Cleaner production method of gellan gum

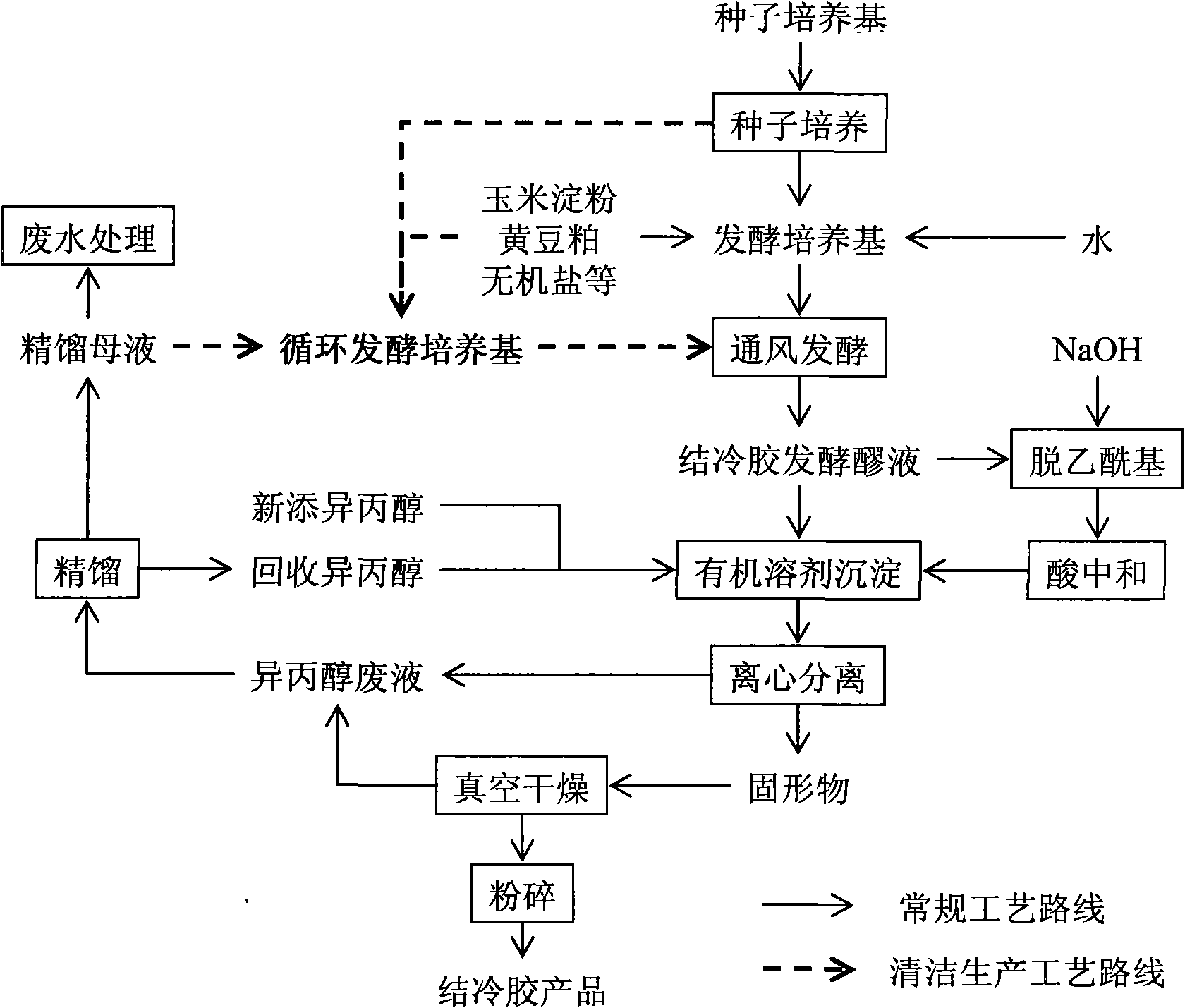

A clean production, gellan gum technology, applied in the field of bioengineering, can solve problems such as efficient treatment of unfavorable organic wastewater, heavy treatment load and economic cost, achieve obvious environmental and social benefits, reduce construction investment and operating costs, reduce The effect of water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: the preparation of gellan gum fermentation broth

[0015] The gellan gum-producing strain is P. elodea or Sphingomonas paucimobilis ATCC 31461.

[0016] Seed medium (kg / m 3 ): Sucrose 20; Peptone 5.0; Beef Extract 3.0; Yeast Extract 1.0; pH 7.0.

[0017] Initial fermentation medium (kg / m 3 ): corn starch 30; soybean meal 3.0; K 2 HPO 4 1.0; KH 2 PO 4 3.0; MgSO 4 ·7H 2 O 1.0; pH 7.0.

[0018] Fermentation conditions: the fermentation process is carried out in a fermenter of 5 cubic meters, the inoculum size is 5% (v / v), the stirring speed is 300r / min, the ventilation rate is 1.0vvm, the tank pressure is 0.05MPa, and the fermentation temperature is 30°C. During the fermentation process, NaOH solution was used to adjust the pH value of the fermentation broth. After 18 hours, the pH value was kept constant at about 5.6. After 72 hours of fermentation and cultivation, the gellan gum production and quality control parameters were measured.

Embodiment 2

[0019] Embodiment 2: the product preparation of gellan gum

[0020] Measure 1000 liters of gellan gum fermentation liquid, slowly add 2000 liters of ethanol solvent, stir and mix well and let it stand for 30 minutes, then continuously centrifuge under the condition of 6000r / min to obtain about 250kg of solid matter, the supernatant is ethanol solution, and transport it to waste Ethanol storage tank. Gained solids are transported to a washing tank, add 400 liters of ethanol solvent, stir and mix well and let stand for 30 minutes, then centrifuge continuously at 6000r / min to obtain 150kg of solids and transport them to a vacuum dryer. The supernatant is ethanol waste The liquid is transported to the waste ethanol storage tank for centralized recycling. The solid matter obtained above was vacuum-dried for 6 hours at a temperature lower than 42°C, the solution obtained by vacuum condensation was transported to a waste ethanol storage tank, and the dried solid matter was crushed a...

Embodiment 3

[0021] Embodiment 3: the product preparation of low acyl degree gellan gum

[0022] Adjust the pH of the fermented mash obtained in Example 1 to 10.0 with 0.3 mol / L NaOH solution, raise the temperature to 80°C and keep it warm for 25 minutes, and then treat it with the method described in Example 2 after cooling to obtain low-acidity gelatin Glue products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com