Combined treatment method for two kinds of waste acid water generated in tetraacetylethylenediamine (TAED) production

A technology of tetraacetylethylenediamine and combined treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high steam energy consumption and complicated on-site operation, etc. Achieve the effect of avoiding solid waste, being conducive to environmental protection and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

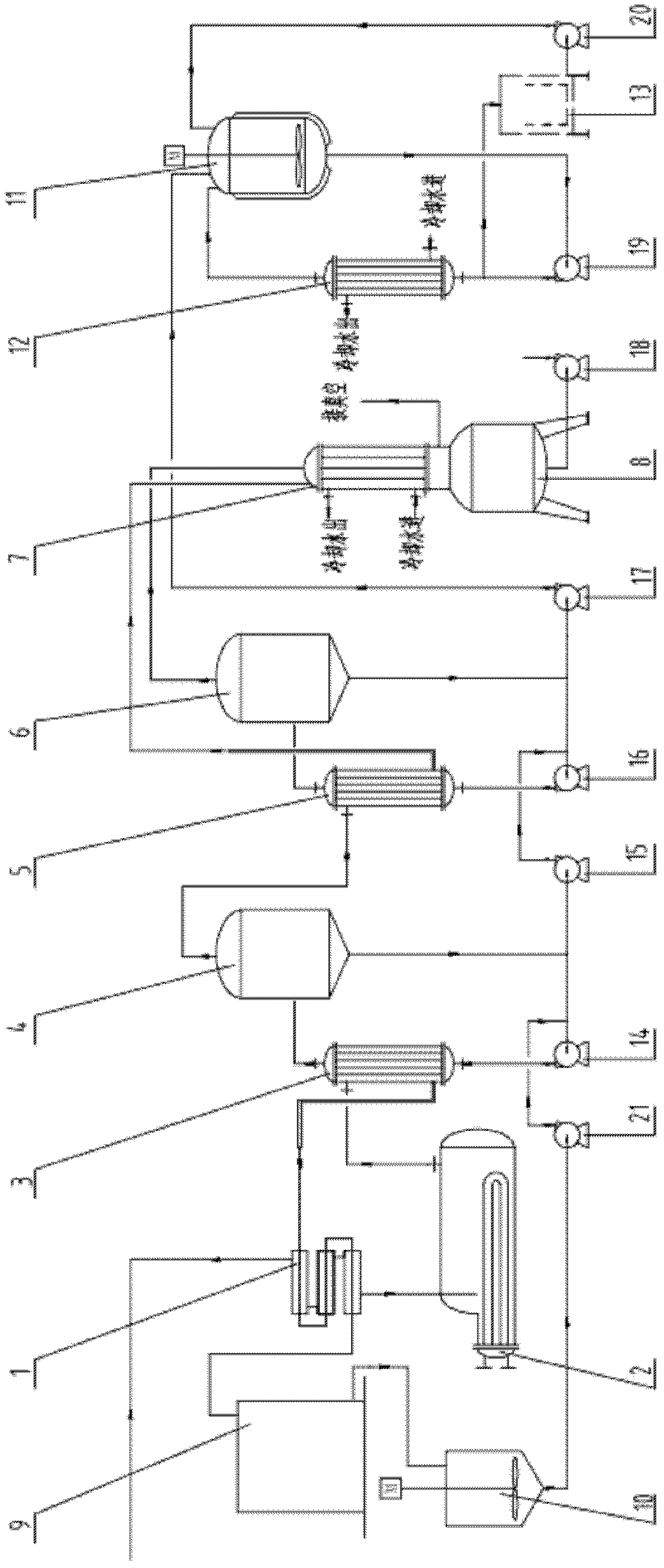

[0030] Such as figure 1 as shown,

[0031] 1. The dark waste acid water with an acetic acid content of 10% passes through the heat exchanger 1, and enters the reboiler 2, and uses 0.7MPa raw steam to heat the dark waste acid water. The flow rate of the raw steam is 1.1t / h. Acid vapor 130°C.

[0032] 2. The acid vapor exchanges heat with the neutralizing liquid entering the first effect in the first-effect heat exchanger 3. After the acid vapor condenses, it passes through the pressure liquid-sealed pipe, and the condensed acid water enters the reboiler dark waste acid water in the heat exchanger 1 pair. Preheating, after heat exchange, the condensed acid water enters the light-colored acid water tank 9, and mixes with the light-colored acid water with 20% acetic acid content.

[0033] 3. The mixed acid water is neutralized with soda ash in the neutralization kettle 10, the end-point Ph value is 7.5, and the temperature is 40°C.

[0034] 4. Add 0.1% thiourea dioxide to the n...

Embodiment 2

[0045] 1. The dark waste acid water with an acetic acid content of 10% passes through the heat exchanger 1 and then enters the reboiler 2. The dark waste acid water is heated by 0.4MPa raw steam, and the flow rate of the raw steam is 1.1t / h. Acid vapor 110°C.

[0046] 2. The acid vapor exchanges heat with the neutralizing liquid entering the first effect in the first-effect heat exchanger 3. After the acid vapor condenses, it passes through the pressure liquid-sealed pipe, and the condensed acid water enters the reboiler dark waste acid water in the heat exchanger 1 pair. Preheating, after heat exchange, the condensed acid water enters the light-colored acid water tank 9, and mixes with the light-colored acid water with 20% acetic acid content.

[0047] 3. The mixed acid water is neutralized with soda ash in the neutralization kettle 10, the end-point Ph value is 10.5, and the temperature is 80°C.

[0048] 4. Add 0.02% thiourea dioxide to the neutralizing solution and stir fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com