An energy-saving urea production system and its production process

A production system and energy-saving technology, applied in the chemical industry, preparation of urea derivatives, sustainable manufacturing/processing, etc., can solve the problems of low urea synthesis rate, high steam consumption, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

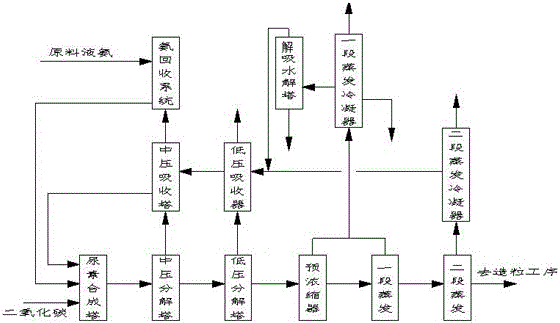

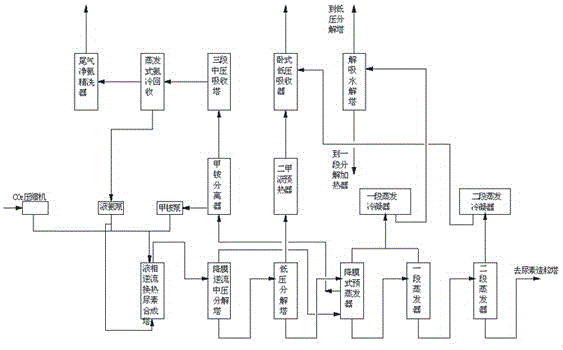

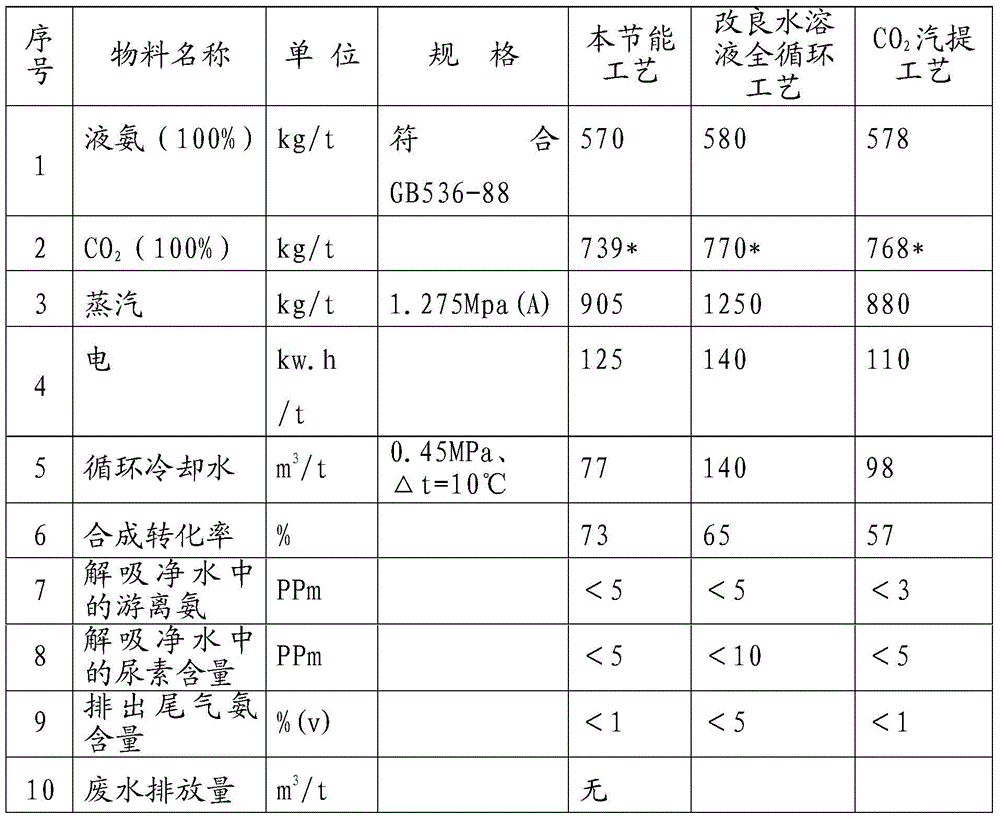

[0066] The energy-saving full cycle urea production system described in this embodiment is as follows figure 2 As shown, the system includes: CO 2 Compressor, ammonium carbamate pump (abbreviation of ammonium carbamate pump), liquid ammonia pump and urea synthesis tower, CO 2 The compressor is respectively connected with the ammonium methyl ammonium pump and the liquid ammonia pump, and the liquid ammonia pump is connected with the urea synthesis tower. After the urea synthesis tower, there are falling film countercurrent medium pressure decomposition tower and heater, a methyl ammonium condenser, and a methyl ammonium synthesis tower in series. Separator, three-stage medium-pressure absorption tower and evaporative ammonia cold recovery device, liquid ammonia buffer tank, inert gas scrubber, tail gas ammonia fine scrubber, low-pressure decomposition tower and heater, dimethyl liquid preheater, horizontal Low-pressure absorber, falling film pre-evaporator, one-stage evaporat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com