Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

275results about "Boiling apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

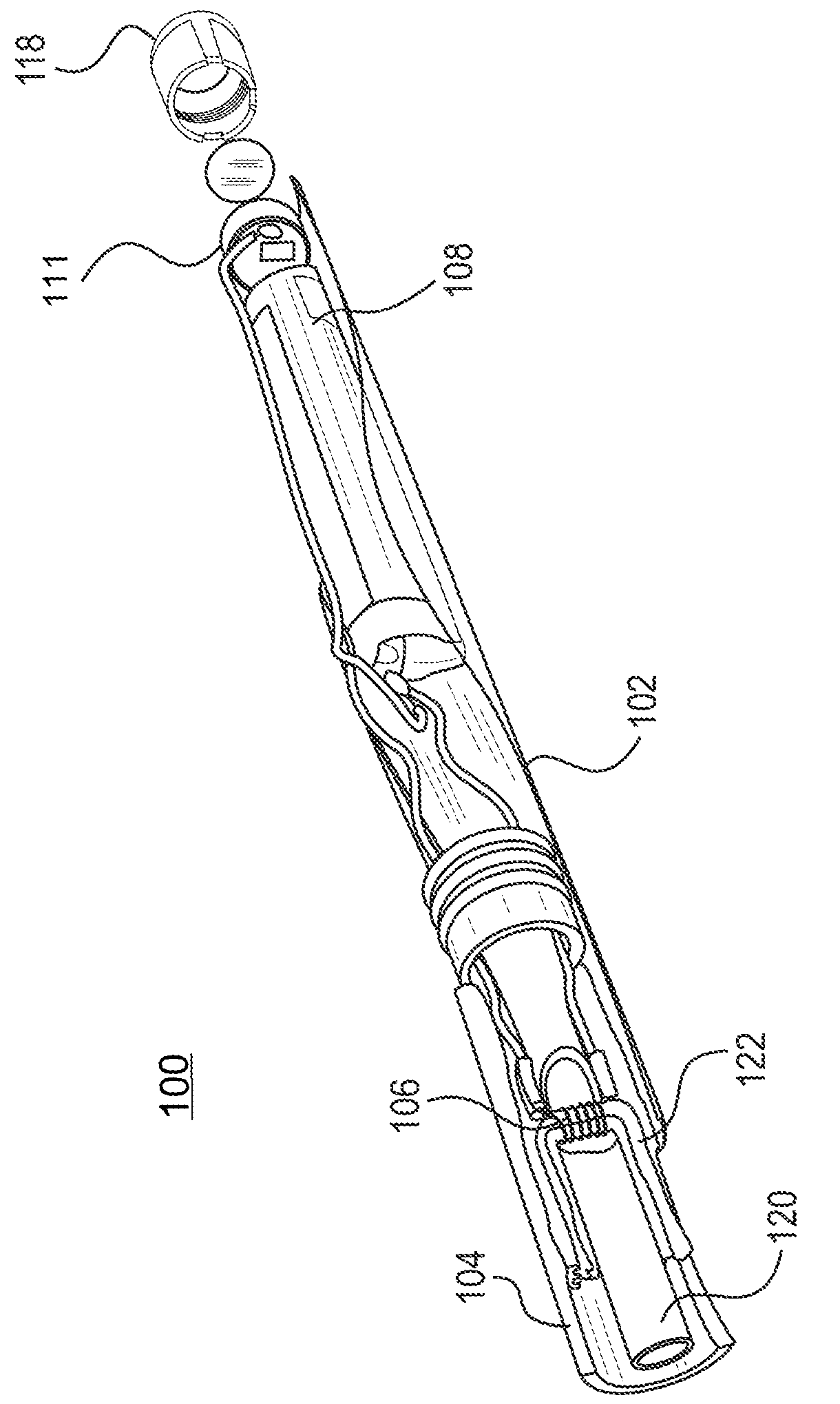

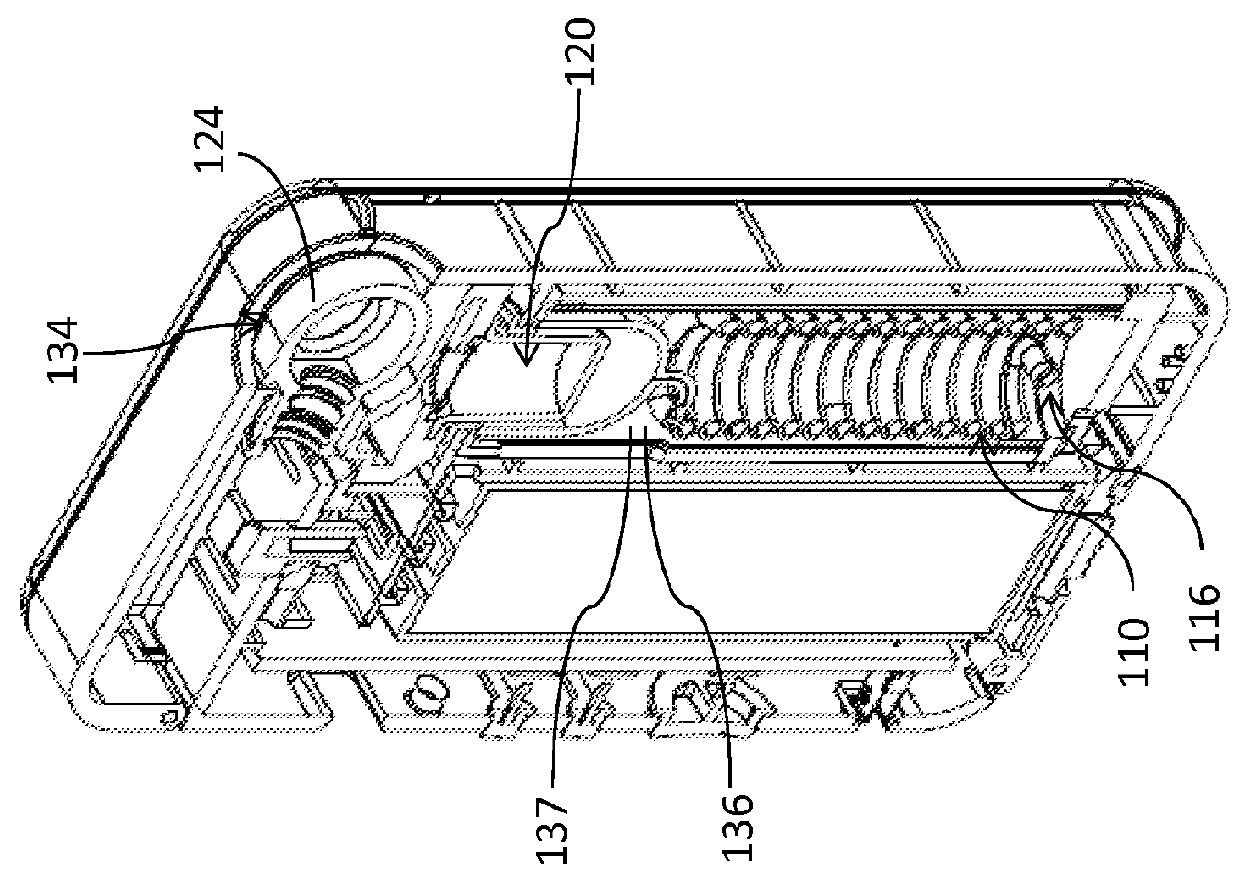

Electronic smoking article comprising one or more microheaters

The present disclosure relates to an electronic smoking article that provides for improved aerosol delivery. Particularly, the article comprises one or more microheaters. In various embodiments, the microheaters provide for improved control of vaporization of an aerosol precursor composition and provide for reduced power requirements to achieve consistent aerosolization. The present disclosure further relates to methods of forming an aerosol in a smoking article.

Owner:RAI STRATEGIC HLDG INC

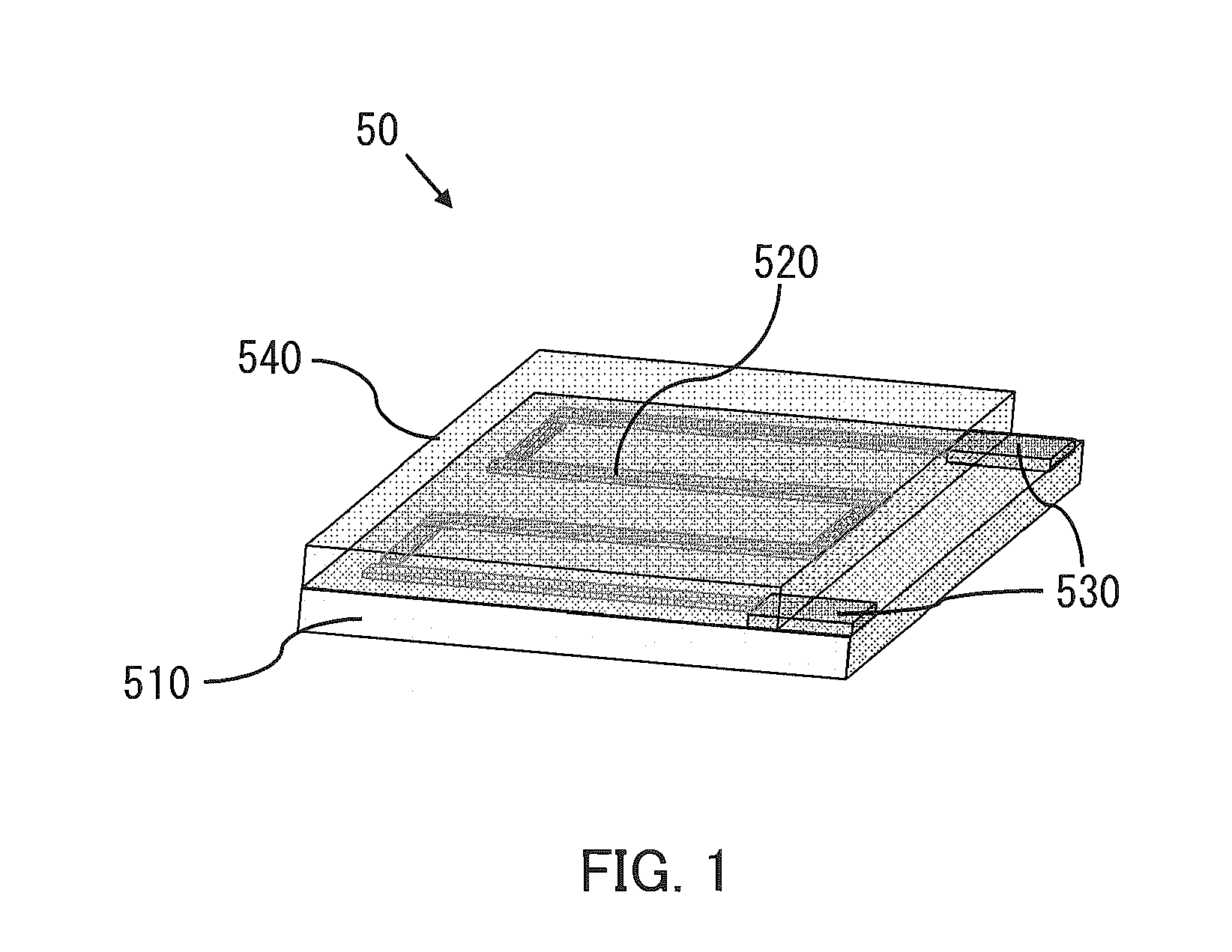

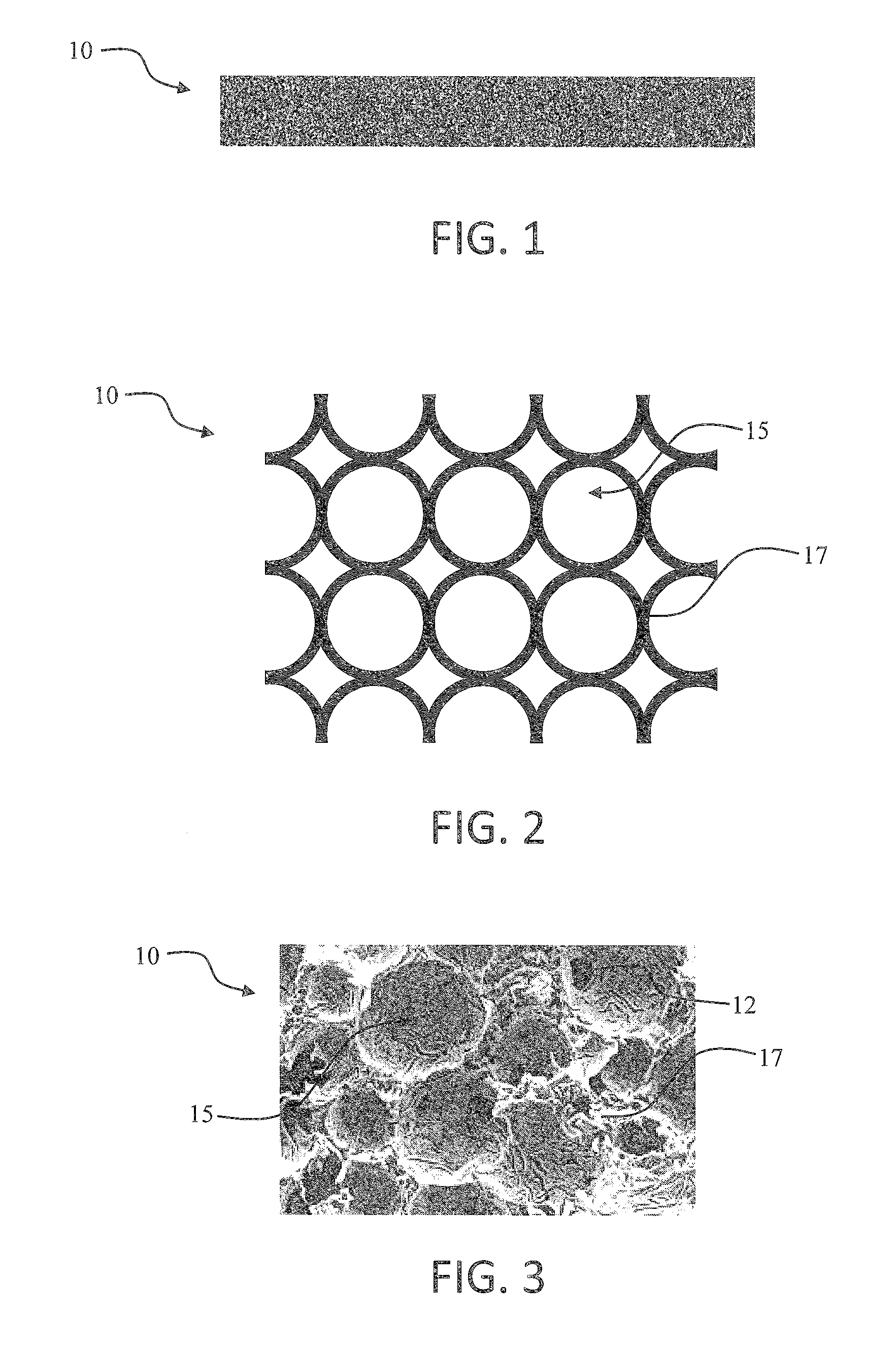

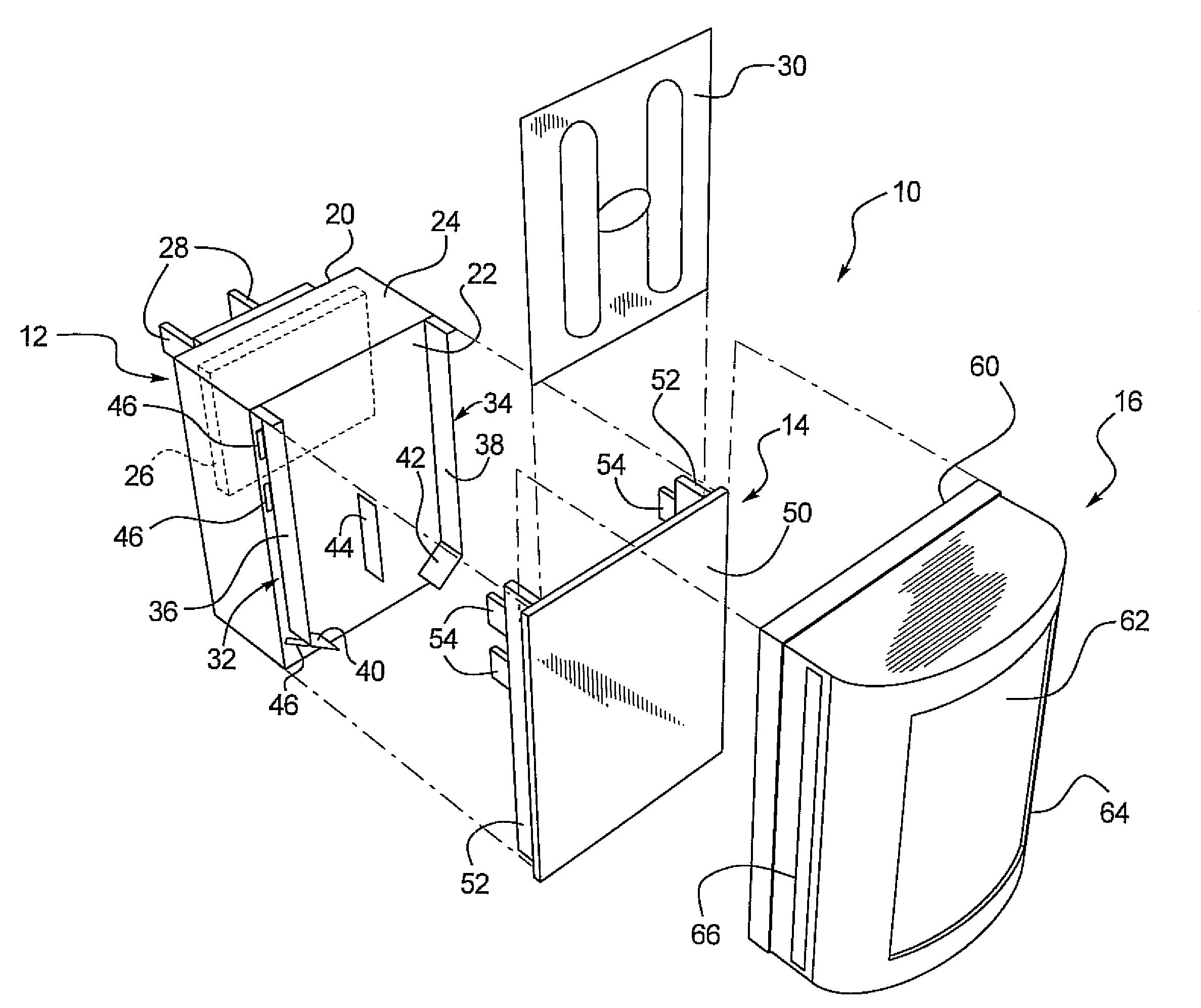

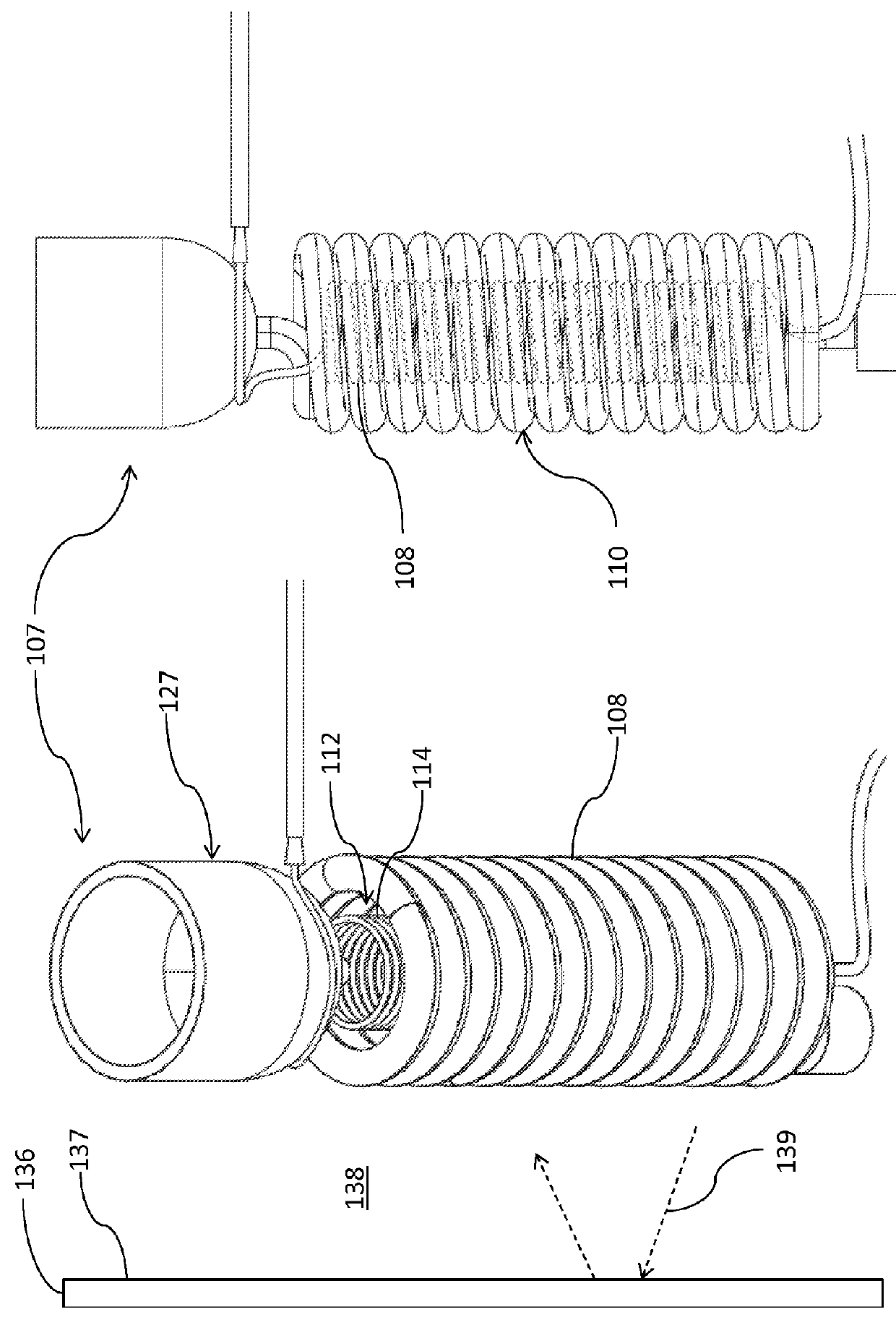

Carbon conductive substrate for electronic smoking article

ActiveUS20150059780A1Improve natureReduce materialSteam generation using steam absorptionTobacco pipesPorous carbonEngineering

The present disclosure provides components useful in heating, particularly heating of an aerosol precursor solution so as to vaporize the solution and form an aerosol. The disclosure particularly provides an electrically conductive, porous carbon heater. The heater may be combined with an aerosol precursor transport element that also is formed of carbon. The heater and transport element may form an atomizer that can be useful in an electronic smoking article, such as in a cartridge that is adapted for attachment to a control body. In some embodiments, the disclosure provides a cartridge of an electronic smoking article, the cartridge being formed substantially completely of carbon.

Owner:RAI STRATEGIC HLDG INC

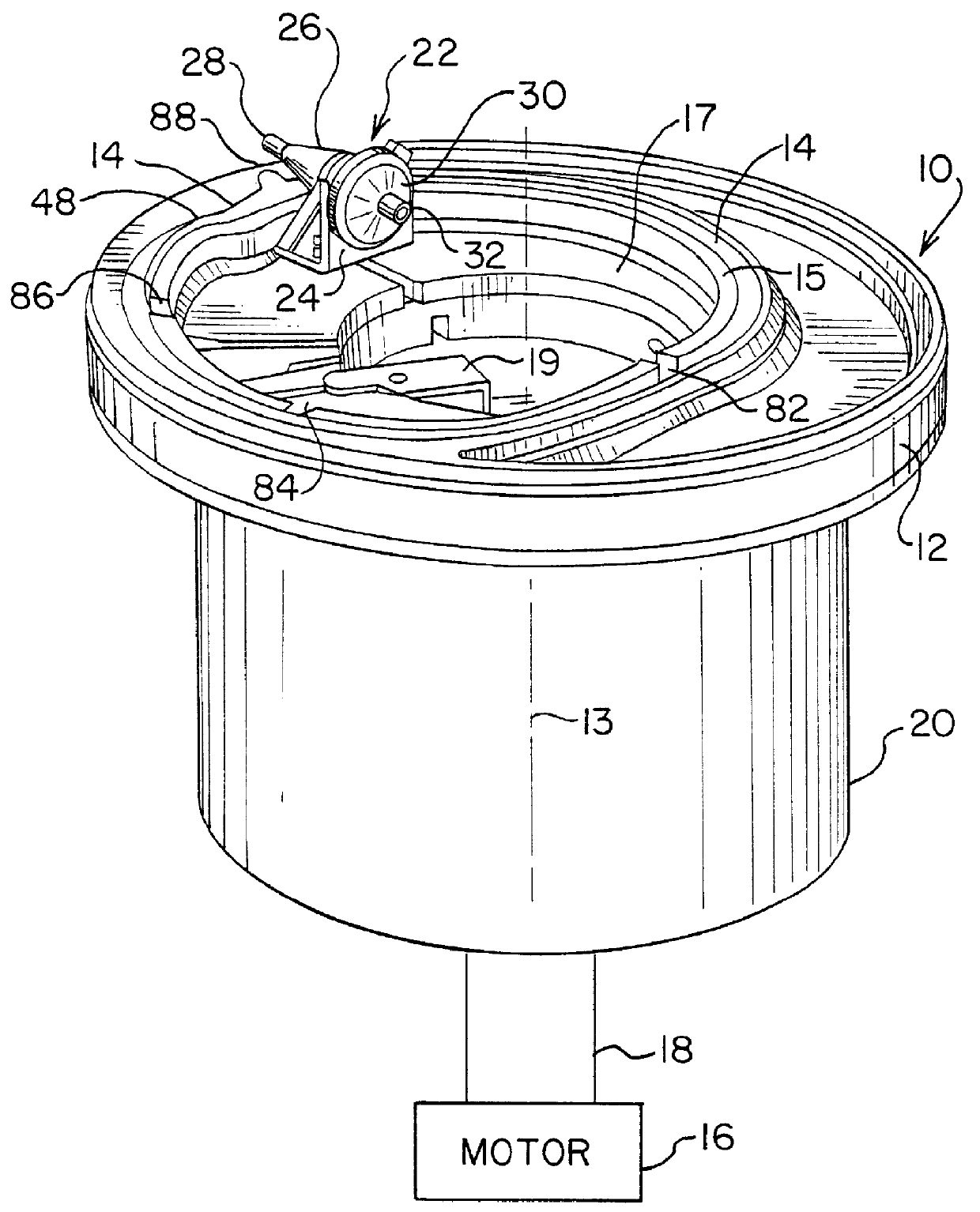

Method and apparatus for collecting hyperconcentrated platelets

InactiveUS6022306AOther blood circulation devicesDispersed particle separationParticle flowPlatelet product

The instant invention relates to a method and the apparatus for collecting a hyperconcentrated platelet product. A fluid containing platelets and other particles flows into a fluid chamber at a flow rate. The flow rate of the fluid is selected to retain the majority of the platelets in the fluid chamber in a saturated bed. The platelets are collected from the fluid chamber without collecting the other particles to form a hyperconcentrated other particle reduced platelet product.

Owner:CARIDIANBCT

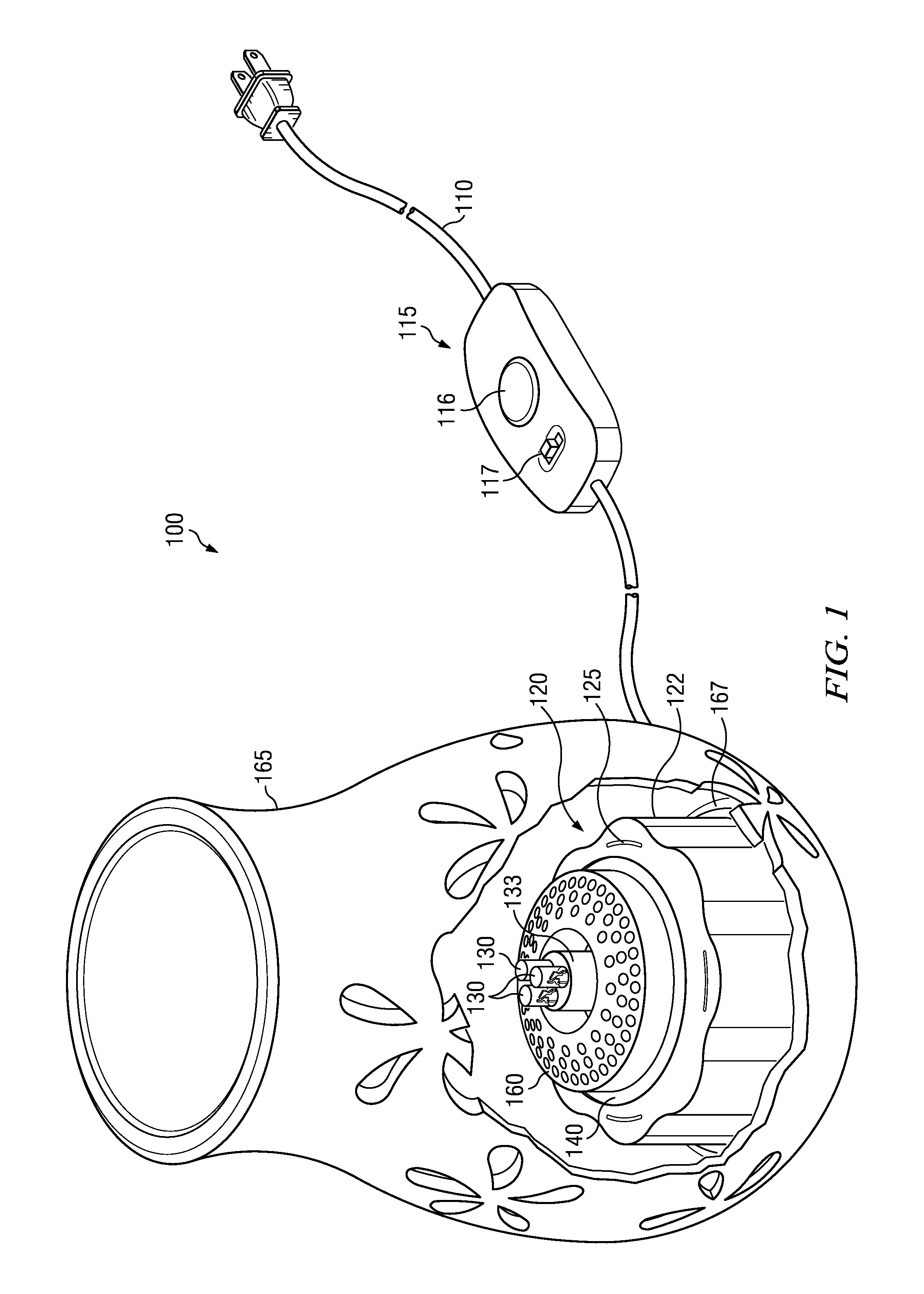

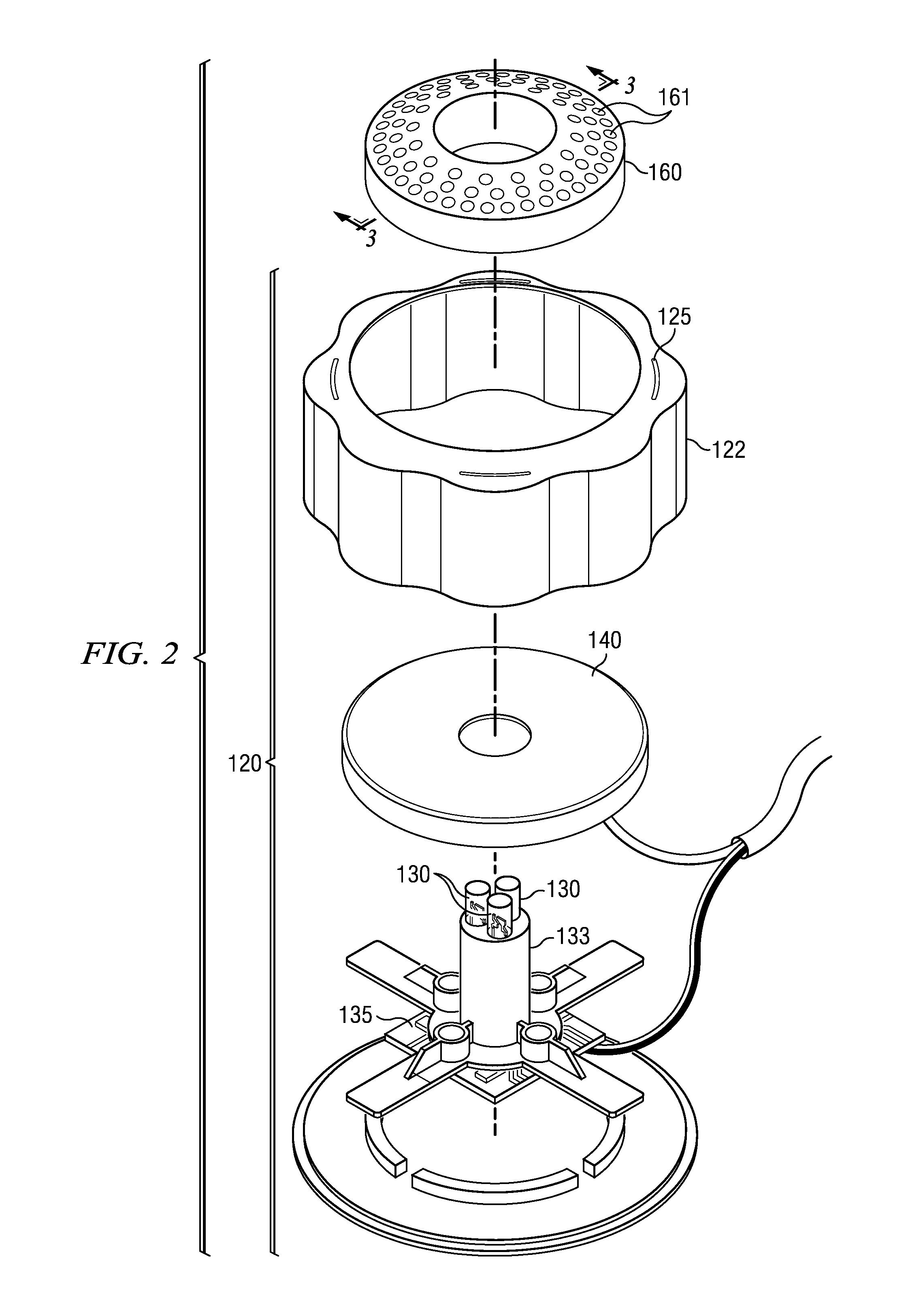

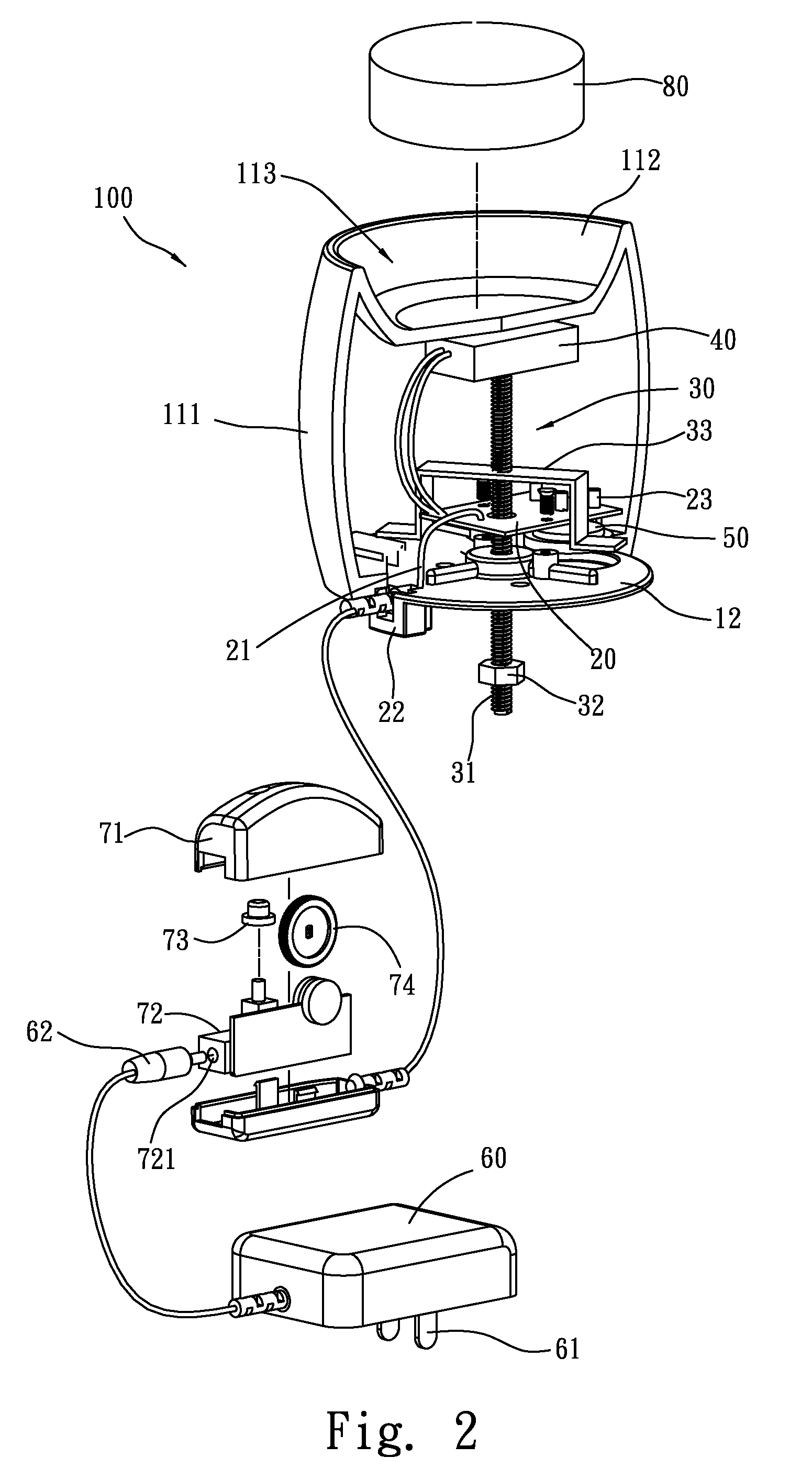

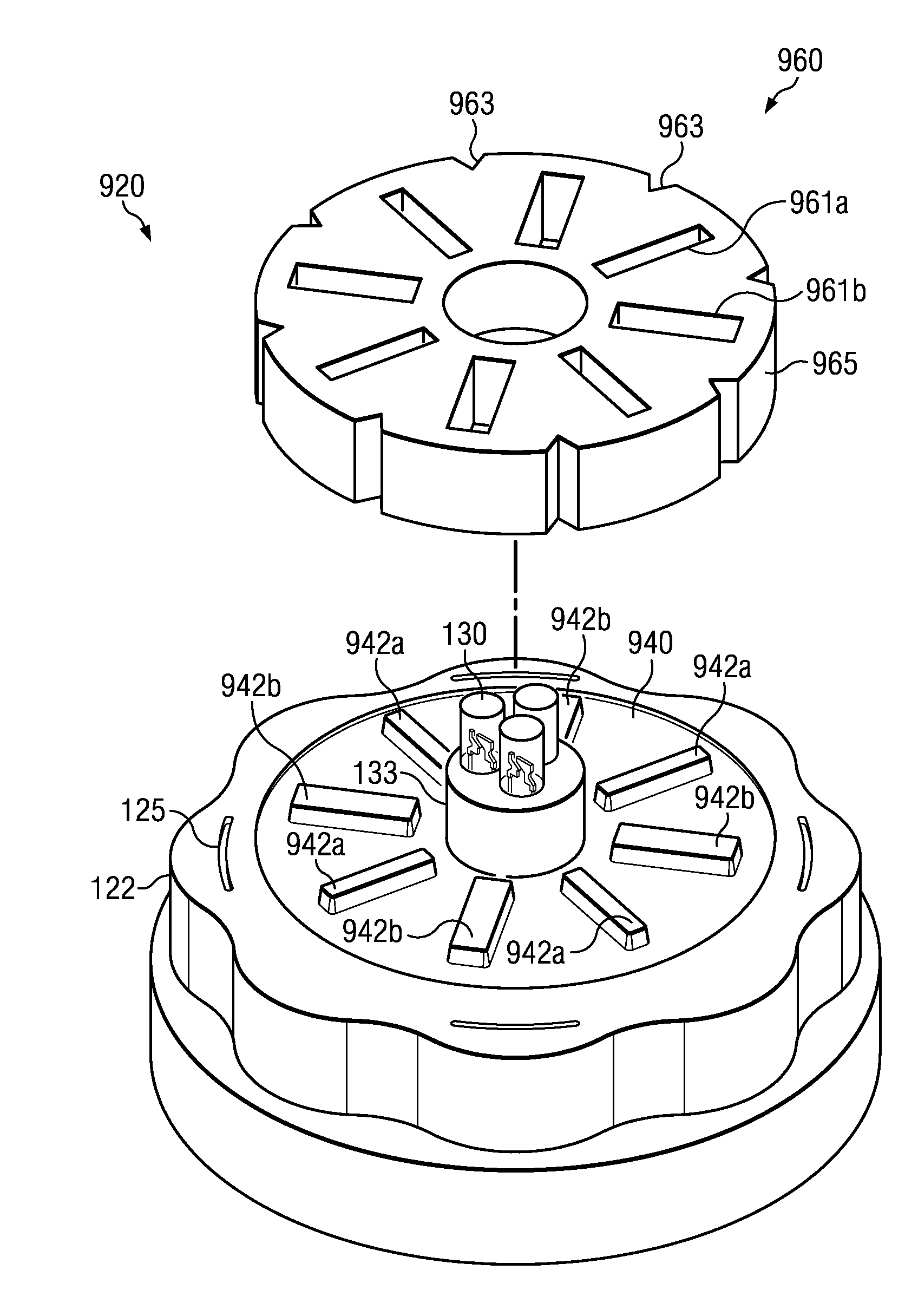

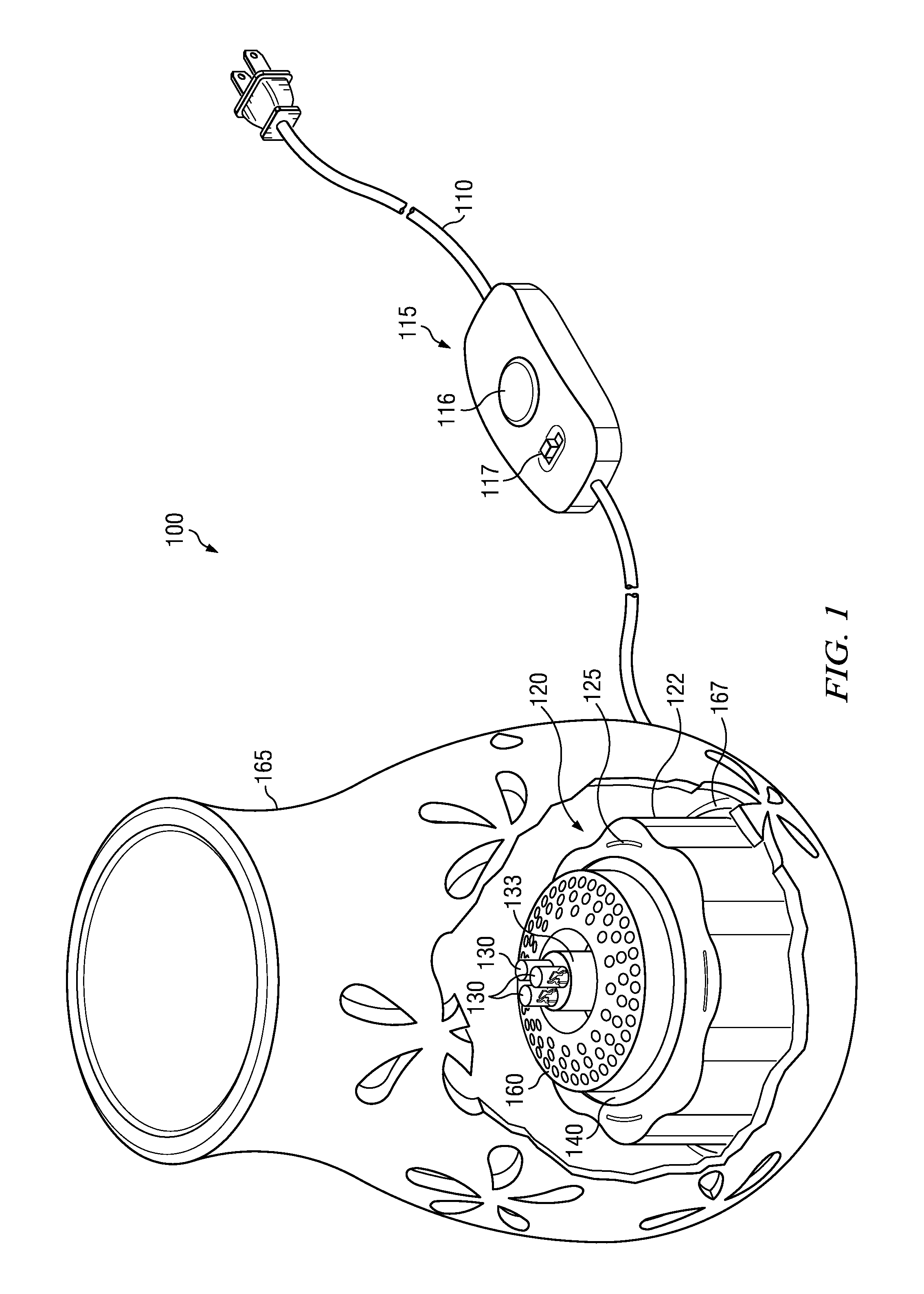

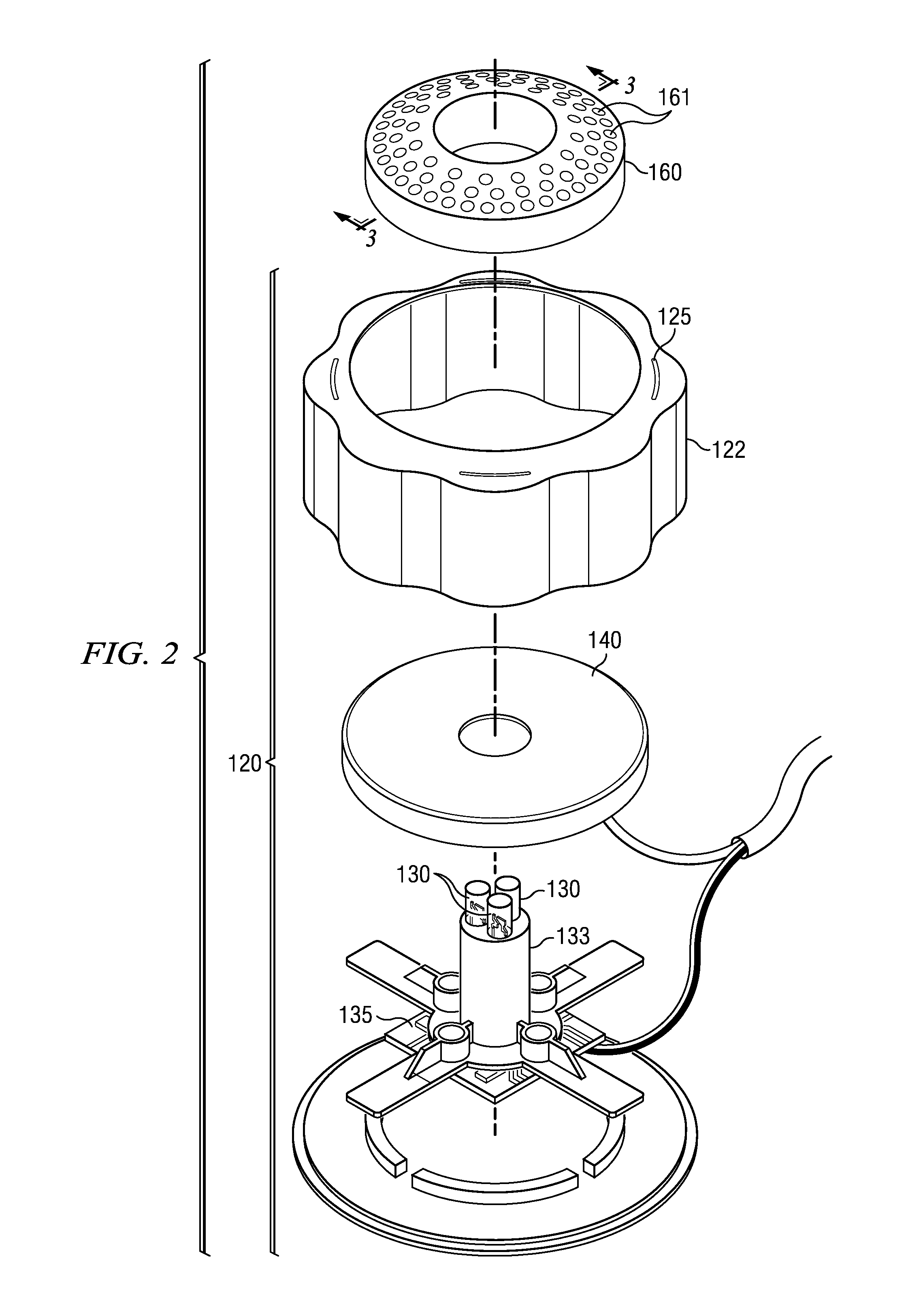

Fragrance producing lighting device

A light and fragrance producing device includes an electrically powered light source and a separate electrically powered heating element. The device also includes a fragrance disk that can emit fragrances when heated by the heating element. The fragrance disk also can be configured to remain solid while heated by the heating element rather than melting or evaporating. The device can also include a decorative outer housing that can be interchangeable.

Owner:SKY RICH STAR LTD

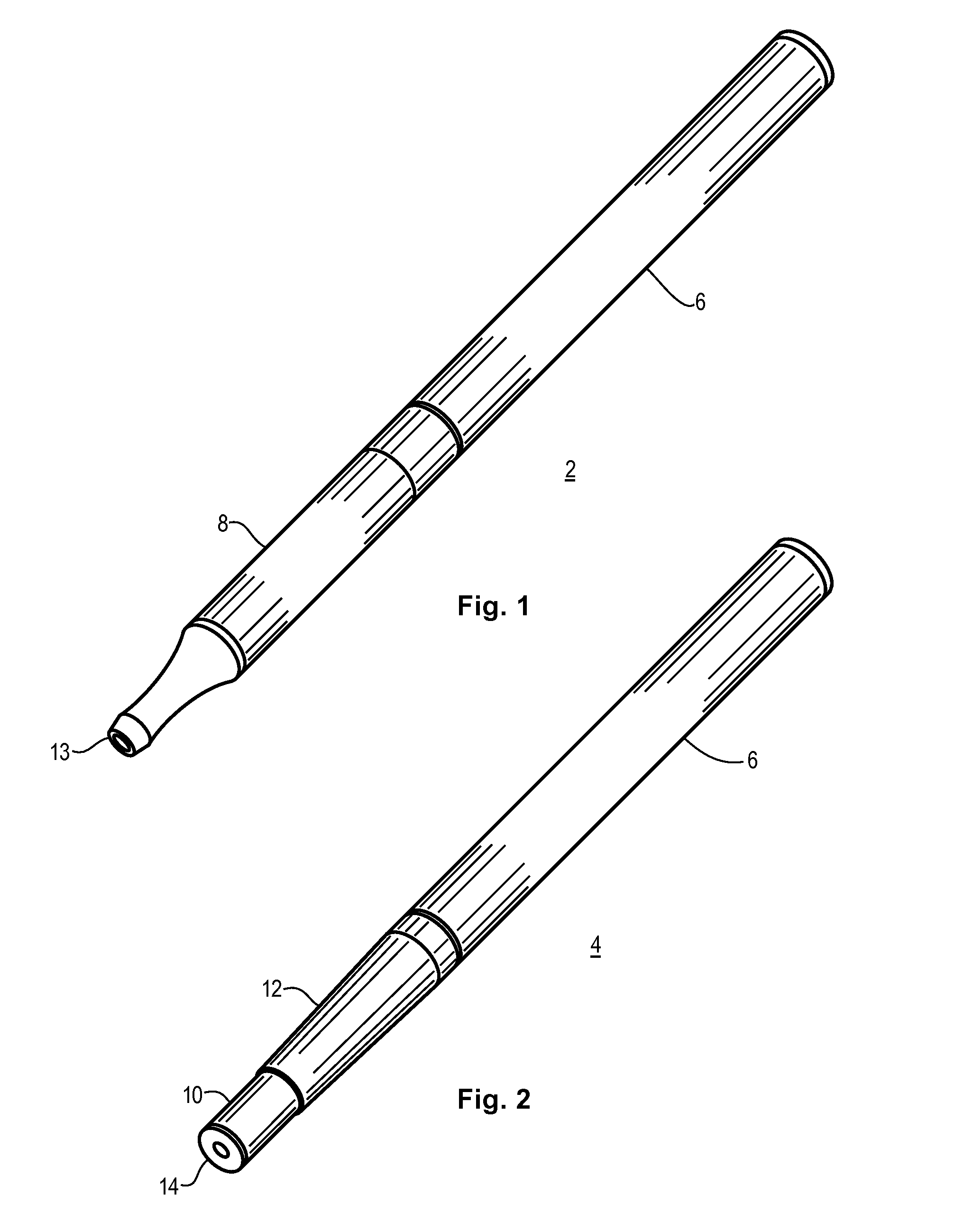

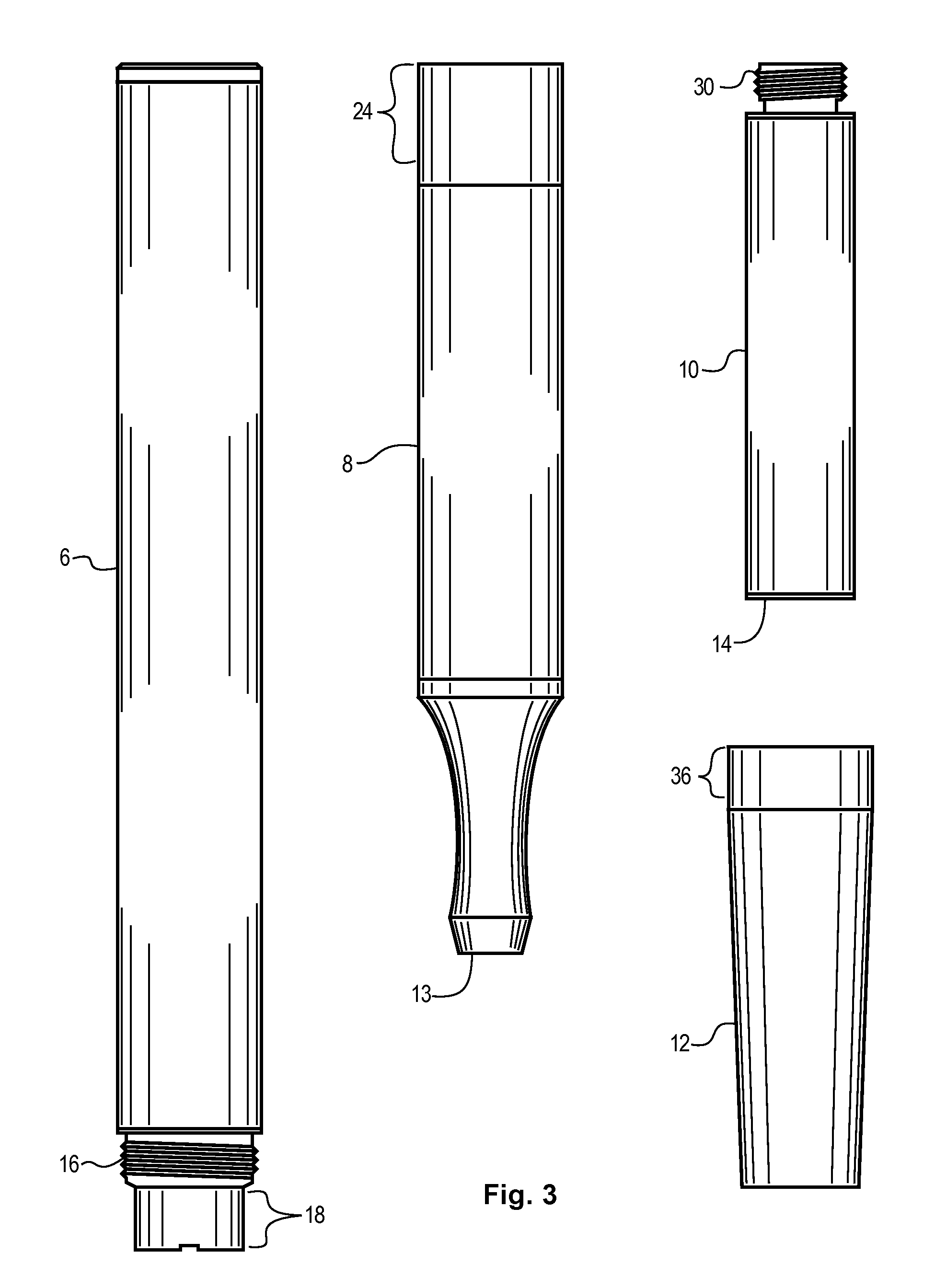

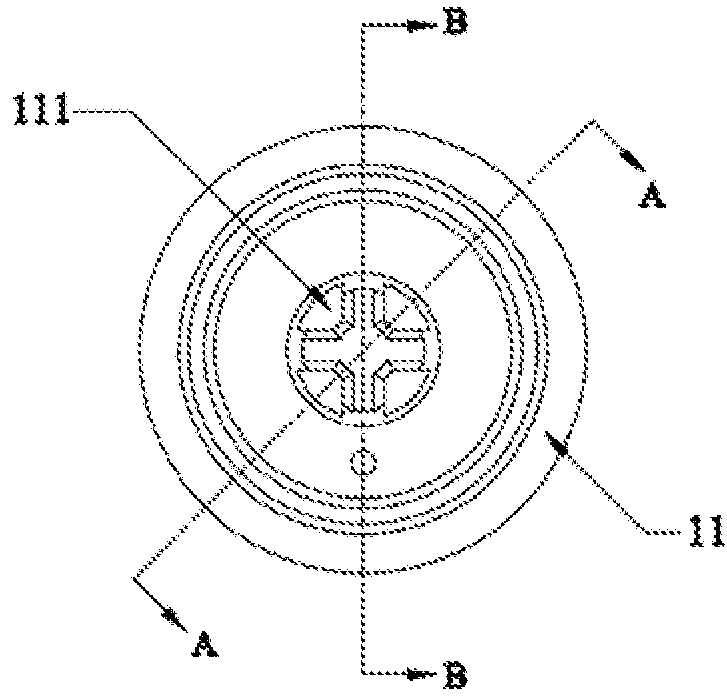

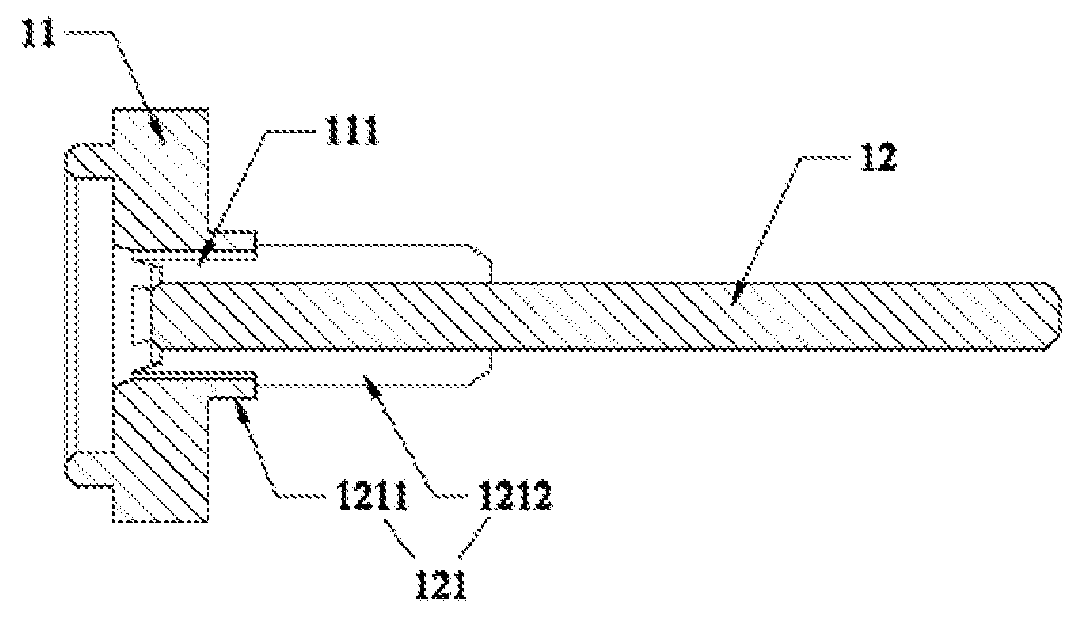

Electronic Cigarette with Dual Atomizer Cartridge Interface

An electronic cigarette with plural of atomizing assembly sizes. A battery assembly contains a battery and control circuit, with a first mechanical connector disposed adjacent to a first end, and a second mechanical connector disposed adjacent to the first connector. The electronic cigarette also has a small atomizer assembly with a mouthpiece, an atomizer, and a liquid reservoir. A small mechanical connector is designed to engage the second mechanical connector of the battery assembly. The assembly includes a connector shroud that has a shroud mechanical connector, and that tapers from a first outer periphery, which corresponds to the elongated housing size of the battery assembly, to a second outer periphery, which corresponds to the small atomizer assembly. When assembled, the mouthpiece of the small atomizing assembly is exposed beyond the second end of the connector shroud.

Owner:VAPETECH

Ethanol-free gel formulation cartridge for e-vaping device

A cartridge for an e-vaping device includes an ethanol-free gel formulation. The ethanol-free gel formulation includes a vapor former, water, and a biopolymer. The biopolymer may be included in an amount ranging from about 0.01% by weight based on the weight of the ethanol-free gel formulation to about 2.0% by weight based on the weight of the ethanol-free gel formulation. The biopolymer may be one or more of agar, kappa carrageenan, gelatin, sodium alginate, gellan gum, pectin, and combinations thereof. The cartridge also includes a heater configured to heat liquid from the gel formulation to a temperature sufficient to release a liquid / semi-liquid component from the gel, which component thereupon forms a vapor.

Owner:AKRIA CLIENT SERVICES LLC

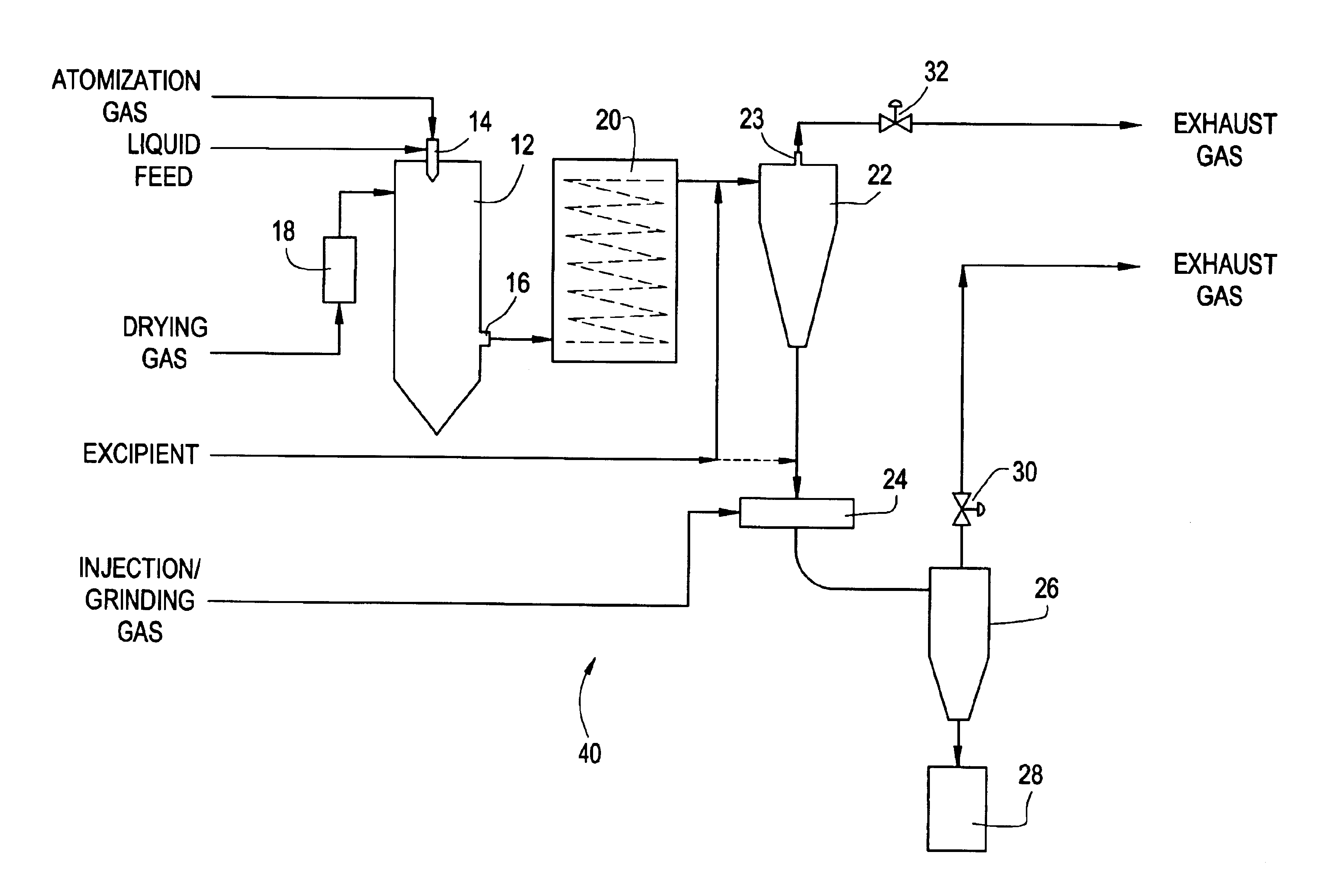

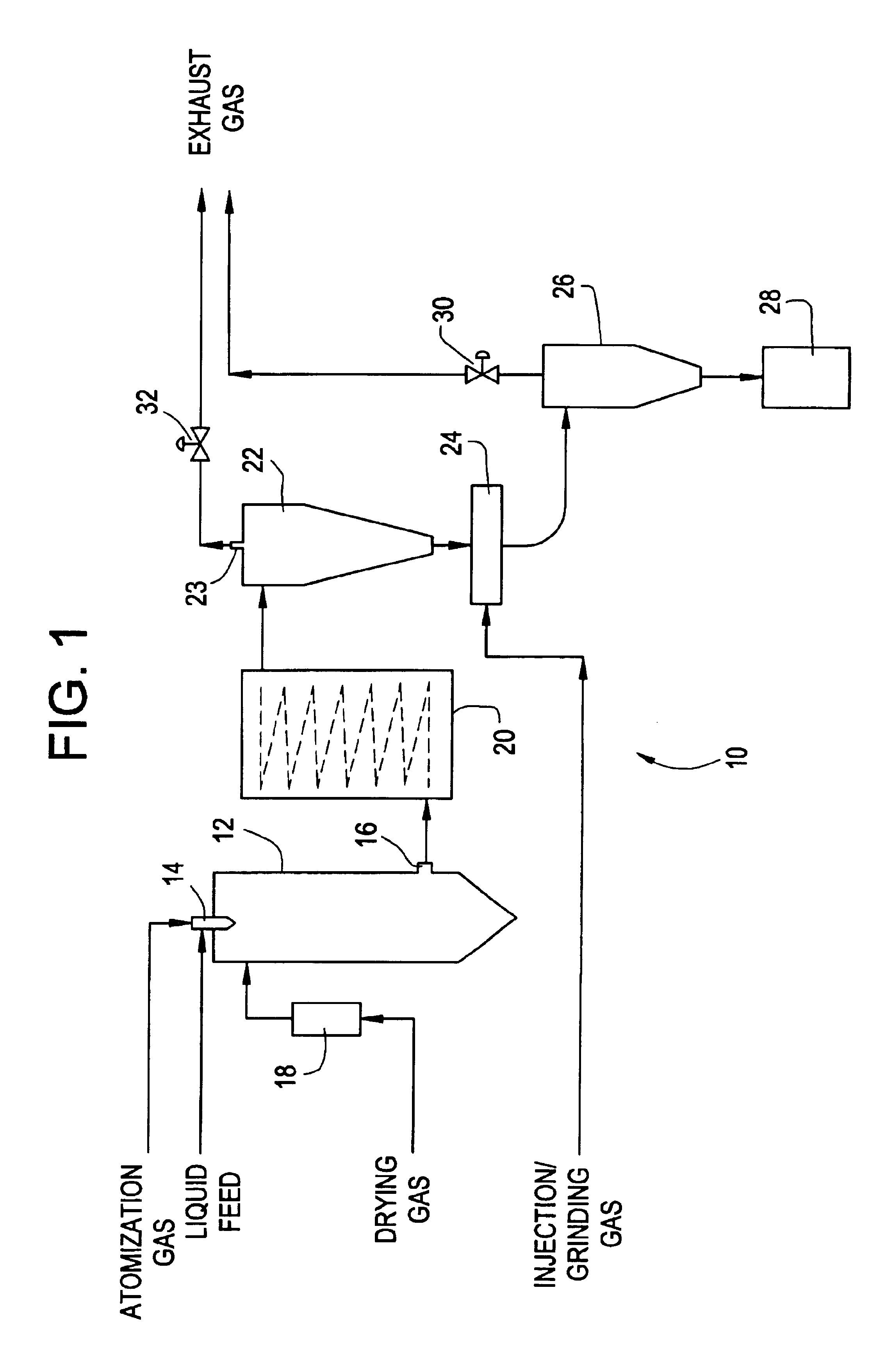

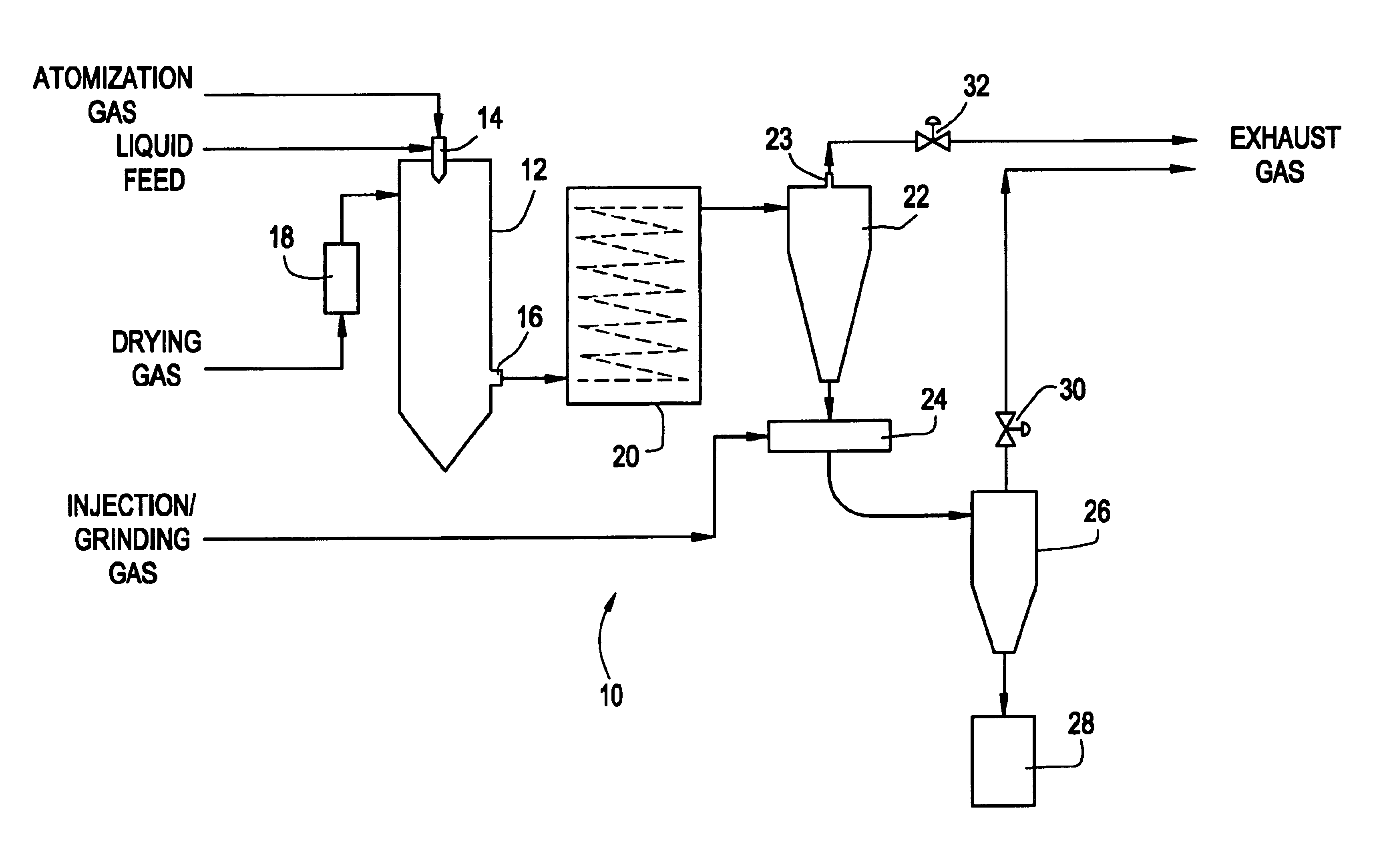

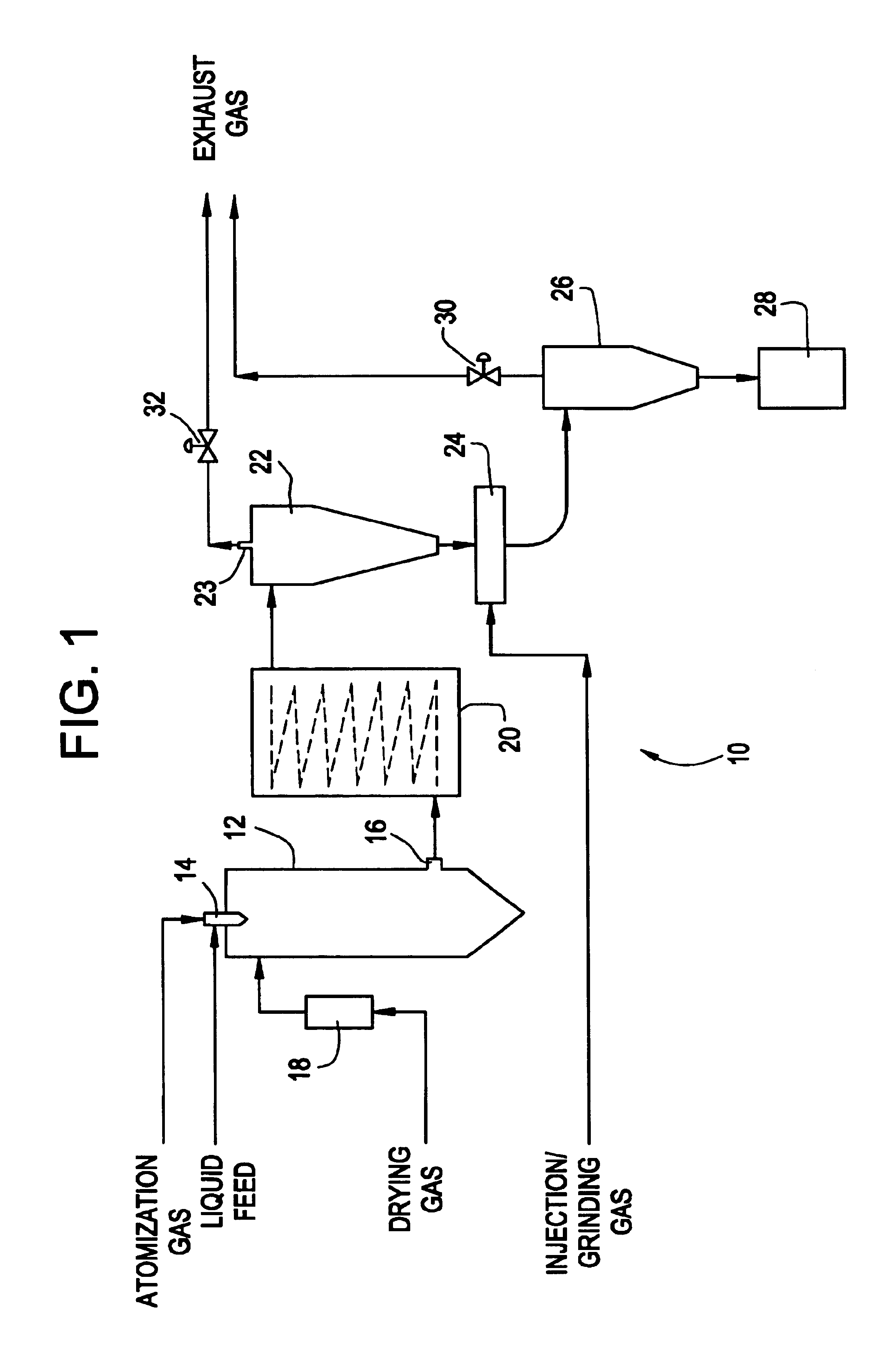

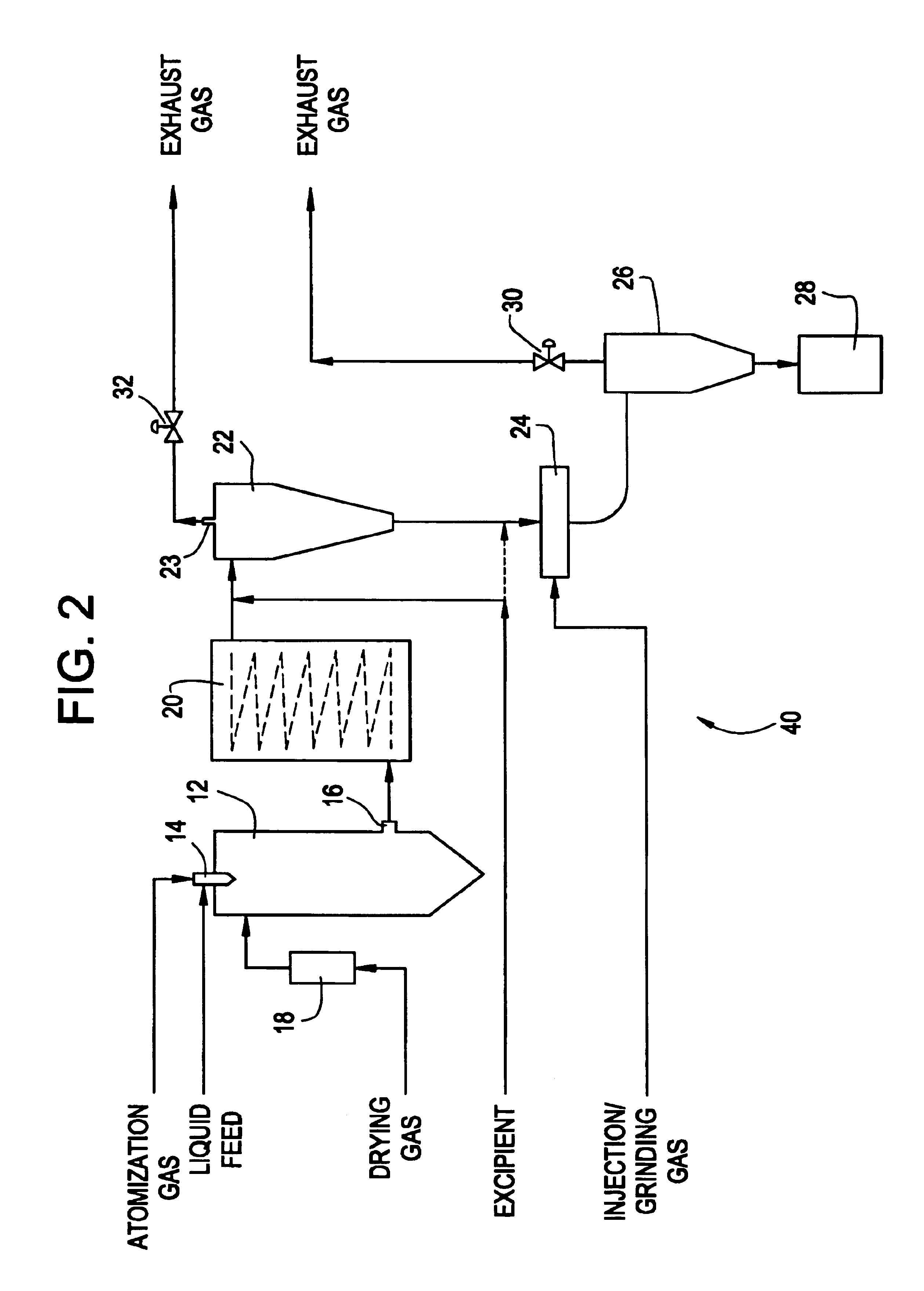

Methods and apparatus for making particles using spray dryer and in-line jet mill

InactiveUS6918991B2Reduce processing timeDrying solid materials with heatGranulation by liquid drop formationPolymer scienceEmulsion

Methods and apparatus are provided for making particles comprising: (a) spraying an emulsion, solution, or suspension, which comprises a solvent and a bulk material (e.g., a pharmaceutical agent), through an atomizer and into a primary drying chamber, having a drying gas flowing therethrough, to form droplets comprising the solvent and bulk material dispersed in the drying gas; (b) evaporating, in the primary drying chamber, at least a portion of the solvent into the drying gas to solidify the droplets and form particles dispersed in drying gas; and (c) flowing the particles and at least a portion of the drying gas through a jet mill to deagglomerate or grind the particles. By coupling spray drying with “in-line” jet milling, a single step process is created from two separate unit operations, and an additional collection step is advantageously eliminated. The one-step, in-line process has further advantages in time and cost of processing.

Owner:ACUSPHERE INC

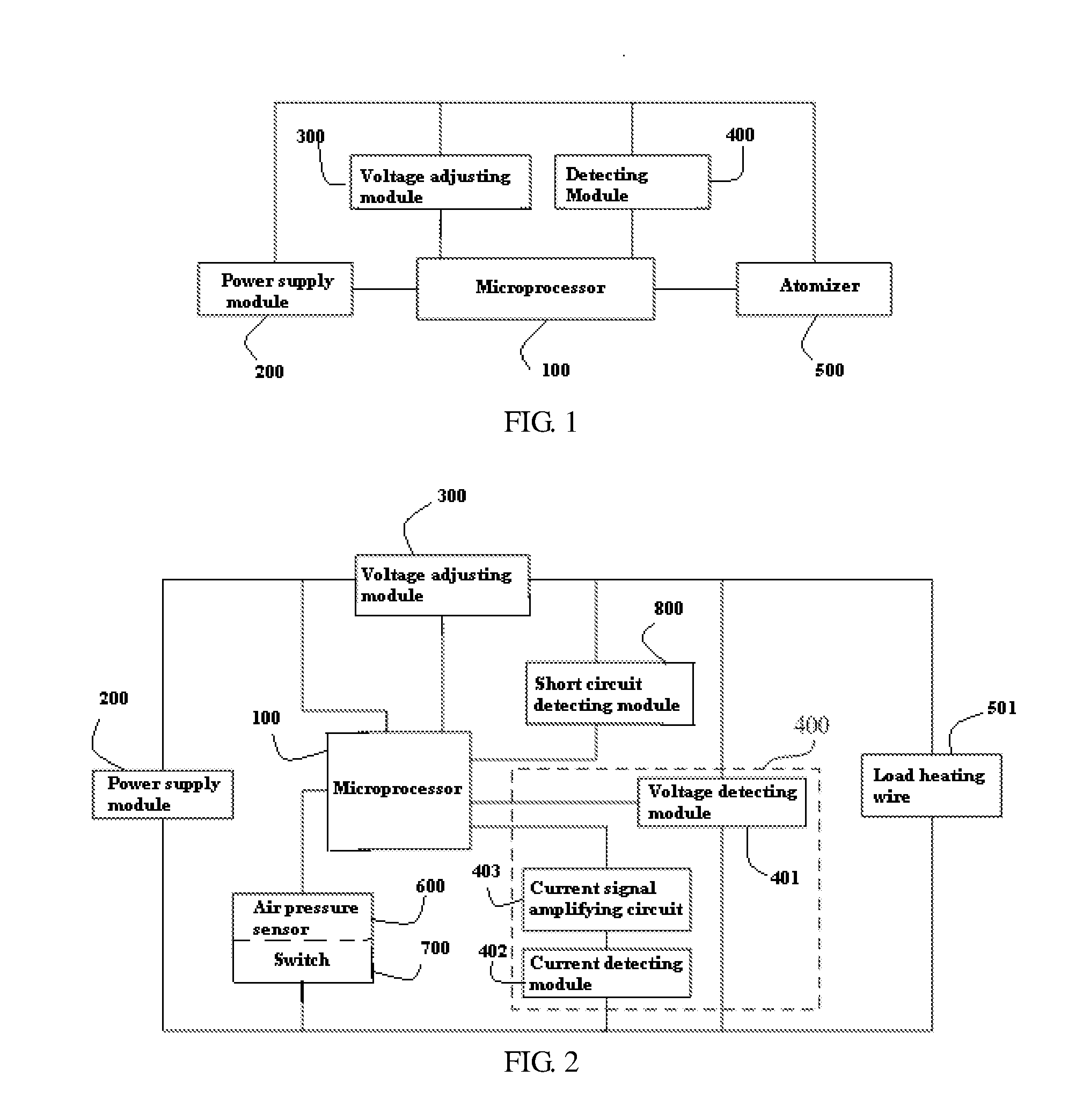

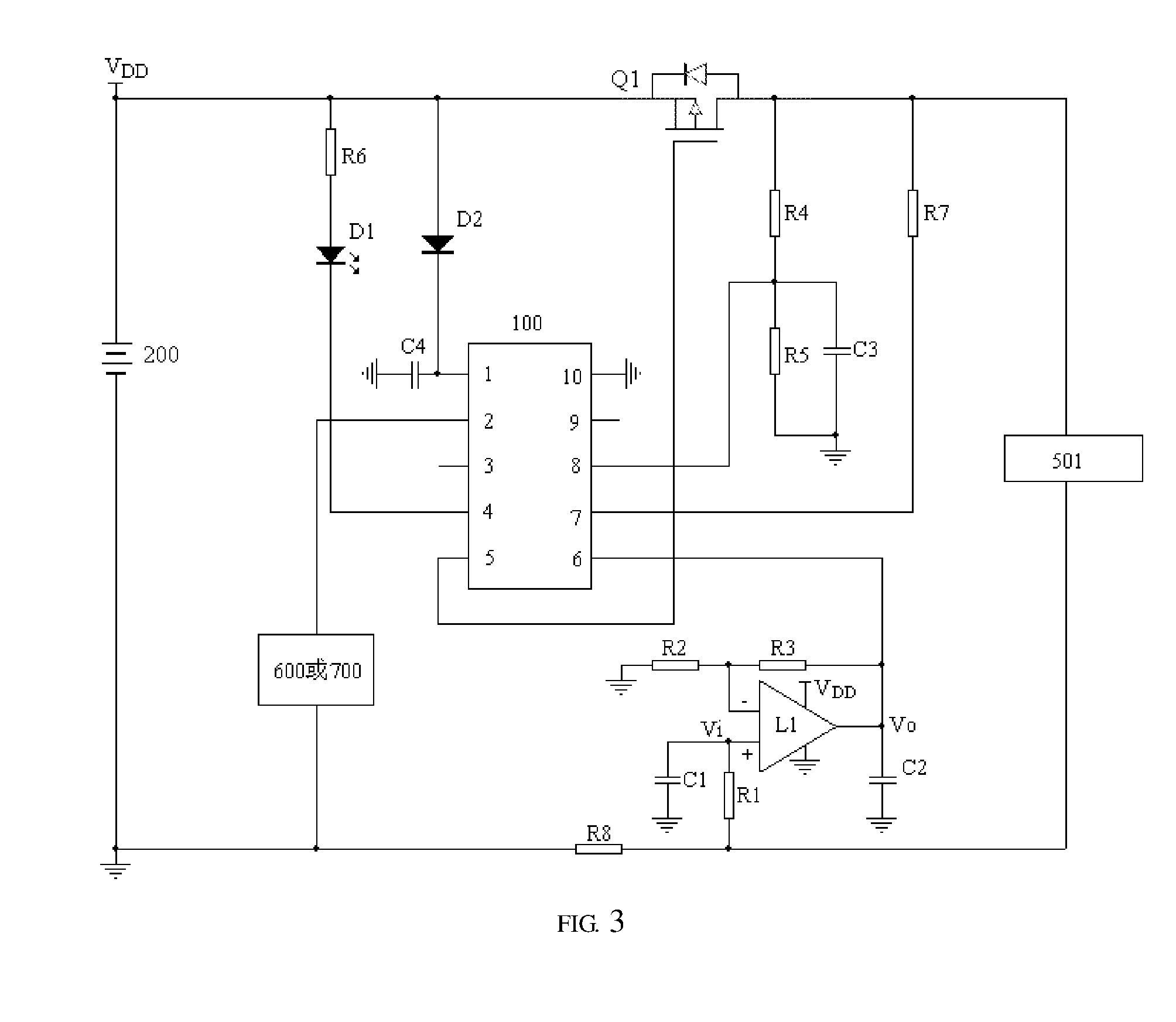

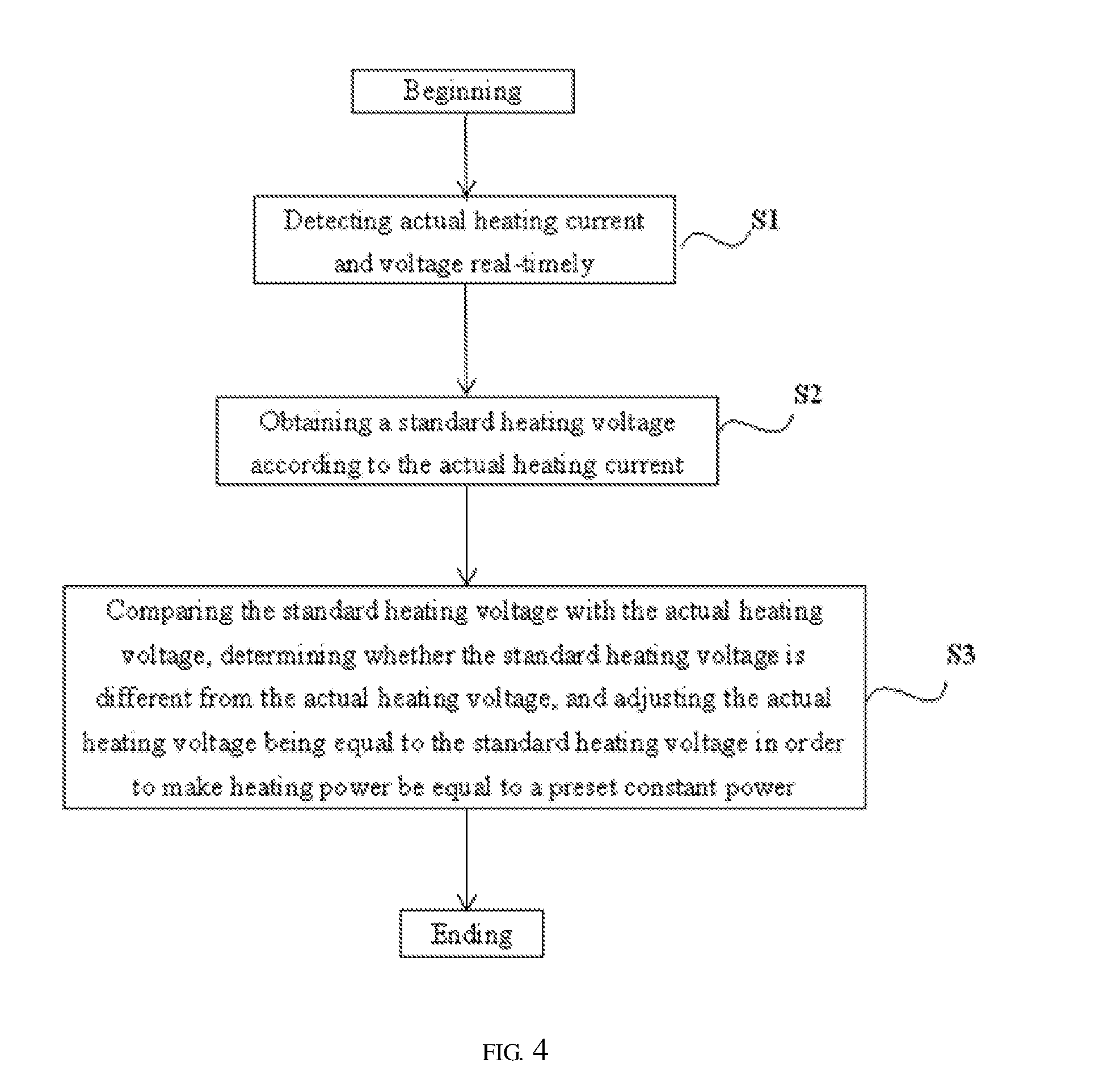

Electronic cigarette and method for supplying constant power therein

InactiveUS20160143359A1Meeting demandMeet needsSteam generation using steam absorptionElectric heatingVoltage regulator moduleConstant power

An electronic cigarette and a method for supplying a constant power therein, the electronic cigarette comprises an atomizer with a heating wire. The electronic cigarette also comprises a power supply module for supplying power to the heating wire to heat the heating wire, and further comprises a microprocessor, a detecting module connected to the microprocessor, and a voltage adjusting module. A preset constant power can supply to the heating wire of the atomizer in the electronic cigarette, so that a consistent heating power can be applied to each of the electronic cigarettes produced in batch production, and smoke amount and flavor of each of the electronic cigarettes are more consistent, thereby better meeting demands of consumers.

Owner:HUIZHOU KIMREE TECH

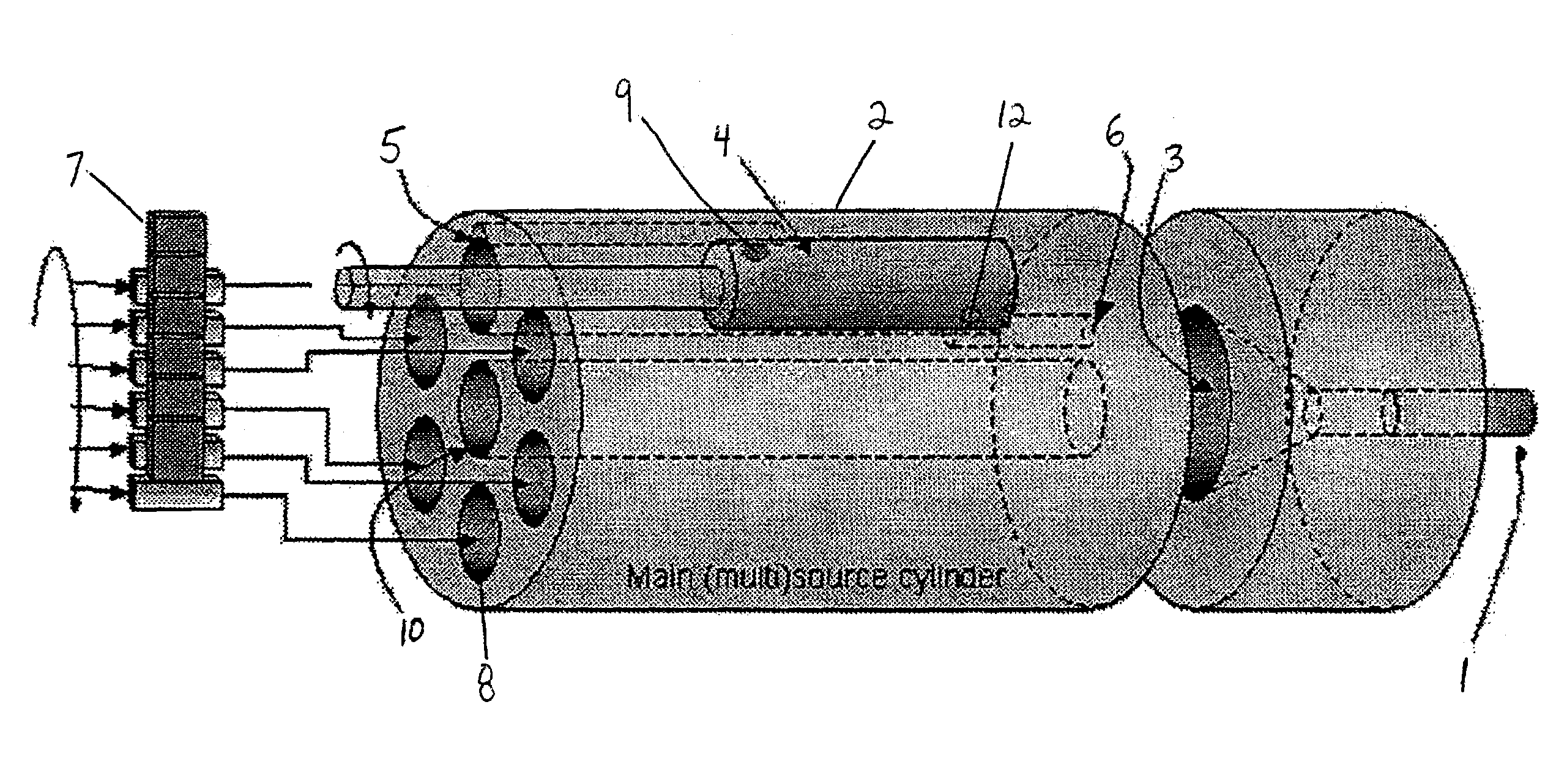

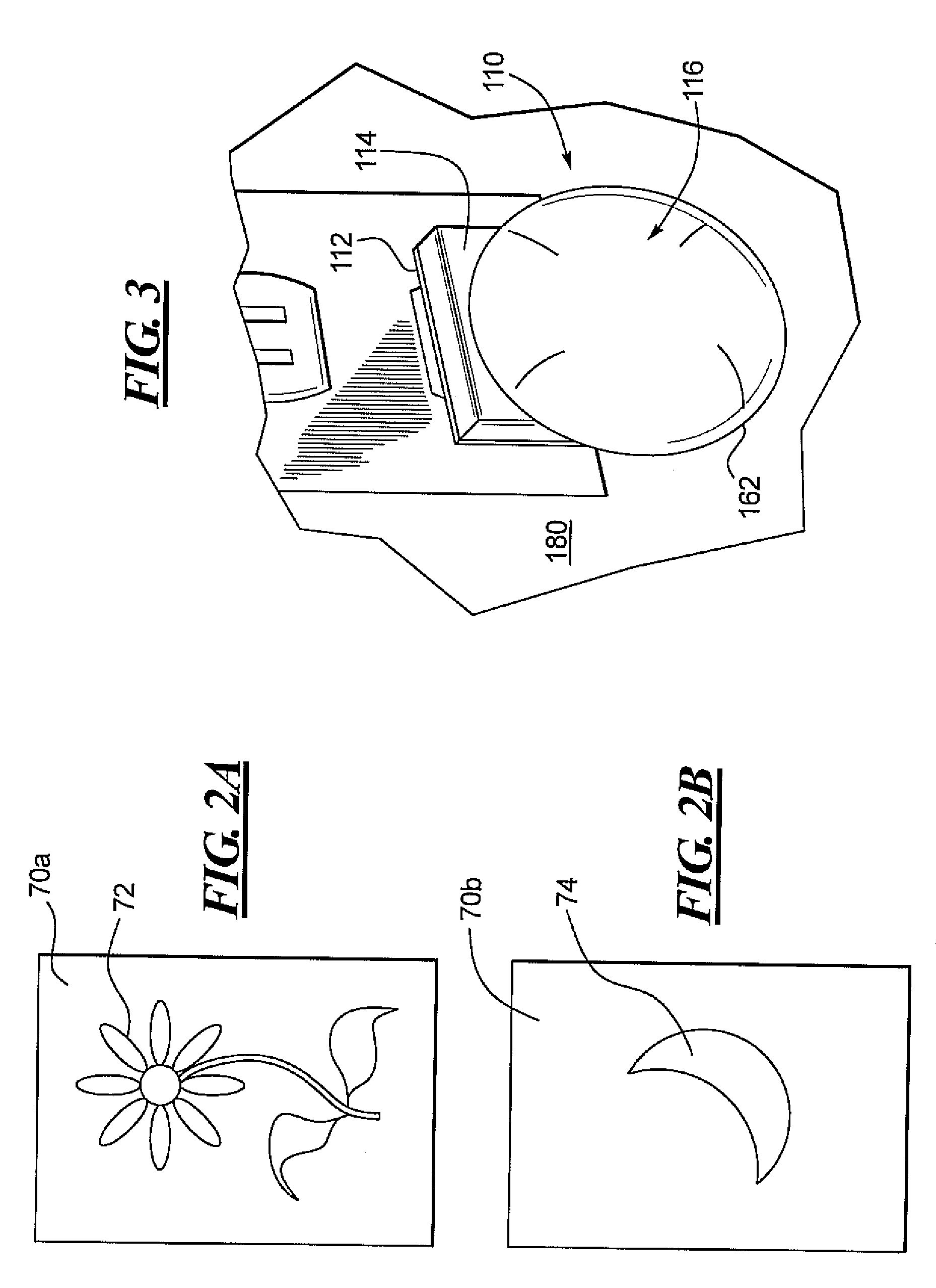

Device and method for organic vapor jet deposition

A device and a method for facilitating the deposition and patterning of organic materials onto substrates utilizing the vapor transport mechanisms of organic vapor phase deposition is provided. The device includes one or more nozzles, and an apparatus integrally connected to the one or more nozzles, wherein the apparatus includes one or more source cells, a carrier gas inlet, a carrier gas outlet, and a first valve capable of controlling the flow of a carrier gas through the one or more source cells. The method includes moving a substrate relative to an apparatus, and controlling the composition of the organic material and / or the rate of the organic material ejected by the one or more nozzles while moving the substrate relative to the apparatus, such that a patterned organic layer is deposited over the substrate.

Owner:THE TRUSTEES FOR PRINCETON UNIV

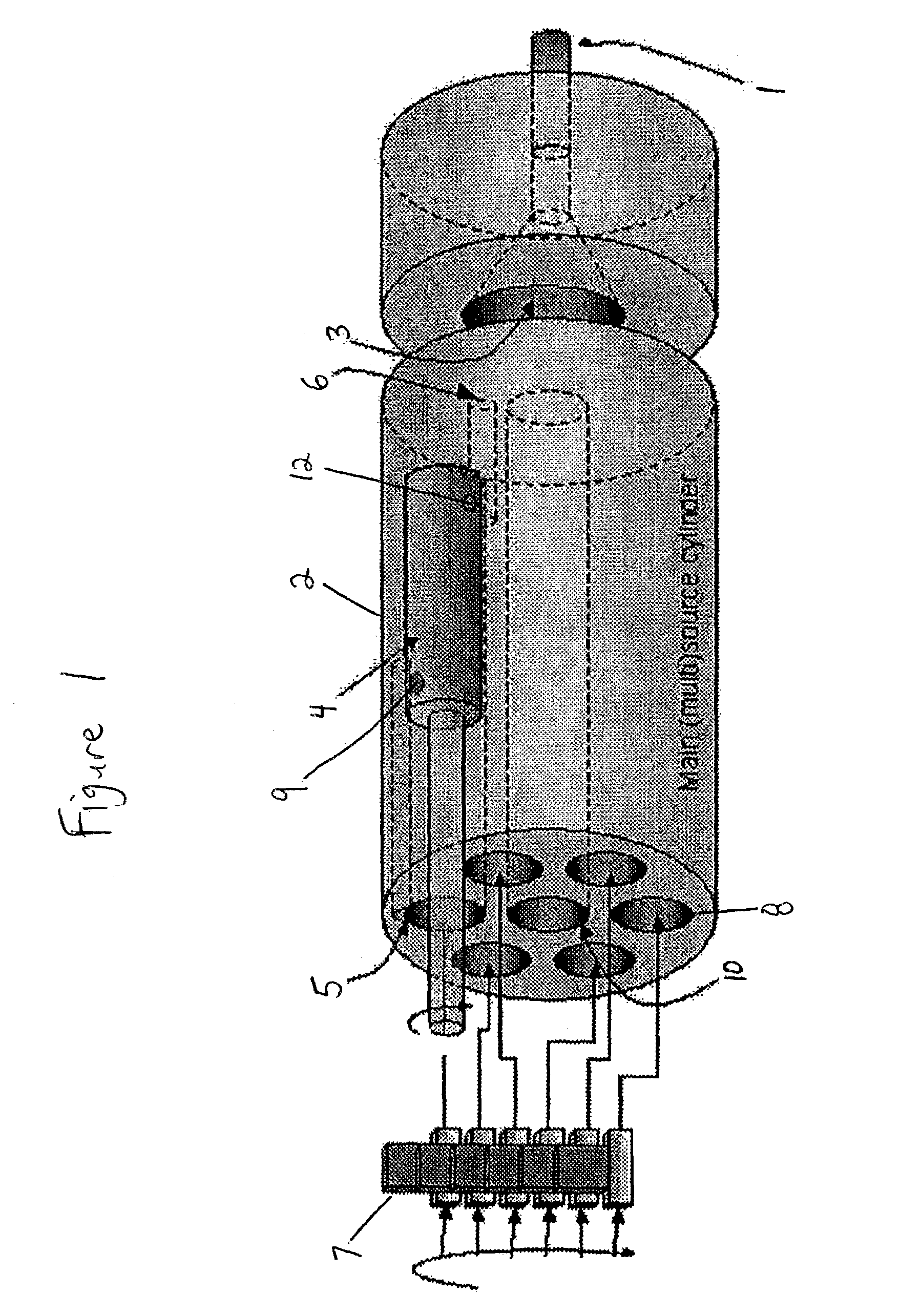

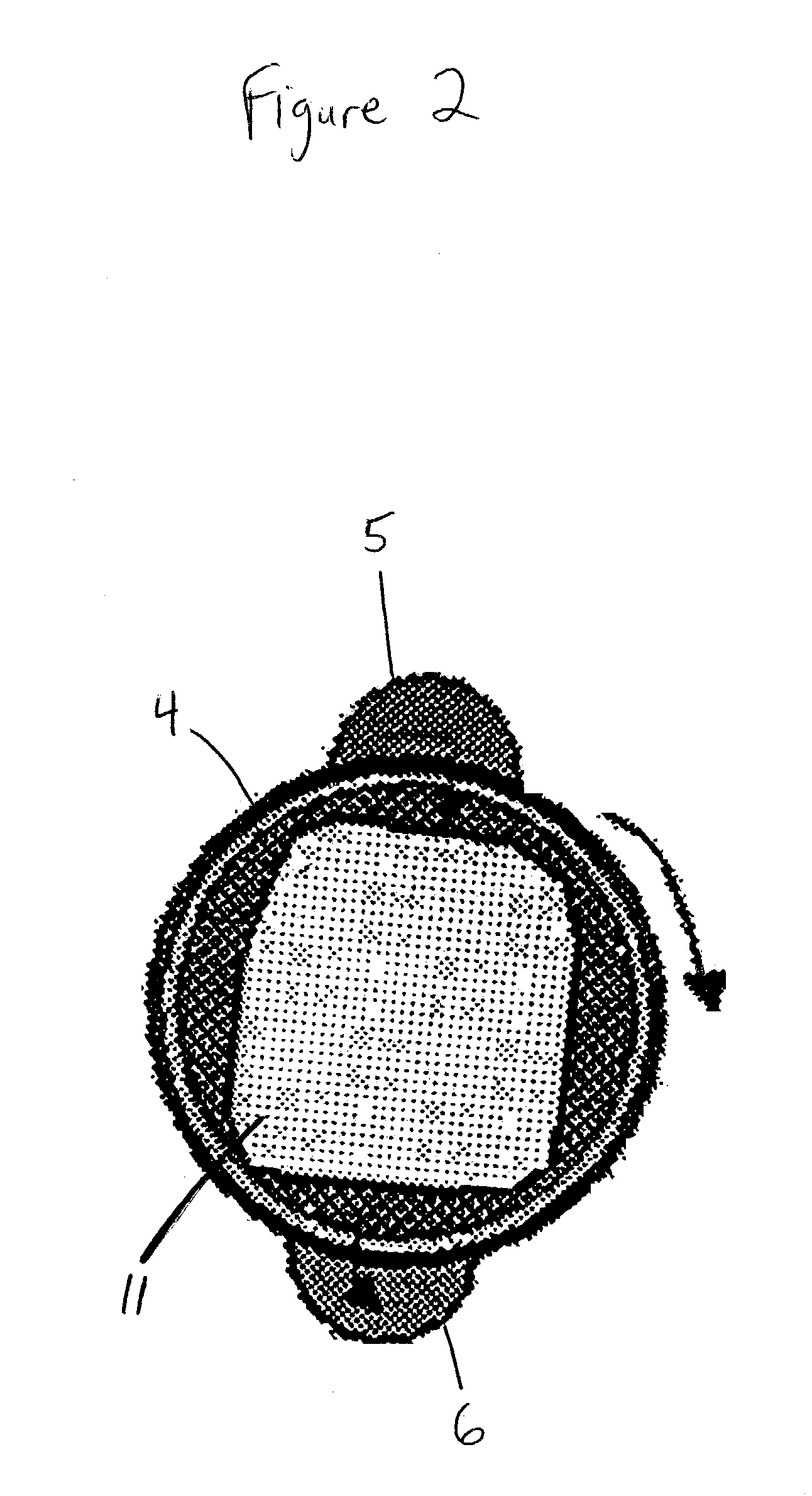

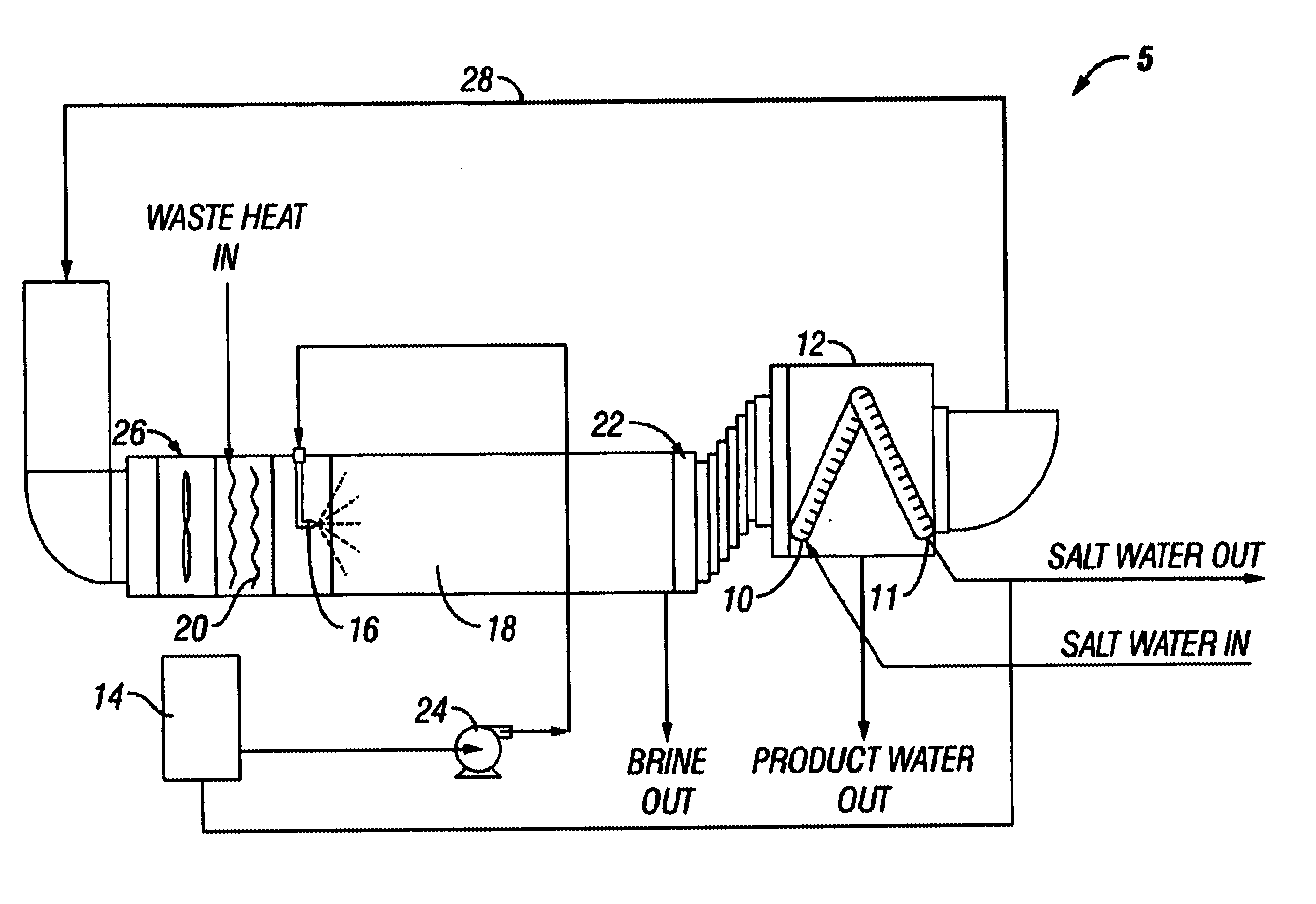

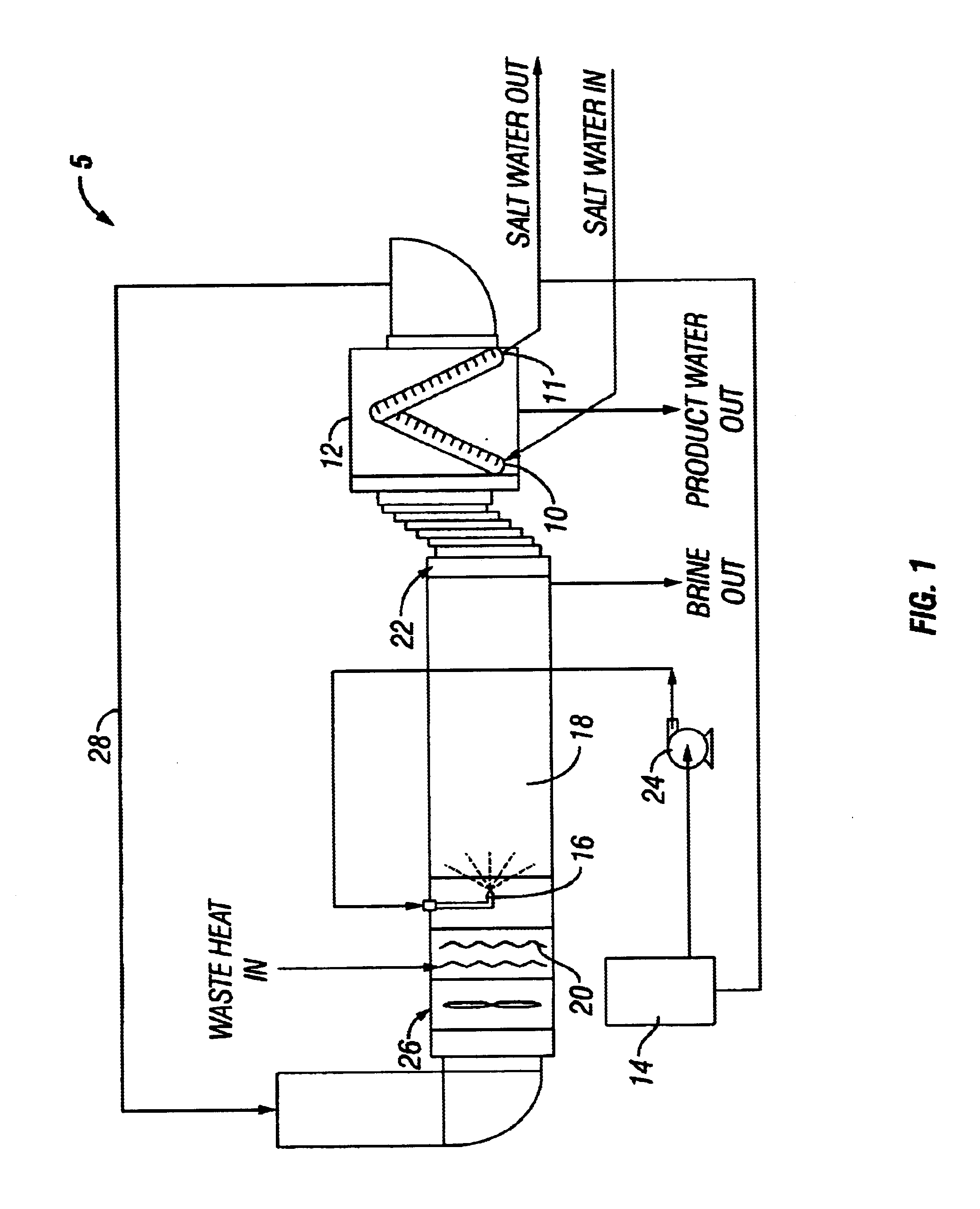

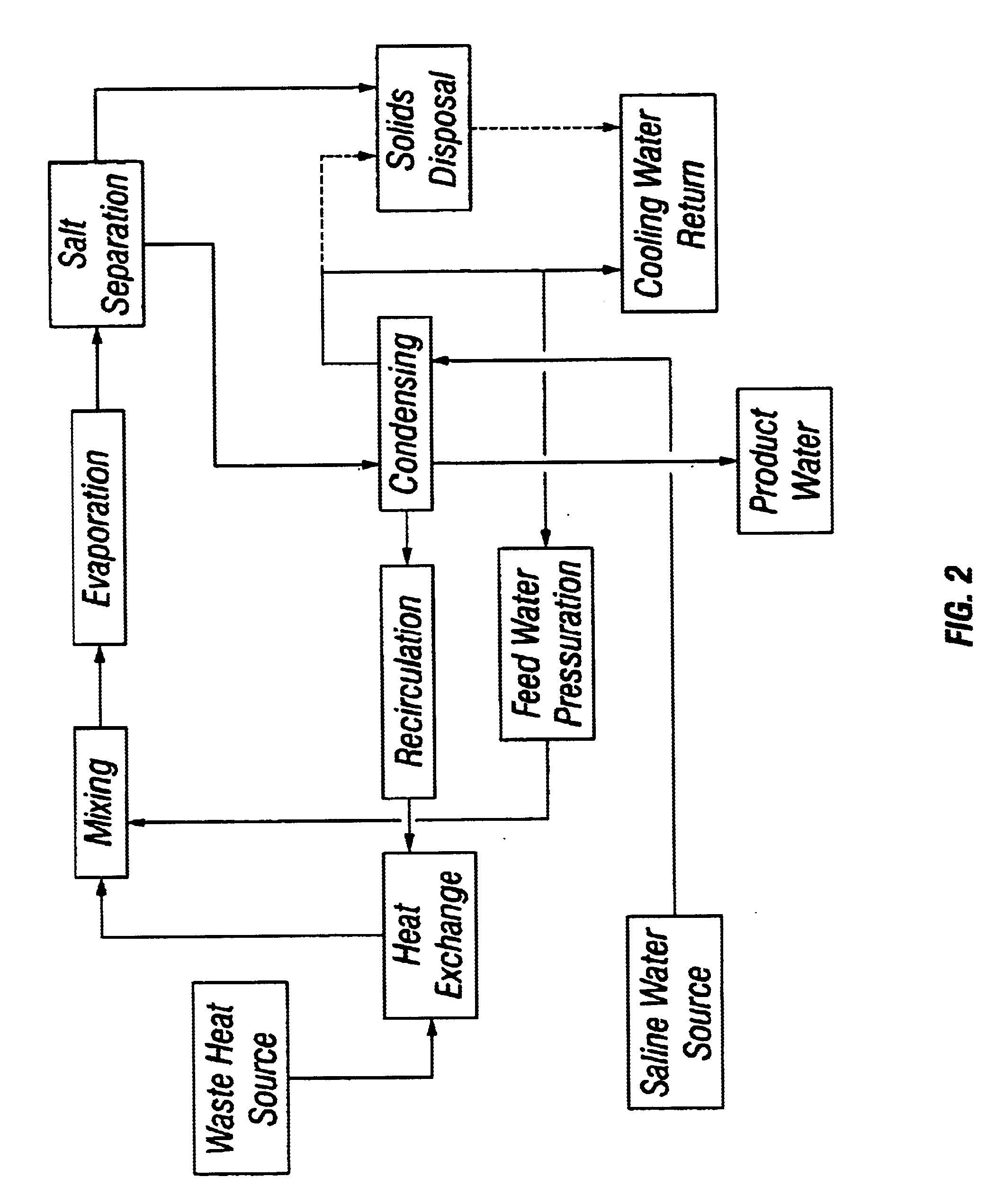

Apparatus and method for thermal desalination based on pressurized formation and evaporation of droplets

A method for removing dissolved solids, particularly salts, from water. An apparatus for performing the inventive method is disclosed. The aqueous solution to be treated, for example sea water, is atomized using special non-pneumatic nozzles, and sprayed into an evaporation chamber through which air, heated by waste heat, is blown. The micro-droplets undergo rapid evaporation in the chamber, resulting in the separation of the salt solids from the vapor phase of the water. The mixture of suspended solids and water vapor is filtered to remove and collect the salts, and the water vapor is condensed to collect the salt-free water.

Owner:AQUASONICS RSE INC

Methods and apparatus for making particles using spray dryer and in-line jet mill

InactiveUS6921458B2Reduce processing timeDrying solid materials with heatGranulation by liquid drop formationPolymer scienceEmulsion

Methods and apparatus are provided for making particles comprising: (a) spraying an emulsion, solution, or suspension, which comprises a solvent and a bulk material (e.g., a pharmaceutical agent), through an atomizer and into a primary drying chamber, having a drying gas flowing therethrough, to form droplets comprising the solvent and bulk material dispersed in the drying gas; (b) evaporating, in the primary drying chamber, at least a portion of the solvent into the drying gas to solidify the droplets and form particles dispersed in drying gas; and (c) flowing the particles and at least a portion of the drying gas through a jet mill to deagglomerate or grind the particles. By coupling spray drying with “in-line” jet milling, a single step process is created from two separate unit operations, and an additional collection step is advantageously eliminated. The one-step, in-line process has further advantages in time and cost of processing.

Owner:ACUSPHERE INC

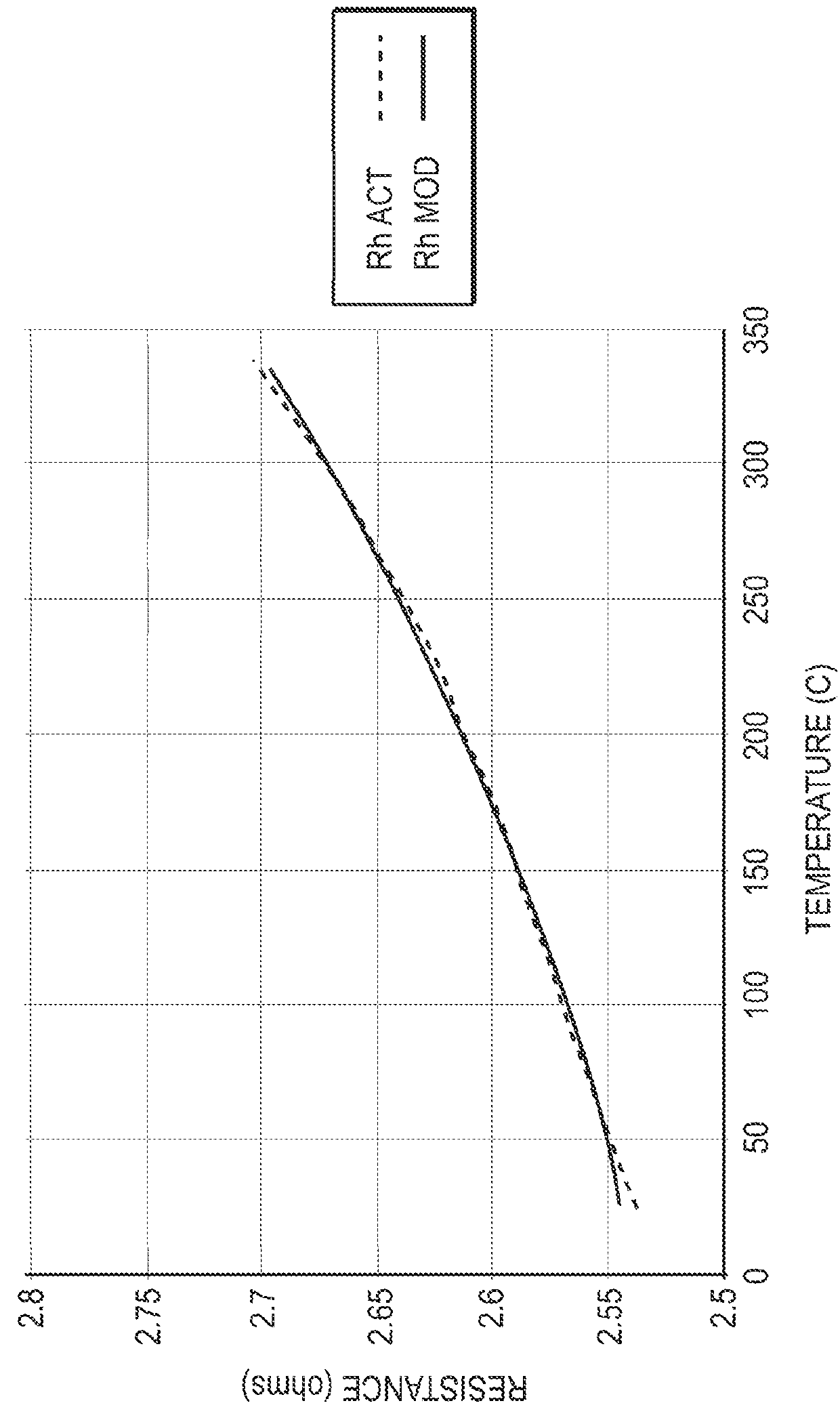

Heating control for vaporizing device

ActiveUS20160053988A1Machines/enginesGaseous substancesElectrical resistance and conductanceElectronic communication

The temperature of a vaporizing device, e.g., the temperature of a heating element of the vaporizing device, may be controlled according to various aspects of the present disclosure. The vaporizing device may comprise a heating element, a power source, at least one sensor in electronic communication with the heating element and the power source, and a processor configured to control the temperature of the heating element. The method of controlling the temperature may comprise receiving a resistance measurement of the heating element from the at least one sensor, determining the temperature of the heating element based on the resistance measurement, and adjusting the amount of power supplied to the heating element based on the determined temperature of the heating element.

Owner:NJOY LLC

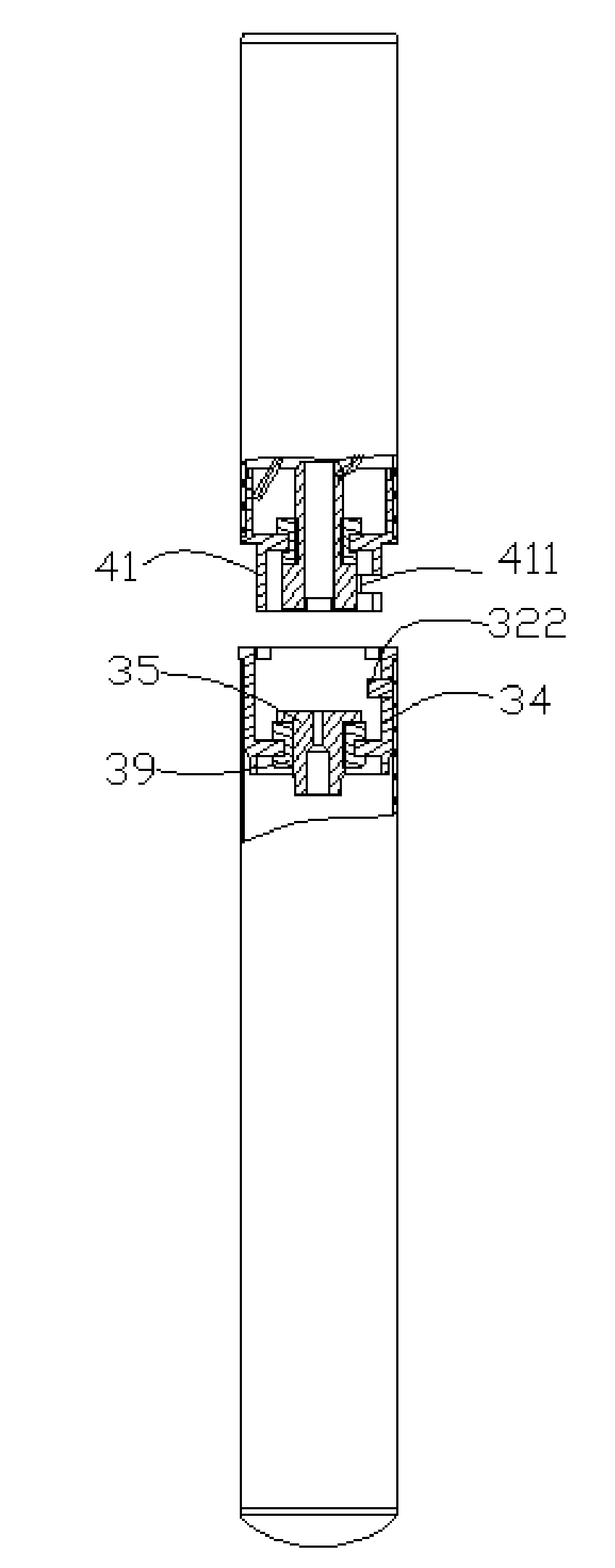

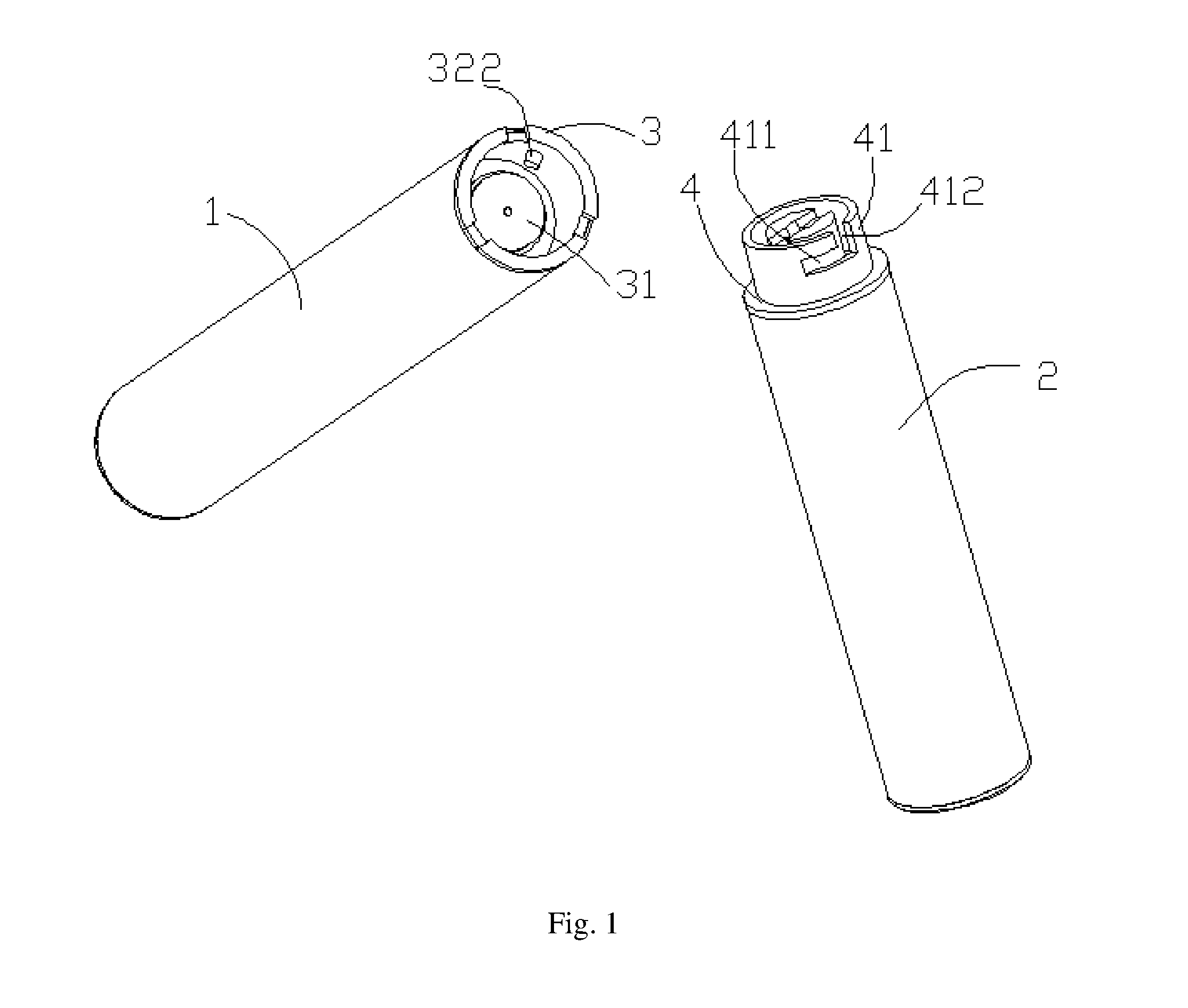

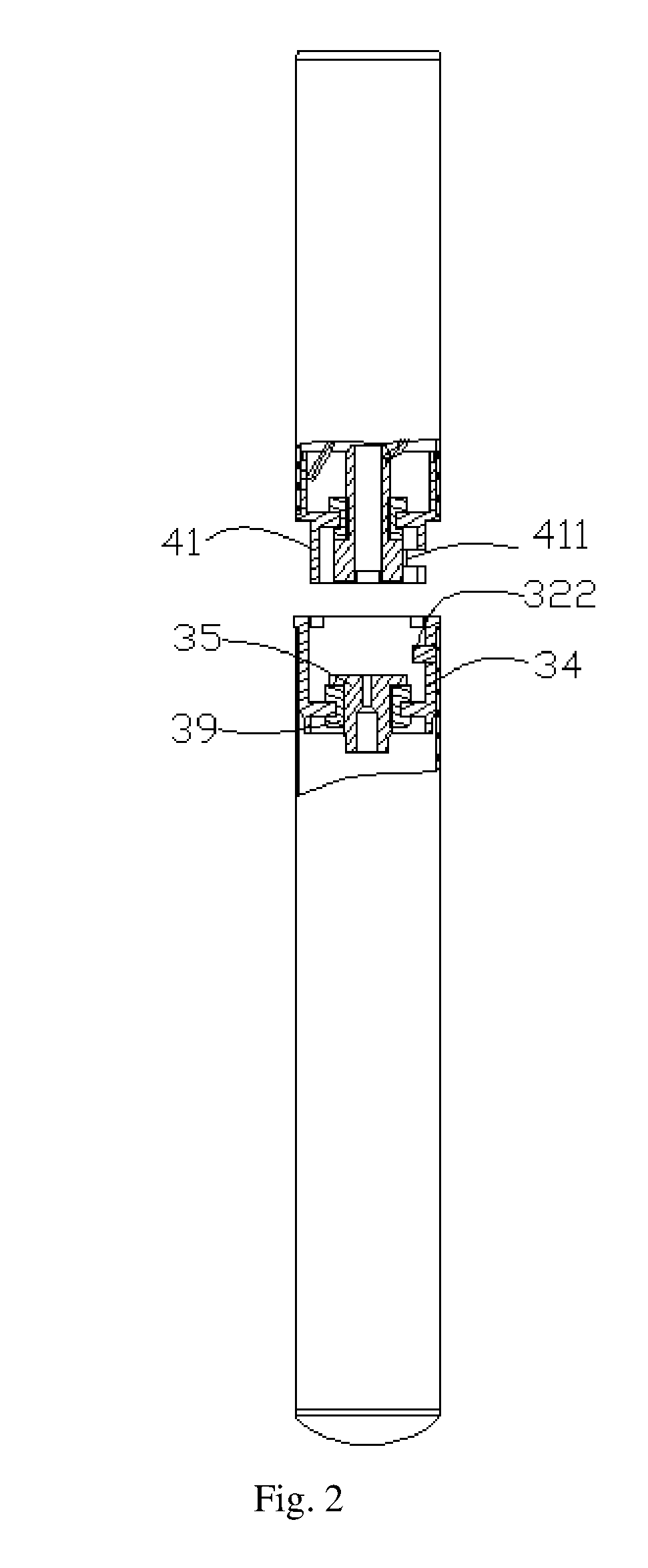

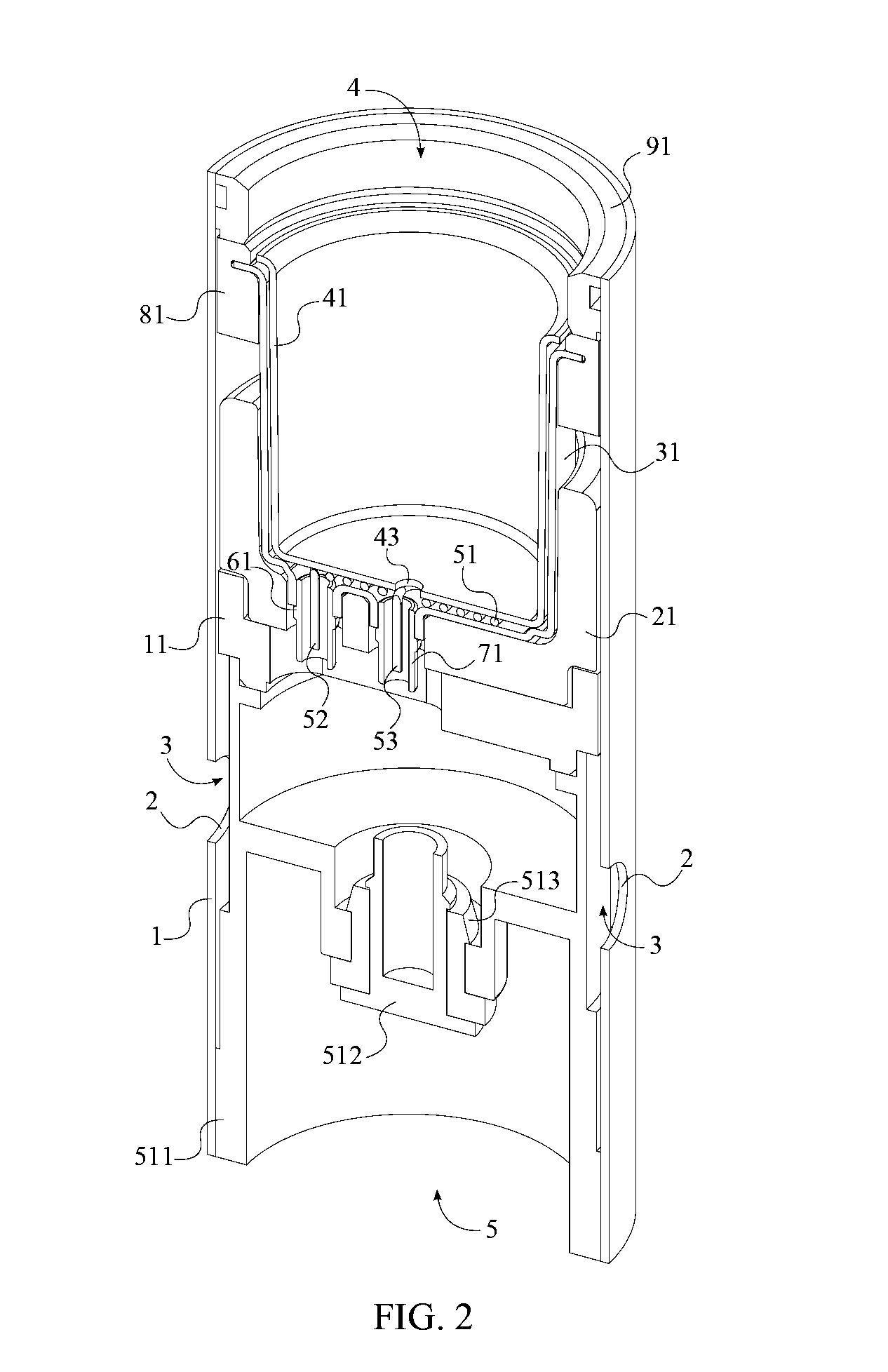

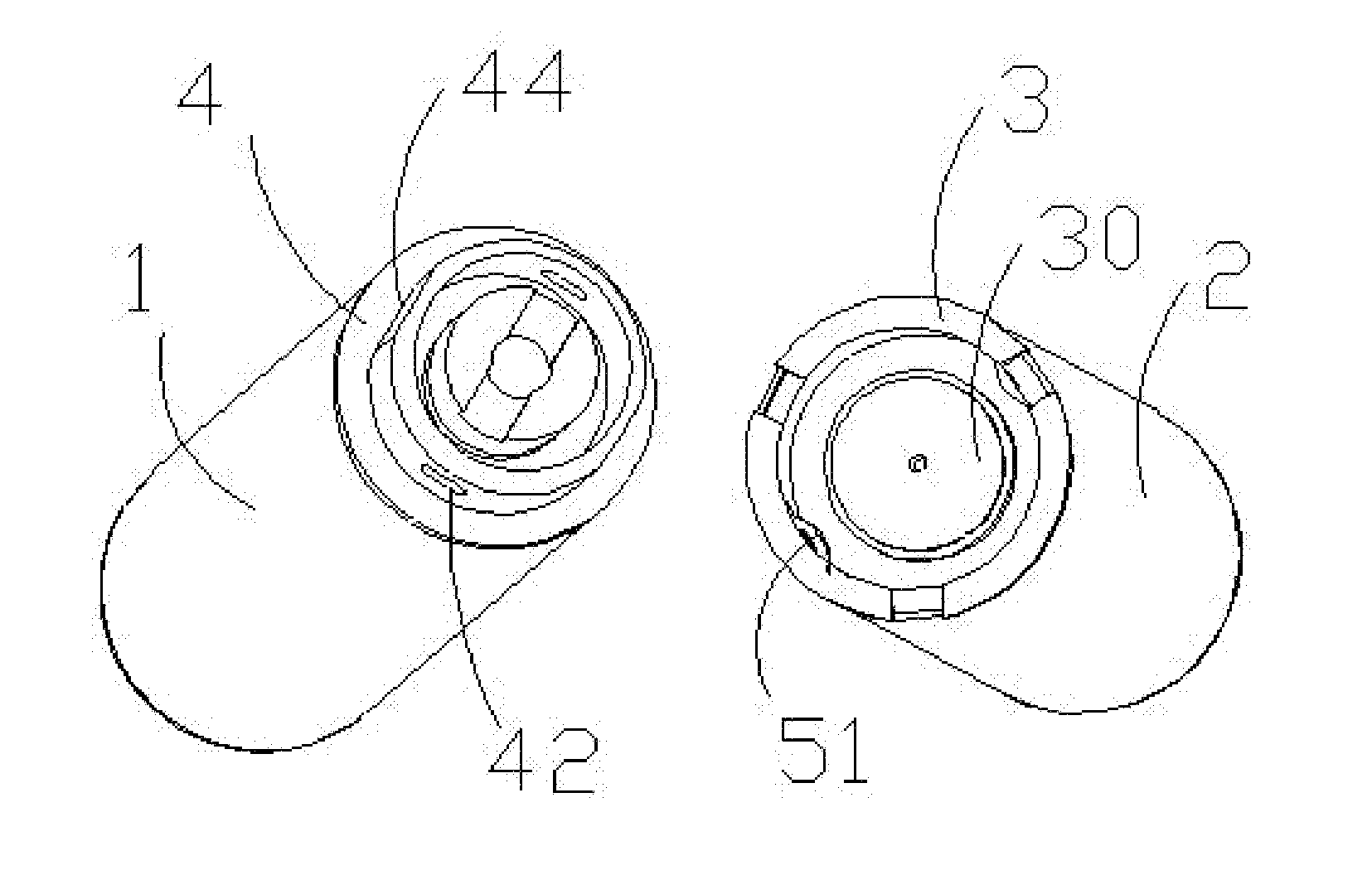

Electronic cigarette

InactiveUS20160183593A1Easy to replaceQuick assemblyTobacco devicesMachines/enginesElectronic cigaretteEngineering

An electronic cigarette comprises an atomizer (1) and a battery rod (2). A connecting structure is provided at where the atomizer (3) and the battery rod (2) are connected. The connecting structure comprises a first connecting element (3) and a second connecting element (4) that are docked with each other. The first connecting element (3) is provided with a docking groove (31) used for insertion of the second connecting element (4). An engaging part is provided within the docking groove (31). An engaging-retaining notch extended to an end face of the second connecting element (4) is provided at an outer-side extremity of the second connecting element (4) in proximity to the first connecting element (3). When engaging, the engaging part is inserted along the engaging-retaining notch and is rotated and engaged on the engaging notch.

Owner:HUIZHOU KIMREE TECH

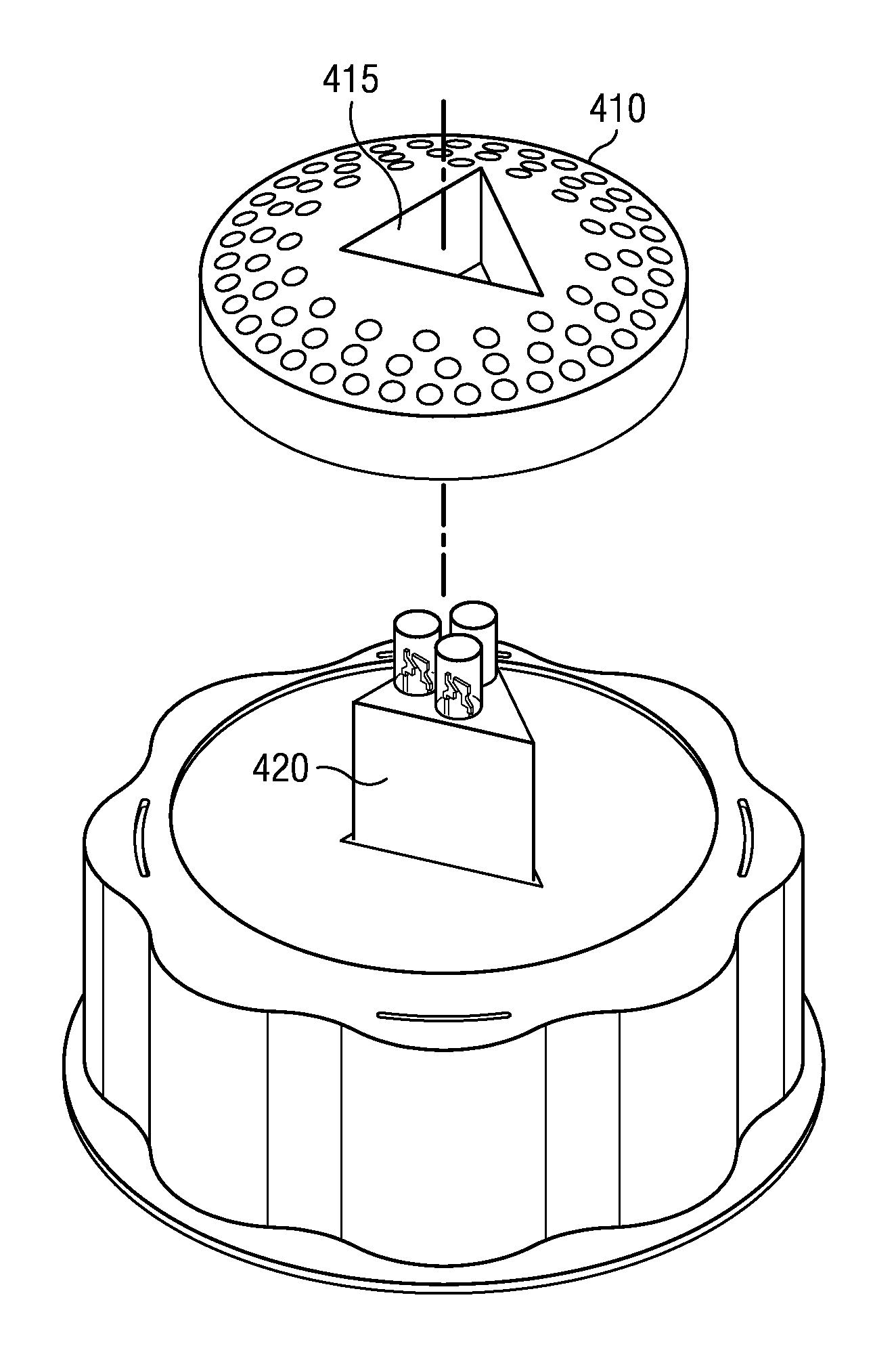

Electric Vaporizer Heating Assembly with Dual Anodized Heating Compartments

InactiveUS20140314397A1Steam generation using steam absorptionTobacco devicesElectricityElectrical connection

An electric vaporizer heating chamber that provides a user with two options for heating various smoke forming substances has a first heating compartment and a second heating compartment. The first heating compartment and second heating compartment are enclosed by a chamber casing and are positioned in between a lower heat insulator and an upper heat insulator. The first heating compartment is supported by a heater seat which also insulates the chamber casing. A heating coil is positioned within the first heating compartment and allows substances placed in the first heating compartment to be combusted. The second heating compartment can be placed within the first heating compartment overtop of the heating coil in order to vaporize substances placed in the second heating compartment. A battery connector is also housed within the chamber casing and provides electrical connections for supplying current to the heating coil in order to heat the heating coil.

Owner:ATMOS NATION

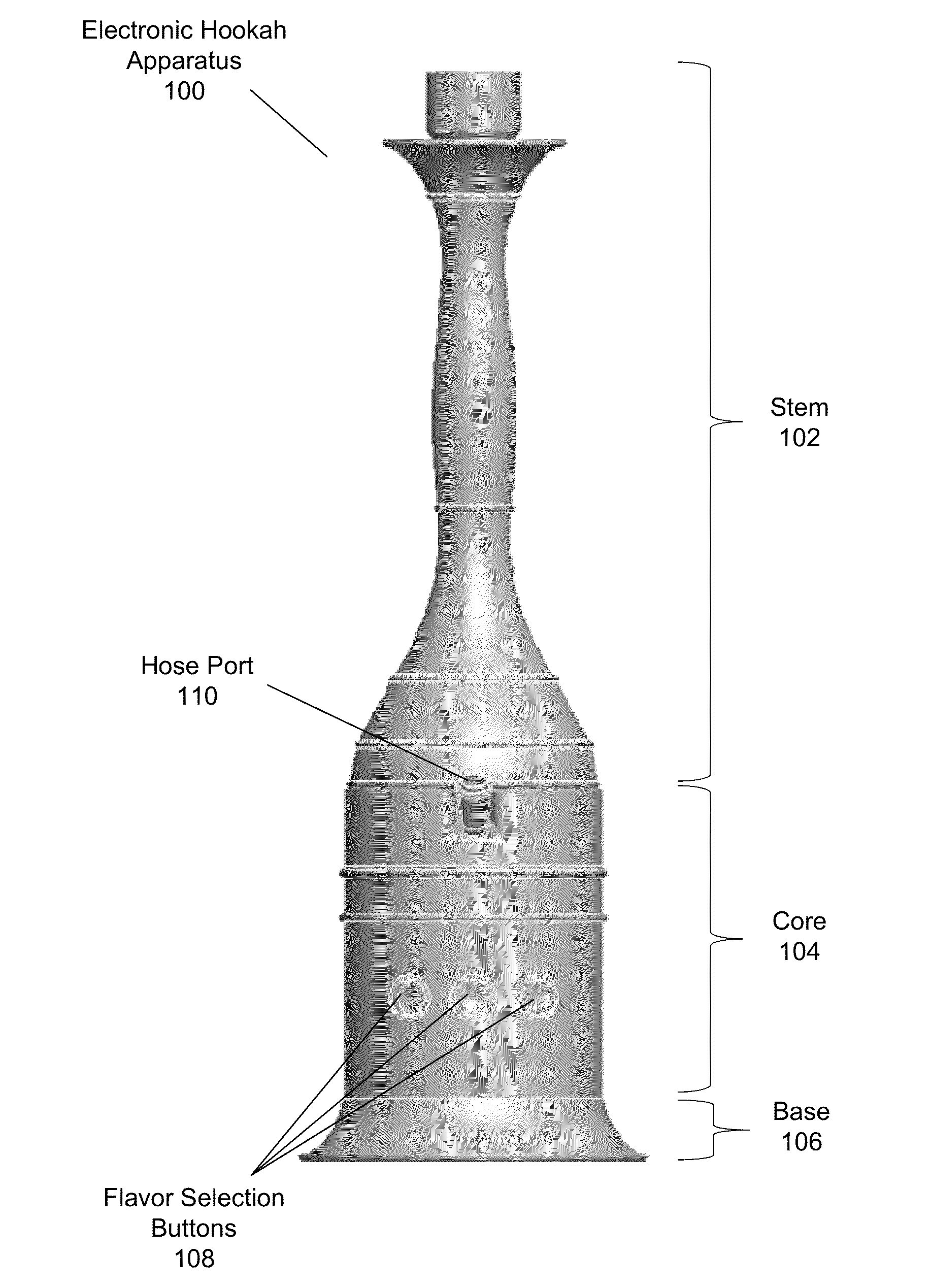

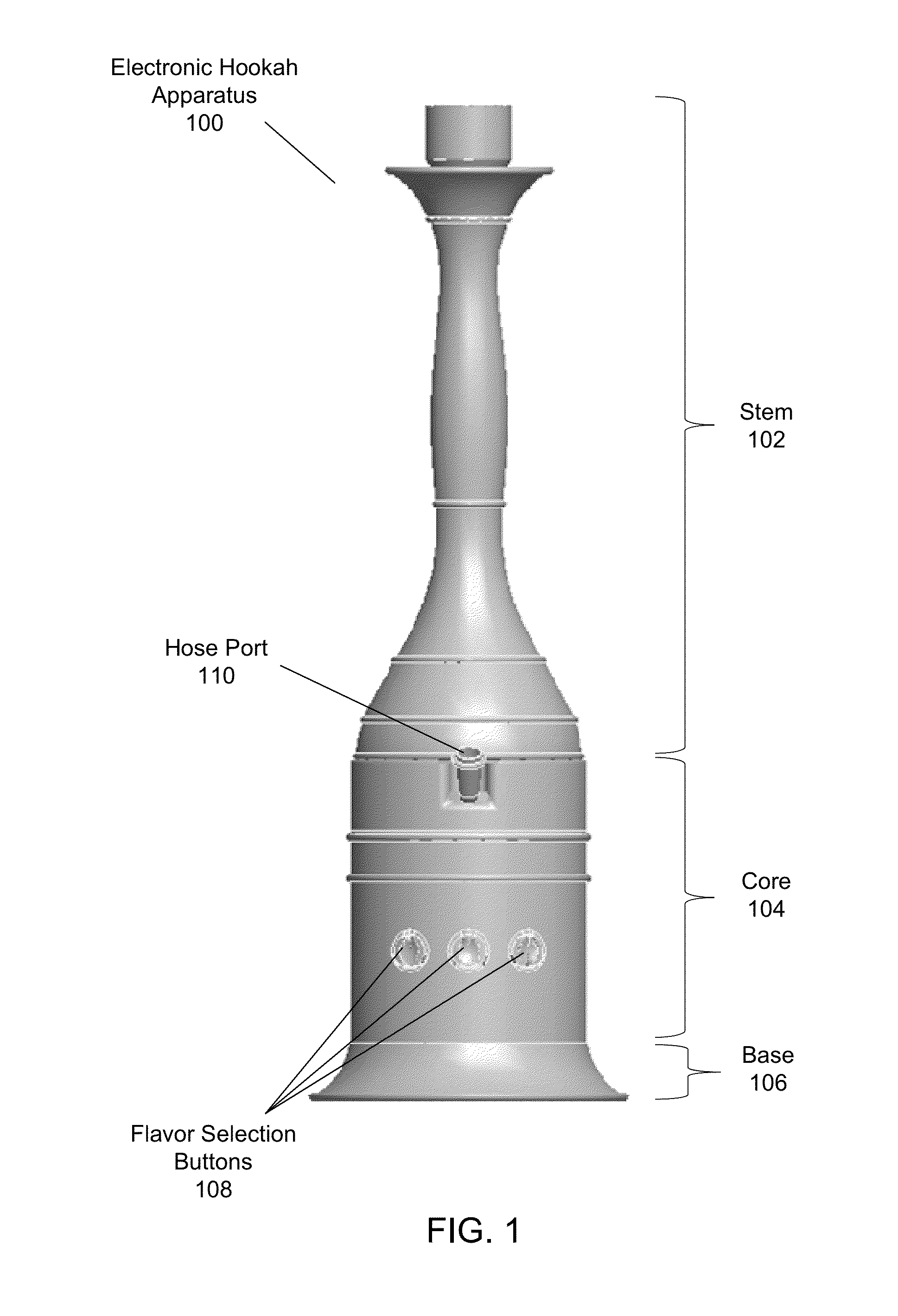

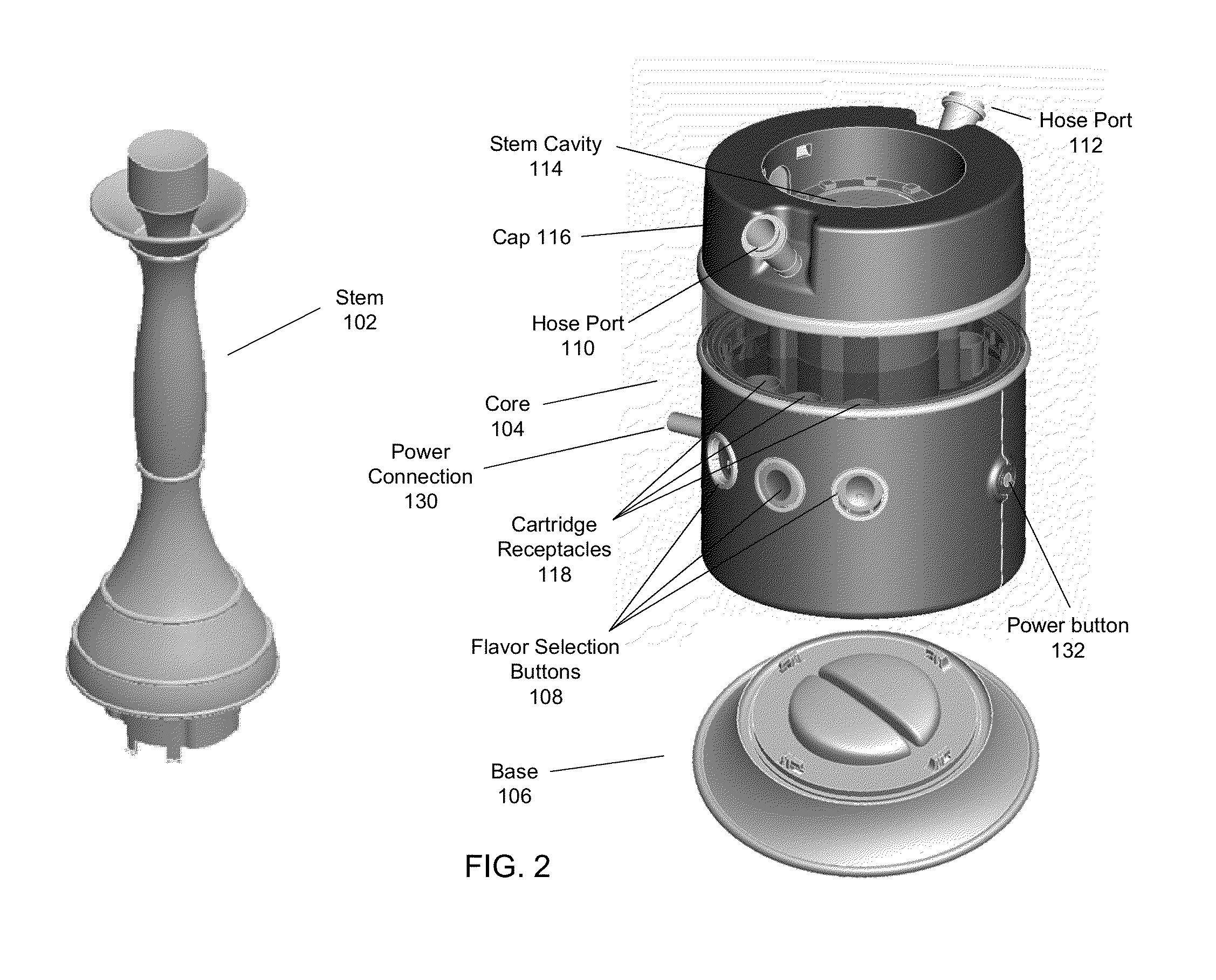

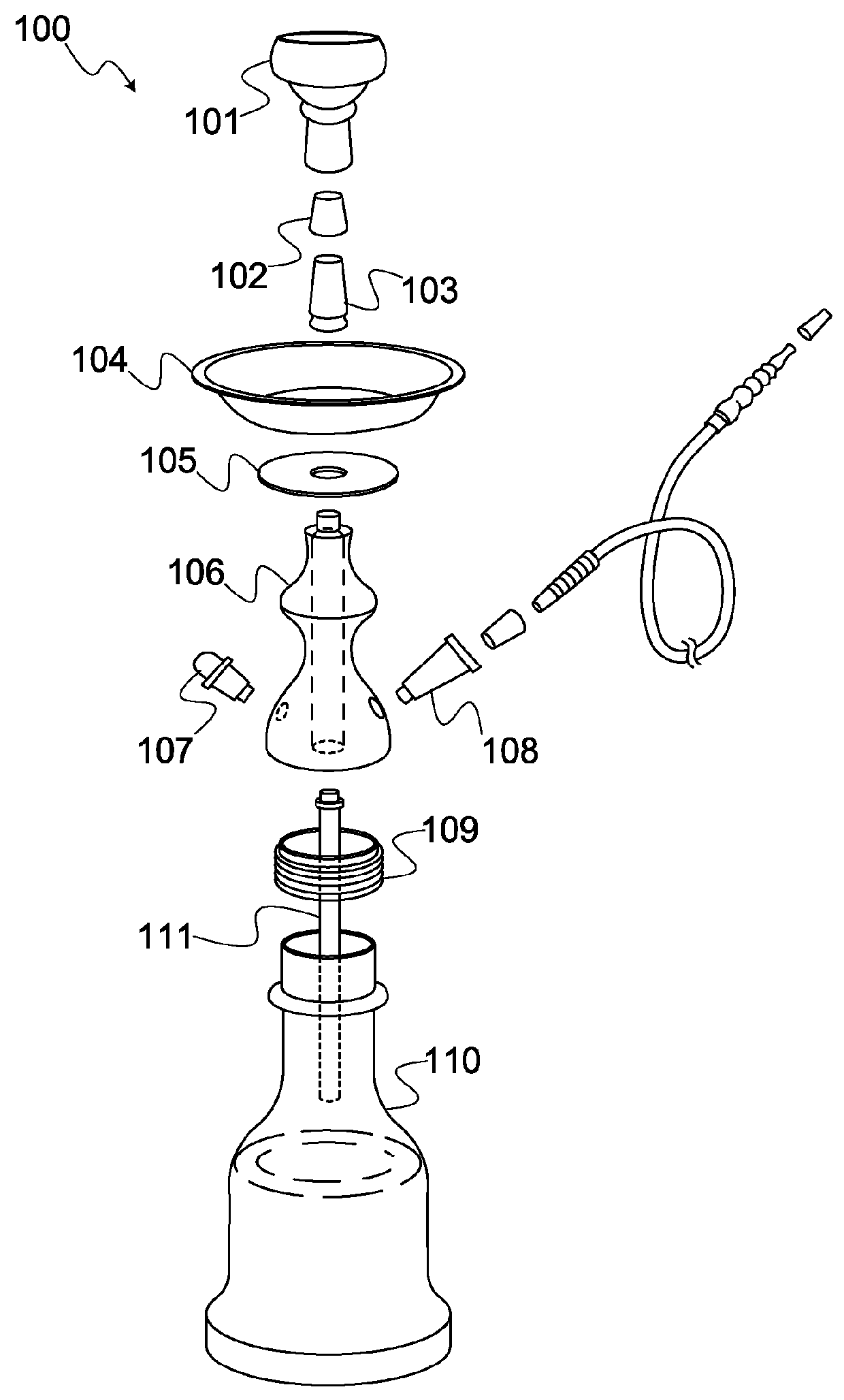

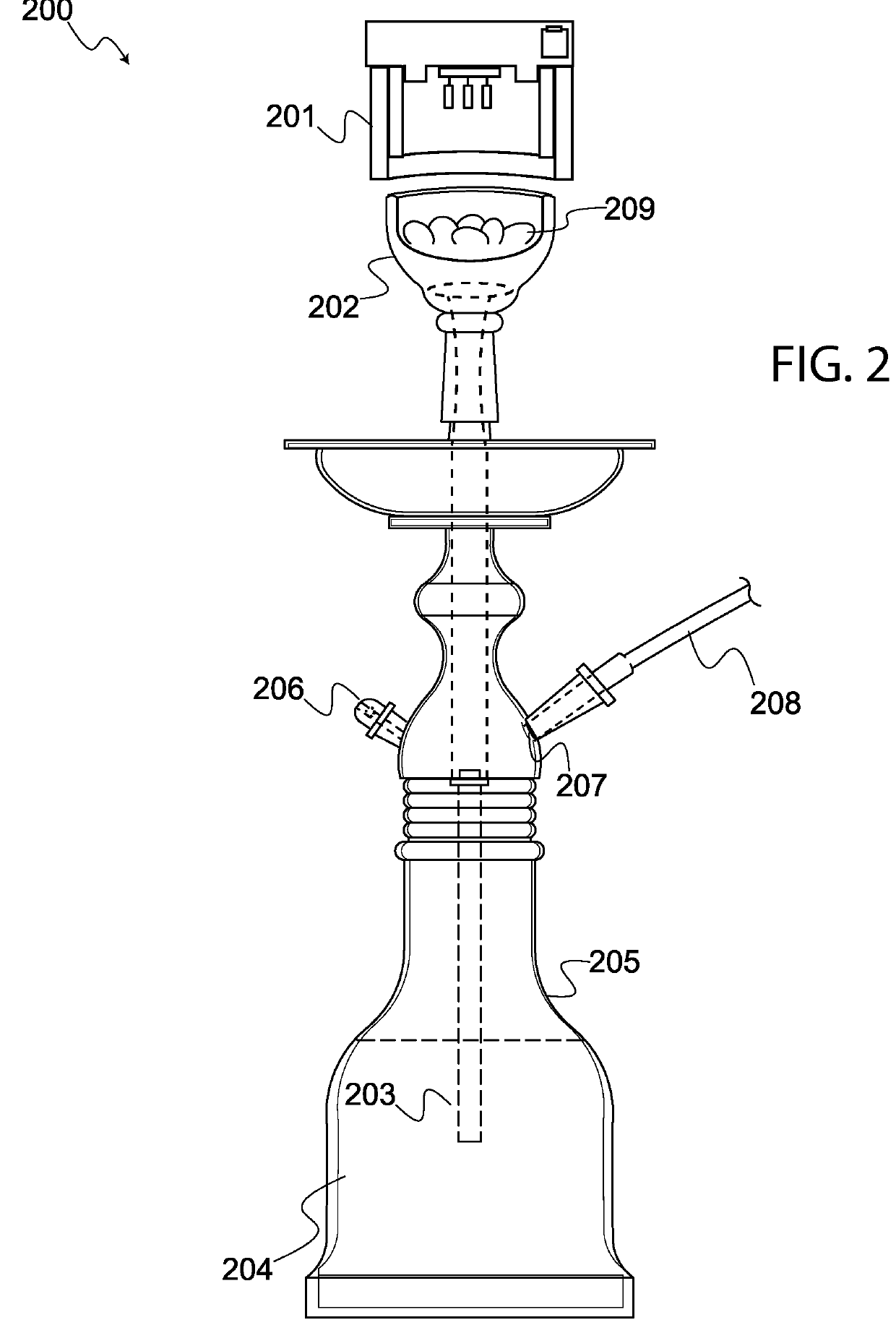

Electronic hookah apparatus

ActiveUS20160206001A1Limit duration of timeIncrease brightnessTobacco pipesTobacco devicesMicrocontrollerEngineering

An electronic hookah apparatus comprising a core unit attachable with a stem piece and a base. The core comprises at least one airflow sensor to detect airflow from air pathways, a plurality of cartridges including a wick and a heating element, and a plurality of flavor selection buttons, each of the flavor selection buttons connected to a switch that activates and deactivates a respective one of the plurality of cartridges. The core further comprises a microcontroller that provides power to cartridges activated by the flavor selection buttons based on the detection of airflow by the airflow sensor, wherein providing power to the cartridges causes the cartridges to produce vapor, at least one air chamber that collects flows of vapor from a set of activated cartridges, and at least one hose port coupled to a hose, the at least one hose port tapping the collected vapor from the at least one air chamber.

Owner:NGEN SMOKE LLC

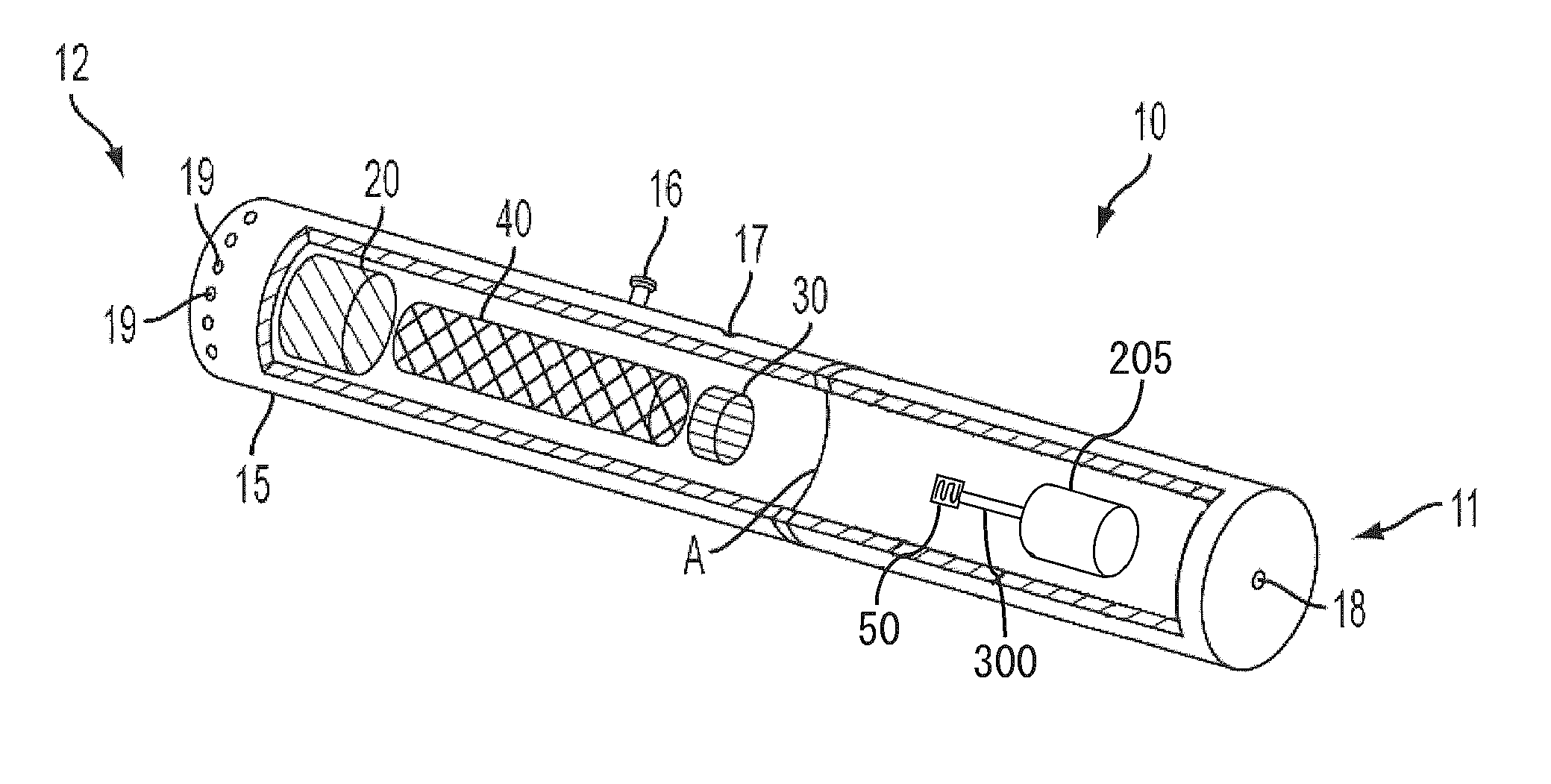

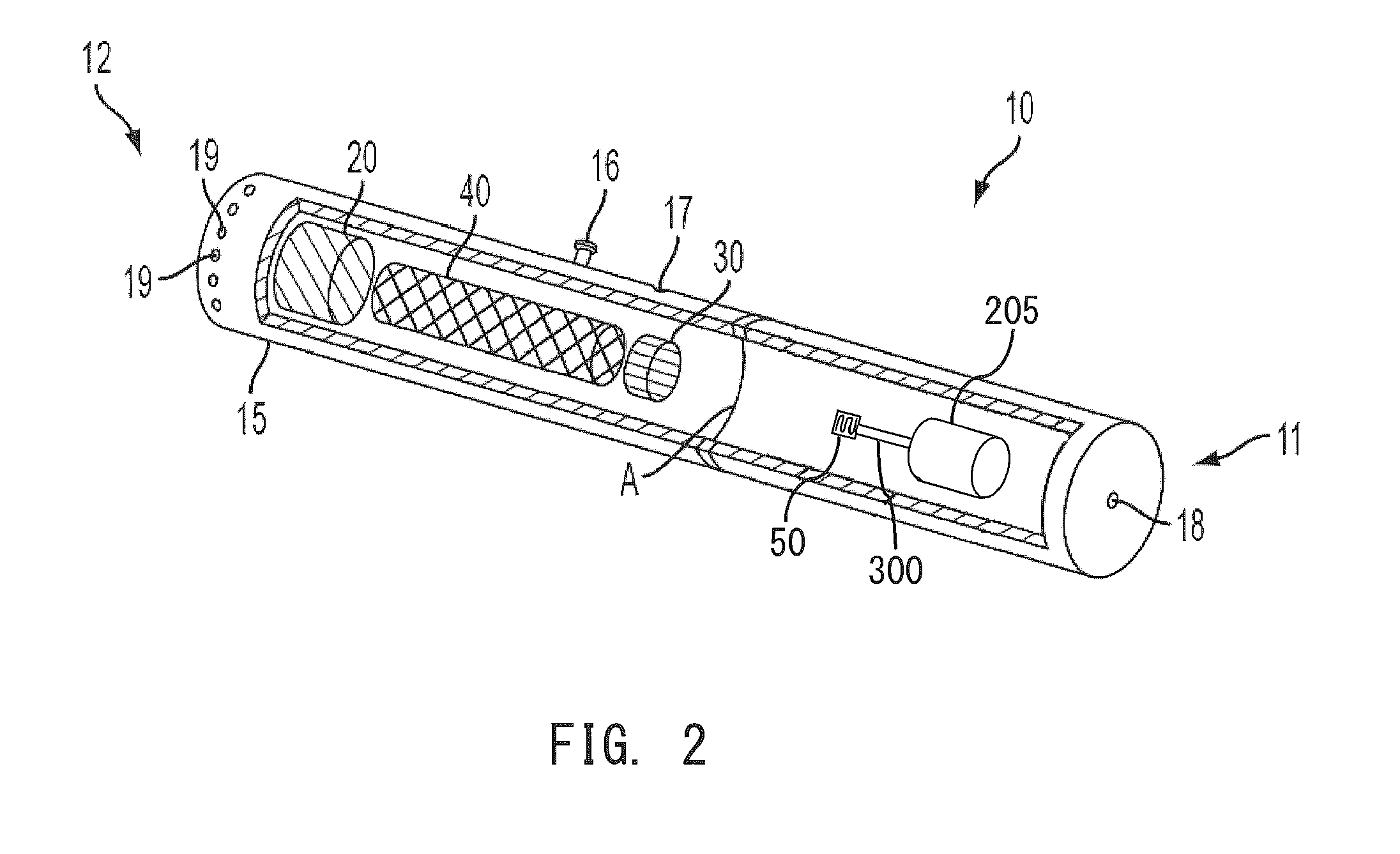

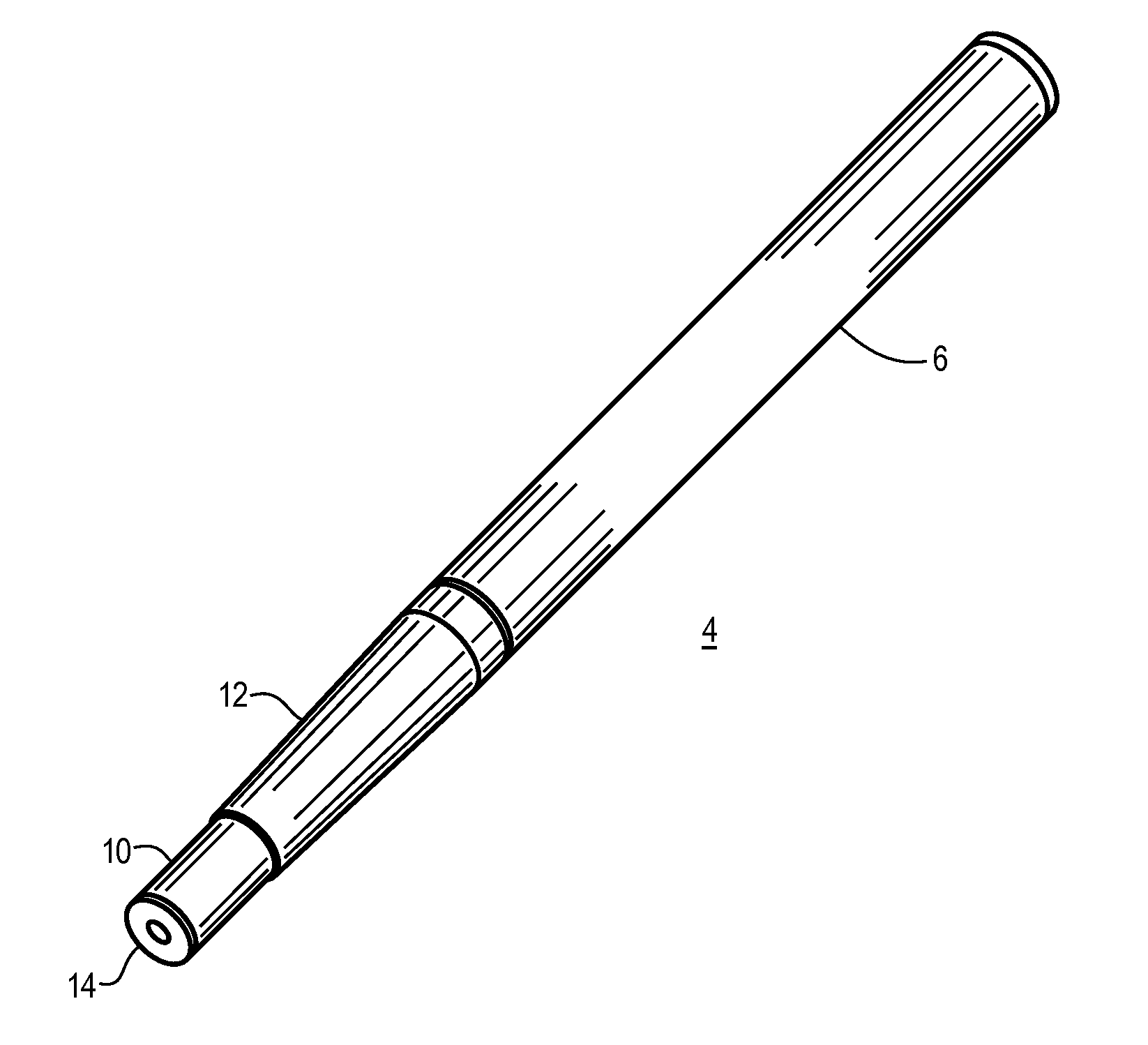

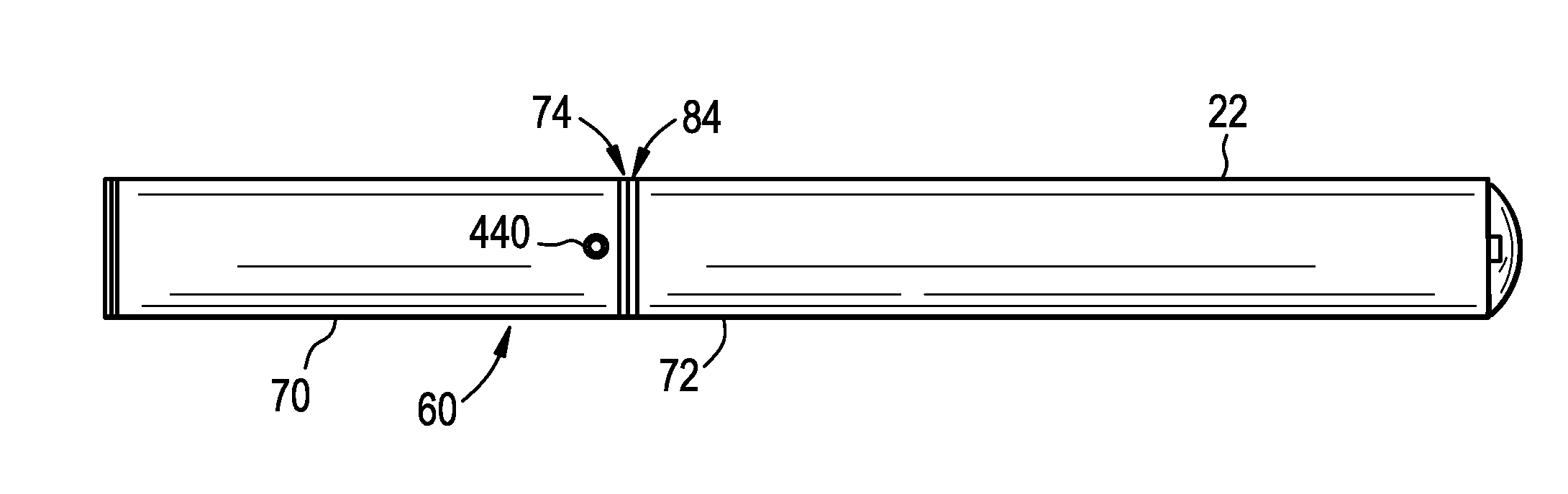

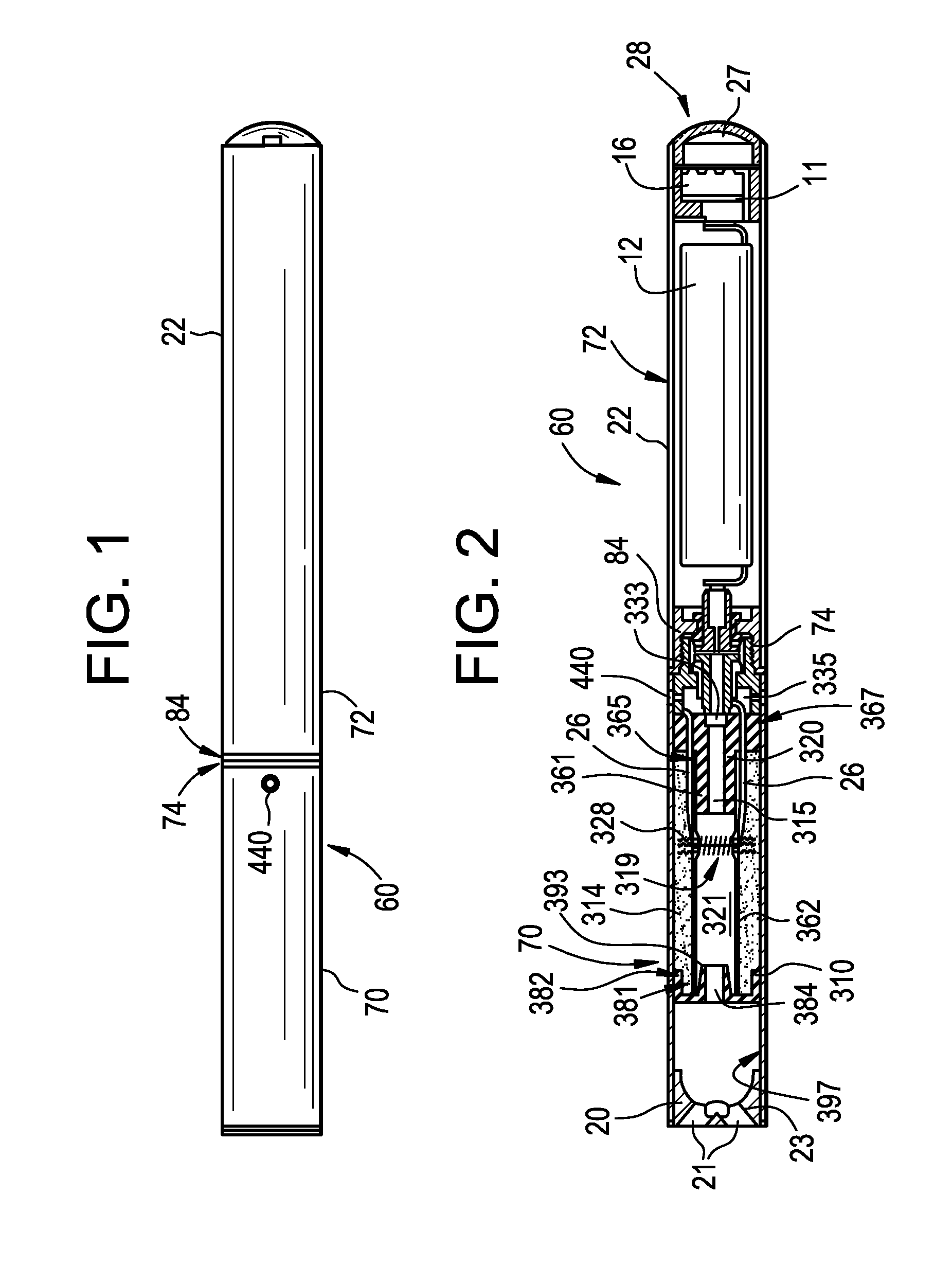

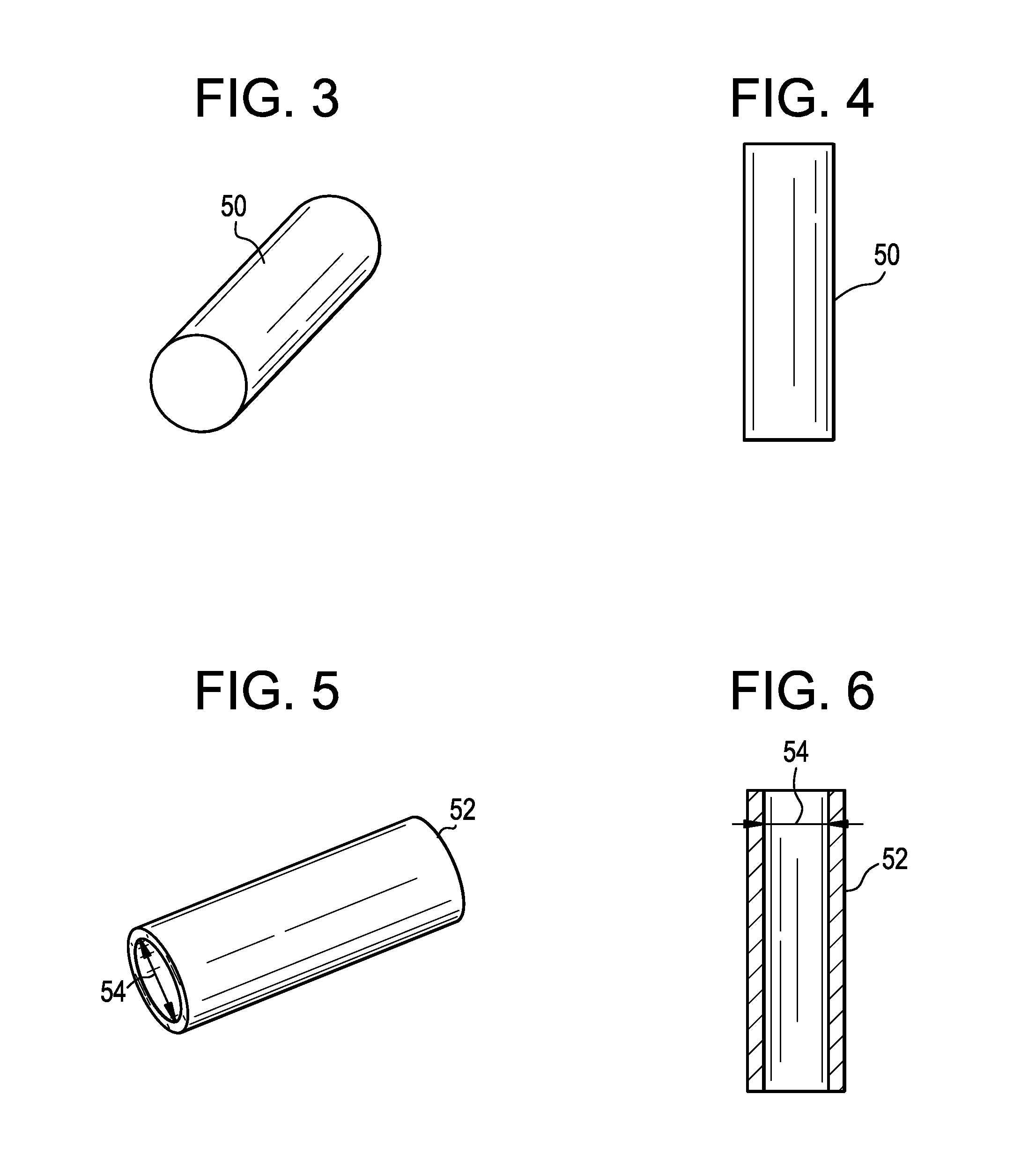

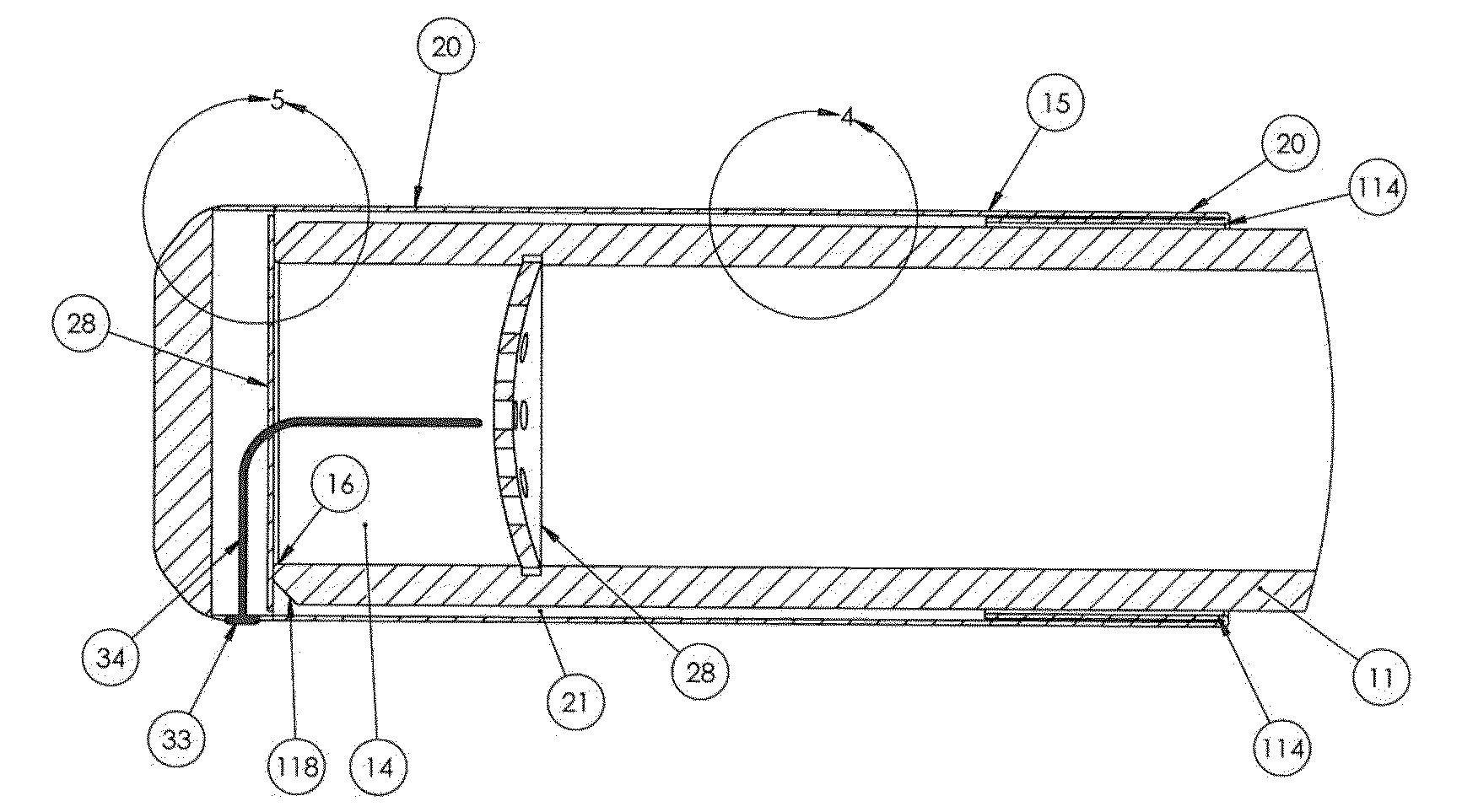

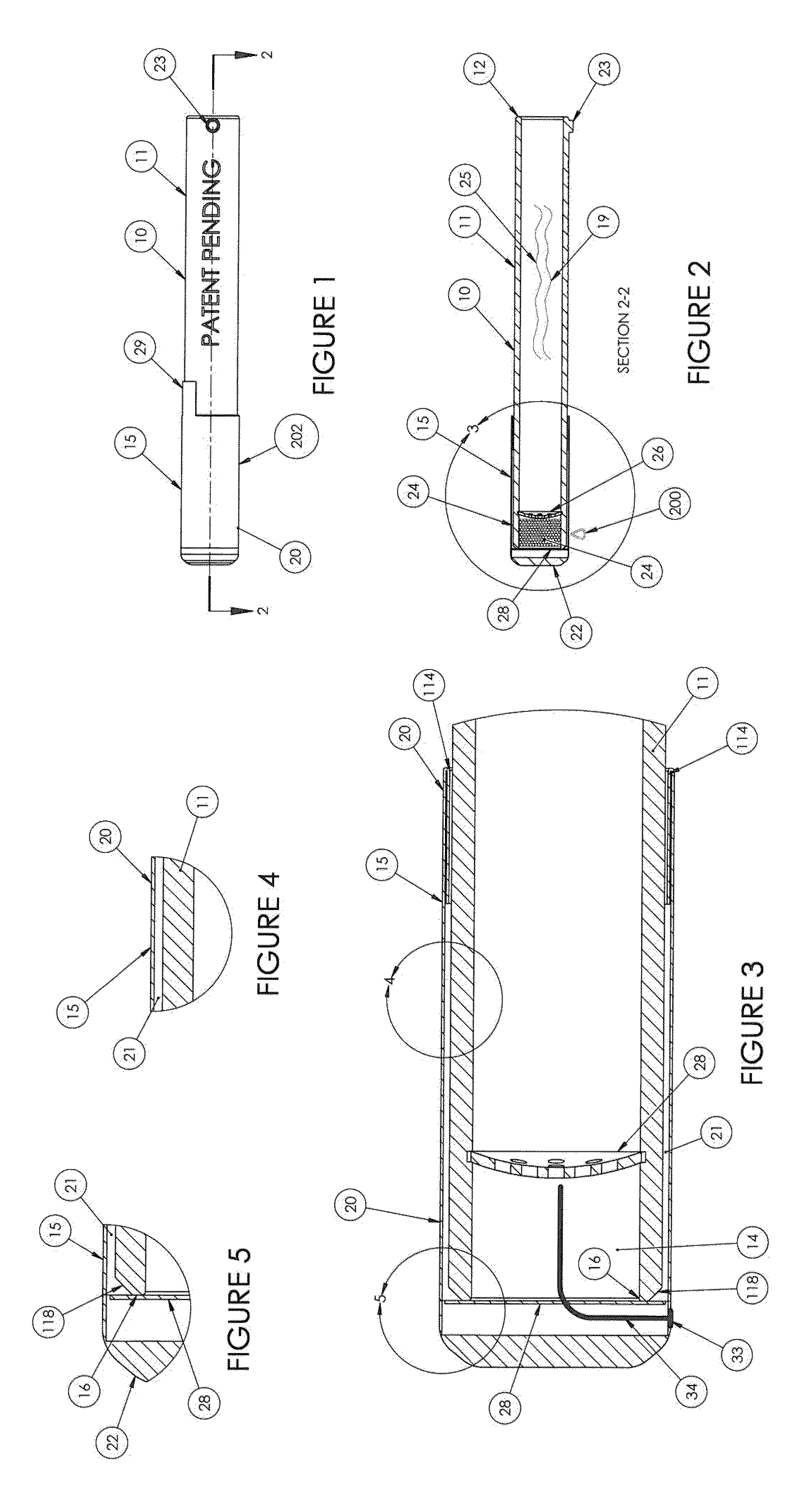

Tubular Volatizing Device

ActiveUS20140186015A1Reduce preparation timeDecreases warm up timeMedical devicesTobacco devicesEngineeringMultiple function

Owner:BREIWA III GEORGE R +2

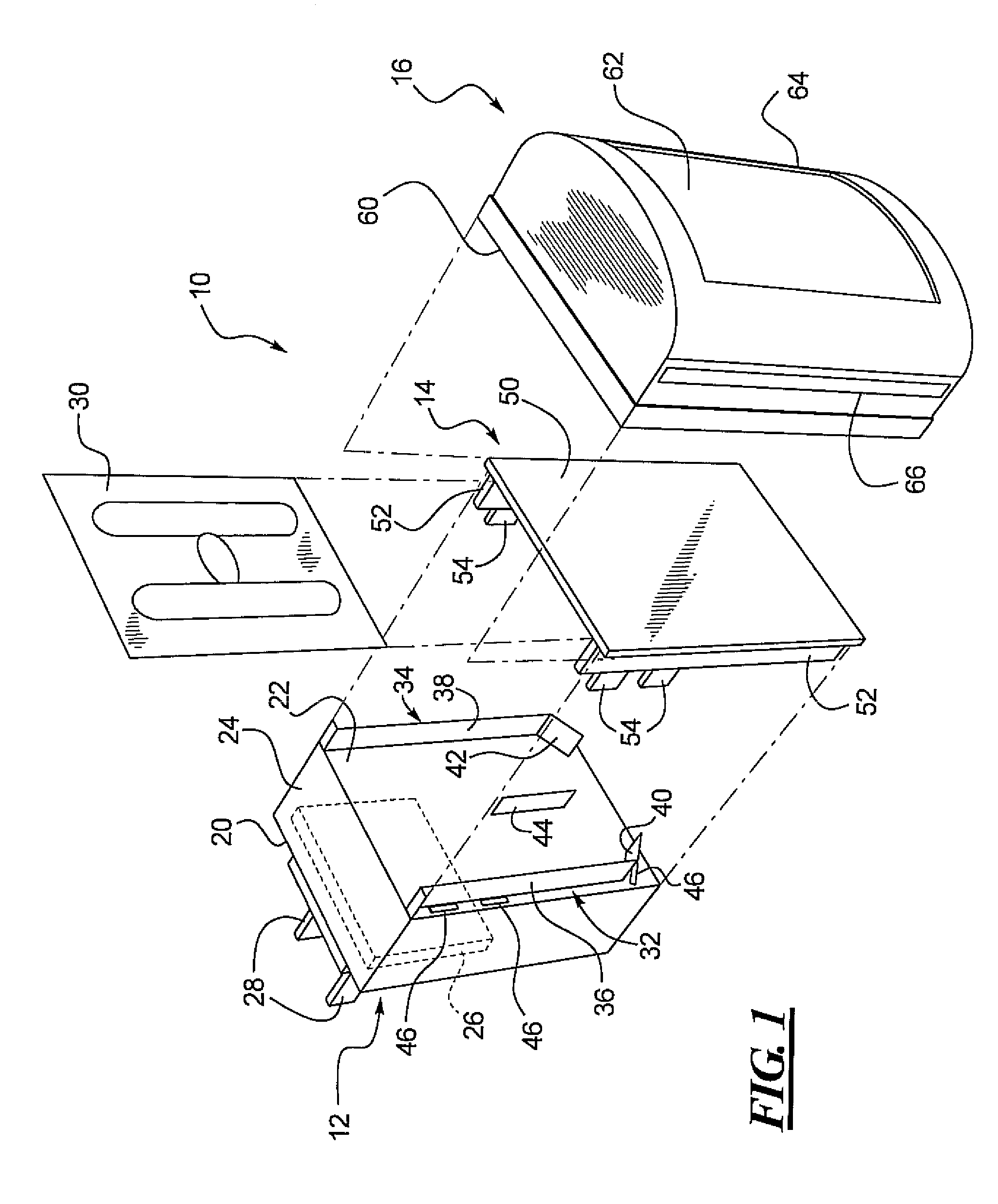

Volatile material dispenser

InactiveUS20070237498A1Steam generation using steam absorptionTobacco devicesPlastic materialsAir treatment

A dispenser for use with an air-treating composition to be emitted includes a base having a container support and a mounting surface separate from the container support. A container is coupled to the base container support and adapted to receive the air-treating composition, and a diffuser element is coupled to the base and positioned to disperse the air-treating composition from the container into the surrounding environment. A cover is adapted for attachment to the base mounting surface. The container support remains intact when the cover is removed therefrom. The cover may include a frame for holding one of a plurality of substrates carrying different images. In addition, the base may be formed of a plastic material while the cover is formed of a ceramic material.

Owner:SC JOHNSON & SON INC

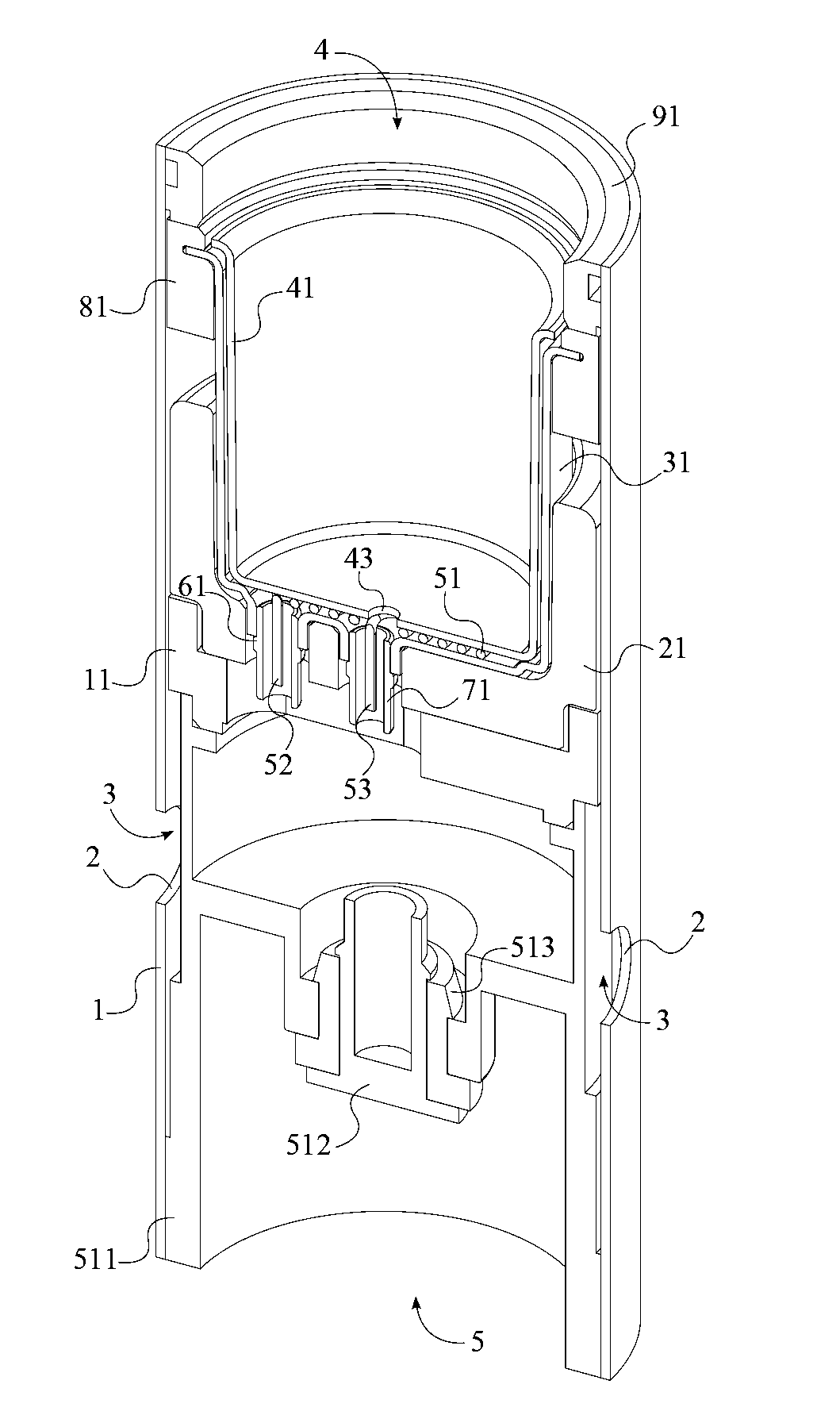

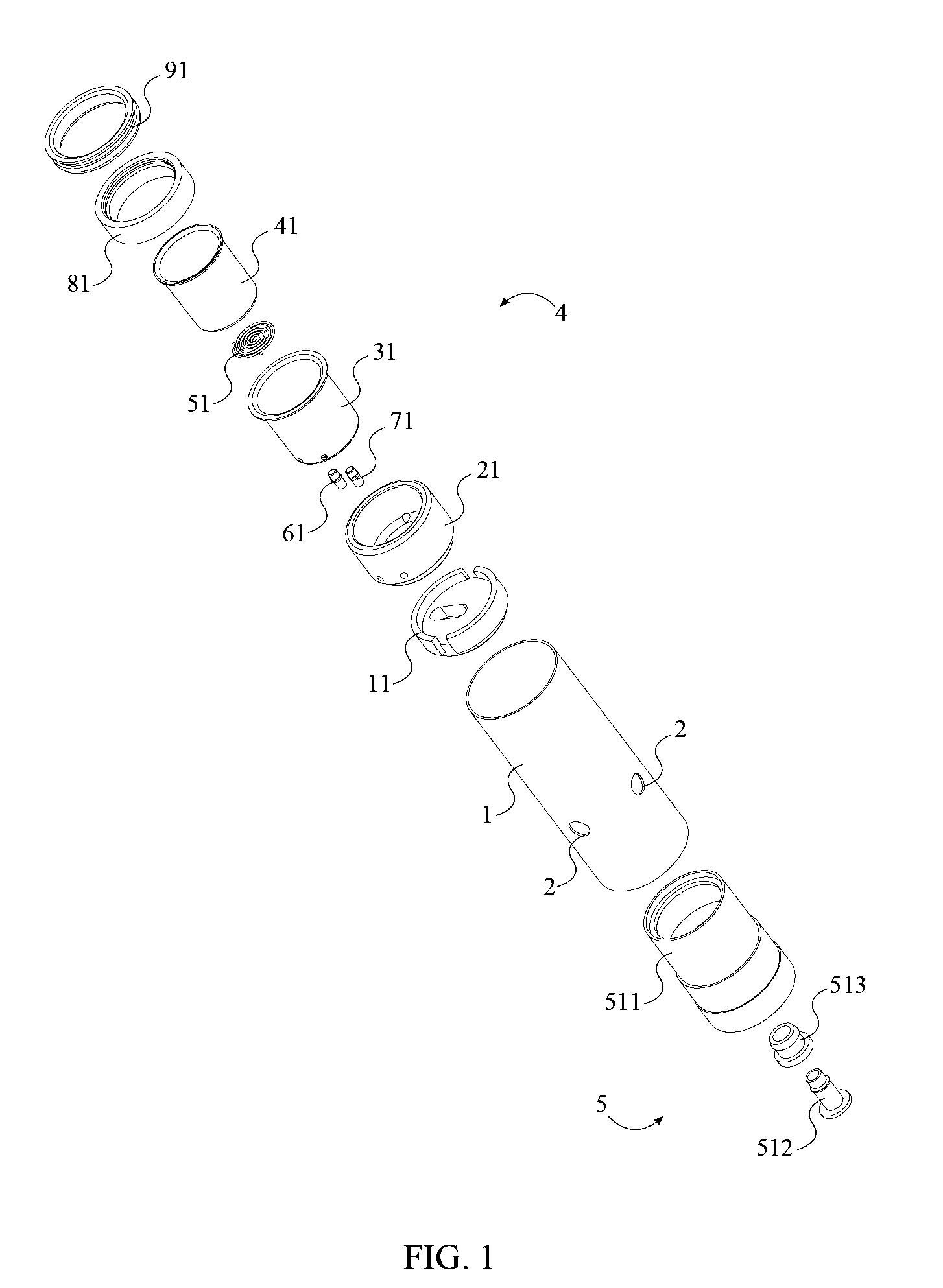

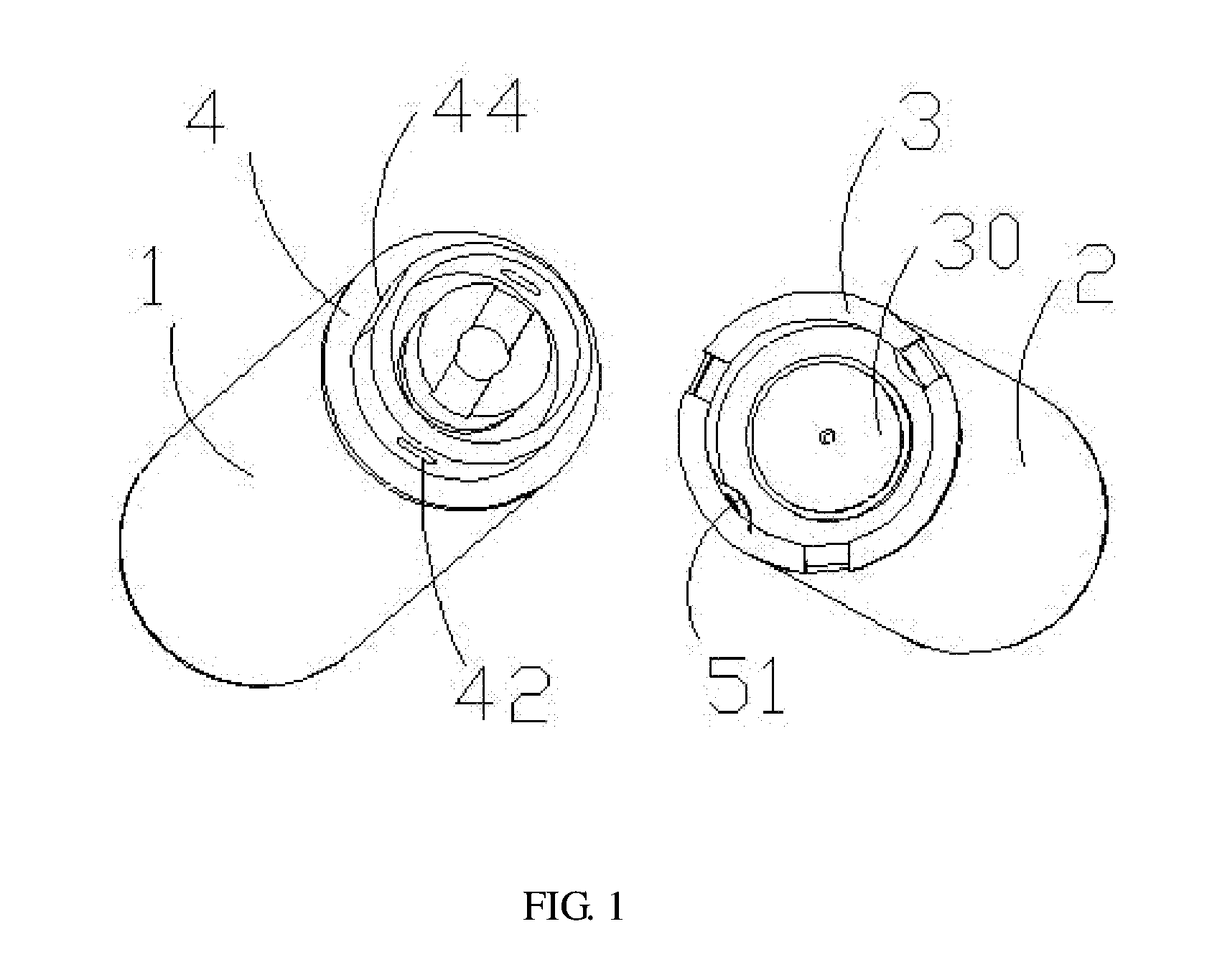

Electronic cigarette

InactiveUS20160183594A1Simple structureFirmly connectedTobacco devicesMachines/enginesCouplingElectronic cigarette

An electronic cigarette comprises an atomizer, a power supply rod and a connecting structure, the connecting structure comprises a first connecting piece and a second connecting piece; the first connecting piece is provided with a coupling groove; the coupling groove is provided with at least one first accommodation position, and the second connecting piece is correspondingly provided with at least one second accommodation position; further comprises an elastic piece with a convex portion and a guide channel; when being fastened, the elastic piece is inserted along the guide channel, and is rotated to make the convex portion be pressed by the fastening area and retracted; and when being rotated to the first accommodation position corresponding to the second accommodation position, the convex portion recovers from deformation. The connecting structure provides reliable connection, and convenient replacement of a fastening structure, thus improves user experience.

Owner:KIMREE HI TECH

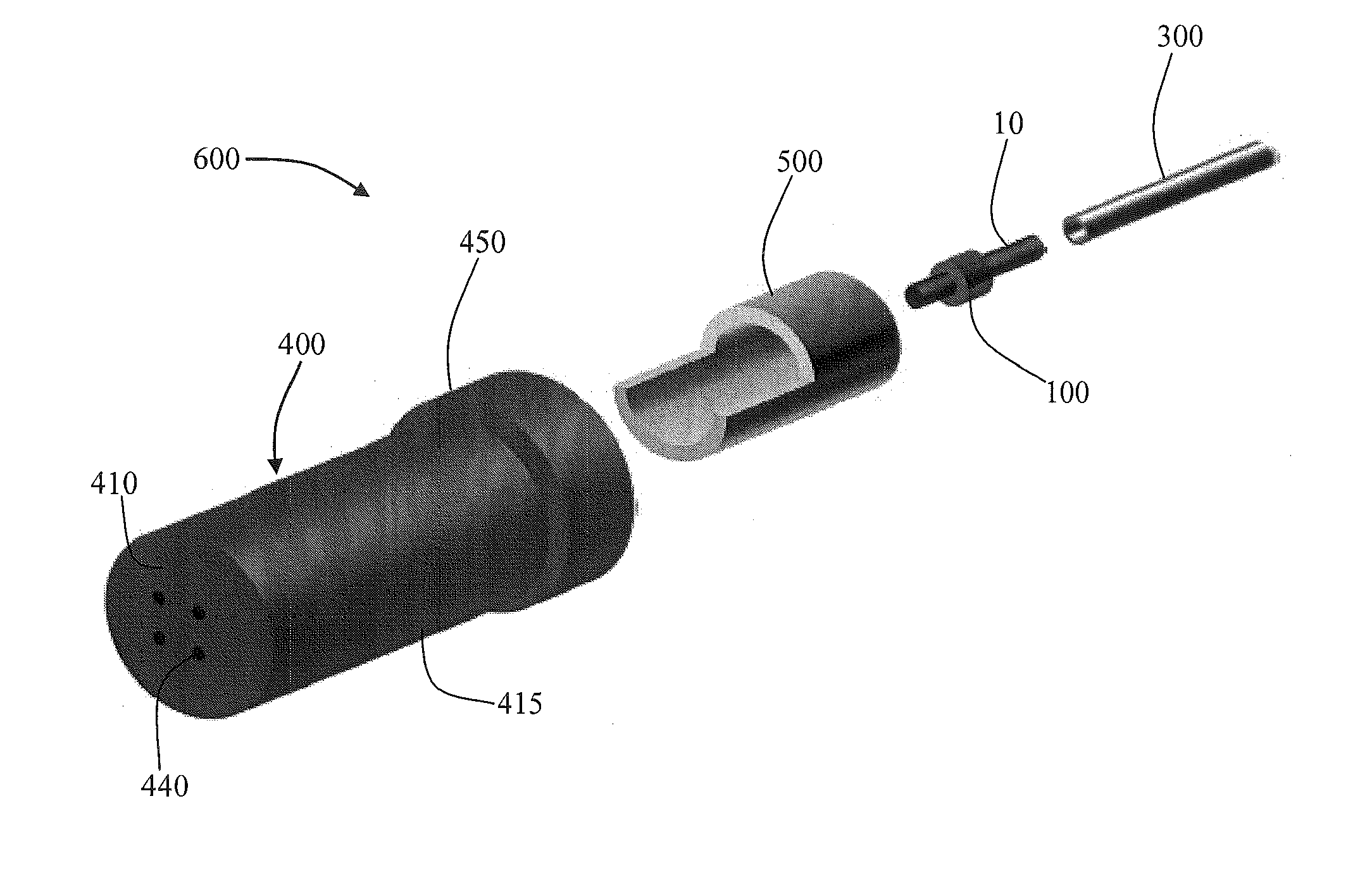

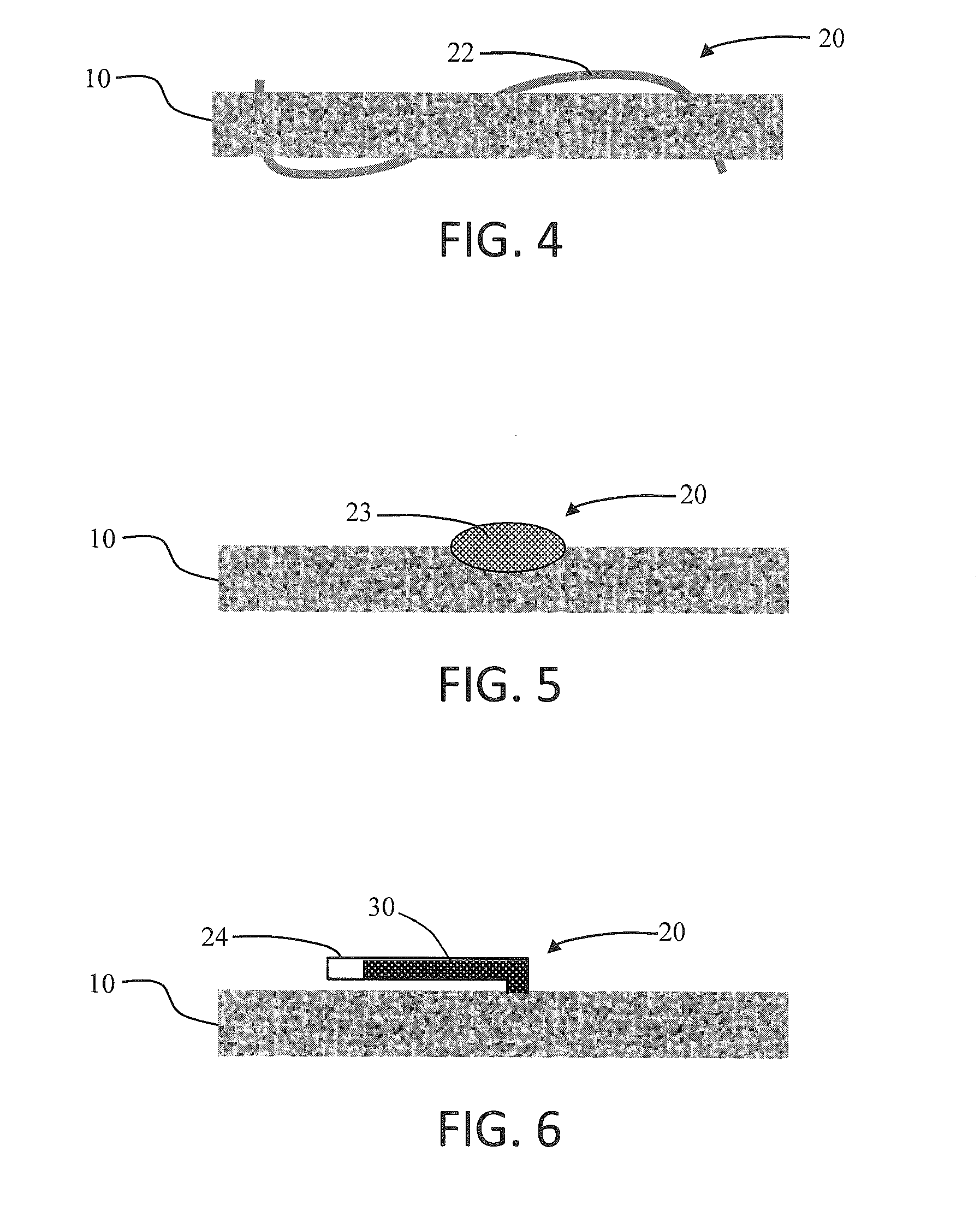

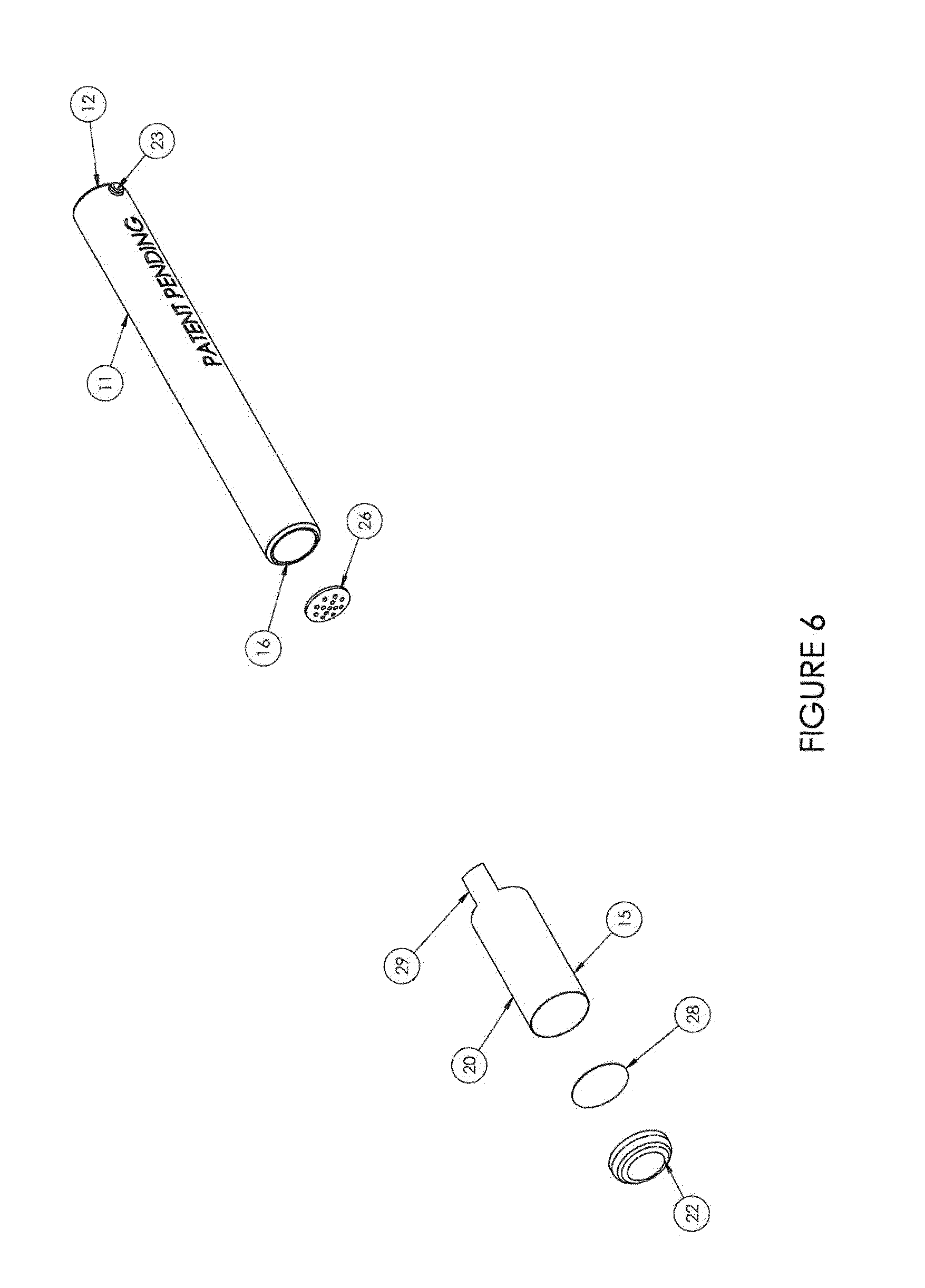

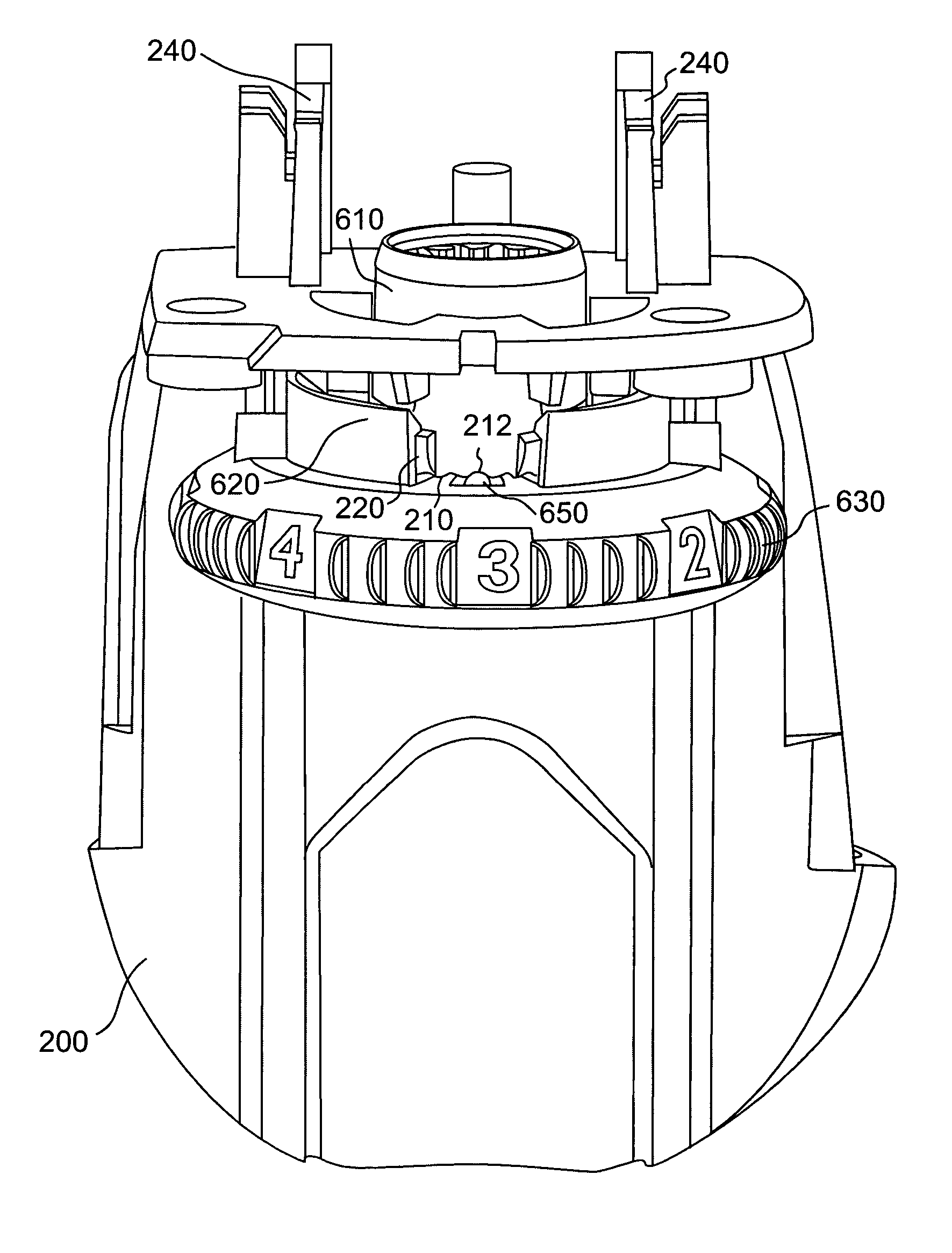

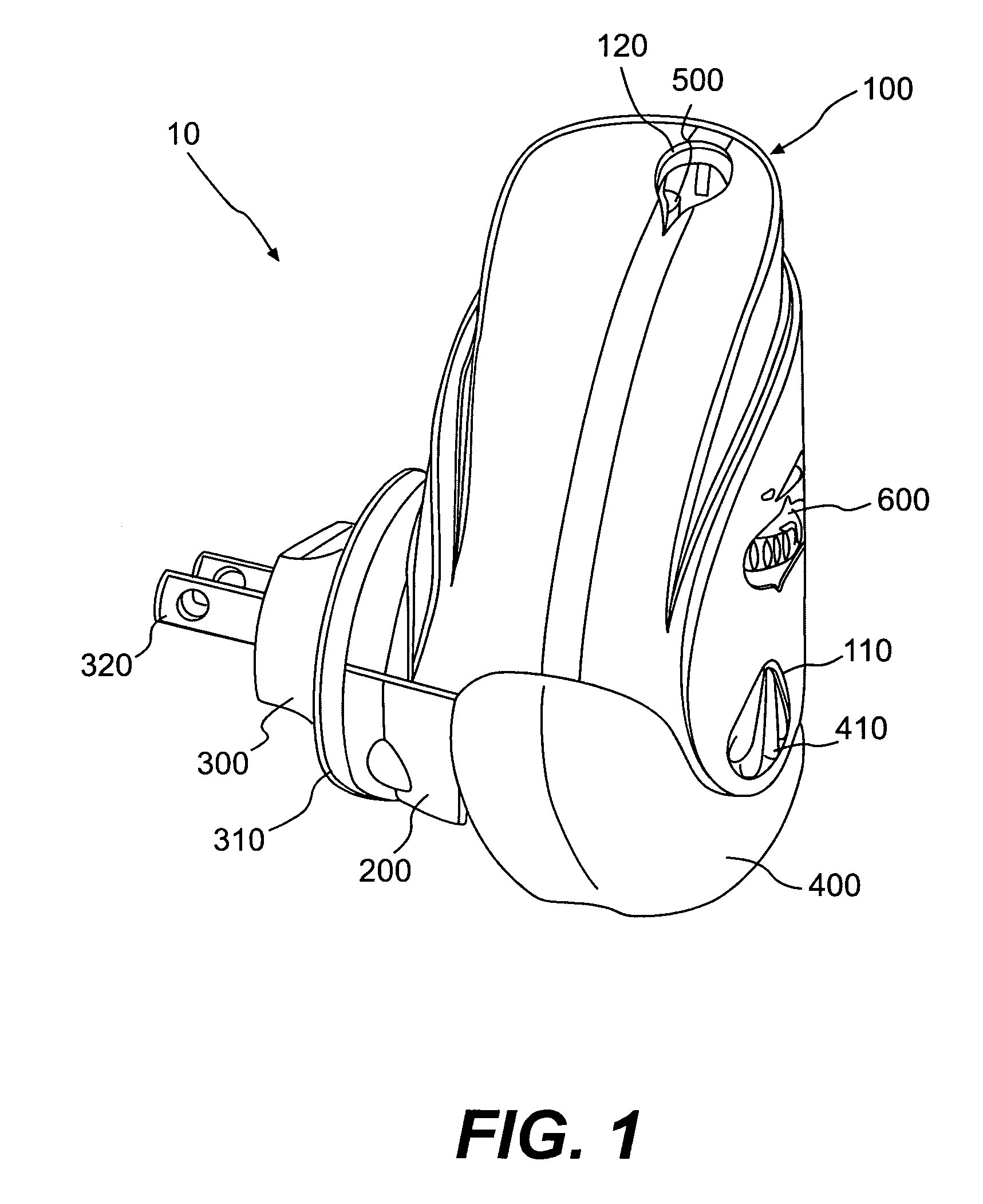

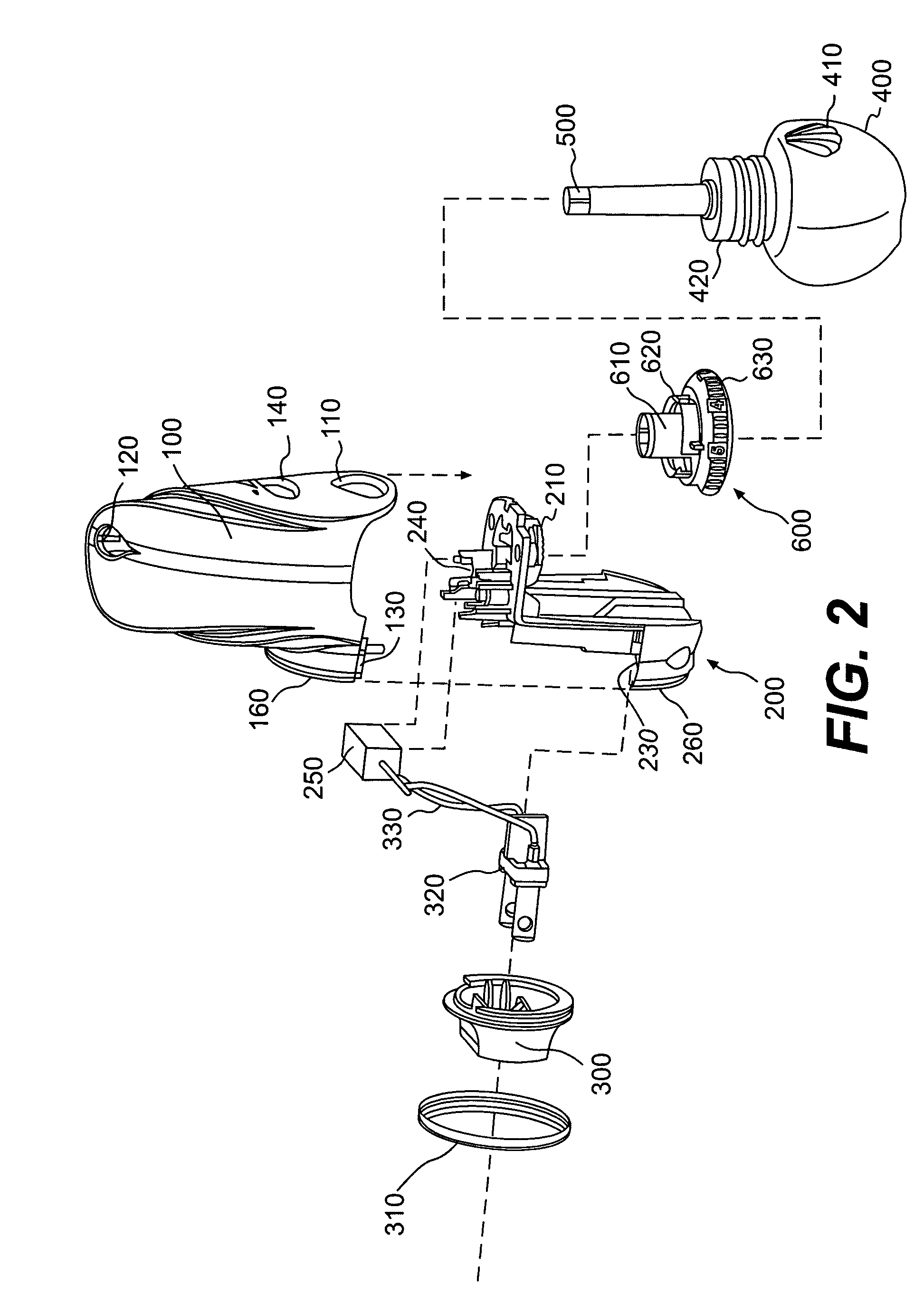

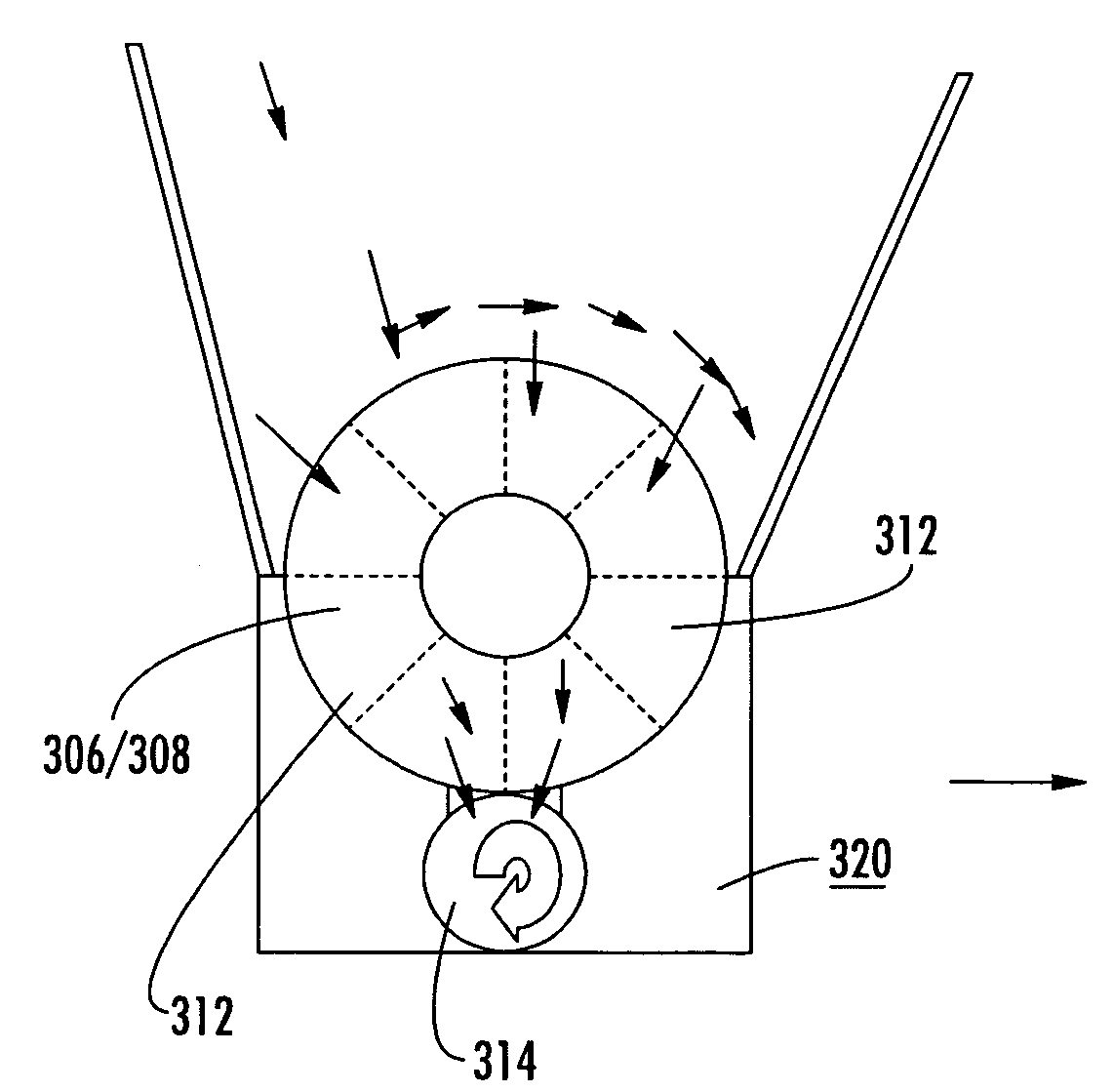

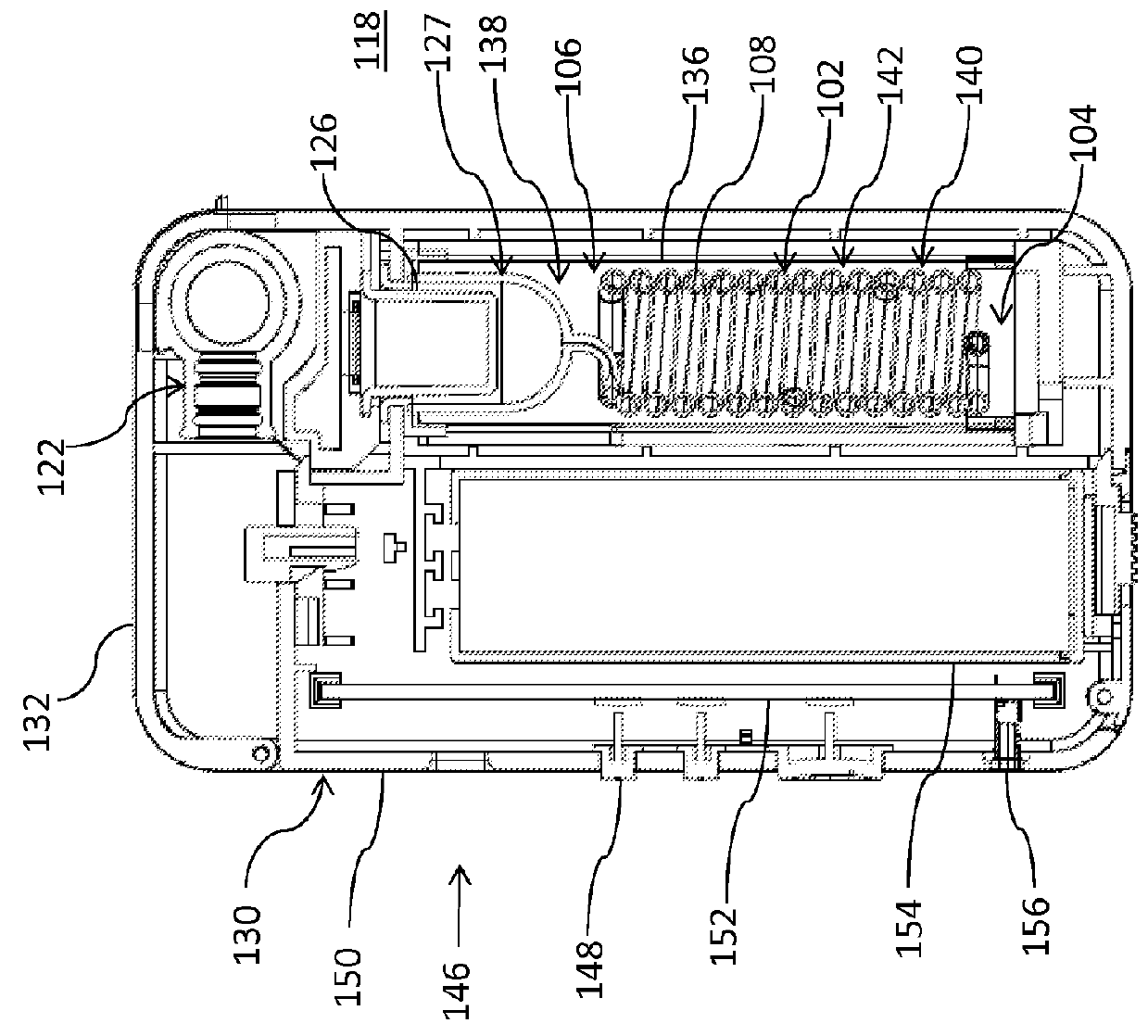

Electrical evaporator with ratcheting wick adjuster

ActiveUS6996335B2Easy to formulateEasily varyingSteam generation using steam absorptionMachines/enginesLocking mechanismEngineering

An evaporator (10) includes a housing (100, 200), a bottle (400) containing a substance to be evaporated, a wick (500) protruding from the bottle (400), a rotatable plug deck (300) for providing electricity to the evaporator (10), a heating device (250) disposed within the housing (100,200), and an adjuster (600) within the housing (100, 200) for displacing the wick (500) toward or away from the heating device (250). The adjuster (600) includes a retaining mechanism (650) that retains the adjuster (600) in a selected one of a plurality of discreet adjustment settings. The plug deck 300 includes a locking mechanism (340, 342) that retains the plug deck (300) in a selected one of a plurality of discrete positions.

Owner:SC JOHNSON & SON INC

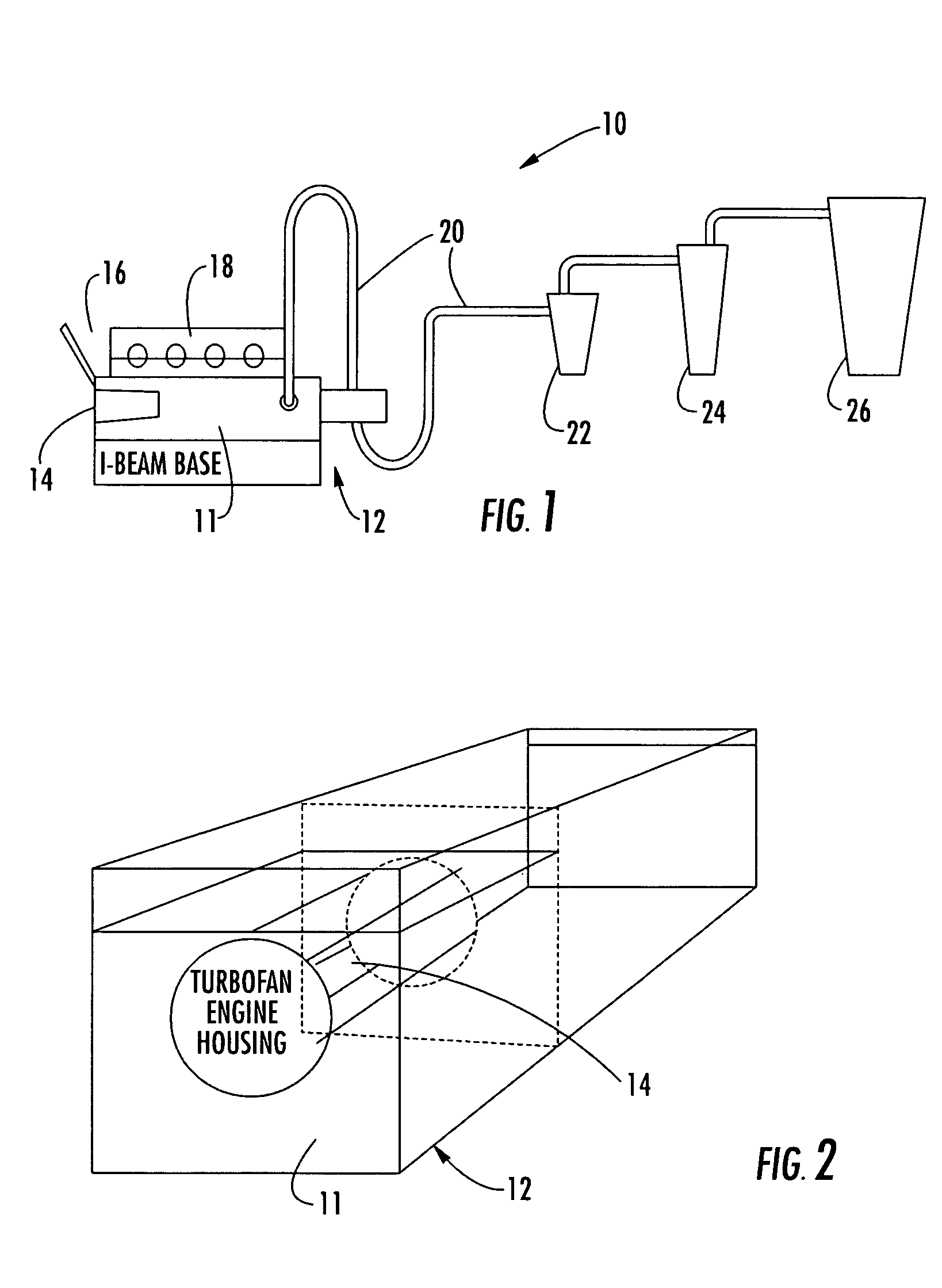

Air dryer system and method employing a jet engine

InactiveUS6944967B1Operate operating costQuality improvementDrying gas arrangementsDrying machines with non-progressive movementsJet engineTurbofan

An air dryer and process employs a jet engine for producing high quality dried products. A turbofan jet engine in an air-drying system uses both thermal and non-thermal air-drying. The turbofan jet engine is housed within an air distribution chamber for directing exhaust air and bypass air from the jet engine into a product drying tube, where it is dried through a combination of thermal drying from heat content in an engine exhaust, and by the kinetic energy of air flowing past the product traveling through the drying tube, that may include a physical impediment for retarding retard the speed of the product solids flowing in the air stream through the tube.

Owner:STAPLES WESLEY A

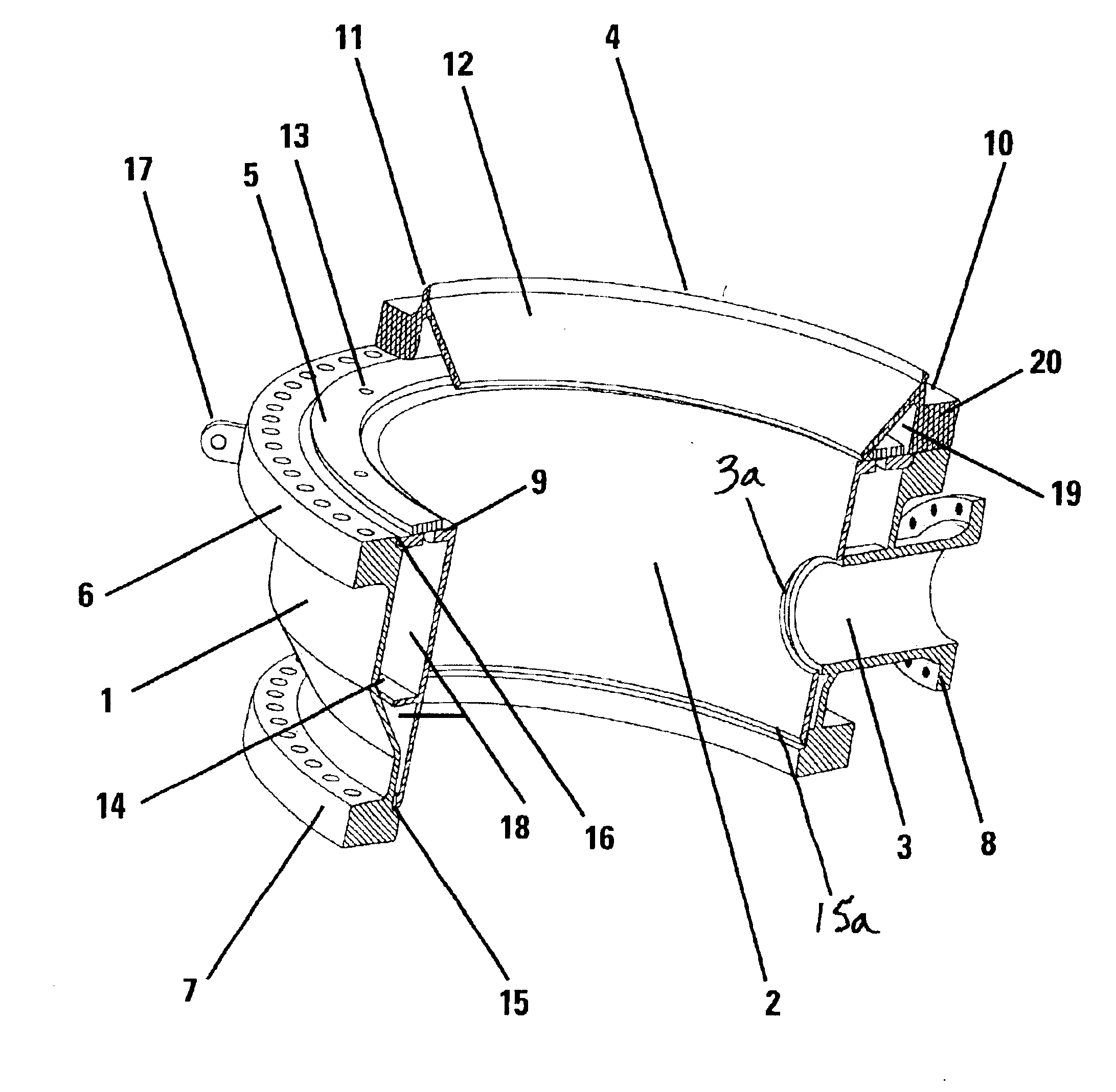

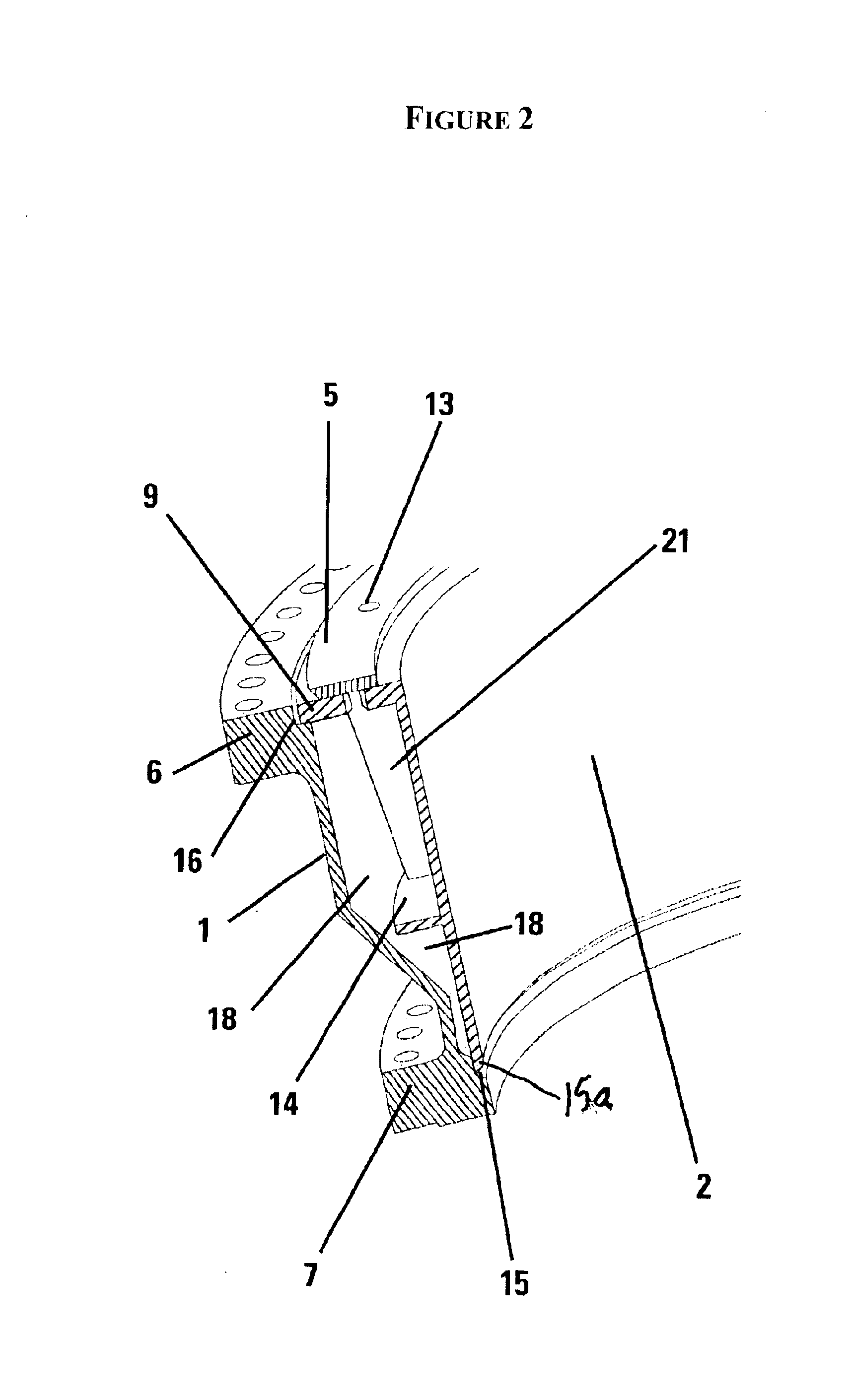

Insulated transition spool apparatus

ActiveUS6926807B2Pipe protection by thermal insulationPipe units with cleaning aperturesEngineeringPressure vessel

An insulated transition spool apparatus for mounting unheading devices to pressure vessels, such as coker vessels, and enabling repetitive operation thereof is disclosed. The apparatus comprises an outer housing, an inner housing that encloses an insulating space between the inner and outer housing, a side feed entry aperture in each housing and a spool adapter flange to facilitate attachment of the spool to the vessel.

Owner:CHEVROU USA INC

Thermally efficient portable vaporizer heating assembly

InactiveUS20160051716A1Improve thermal efficiencyReduce thermal inertiaMedical devicesMachines/enginesHand heldEngineering

A portable hand-held vaporizer assembly having a glass body defining an airflow passage is disclosed. A heating element is thermally coupled to the glass body and a material placement zone is downstream from the airflow passage. Furthermore, a thermally conductive layer covers at least a portion of an outer surface of the glass body and a thermally reflective substance is included with walls encapsulating the glass body and the heating element.

Owner:VAPORFECTION INT

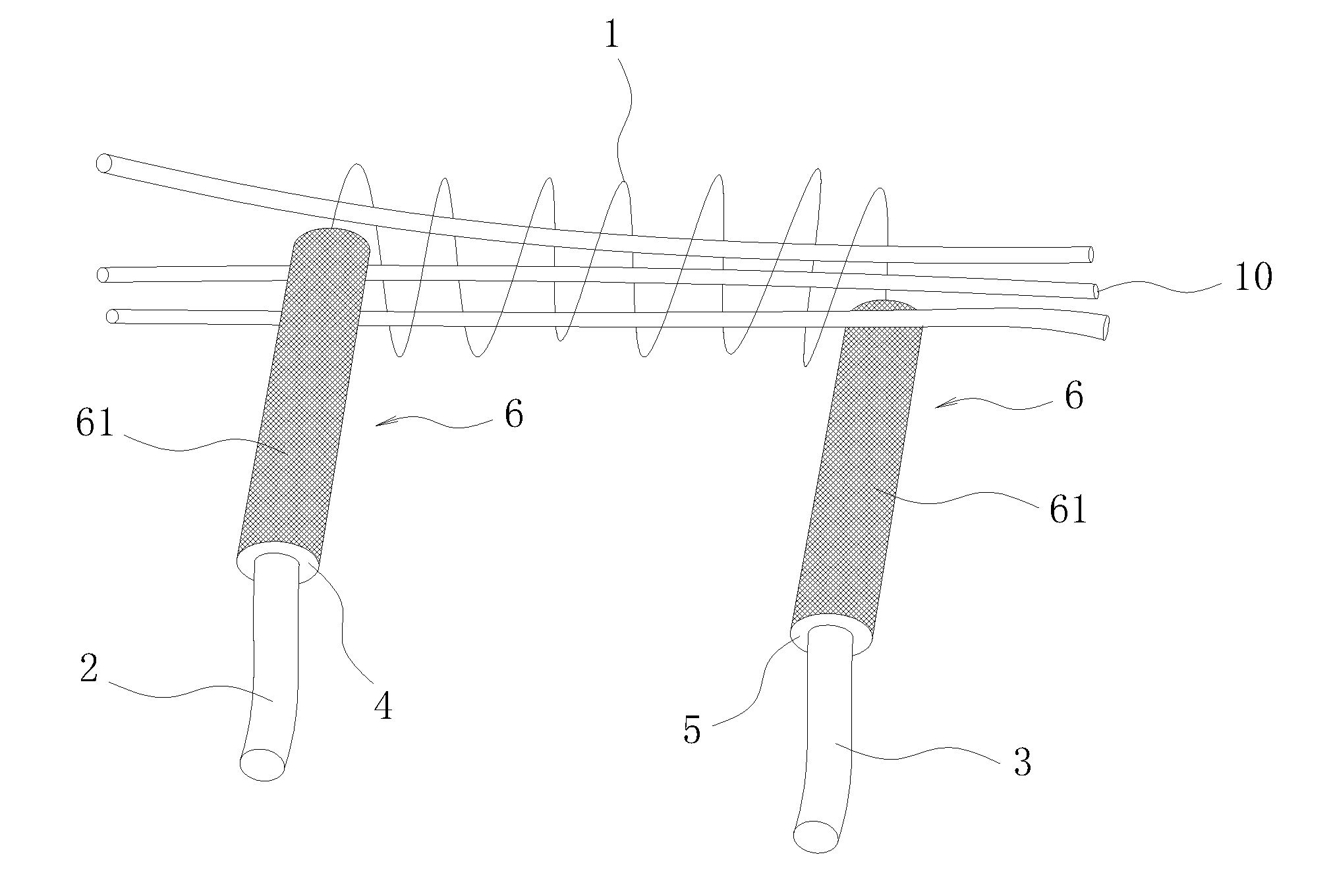

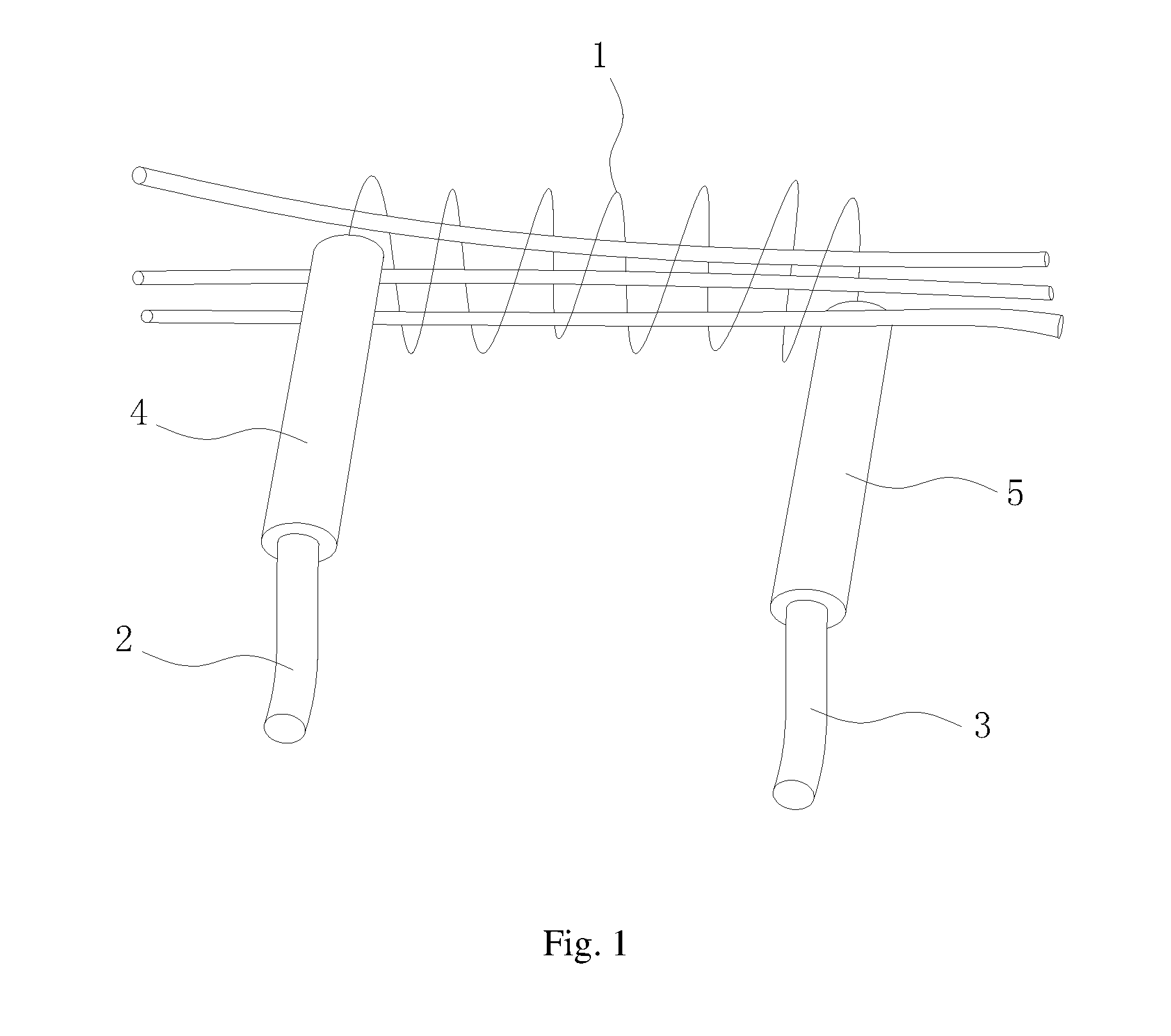

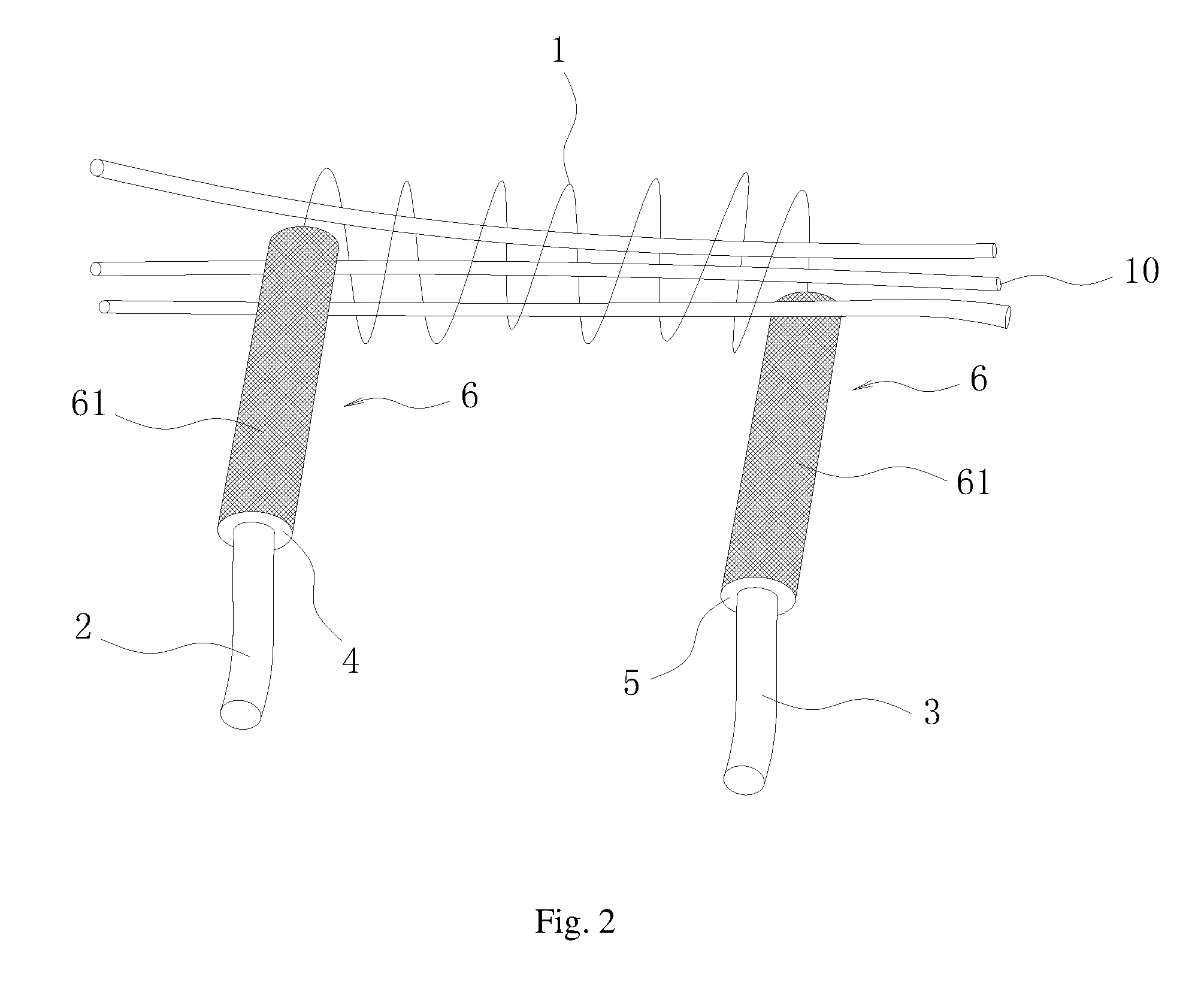

Electronic cigarette heat-generating device and electronic cigarette

InactiveUS20160128390A1Affect tasteImprove consistencySteam generation using steam absorptionOhmic-resistance electrodesElectronic cigaretteEngineering

An electronic cigarette heating device and an electronic cigarette are provided. The electronic cigarette heating device comprises a heating filament, a first electrode, a second electrode, a first riveting terminal, and a second riveting terminal. One end of filament is riveted to first electrode via the first riveting terminal; the other end of heating filament is riveted to second electrode via the second rivet terminal. The outer wall of at least one of the first riveting terminal and second riveting terminal is coated with an insulating layer.

Owner:KIMREE HI TECH

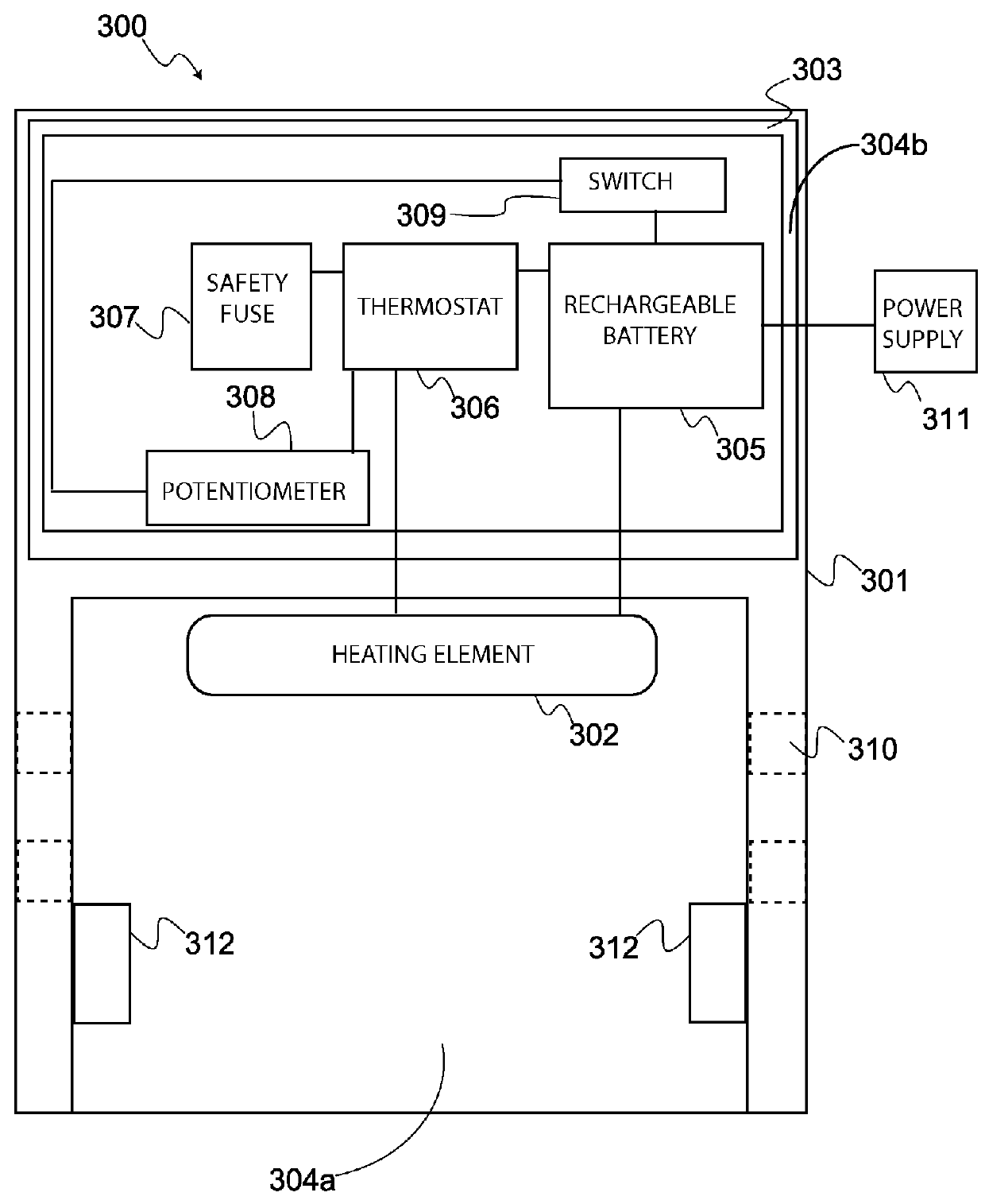

Electrical heating device for water pipes

InactiveUS20160029696A1Cleaner smokingIncandescent ignitionTobacco pipesThermal isolationElectricity

The invention is generally an electrical heating device for water pipes, and more specifically, a device for enabling a water pipe with electrical heating, which ignites or vaporizes aromatic substances via an electric-powered heating element. In exemplary embodiments, the device includes a housing that keeps the device's circuitry in thermal isolation from the heating element. The housing of the device may include openings to allow proper airflow and may be adapted for secure placement on top of the bowl of a water pipe. The device is placed on top of a bowl containing an aromatic substance, and a heating element is thereby placed in close proximity or in contact with the aromatic substance. Upon generating a heat output, the aromatic substance may be either vaporized or ignited for inhalation. Users may simply turn the device on and enjoy their experience.

Owner:OBEIDALLAH OBEIDALLAH JAMIL

Atomizing core and electronic cigarette having same

Owner:SHENZHEN FIRST UNION TECH CO LTD

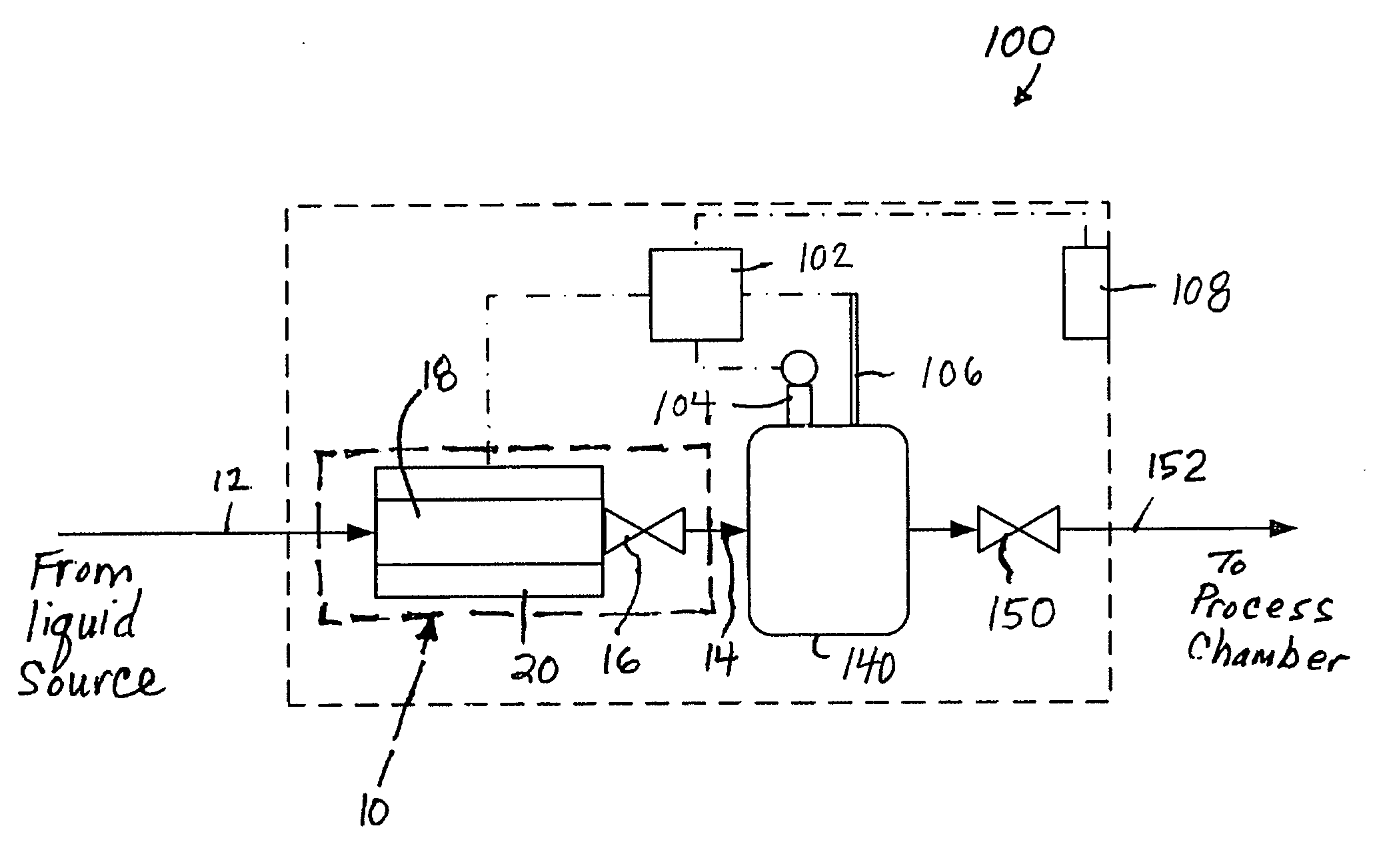

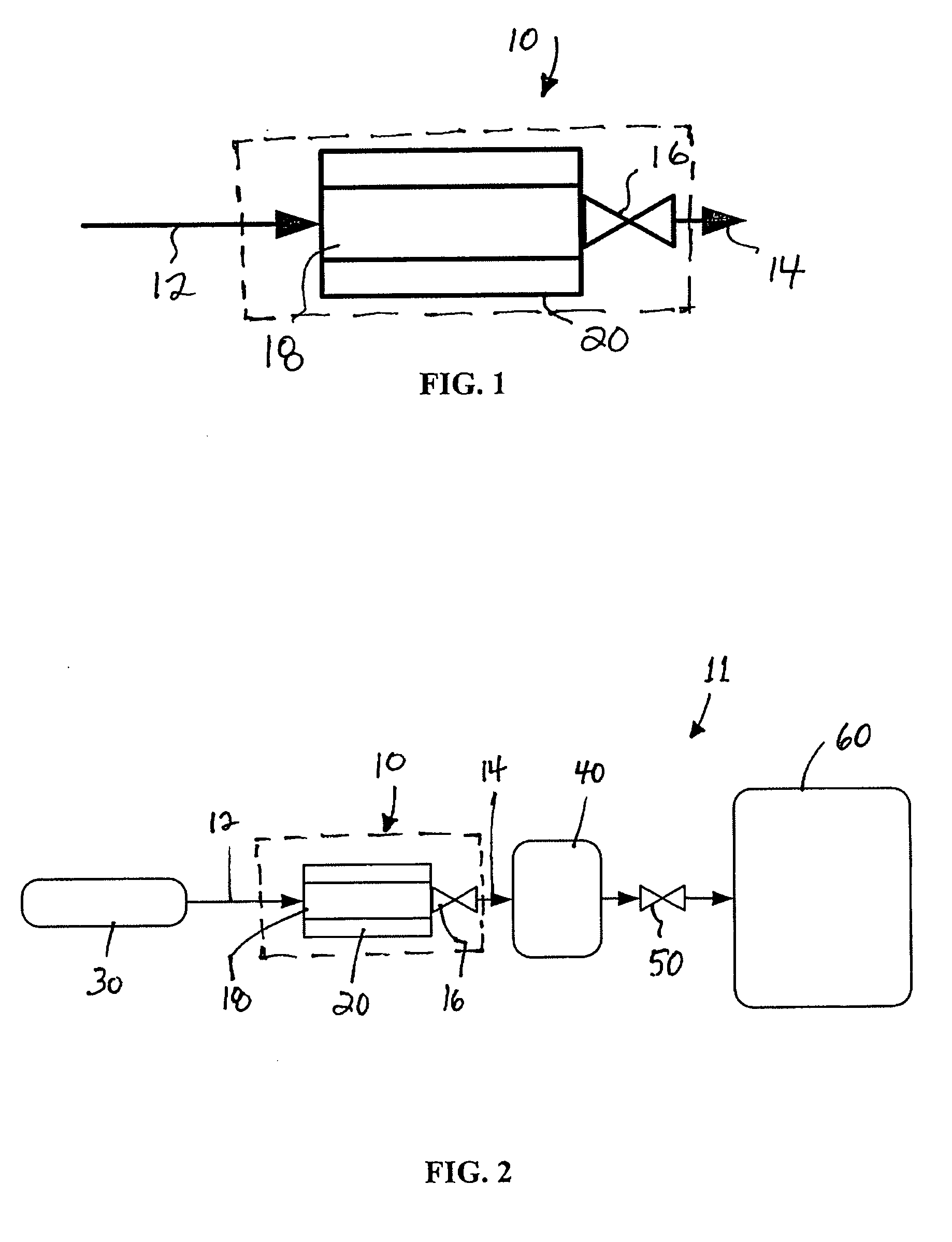

Vaporizer and method of vaporizing a liquid for thin film delivery

InactiveUS20060207503A1Simple designIncrease heat transfer rateBoiling apparatusChemical vapor deposition coatingTransition pressurePorous medium

A vaporizer including an inlet for liquid and an outlet for gas, a gas valve controlling gas flow to the outlet of the vaporizer, and means for heating liquid flowing between the liquid inlet and the gas valve. The vaporizer also includes means for increasing a heat transfer rate of the liquid flowing between the liquid inlet and the gas valve, and for causing a pressure drop in the liquid so that a pressure of the liquid drops below a vapor transition pressure of the liquid upon reaching the gas valve. The pressure drop occurs under isothermal conditions, and the liquid is vaporized on demand only when the valve is opened. The means for increasing a heat transfer rate and for causing a pressure drop can be a plug of porous media.

Owner:MKS INSTR INC

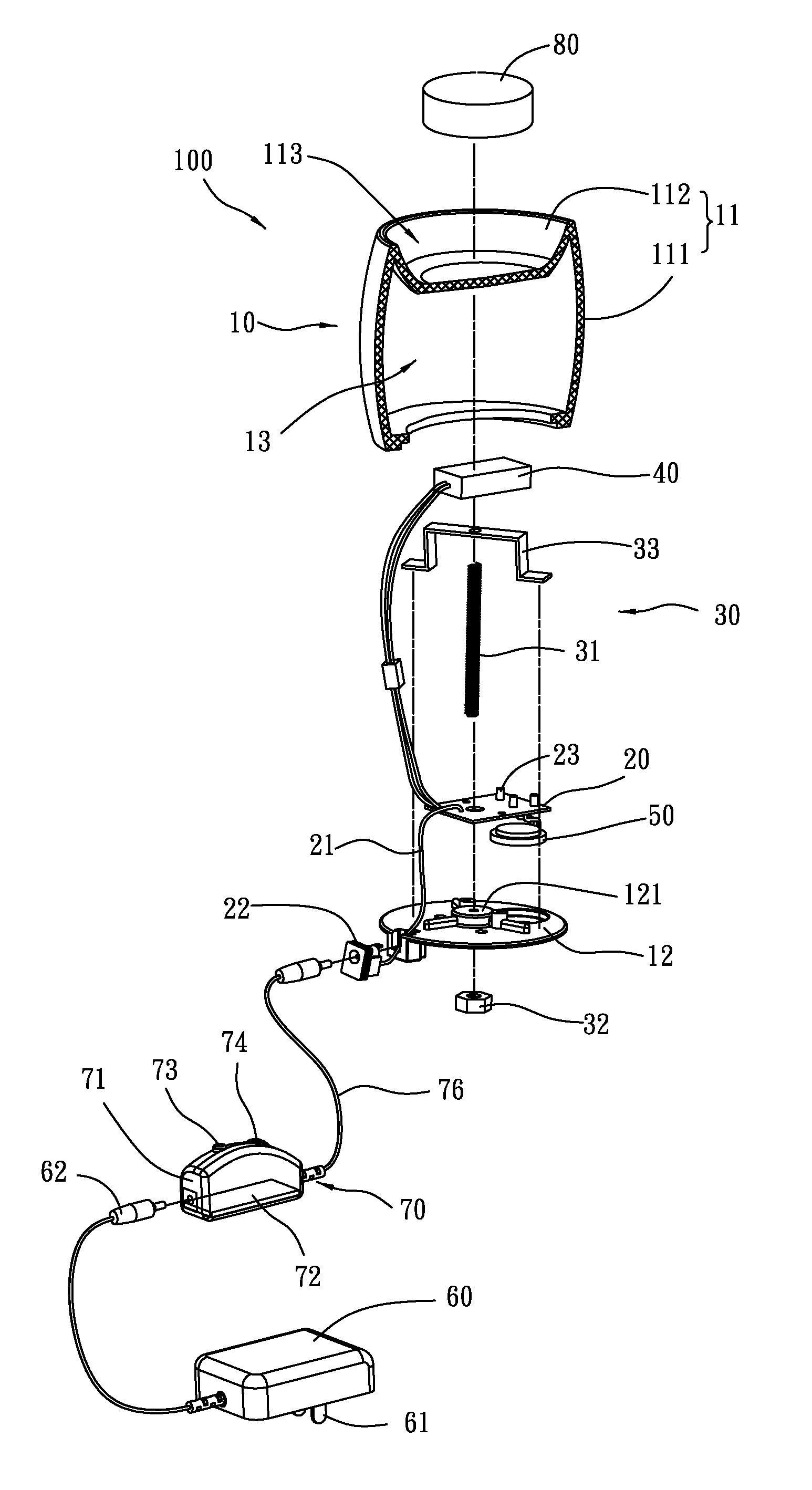

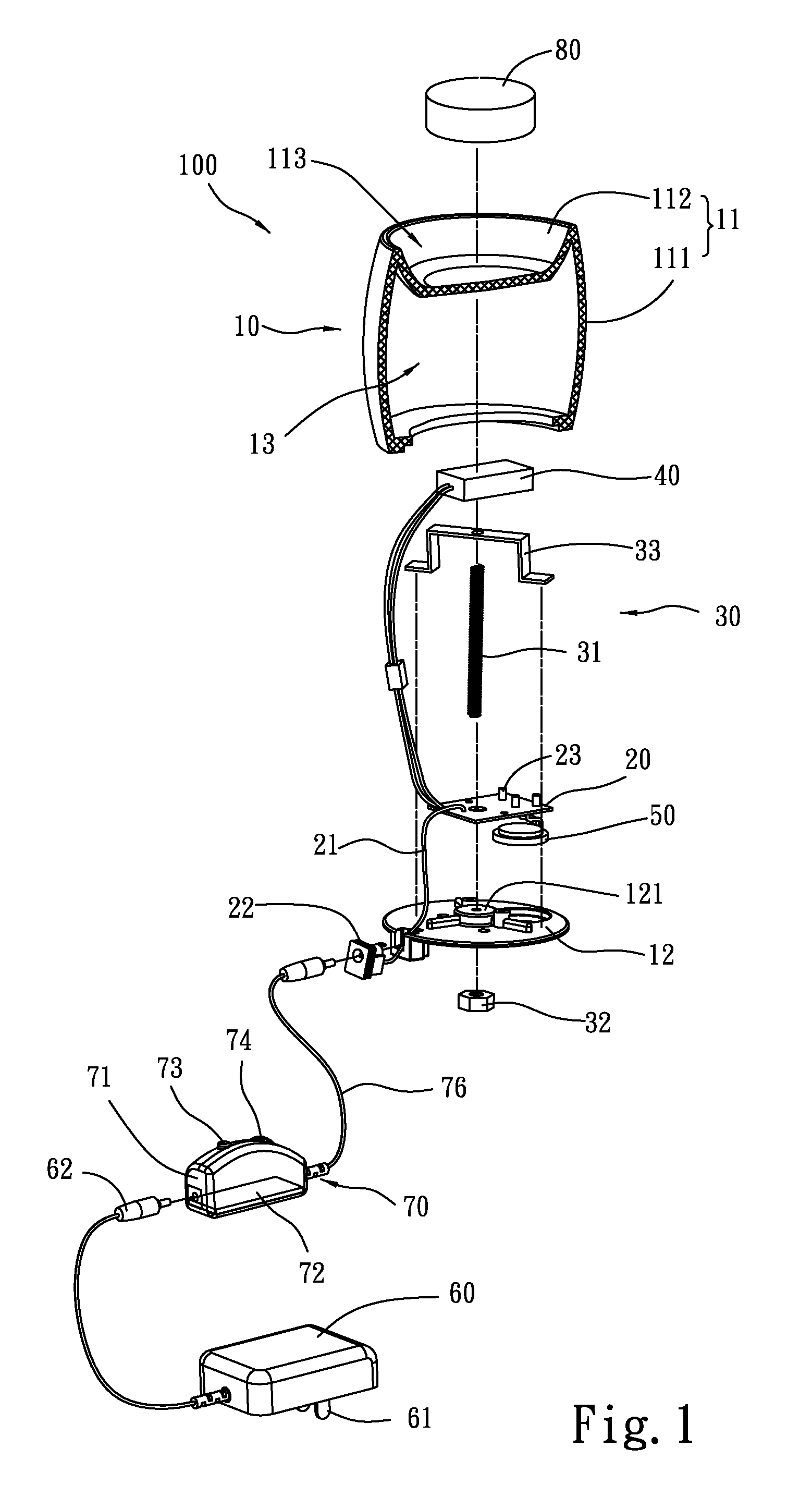

Music generating and aromatic substance retaining and heating system

InactiveUS20100096376A1Excellent aroma heating effectEasy to installSteam generation using steam absorptionMachines/enginesElectricityTransformer

A music generating and aromatic substance retaining and heating system includes an aromatic substance, and a combination structure of music generator and heater, which includes a housing holding the aromatic substance on the top side, a rectifier transformer disposed outside the housing for converting AC into DC, a music controller disposed outside the housing and electrically connected to the rectifier transformer for outputting a music signal, a heating control circuit board mounted inside the housing and electrically connected to the music controller for controlling a speaker to output music and an electronic heater to heat the aromatic substance to release a scent.

Owner:HSIAO MING JEN

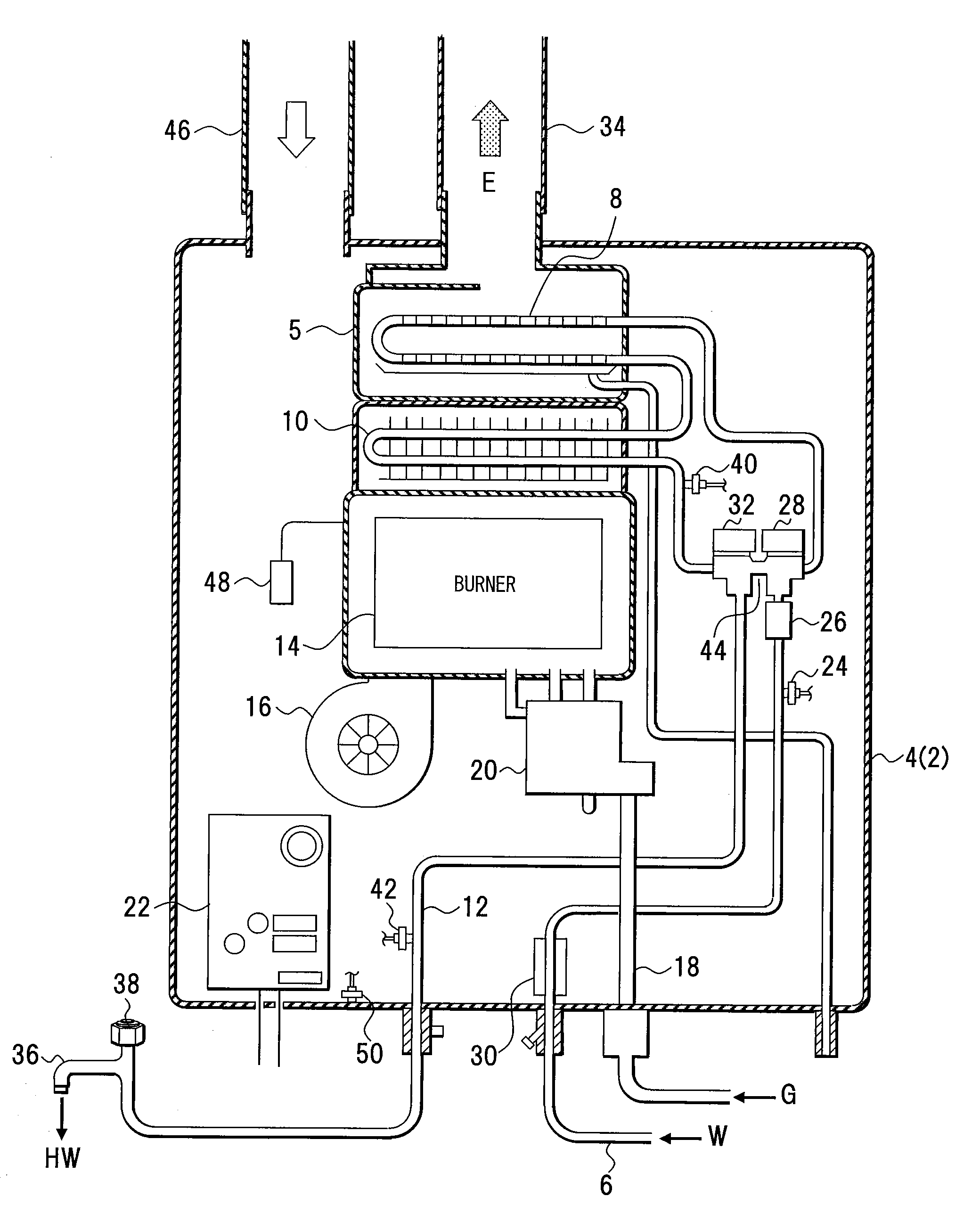

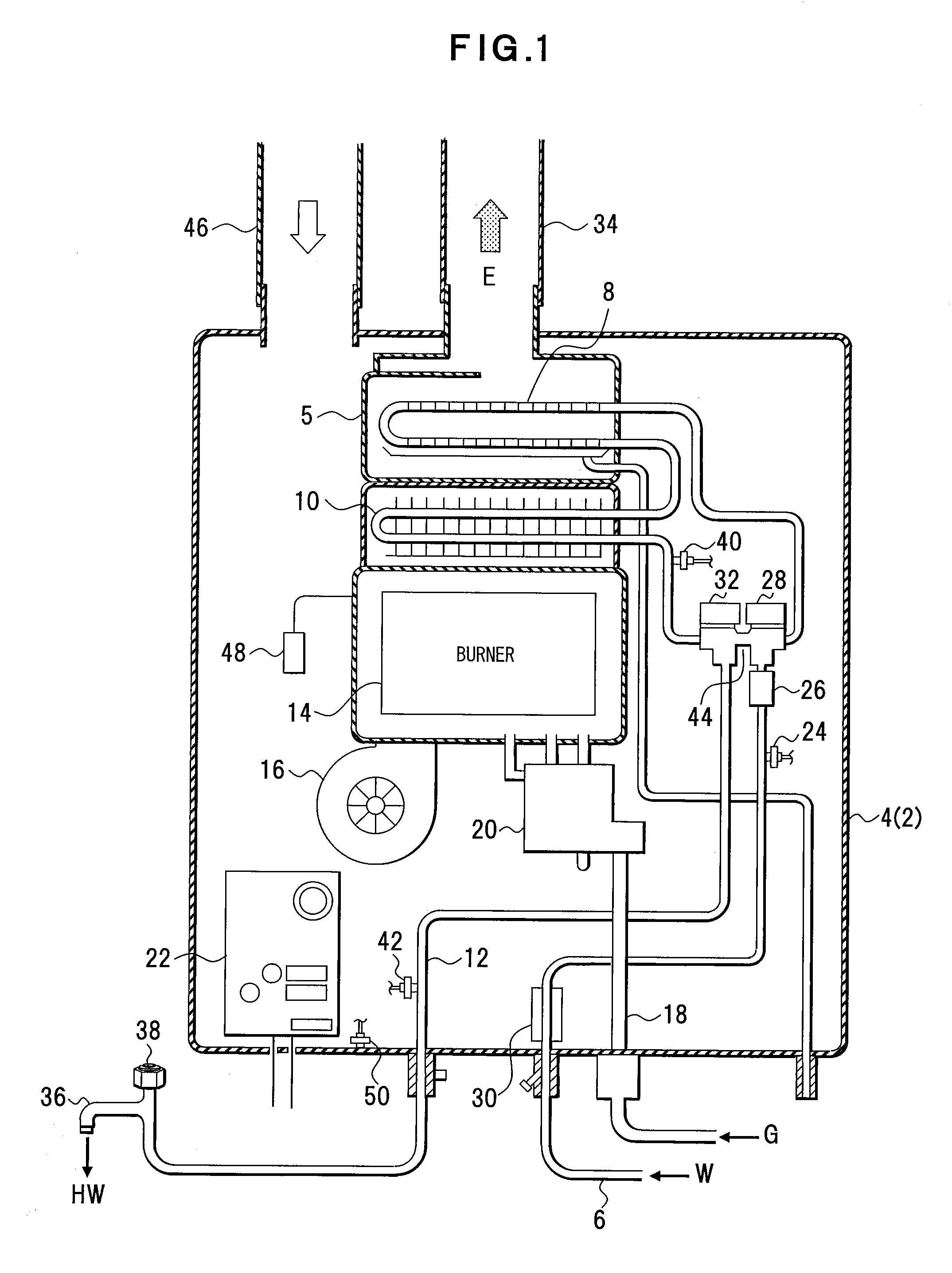

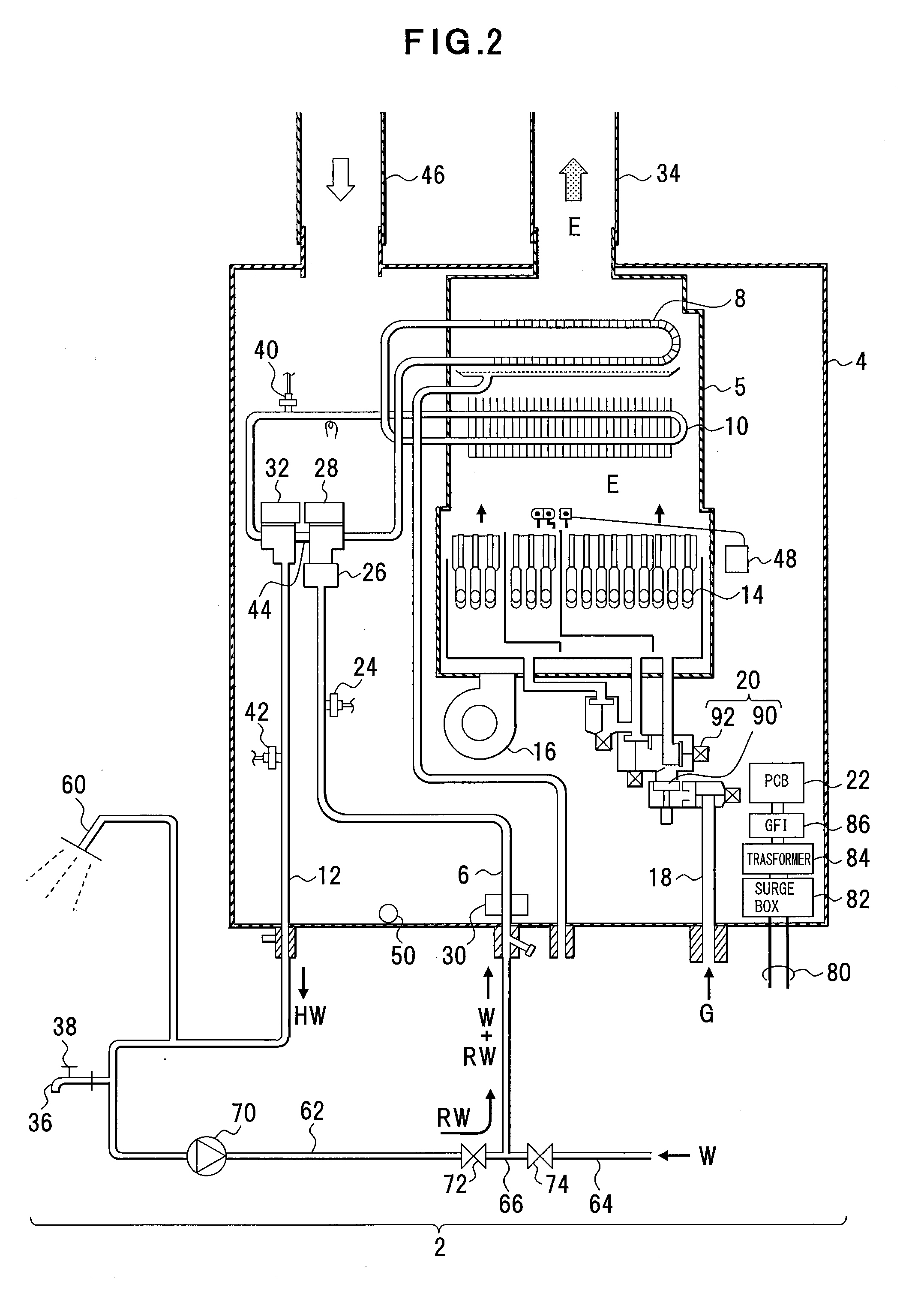

Water heater and control method therefor

ActiveUS20120090341A1Simple control structureSimple structureHeating fuelSpace heating and ventilation detailsCirculator pumpStop time

A water heater includes one or a plurality of heat pumps that heat tap water or return water from a hot water supply part, a circulation line that supplies hot water heated in the heat pumps to the hot water supply part, and introduces the return water from the hot water supply part to the heat pumps, an incoming water pipe that joins to between the hot water supply part in the circulation line and the heat pumps and supplies the tap water, a circulation pump that returns the return water to the heat pumps and circulates the return water through the circulation line, and a control unit that controls operation or stop of the circulation pump according to driving operation time or elapsed stop time by linking a combustion process of the heat pumps.

Owner:PURPOSE CO LTD

Fragrance producing lighting device

Owner:SKY RICH STAR LTD

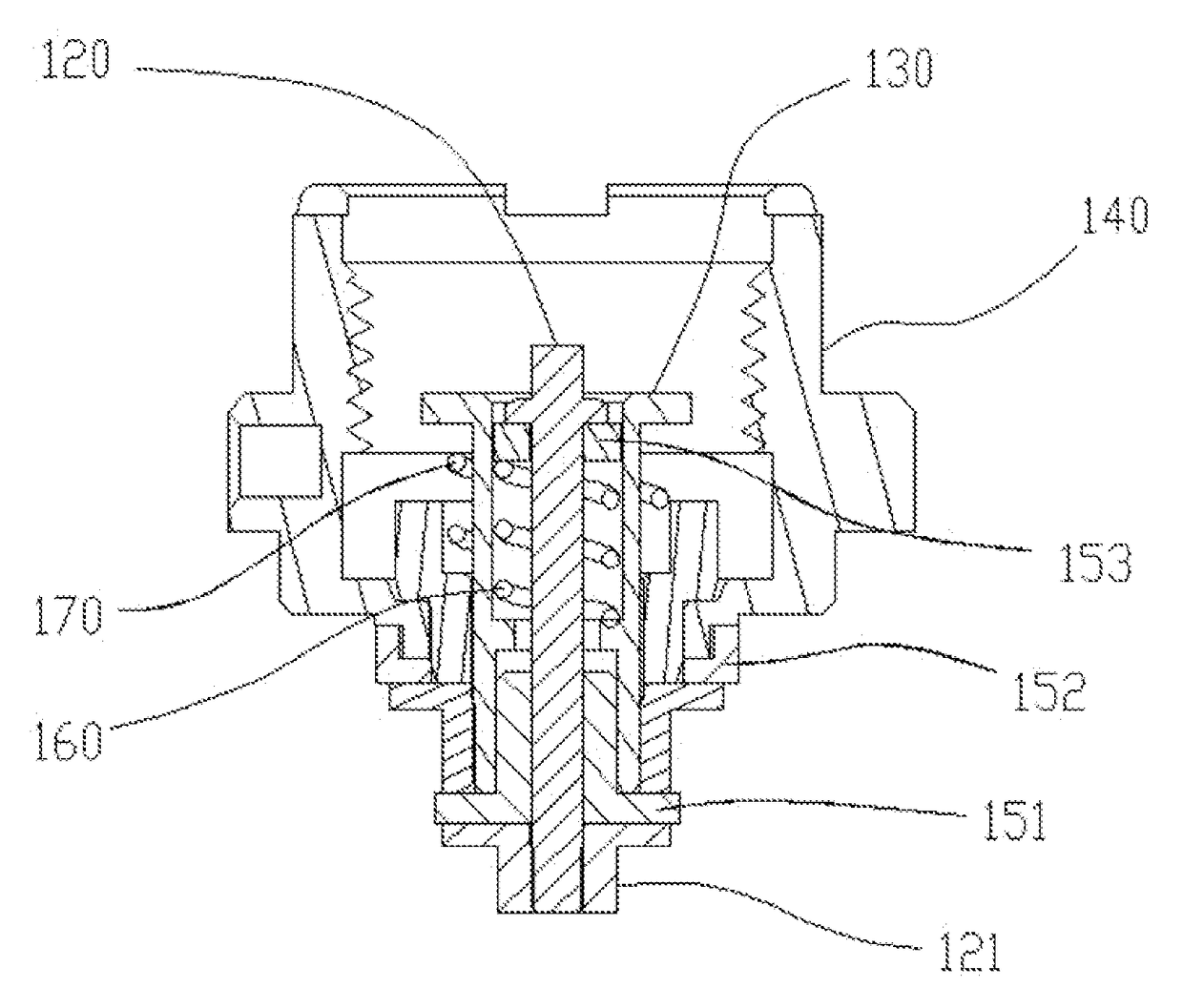

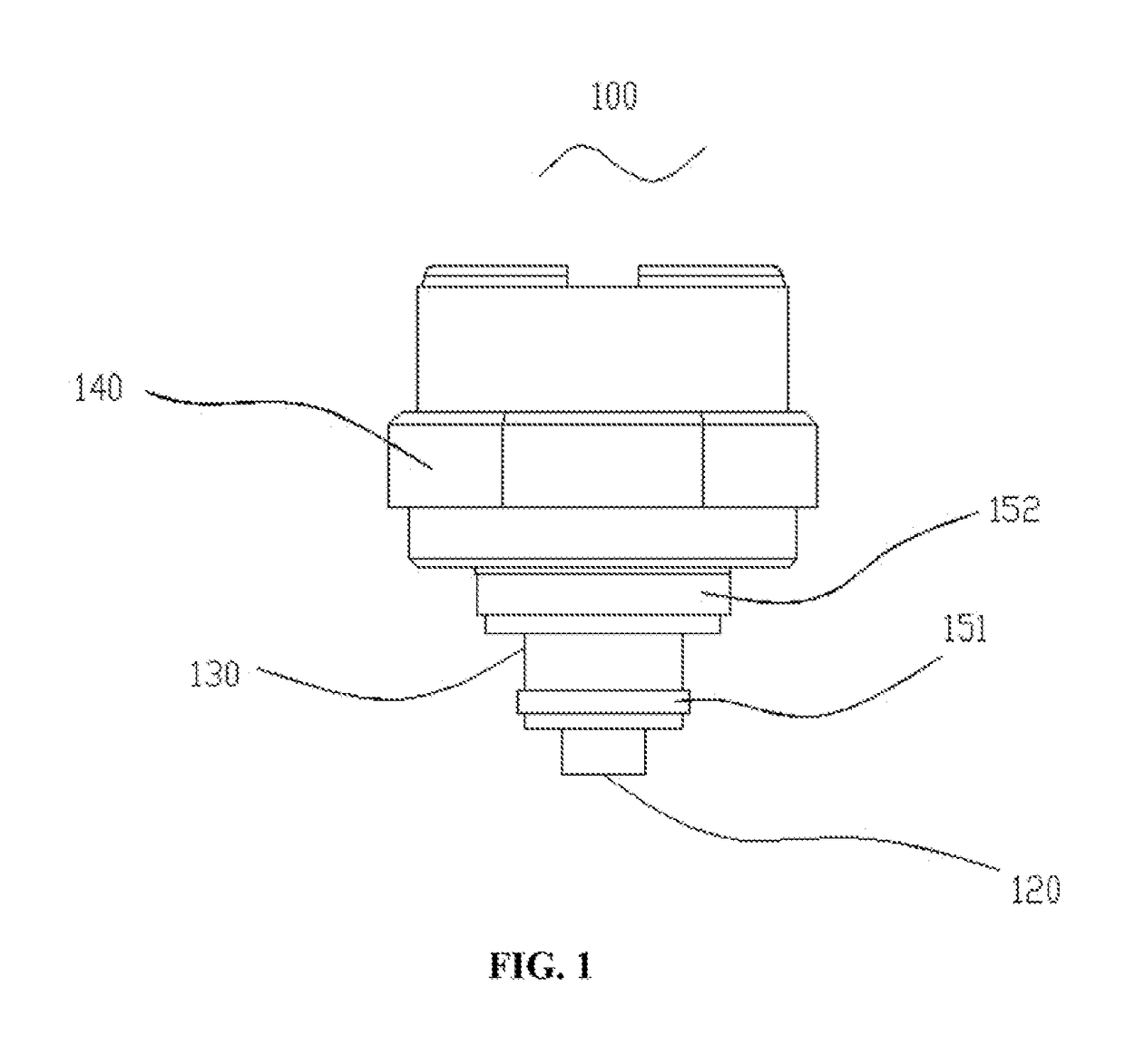

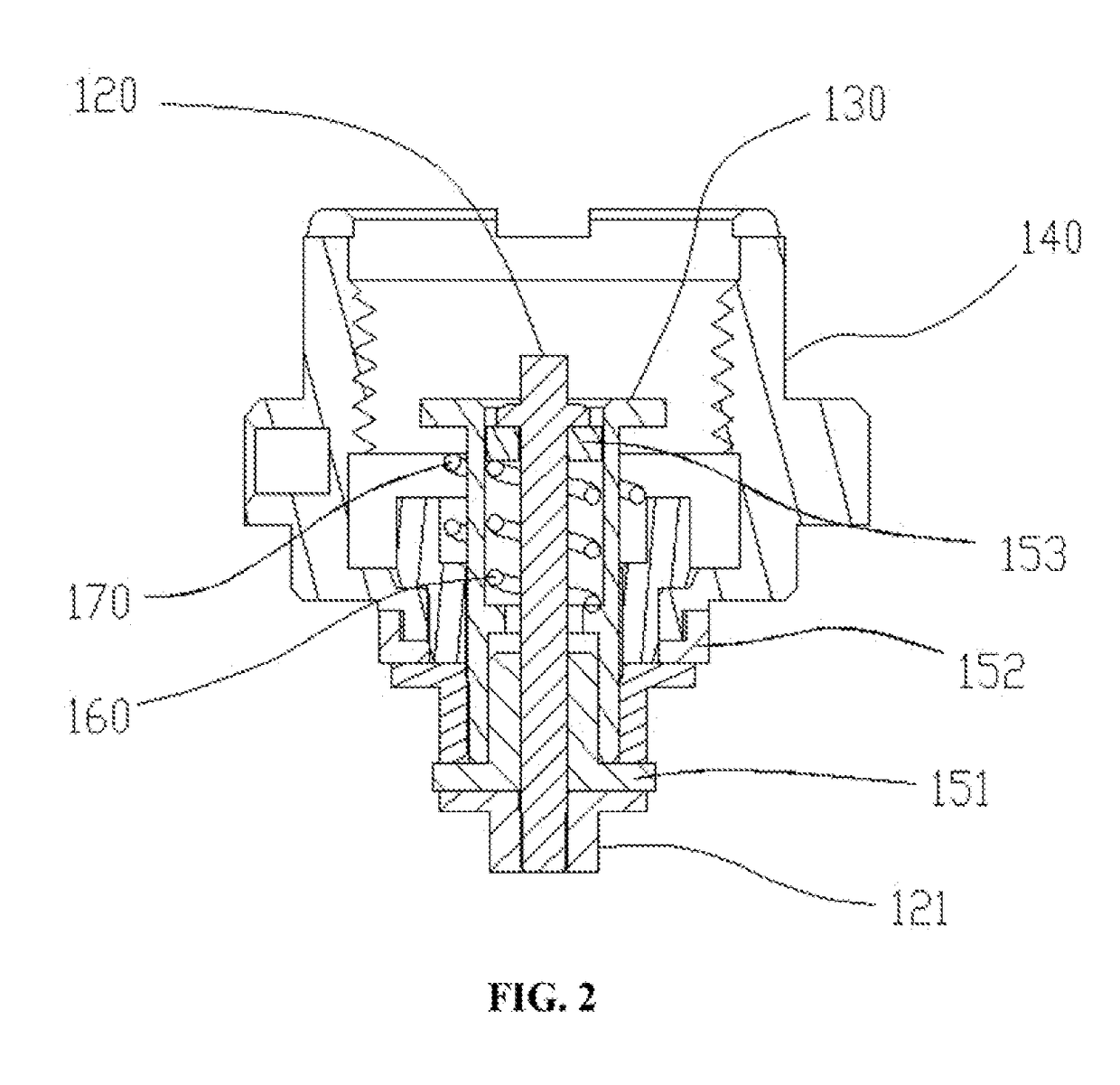

Connector, power supply, and electronic cigarette having same

The present disclosure relates to an exemplary connector for an electronic cigarette, and the connector is configured for connecting an atomizer and a power supply. The connector includes a substrate served as a first electrode, a second electrode, a third electrode, and a first elastic element. The substrate and the second electrode are configured for inputting power to the atomizer. The third electrode is insulated from the substrate. The second electrode nests the third electrode. The third electrode is configured for feeding back an electronic signal, and is an elastic electrode. The third electrode is movable along an axial direction of the connector relative to the second electrode. The first elastic element nests the second electrode, and is configured such that the second and the third electrodes as a whole are movable along an axial direction of the connector relative to the substrate.

Owner:SHENZHEN FIRST UNION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com