Method for reducing temperature of baked aluminum oxide by boiler desalted water

An alumina and brine technology, applied in the field of boiler demineralization, roasting alumina to cool down, can solve the problems of not being used, low demineralized water temperature, waste of electricity, manpower, etc., and achieve the effect of reducing steam consumption and significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

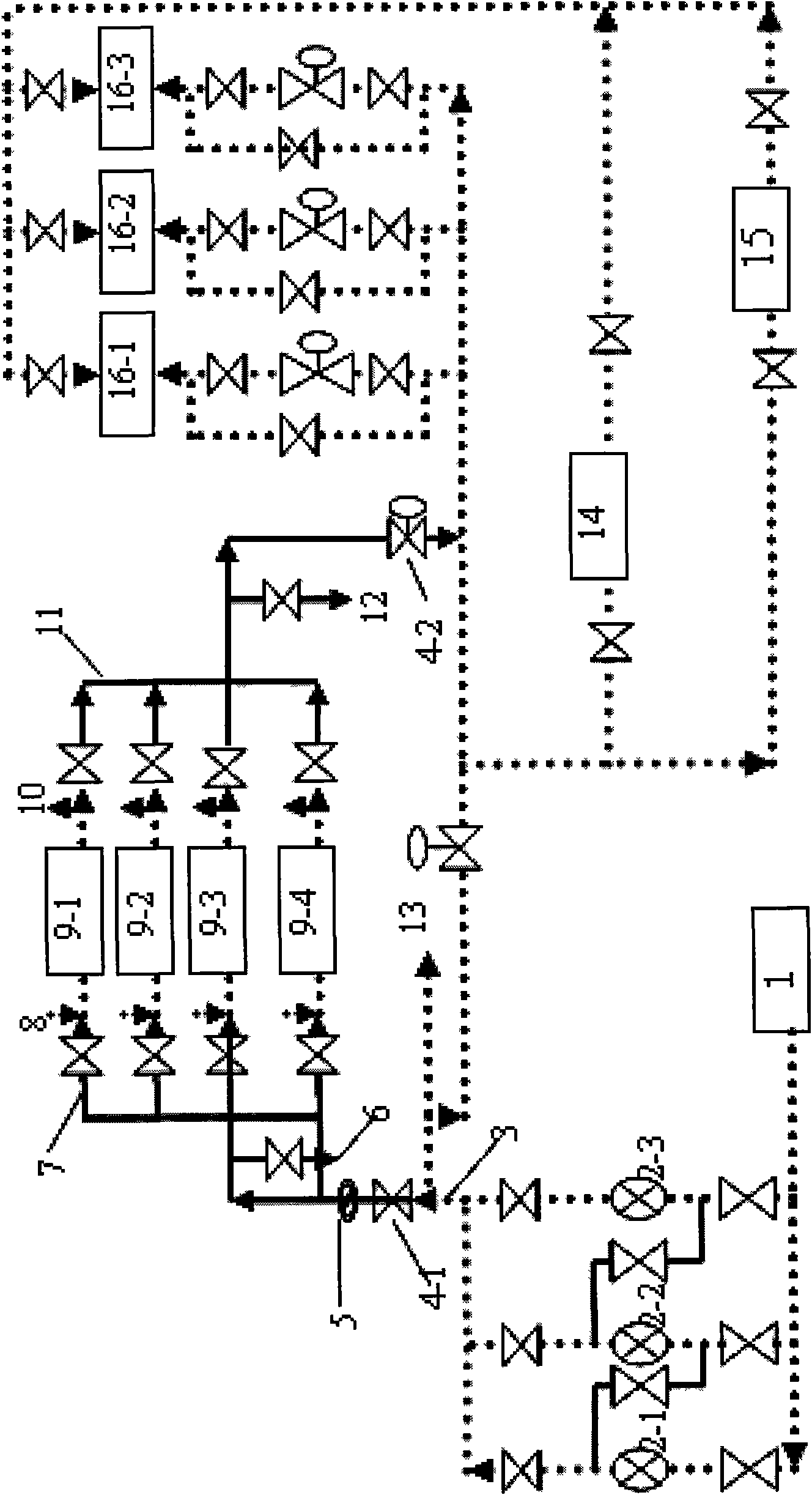

[0021] like image 3 "Schematic Diagram of Transformation Scheme Using Calcined Fluidized Bed to Heat Desalted Water".

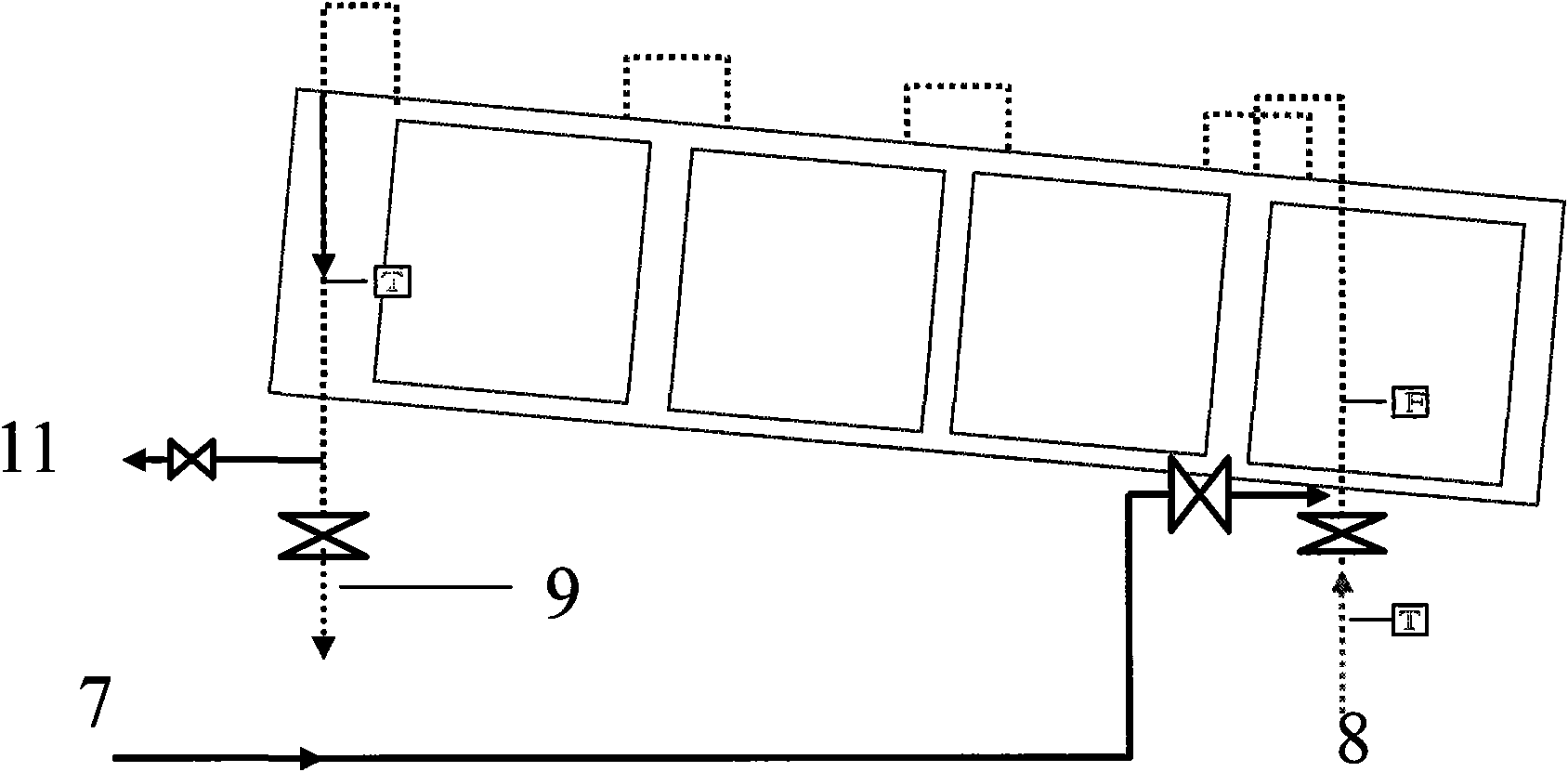

[0022] ① The original desalinated water supply process (dotted line in the figure) is retained, and a DN250 pipeline is led from the desalinated water main pipe 3 to each fluidized bed 9-1, 9-2, 9-3, 9 of the alumina roasting furnace -4 In the cooler process, a valve 4-1 and an orifice flowmeter 5 are installed near the connection point.

[0023] ② After the desalted water comes out of the fluidized bed, it is merged into the desalted water main pipe through a DN250 pipeline, and then enters the low-pressure deaerators 16-1, 16-2, and 16-3.

[0024] ③ Install a DN25 drain valve 6 and 12 at the lowest point of the desalted water inlet and outlet pipes as the sewage outlet.

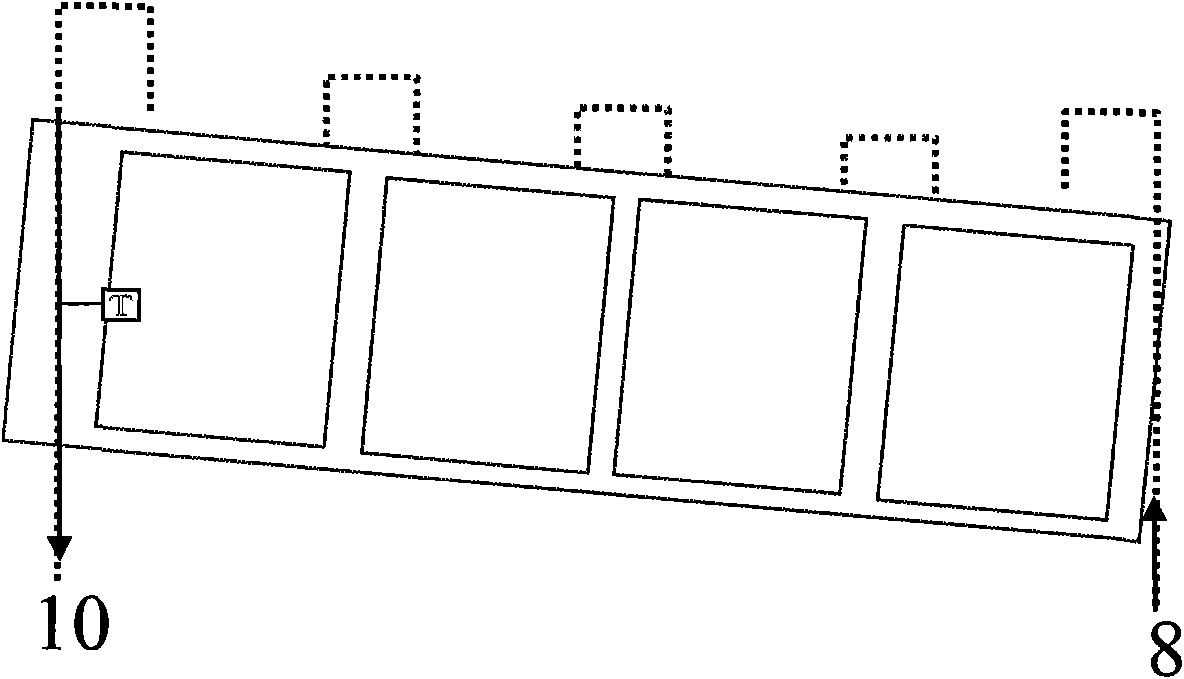

[0025] ④Our company has 3 roasting furnaces, each of which has 2 fluidized beds, and each fluidized bed has 4 coolers connected in series, and the area of each cooler is 50.62m 2 . F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com