Waste heat recovery device

A waste heat recovery device and heat exchanger technology, which can be used in drying gas layout, lighting and heating equipment, dryers, etc., can solve problems such as waste and reuse of anion exchangers, and achieve the effect of reducing steam consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The following examples illustrate the present invention in more detail, but are not limited to the following examples as long as it falls within the scope of the present invention.

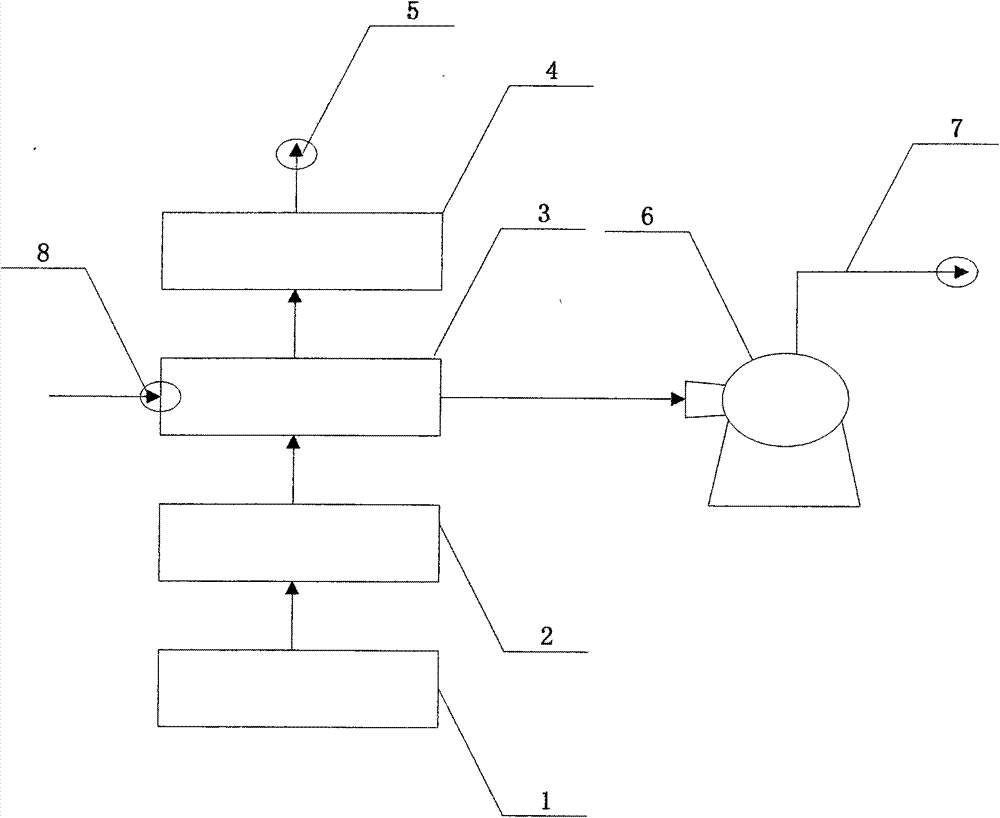

[0010] A waste heat recovery device, comprising a one-effect heat exchanger (1), a condensed water tank (2), a tubular water heater (3), a cooled condensed water tank (4), a desalinated water station port (5 ), a drying blower (6), a hot air delivery pipe (7), and an air inlet pipe (8). The one-effect heat exchanger (1) is sequentially connected with a condensed water tank (2), a shell and tube water heater (3), and a cooled condensed water tank (4), and one end of the shell and tube water heater (3) is connected to There is an air input pipe (8), one end is connected to the drying fan (6), the cooled condensate tank (4) is connected to the desalinated water station port (5), and the hot air delivery pipe (7) is located on the drying fan (6) .

[0011] The above-described embodiment is on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com