Efficient and energy-saving process for preparing pectin

A high-efficiency, energy-saving, and high-tech technology, applied in the field of pectin extraction, can solve the problems of long extraction time and high energy consumption of the production process, and achieve the effects of improving extraction rate and purity, appropriate size, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A high-efficiency and energy-saving process for preparing pectin, which specifically includes the following steps:

[0033] 1) Take 100 kg of dried sunflower discs and grind them through a 40-mesh sieve with a pulverizer.

[0034] 2) Wash the crushed sunflower disc, add 800kg of water, filter the filter residue to adjust pH=7.0 with 8% (mass fraction) sodium carbonate, then perform high-voltage pulse electric field treatment, then heat to 30°C and stir for 60min; After filtration, the filter residue is used for later use.

[0035] The parameters of the high-voltage pulsed electric field treatment are: field strength 20kv / cm, total treatment time 400μs, pulse width 4μs, pulse frequency 400pps.

[0036] 3) Soak the filter residue with 2 t of water and stir for 60 minutes, then add 5 kg of ammonium oxalate to the extract, adjust the pH to 2 with oxalic acid, soak and stir for 2 hours at a temperature of 75°C.

[0037] 4) The mixed solution is centrifugally filtered, the ...

Embodiment 2

[0044] A high-efficiency and energy-saving process for preparing pectin, which specifically includes the following steps:

[0045] 1) Take 100 kg of dried sunflower discs and grind them through a 60-mesh sieve with a pulverizer.

[0046] 2) Wash the crushed sunflower disc, add 900kg of water, filter the filter residue to adjust pH=7.2 with 68% (mass fraction) sodium acetate, then perform high-voltage pulse electric field treatment, then heat to 45°C and stir for 60min; After filtration, the filter residue is used for later use.

[0047] The parameters of the high-voltage pulsed electric field treatment are: field strength 30kv / cm, total treatment time 300μs, pulse width 4μs, pulse frequency 400pps.

[0048] 3) Soak the filter residue with 2.2 t of water and stir for 50 minutes, then add 8 kg of ammonium oxalate to the extract, adjust the pH to 3.5 with oxalic acid, soak and stir for 1.5 hours at a temperature of 80°C.

[0049] 4) The mixed solution is centrifugally filtered,...

Embodiment 3

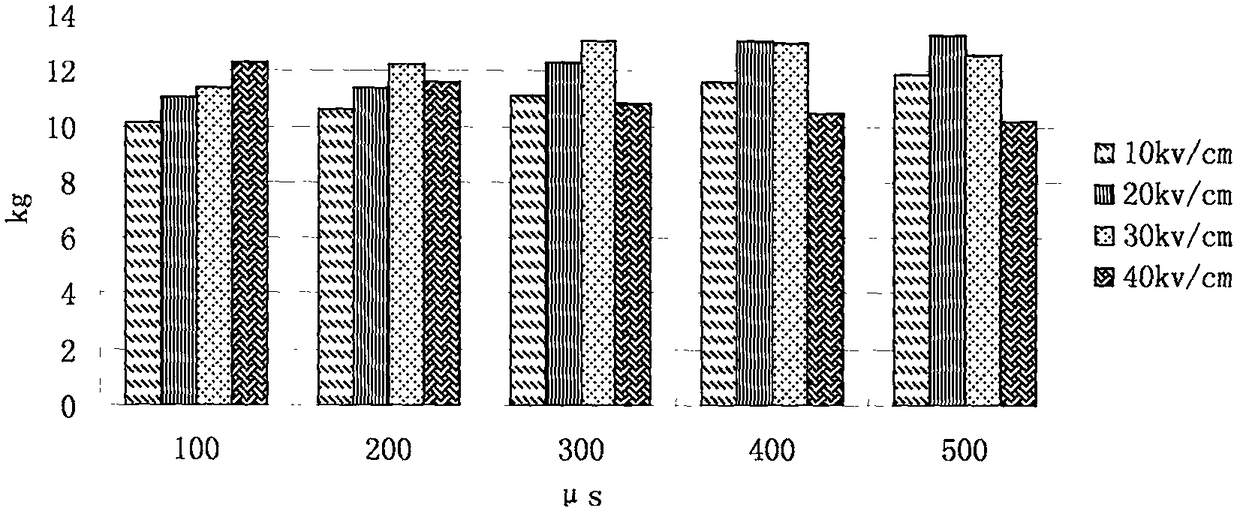

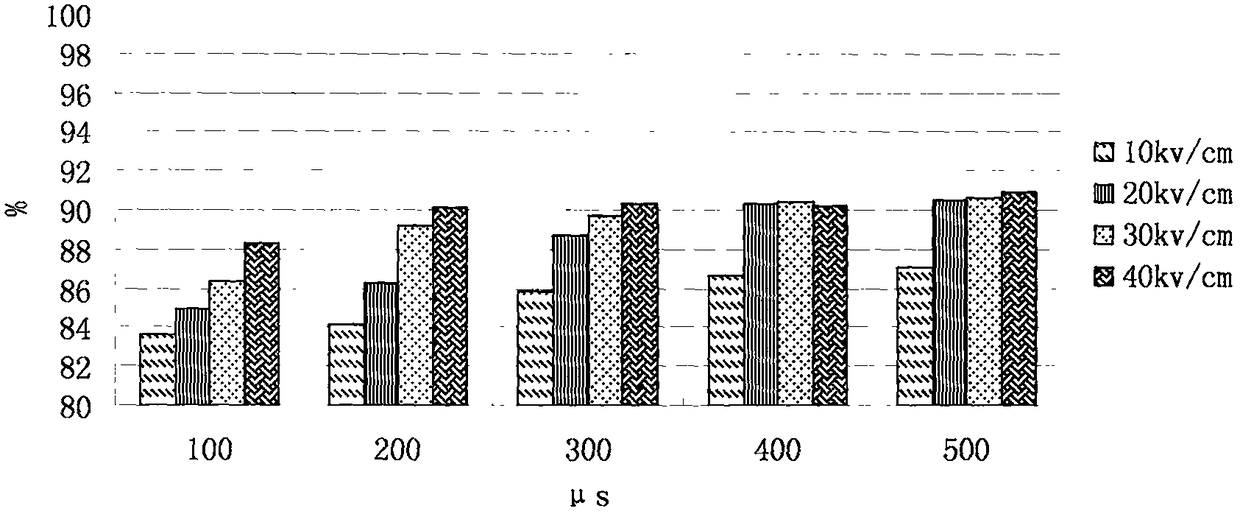

[0068] Effects of high-voltage pulsed electric field strength and total processing time on the yield and purity of pectin:

[0069] Set the four groups of field strength 10kv / cm, 20kv / cm, 30kv / cm, and 40kv / cm respectively, and set the time as 100μs, 200μs, 300μs, 400μs, and 500μs. Refer to Example 1 for other operating modes. Such as Figure 1-2 As shown, increasing the field strength from 10kv / cm to 20kv / cm can greatly increase the yield and purity of pectin, and then with the increase of strength, the yield and purity of pectin will not increase significantly, but reaching 40kv / cm will reduce the yield of pectin. Glue production, probably because the cell wall is severely damaged due to excessive field strength, and part of the pectin is lost; similarly, the action time is controlled at 300-500μs, and the pectin production and purity are at the best level, and the high-intensity field strength acts for too long It also leads to a decrease in pectin production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com