Method for producing zinc sulfide by acidic waste gas

A technology of acid waste gas and zinc sulfide, applied in the direction of zinc sulfide, chemical instruments and methods, separation methods, etc., can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

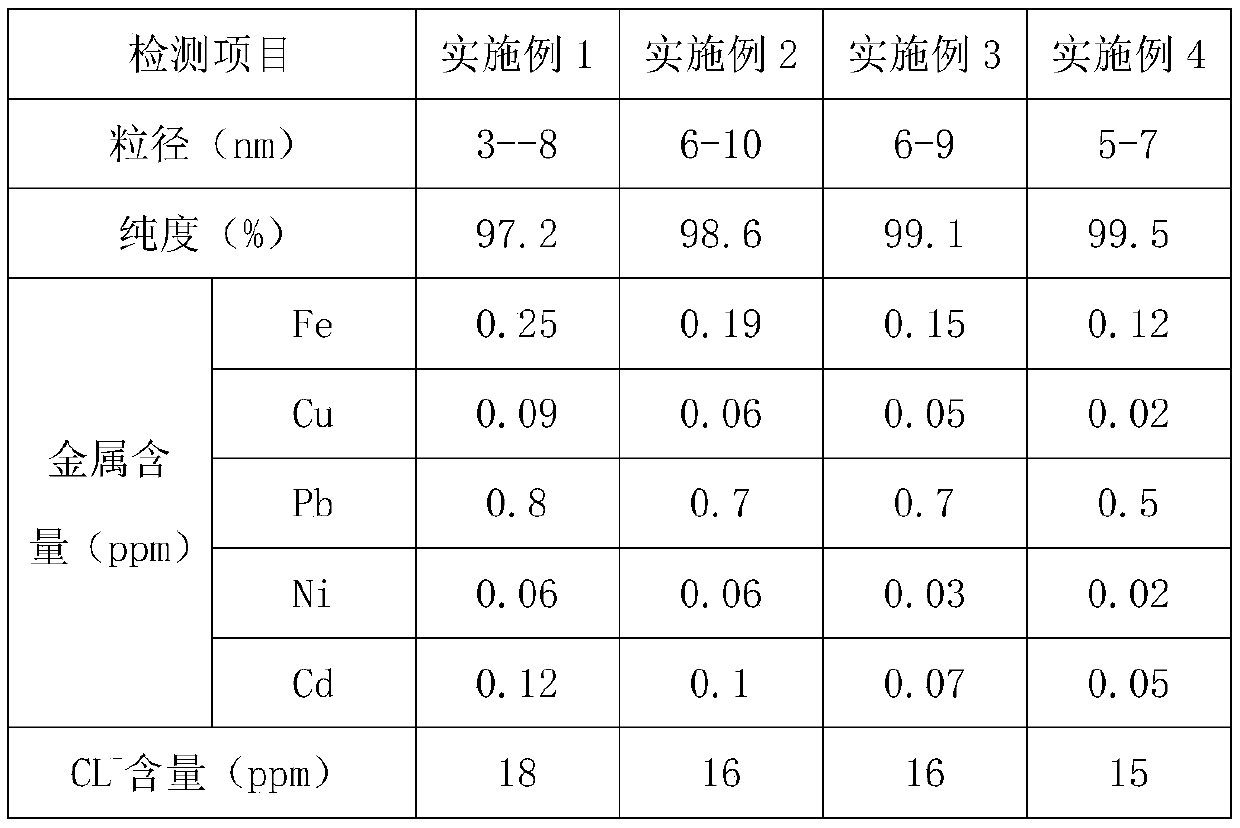

Embodiment 1

[0042] Industrial zinc sulfate is dissolved in water to make about 1.70mol / L. After the infusion pump of the liquid supply system is filtered by a multi-stage filter, it is purified in the channel. Under heating, heat to 65°C to reach the reaction temperature. After the zinc sulfate solution enters the reaction kettle, hydrogen sulfide gas is introduced, and the zinc sulfate and hydrogen sulfide react fully under the stirring condition. Add water to wash. Aging: Aging is carried out on the powder slurry after water washing, and it is heated and kept at 90-93°C for about 150 minutes to improve the crystallinity of zinc sulfide, so that zinc sulfide shows special particle size distribution and dispersibility effects. The matured slurry is introduced into the post-water washing tank to wash away impurities such as sulfate in the crystal. Filter out mechanical impurities through a water sieve machine, and then guide the slurry into a dehydrator for dehydration. The dehydrated p...

Embodiment 2

[0044]2# Zinc oxide reacts with industrial sulfuric acid and dissolves in water to make about 1.70mol / L. After the infusion pump of the liquid supply system is filtered by a multi-stage filter, it is purified in the channel, and the impurities <15μm in the droplet are filtered. , The solution was heated to 65°C under 0.4Mpa steam heating to reach the reaction temperature. After the zinc sulfate solution enters the reaction kettle, hydrogen sulfide gas is introduced, and the zinc sulfate and hydrogen sulfide react fully under the stirring condition. Add water to wash. Aging: Aging is carried out on the washed powder slurry, which is heated at 90-93°C for about 150 minutes to improve the crystallinity of zinc sulfide, so that zinc sulfide shows a special effect of particle size distribution and dispersibility. The matured slurry is introduced into the post-water washing tank to wash away impurities such as sulfate in the crystal.

[0045] Filter out mechanical impurities, etc....

Embodiment 3

[0047] 1# Zinc oxide is reacted with refined pure sulfuric acid, dissolved in water to make about 1.70mol / L, filtered by multi-stage filters through the infusion pump of the liquid supply system, and then purified in the channel, and the impurities <15μm in the droplets After being filtered, the solution is heated to 65°C under 0.4Mpa steam heating to reach the reaction temperature. After the zinc sulfide solution enters the reaction kettle, hydrogen sulfide gas is introduced, and the zinc sulfate and hydrogen sulfide react fully under the condition of stirring. Add water to wash. Aging: Aging is carried out on the powder slurry after washing, and it is heated and kept at 90-93°C for about 150 minutes to improve the crystallinity of zinc sulfide, so that zinc sulfide shows a special particle size distribution and dispersibility effect. The matured slurry is introduced into the post-water washing tank to wash away impurities such as sulfate in the crystal. Filter out mechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com