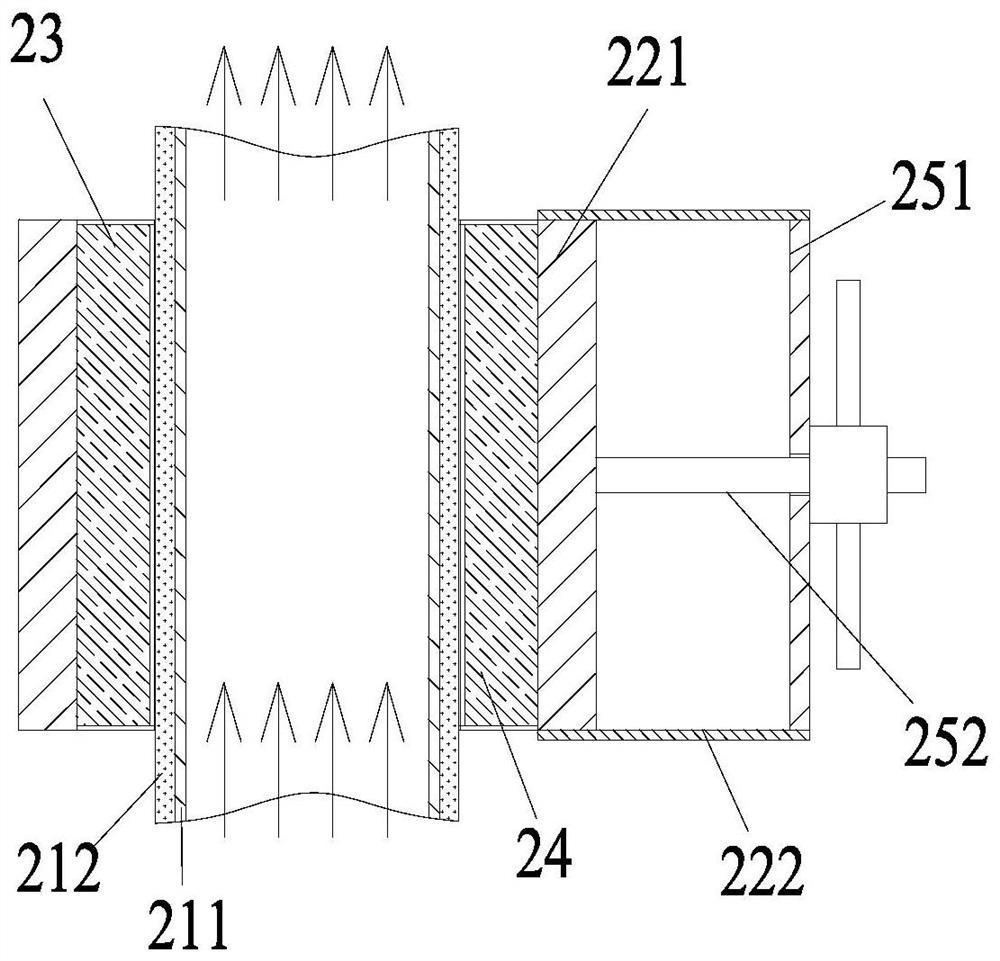

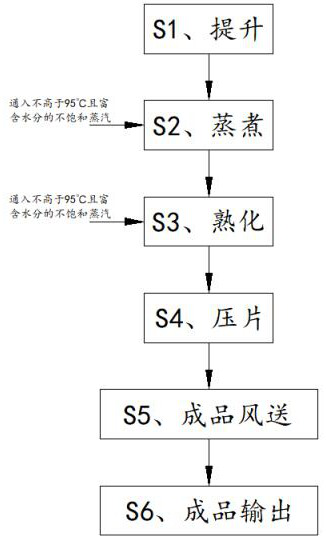

Cereal low-temperature cooking and tabletting process

PendingCN113973988AReduce steam usageIncreased grain gelatinizationAnimal feeding stuffWorking-up animal fodderProcess engineeringEnvironmental geology

The invention provides a cereal low-temperature cooking and tabletting process, which comprises the following steps: S1, lifting; namely a lifting device conveys the grains to a cooking device in the next step through a pipeline for cooking; S2, performing cooking; namely a cooking device is used for cooking the grains, primary curing is carried out, a cooking medium is steam, and the steam temperature is unsaturated steam which is not higher than 100 DEG C and is rich in moisture; S3, performing curing; namely secondary curing is conducted, and the grains are conveyed to a tabletting device through a discharging opening of the curing device to be tabletted; S4, performing tabletting; namely after tabletting is completed, the grains are conveyed to a finished product air conveying device; S5, air conveying of finished products; namely a finished product air conveying device is used for cooling and conveying the pressed grains; and S6, outputting of a finished product; namely the cooled tabletted grains are packaged and stored. The method is simple in process, low in energy consumption, high in production quality and suitable for the production technology for processing feed in small and medium-sized farming and pastoral farms, families and cooperative farms.

Owner:山东冠峰机械股份有限公司

High-efficiency falling film type rectifier

InactiveCN102527068BGuaranteed evaporation residence timeHeat up and evaporate quicklyChlorine/hydrogen-chloride purificationOrganic compound preparationGraphiteMechanical engineering

Owner:JILIN SHUANGNING TECH

Falling film evaporation reboiler

InactiveCN102350068BHeat up and evaporate quicklyExtended stayEvaporator accessoriesBoiling apparatusWorking pressureReboiler

The invention relates to a high-efficiency falling film evaporation reboiler which is characterized by comprising a cylinder body, wherein at least two porous evaporating and reboiling block bodies, a distributing cone, a thin-film evaporating and absorbing lower single block, at least one thin-film evaporating and absorbing middle single block, a thin-film evaporating and absorbing upper single block, a gas-liquid distributing disk and a gas-liquid mixing chamber are sequentially arranged in the cylinder body from bottom to top in an accumulating way, the gas-liquid distributing disk is fixedly connected with a plurality of absorbing weirs communicated with the gas-liquid mixing chamber, the upper part of the gas-liquid mixing chamber is provided with a defogger, and the top end of the gas-liquid mixing chamber is fixedly connected with an upper cover plate by a graphite cover plate. The Hcl and the C2H5OH of the mixed liquid material of isobutyric acid, the Hcl and triethyl phosphate can be removed by the heat exchange of steam so as to separate out a finished product of the triethyl phosphate. The high-efficiency falling film evaporation reboiler has the advantages of reasonable structure, low height, small floor area, low cost, high separation efficiency, good effect, energy saving, the environmental friendliness, simpleness for operation, low working pressure, high safety performance and the like.

Owner:宁晓初

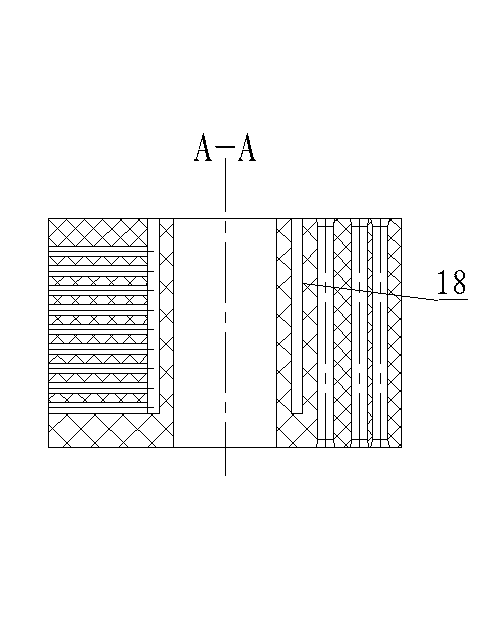

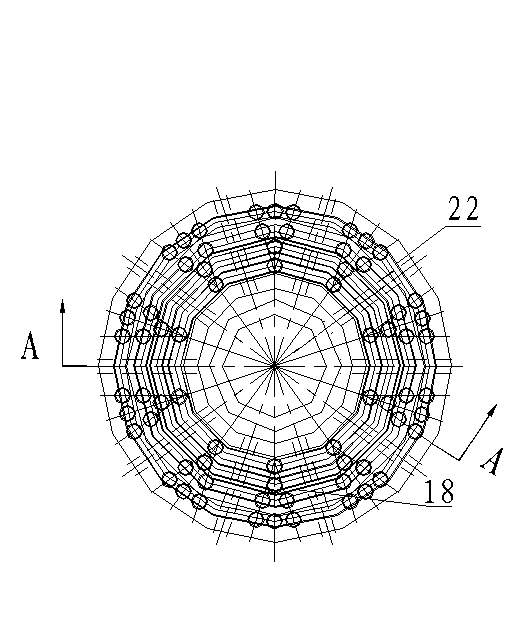

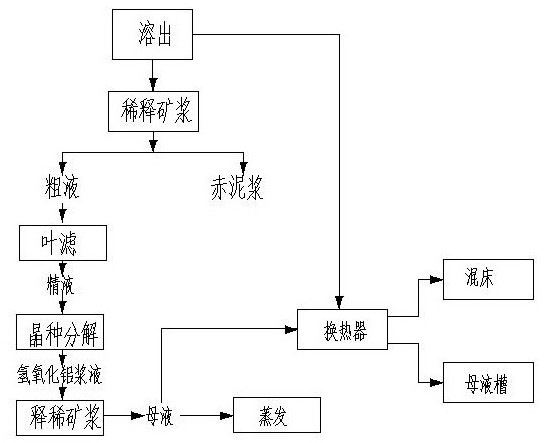

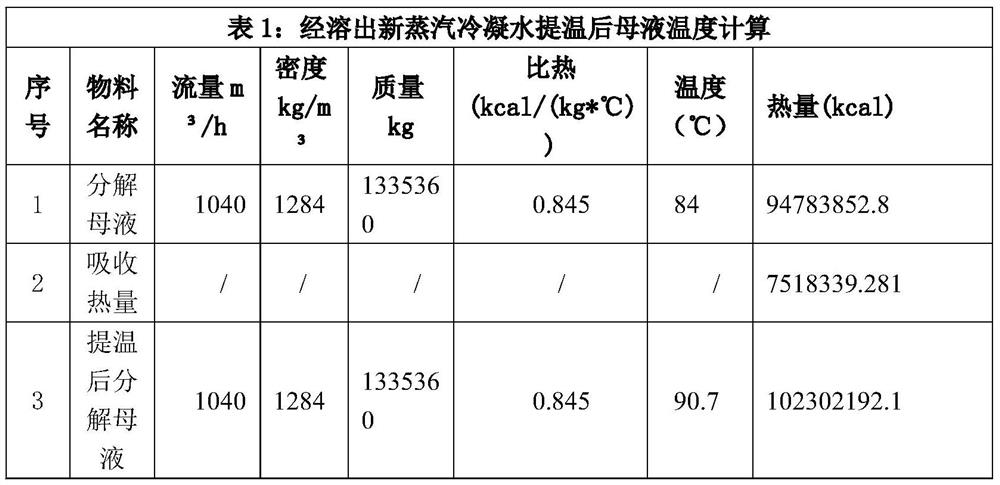

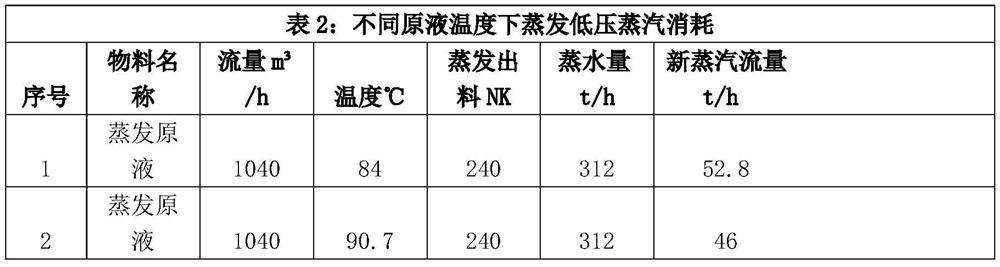

Unqualified fresh steam condensate water waste heat utilization and secondary recovery method

InactiveCN112344756AReduce steam usageReduce steamRecuperative heat exchangersSteam/vapor condensersSteam condensationWater treatment

The invention discloses an unqualified fresh steam condensate water waste heat utilization and secondary recovery method. The method comprises the following process steps of 1) conveying unqualified fresh steam condensate water to a tubular heat exchanger with a heat exchange area of 350m <2> at a flow rate of 98.4t / h, taking another heat exchange substance in the heat exchanger as a decompositionmother liquor, and ensuring that the flow rate of the decomposition mother liquor is 300m<3> / h; 2) conveying the fresh steam condensate water to a chemical water treatment mixed bed device after heatexchange, and returning the decomposition mother liquor to a decomposition mother liquor tank after heat exchange. The waste heat of the fresh steam condensate water can be effectively utilized and recycled, loss and waste are avoided, and the production cost is saved.

Owner:靖西天桂铝业有限公司

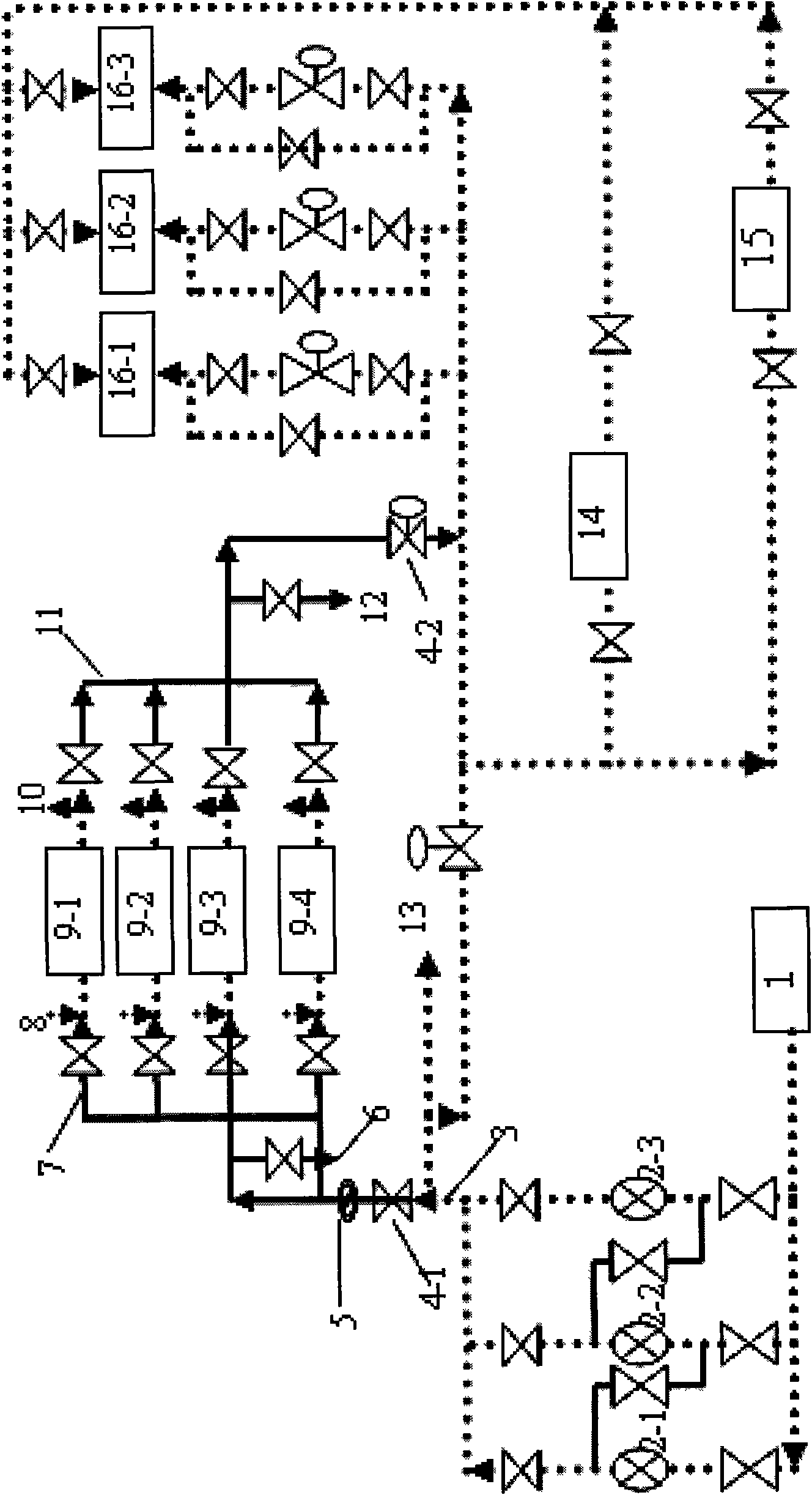

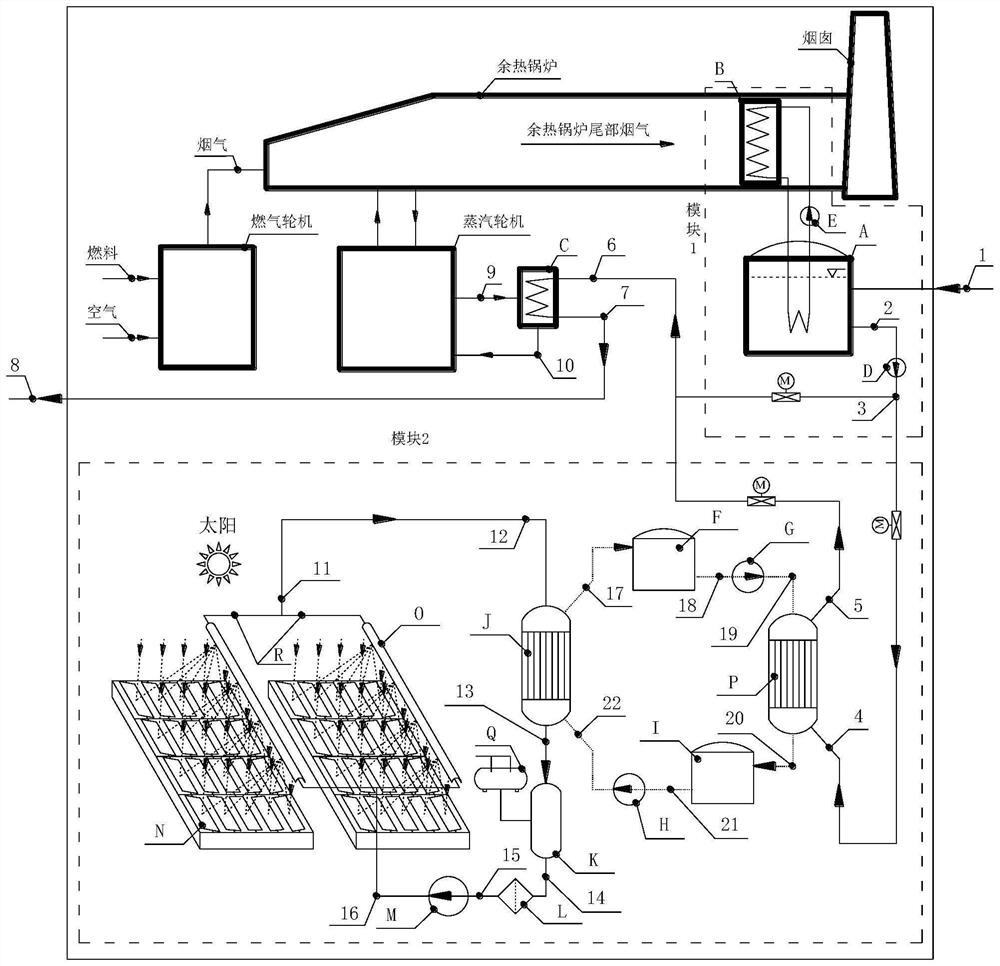

Heat supply system based on Fresnel solar energy and combined cycle unit waste heat utilization

ActiveCN113834118AWith heat storage functionImprove power efficiencySolar heating energySolar heat storageProcess engineeringHeat recirculation

The invention discloses a heat supply system based on Fresnel solar energy and combined cycle unit waste heat utilization. The heat supply system comprises a boiler waste heat utilization heat storage circulating system and a Fresnel solar energy heat utilization system, and a heat supply network circulating water system is reformed and designed. By additionally arranging the systems and improving the design, boiler waste heat and solar energy can be used for heating heat supply network circulating water, and the steam consumption supplied to a secondary heat supply network heater is remarkably reduced, so that the power generation power of a combined cycle unit under the heat supply working condition is remarkably improved, and meanwhile, the operation efficiency of a unit is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Anti-dew ventilation method and facilities for main factory building of cold rolling factory

InactiveCN100516692CImprove ventilationRealize automatic controlMechanical apparatusSpace heating and ventilation safety systemsMonitoring systemDew

The invention relates to a dew prevention and ventilation method and facility for main workshop of cold rolling plant, which comprises the delivery of hot air. The invention gushes high speed hot air via an air blowing port on the pipe network laid on the ground at the peripheral of a steel coil; a hot air screen that isolates with other zones of the plant is formed in the steel coil piling zone, so that the ambient temperature in the steel coil piling zone is higher than the dewing temperature. The invention also comprises a monitoring system and delivers hot air to the ventilation system according to the monitoring signal fed back by the steel coil piling zone, so as to prevent the dewing of steel coil. The facility in the invention comprises: a dew point monitoring system, a monitoring point is positioned at a testing coil pre-arranged at the steel coil piling zone, an equipment for the monitoring and early warning of the dewing temperature of steel coil is positioned in the monitoring point; a hot air delivery system, the hot air delivery pipe network is laid collectively on the ground next to the steel coil and a blowing port (10) is positioned on the pipeline of the pipe network. Therefore, the invention, which can prevent the discard of a great number of steel coil due to dewing, reduces the consumption of energy resources, assures low equipment operation cost, realizes little work load for maintenance and overhaul as well as ensures low investment cost in each time.

Owner:WISDRI ENG & RES INC LTD

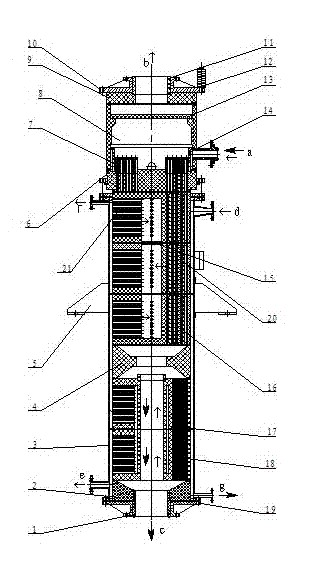

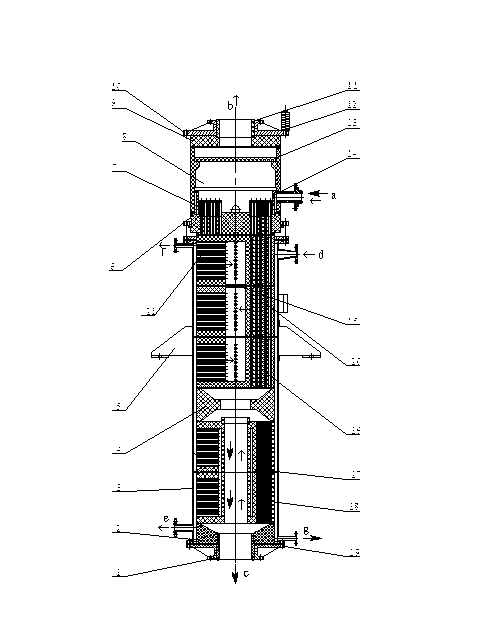

Biological sludge heating and thermal hydrolysis system and process

ActiveCN109205992BHeating fastImprove heat transfer performanceSludge treatment by thermal conditioningProcess engineeringFeed pump

The invention discloses a biological sludge heating and thermal hydrolysis system and process. The system includes a material preheater, a material delivery pump, a primary steam injector, a material storage device, a feed pump, Thermal hydrolysis reactor, discharge pump, steam flasher and pressure relief valve, and secondary steam ejector for heating the biological sludge in the thermal hydrolysis reactor. The process uses the system described above for heating and thermal hydrolysis. The biological sludge heating and thermal hydrolysis system of the present invention has the advantages of good heat transfer effect, good material heating uniformity, small steam consumption, short heating time, good continuous operation stability, etc., and can be widely used to degrade biological sludge, and has the advantages of Very good application value and application prospect. The biological sludge heating and thermal hydrolysis system process of the present invention has the advantages of simple process, convenient operation, low treatment cost, high treatment efficiency, good treatment effect, etc., which is conducive to improving the utilization rate of biological sludge and expanding the application range of anaerobic digestion .

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Method for recovering methanol from tail gas washing water in low-temperature methanol washing technology

ActiveCN103524298BRaise the pHReduce steam usageOrganic compound preparationHydroxy compound separation/purificationAcid washingWastewater

The invention provides a method for recovering methanol from tail gas washing water in a low-temperature methanol washing technology. The method comprises the following flows: exchanging heat of washing water from a tail gas washing tower and wastewater at the bottom of a methanol / water separating tower in a heat exchanger, and sending the wastewater out of a boundary region for processing after cooling; heating the washing water to about 100 DEG C, feeding the washing water into the methanol / water separating tower, providing a distributor in the methanol / water separating tower, evenly distributing the heated washing water on a tower tray through the distributer; distilling and separating the washing water in the methanol / water separating tower after quickly releasing the dissolved CO2, and recovering methanol after condensing an overhead component. By adopting the method for recovering methanol from the tail gas washing water in the low-temperature methanol washing technology disclosed by the invention, corrosion of acid washing water on the wall of the methanol / water separating tower is reduced to the lowest extent; the service life of the methanol / water separating tower can be prolonged; meanwhile, the device and operation costs are reduced.

Owner:NANJING CHENGZHI CLEAN ENERGY CO LTD

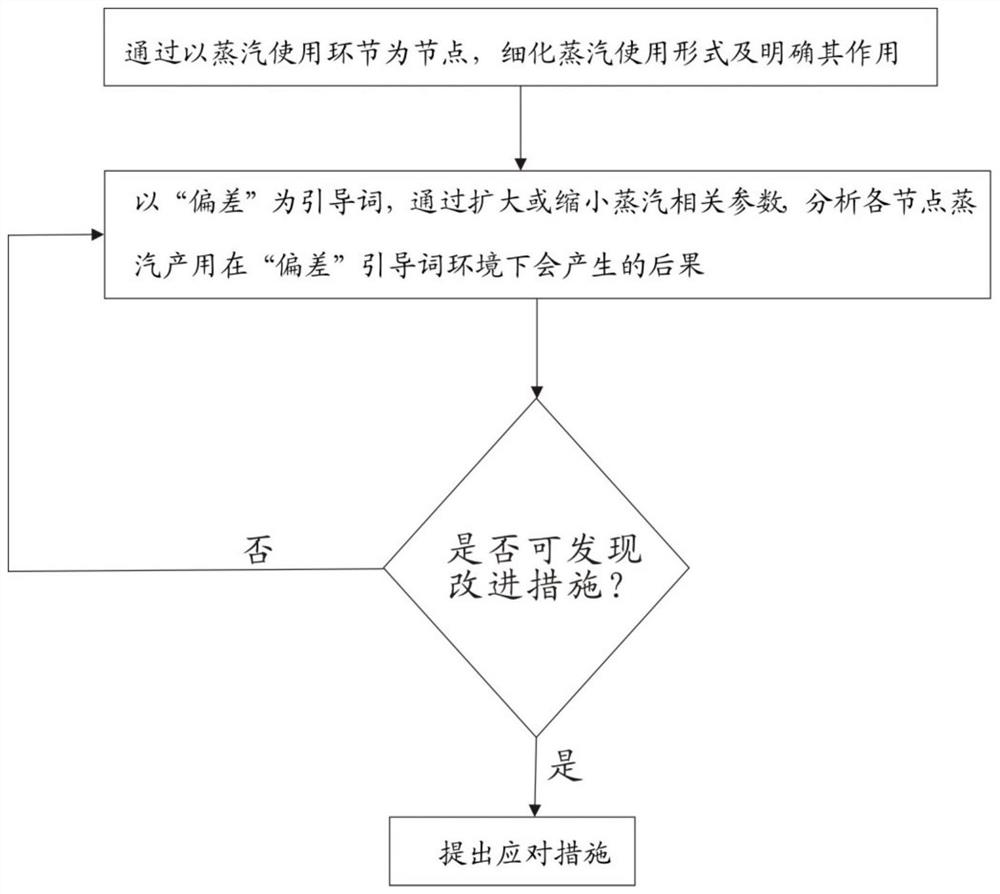

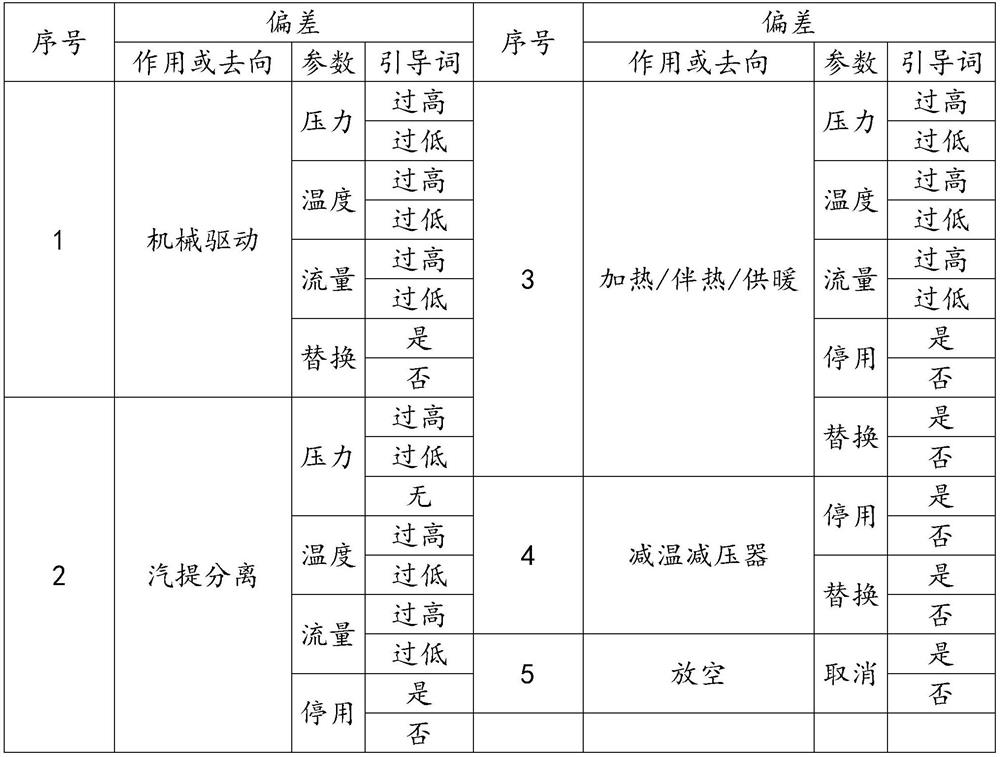

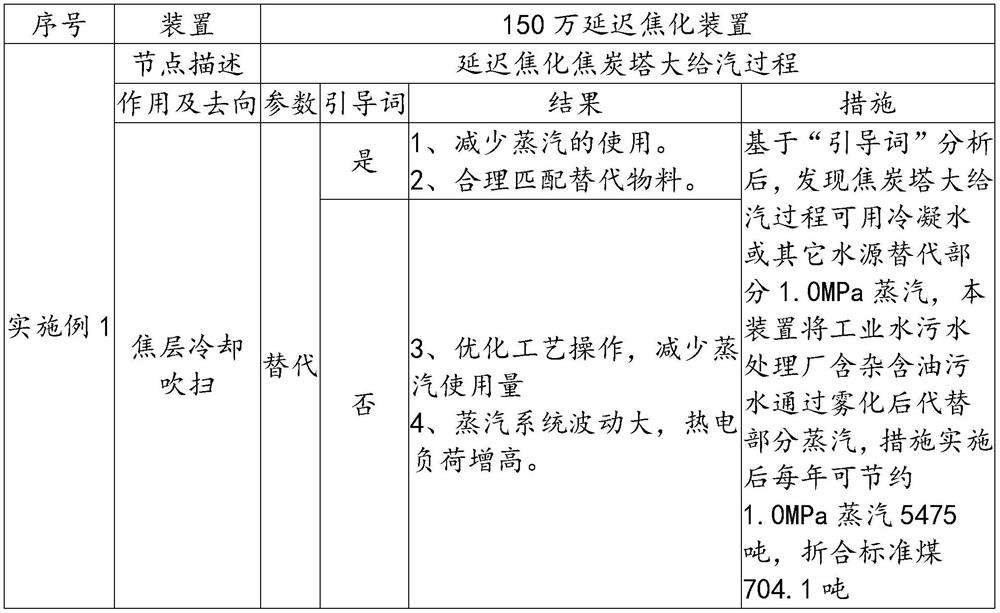

Steam optimization research method based on 'guide word' analysis mode

PendingCN113050560AReduce steam usageImprove steam usage efficiencyTotal factory controlProgramme total factory controlParameter analysisProcess engineering

Owner:青岛中石大环境与安全技术中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com