Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Maximum recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

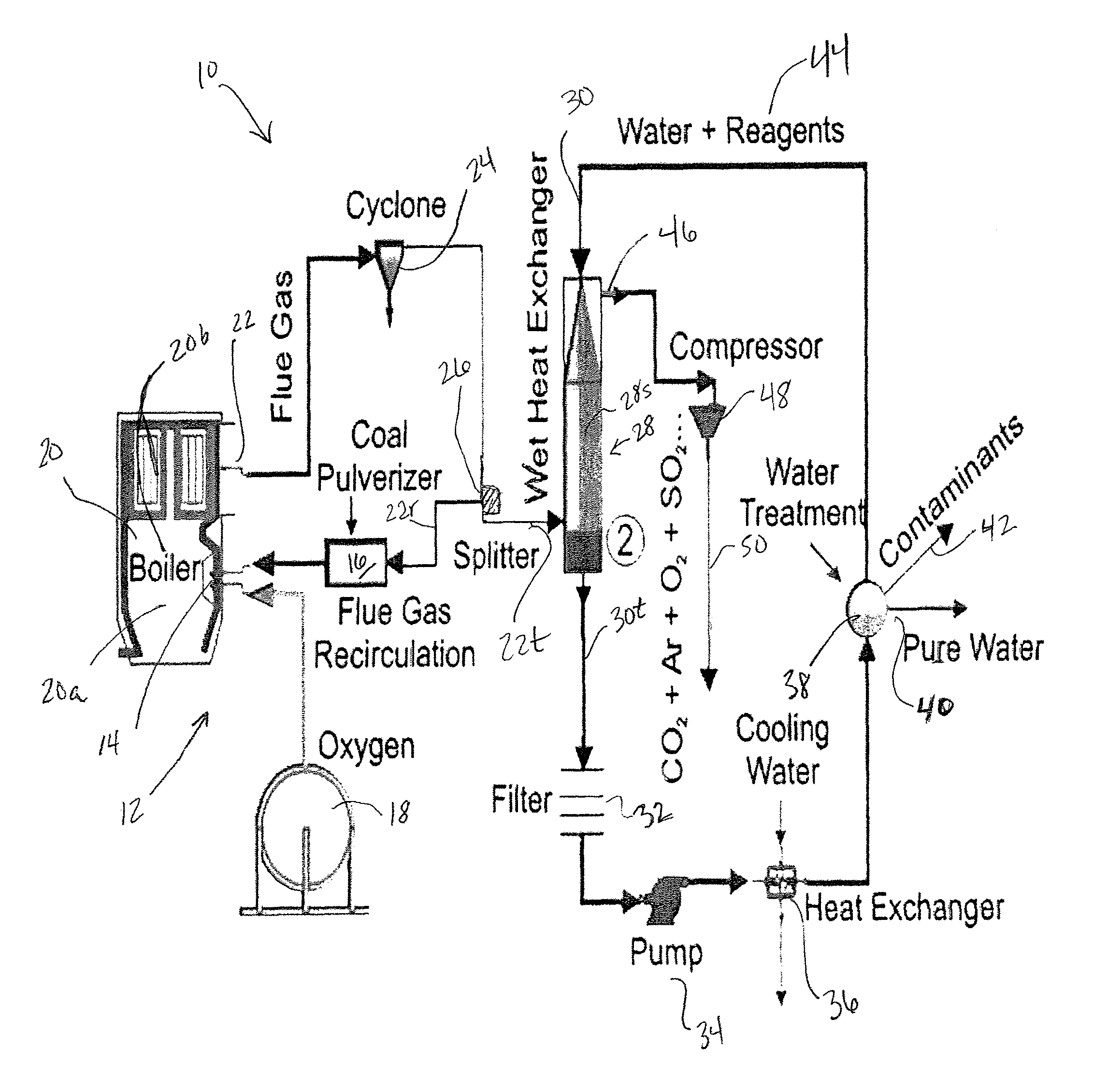

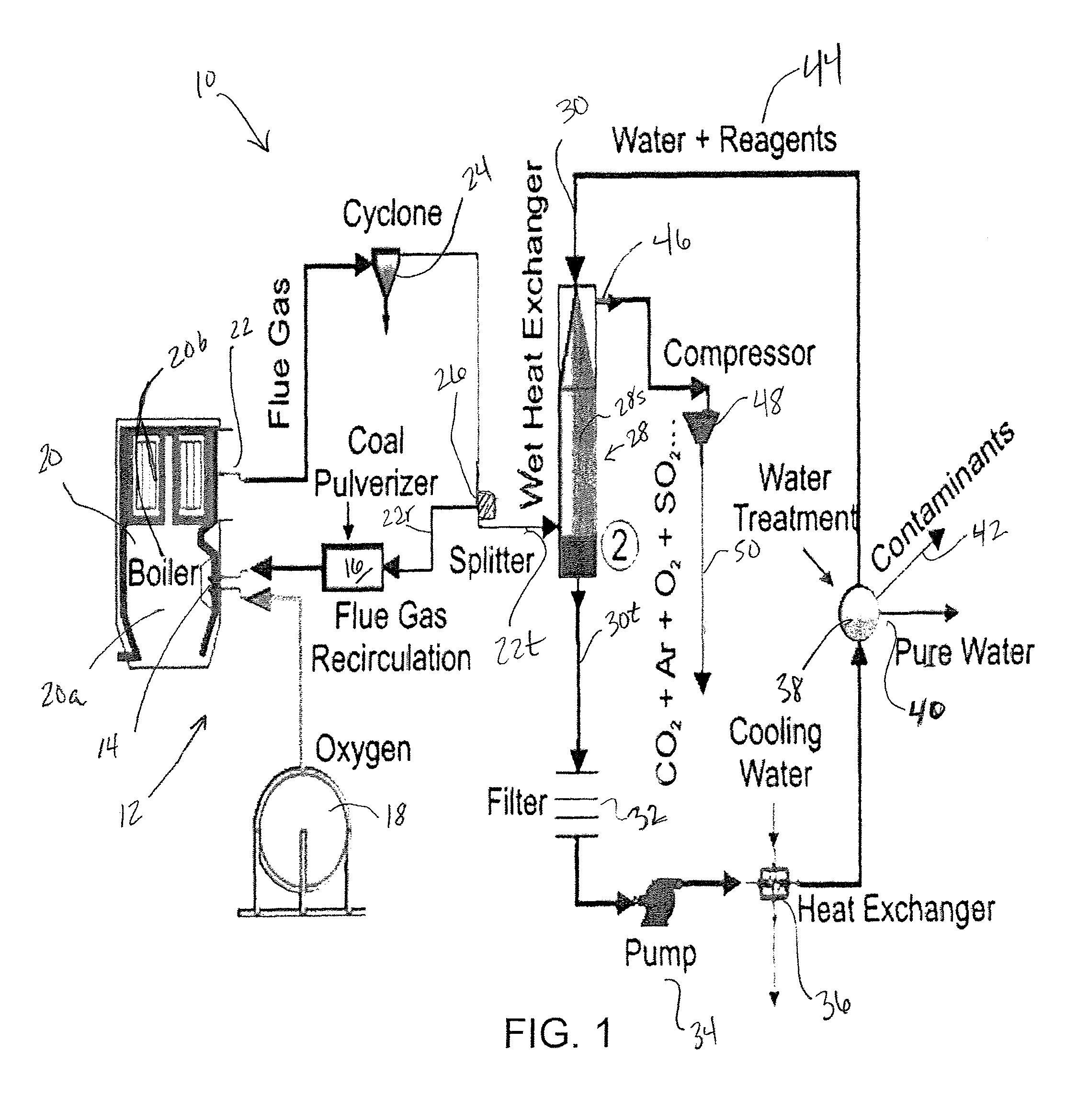

Integrated capture of fossil fuel gas pollutants including CO2 with energy recovery

ActiveUS8038773B2Maximum recoveryUsing liquid separation agentEmission preventionParticulatesAtmospheric air

A method of reducing pollutants exhausted into the atmosphere from the combustion of fossil fuels. The disclosed process removes nitrogen from air for combustion, separates the solid combustion products from the gases and vapors and can capture the entire vapor / gas stream for sequestration leaving near-zero emissions. The invention produces up to three captured material streams. The first stream is contaminant-laden water containing SOx, residual NOx particulates and particulate-bound Hg and other trace contaminants. The second stream can be a low-volume flue gas stream containing N2 and O2 if CO2 purification is needed. The final product stream is a mixture comprising predominantly CO2 with smaller amounts of H2O, Ar, N2, O2, SOX, NOX, Hg, and other trace gases.

Owner:JUPITER OXYGEN CORP

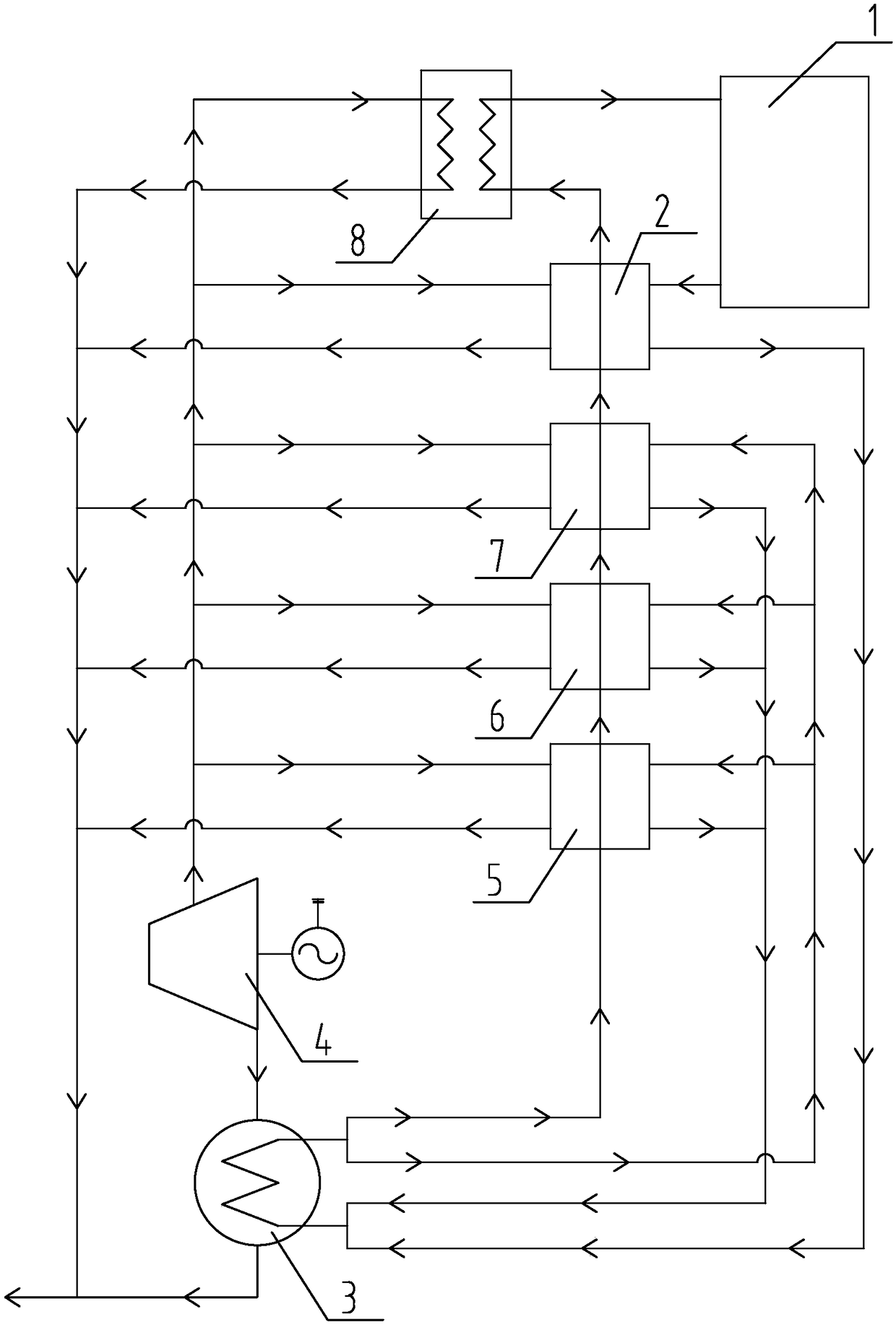

Combined heat and power generation full-condensation afterheat recovery technology

InactiveCN108317579AGuaranteed temperatureReduce dosageFeed water supplySteam useCogenerationTemperature difference

The invention provides a method for directly feeding primary network returned water in the steam condenser as condensed water and a method for reducing the water outlet temperature of the condensed water of a steam condenser step by step, increasing the water supply temperature of a primary network step by step and improving the power generation efficiency and the heat supply effect. The method comprises a thermal power plant steam extraction heat supply system, a returned water temperature adjusting system, a thermal power plant steam condenser cooling water system and a high-temperature-difference heat supply primary pipe network.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

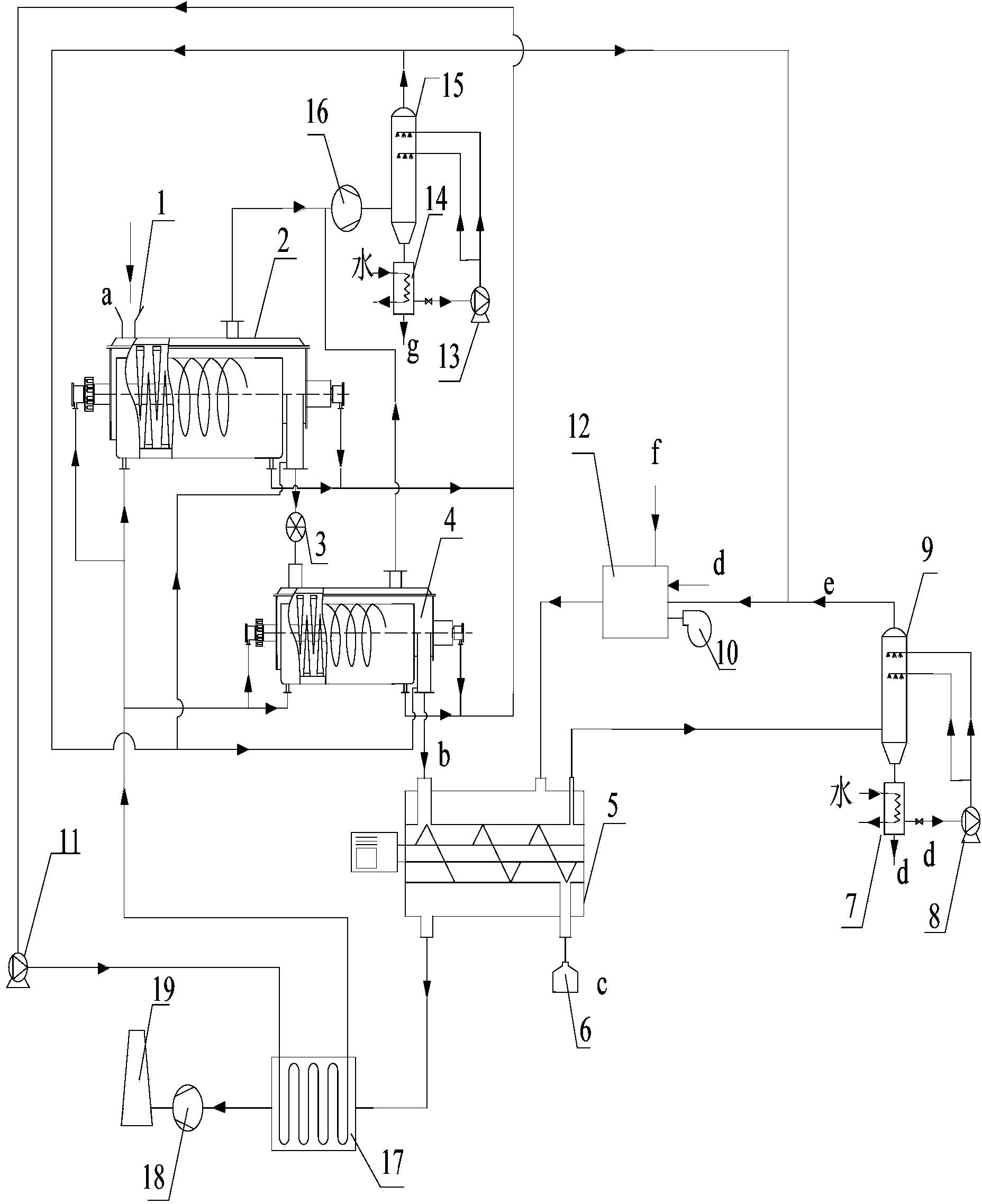

High-efficiency oil sludge pyrolysis oil making method and system

InactiveCN104261649AReduce moisture contentPrevent deflagrationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesAtmospheric airOil sludge

The invention discloses a high-efficiency oil sludge pyrolysis oil making method and system and belongs to the technical field of solid waste recycling and environment. Crude oil sludge is subjected to deep drying and breaking treatment by virtue of a two-stage blade-type dryer and then enters a spiral pyrolyzing furnace, and produced pyrolysis gas is subjected to spray cooling to obtain an oil product; noncondensing gas and part of pyrolysis oil which are produced in a drying and pyrolysis process are fed into a burning furnace to be burned, and high temperature smoke produced during burning is used for providing heat for a pyrolysis furnace; smoke at an outlet of a jacket of the pyrolysis furnace passes through a heat conduction oil heat exchanger to recycle waste heat and then is discharged into the air; and the heat conduction oil after being heated provides heat for the blade-type dryer. Therefore, the high-efficiency oil sludge pyrolysis oil making method and system are safe and reliable, drying pyrolysis efficiency is high, the oil product in the sludge can be recycled, gradient utilization of energy is realized, and oil sludge recycling and harmless treatment is realized.

Owner:SOUTHEAST UNIV

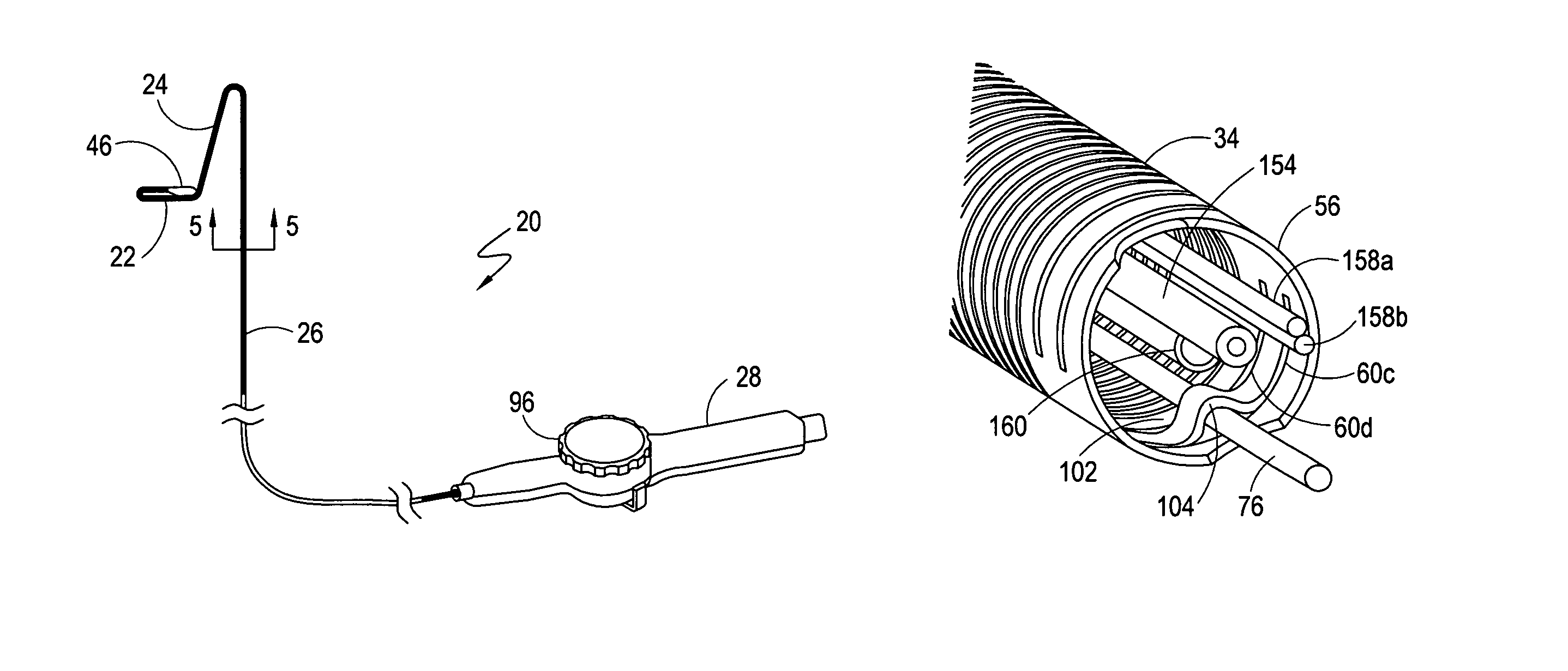

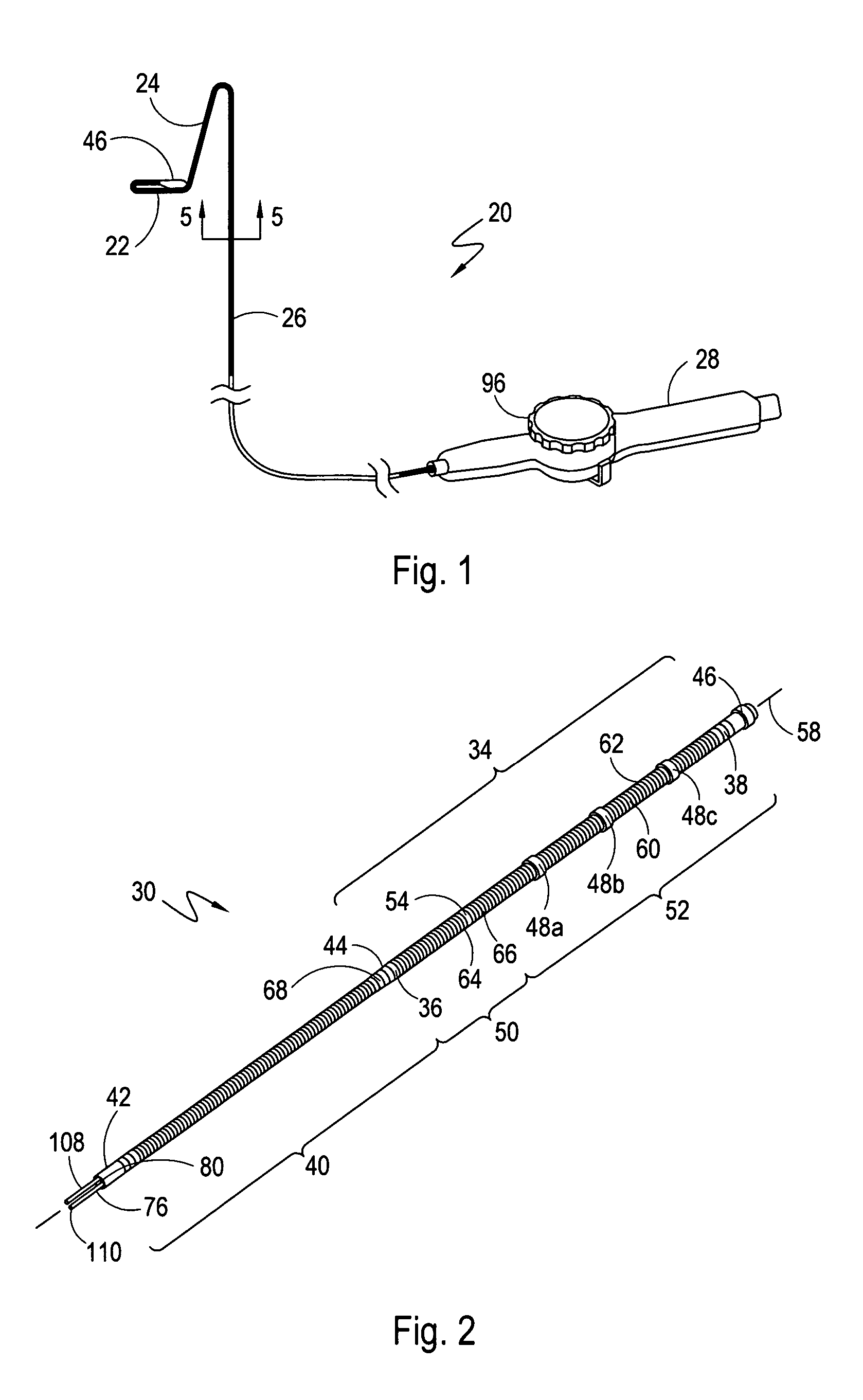

System for bi-directionally controlling the cryo-tip of a cryoablation catheter

InactiveUS7374553B2Restore fluencyMaximum recoveryMedical devicesCatheterLarge deflectionCryoablation

A bi-directional system for actively deflecting the distal tip of a catheter includes a reconfigurable tube that is positioned proximal to the catheter's distal tip. The tube is formed with slits that are arranged to allow the tube to be transformed from a relaxed, cylindrical configuration to a plurality of deflected configurations. First and second pull wires are provided, with each wire having a respective distal end that is attached to the distal end of the tube. Each wire extends to a catheter handle where it is attached to a respective reel. The reels can be rotated, back and forth, to selectively deflect or relax the tube. To ensure a smooth recovery after a relatively large deflection, a mechanism is disclosed for delaying an application of tension on one of the pull wires until at least a portion of any tension on the other pull wire is released.

Owner:CRYOCOR

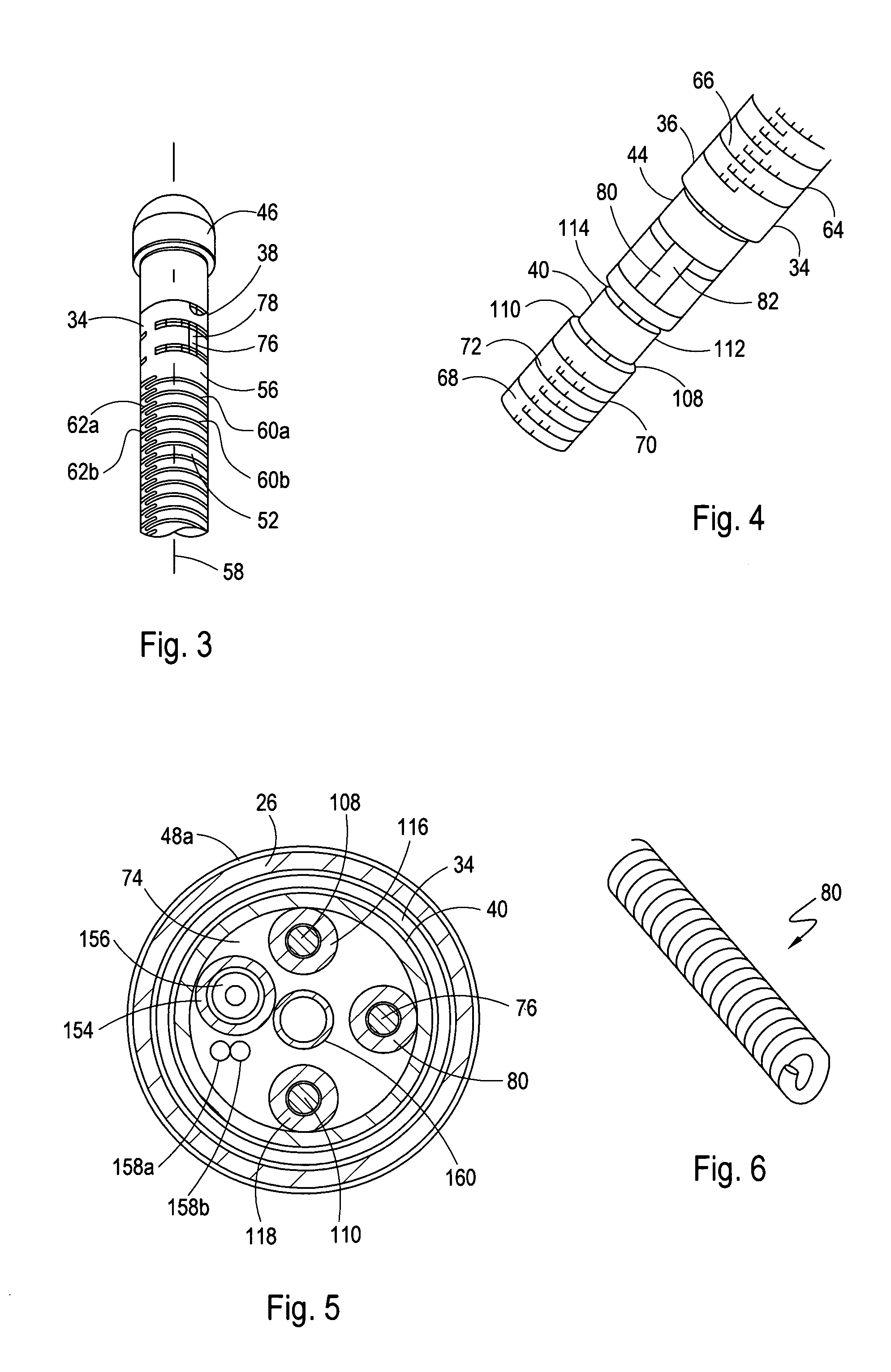

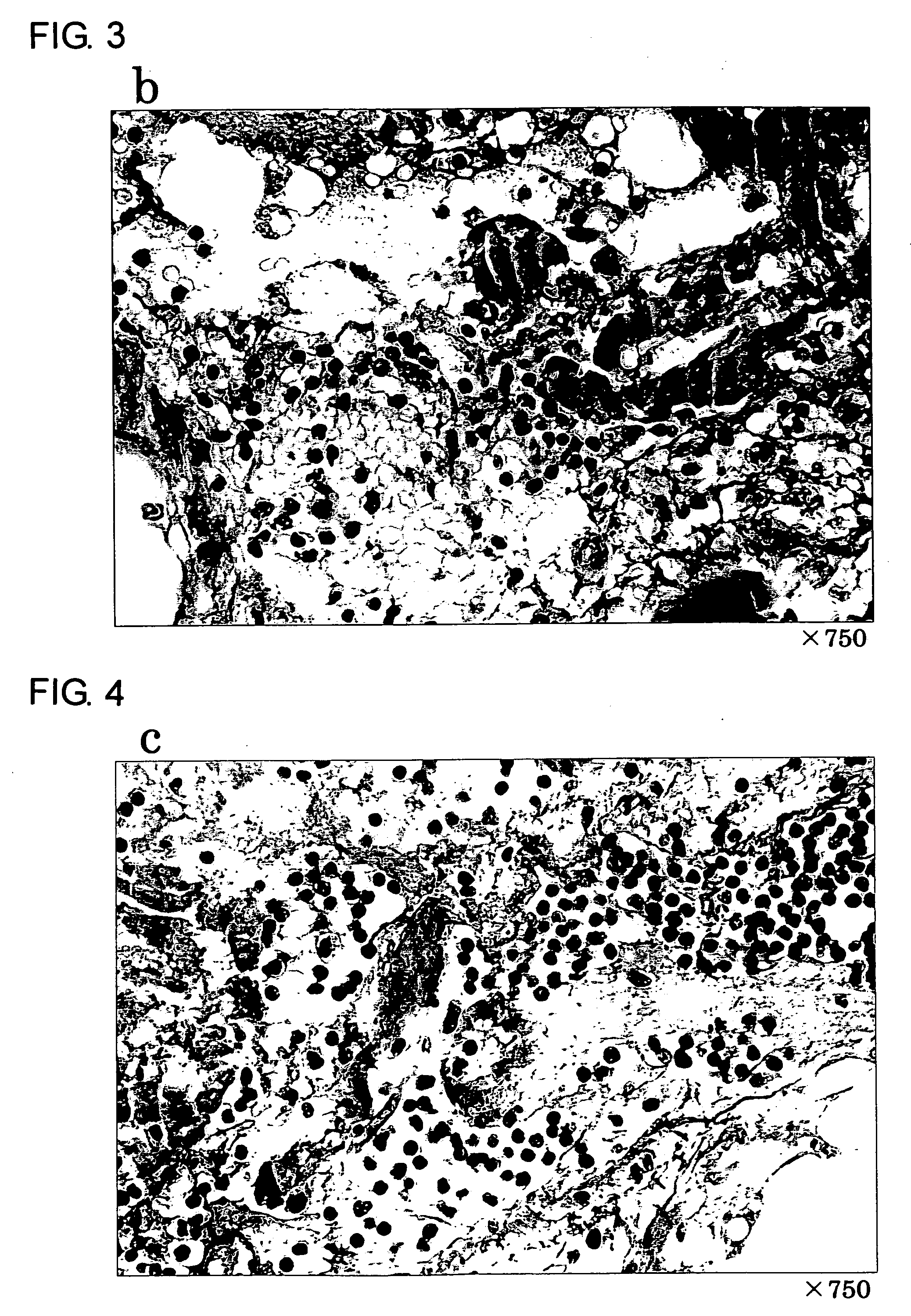

Method of cryopreserving cells

InactiveUS20060063141A1Maximum recoveryDead animal preservationBiological testingMathematical modelCryopreserved Cell

A non-linear cooling cryopreservation method for improving cryopreservation protocols for cells that involves producing a simulation of cellular responses to a range of cooling parameters; determining optimal cooling parameters required to minimize cryoinjury to the cells using simulation of cellular responses and experimental results; and incorporating optimal parameters into the protocol. The simulation is based on mathematical models of cellular parameters. A non-linear cooling cryopreservation protocol for cryopreserving stem cells is also disclosed that does not require cryoprotectants.

Owner:MCGANN LOCKSLEY EARL +2

Fluid flow control for cool, efficient fuel cell operation

InactiveUS6572995B2Reduce the maximum temperatureImprove performanceFuel cell heat exchangeFuel cells groupingFuel cellsCoolant flow

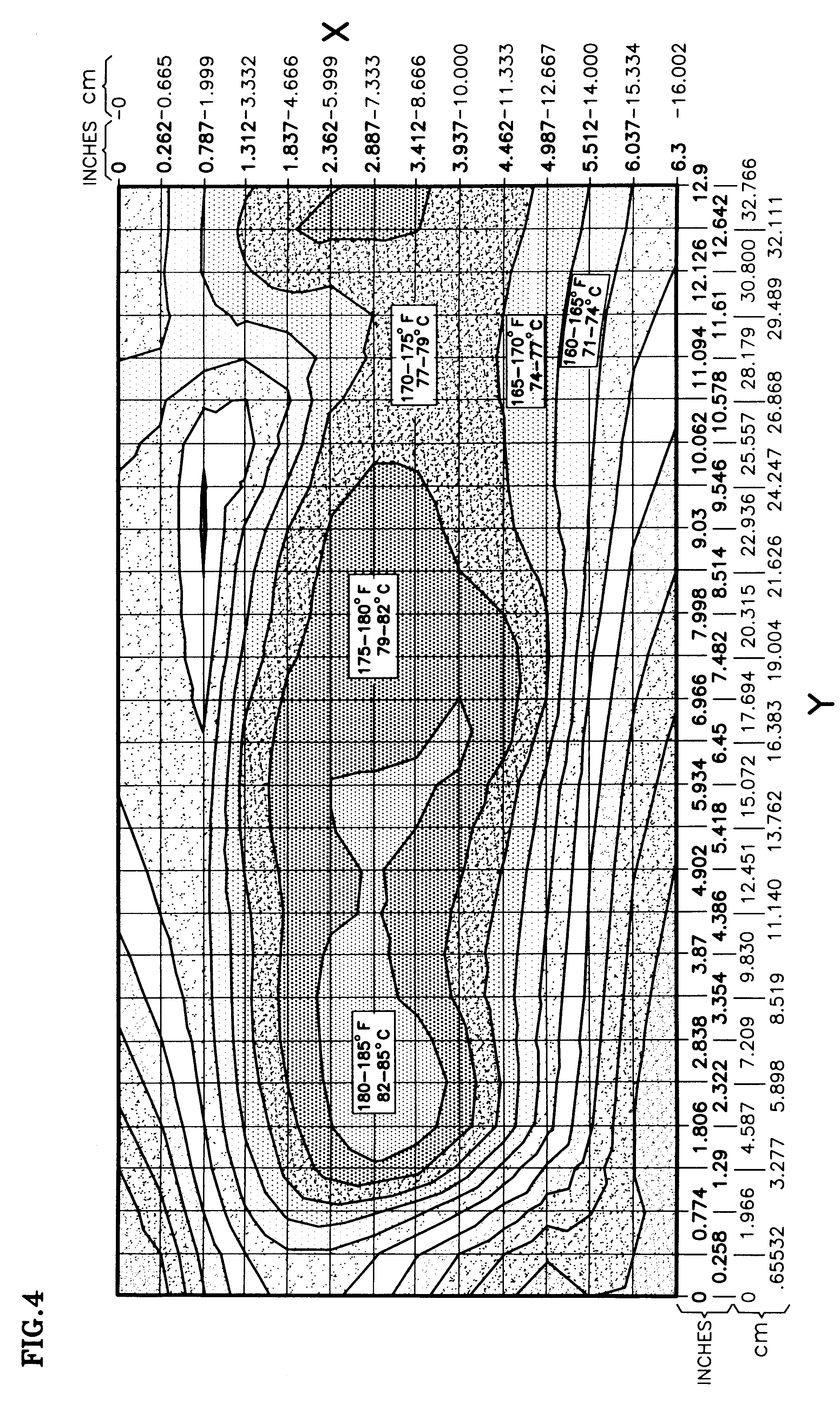

A fuel cell stack (7) has a two-pass fuel flow field (11, 14) extending from a fuel inlet (8) around a fuel turnaround manifold (12) to a fuel outlet (15). The stack has two air flow fields (37, 40) extending from an air inlet (32) through an air turnaround manifold (38) to an air outlet (41), the air outlet (41) being adjacent to the fuel outlet (15). The stack includes a coolant flow field (23, 25, 27) which extends from a coolant inlet (21) to a coolant outlet (28), the coolant inlet being adjacent to both the fuel outlet and the air outlet. The fluid flow configuration provides lower temperature, a more even temperature profile, a higher coolant exit temperature, and permits operation with higher air utilization and lower coolant flow.

Owner:AUDI AG

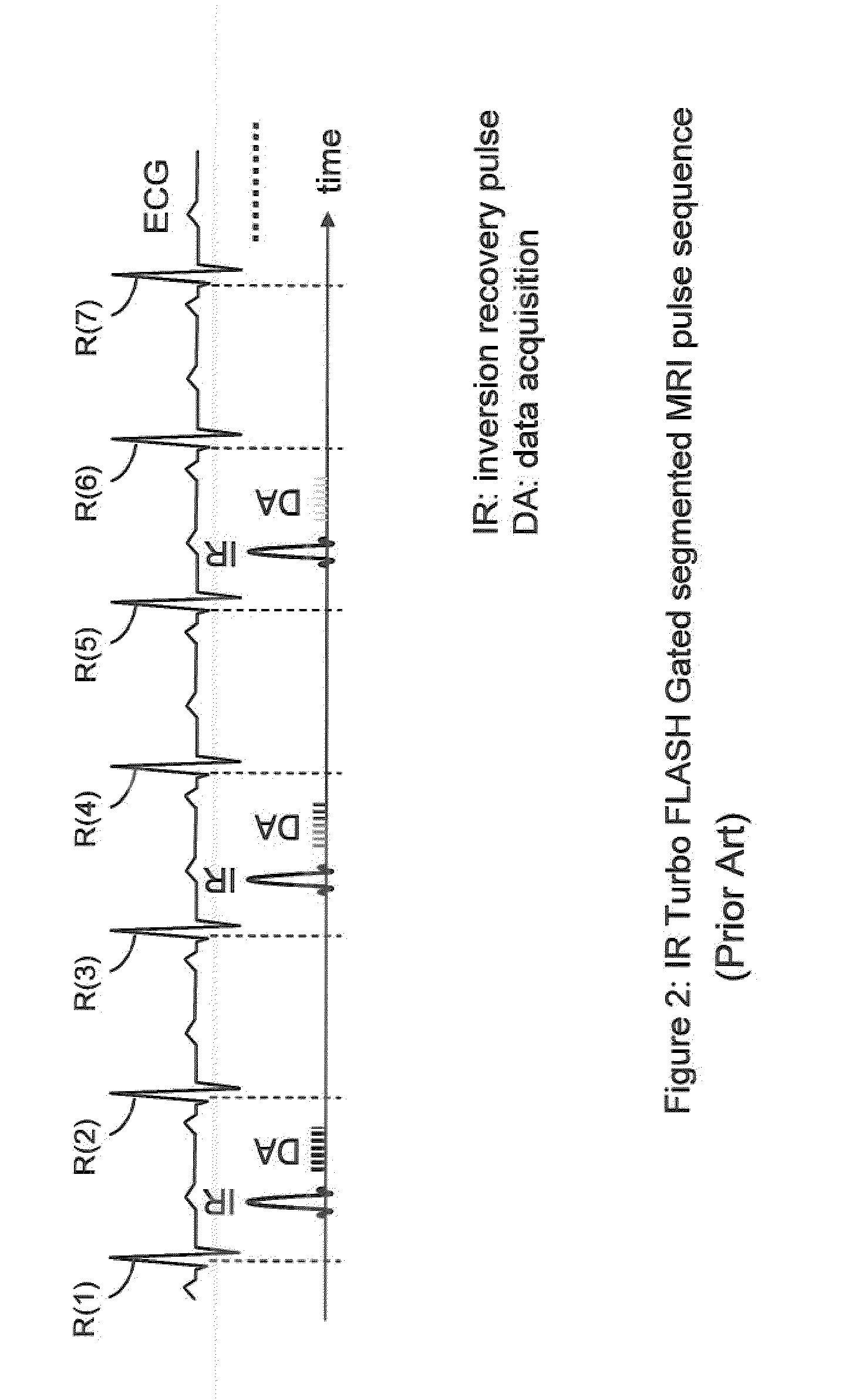

Long t1 artifact suppression techniques for magnetic resonance imaging

ActiveUS20100219829A1Suppression of signalMaximum recoveryMeasurements using NMR imaging systemsElectric/magnetic detectionPhysicsSelective inhibition

A method of suppressing artifacts arising from tissue, fluids, or other long-T1 species when acquiring magnetic resonance data with a segmented pulse sequence that assumes that magnetization is at steady state, said method including suppressing artifacts by producing an artifact suppression module (ASM) before the segmented sequence, the artifact suppression module comprising at least one selective, non-selective, or volume-selective suppression pulse and a time delay.

Owner:DUKE UNIV +1

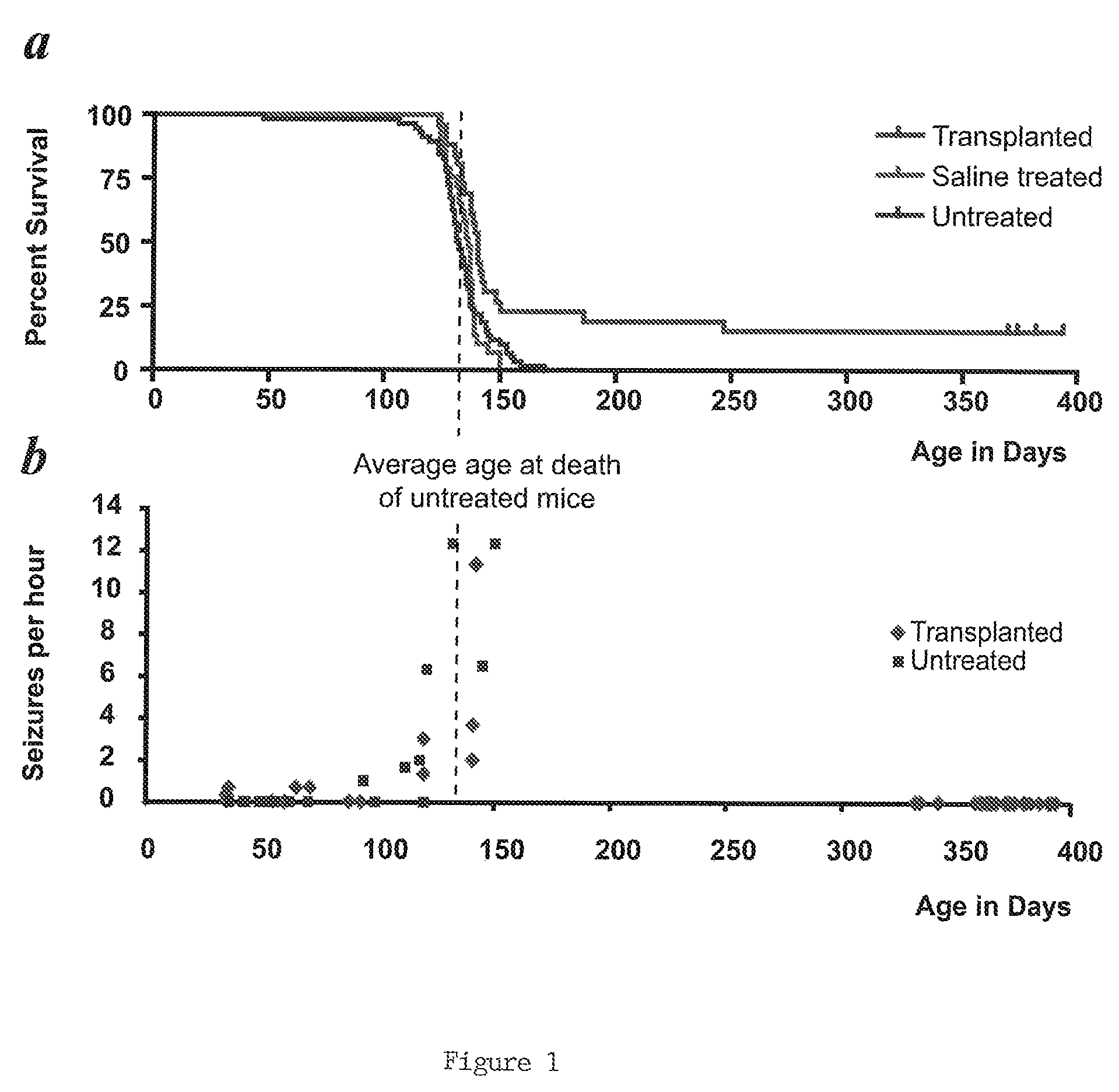

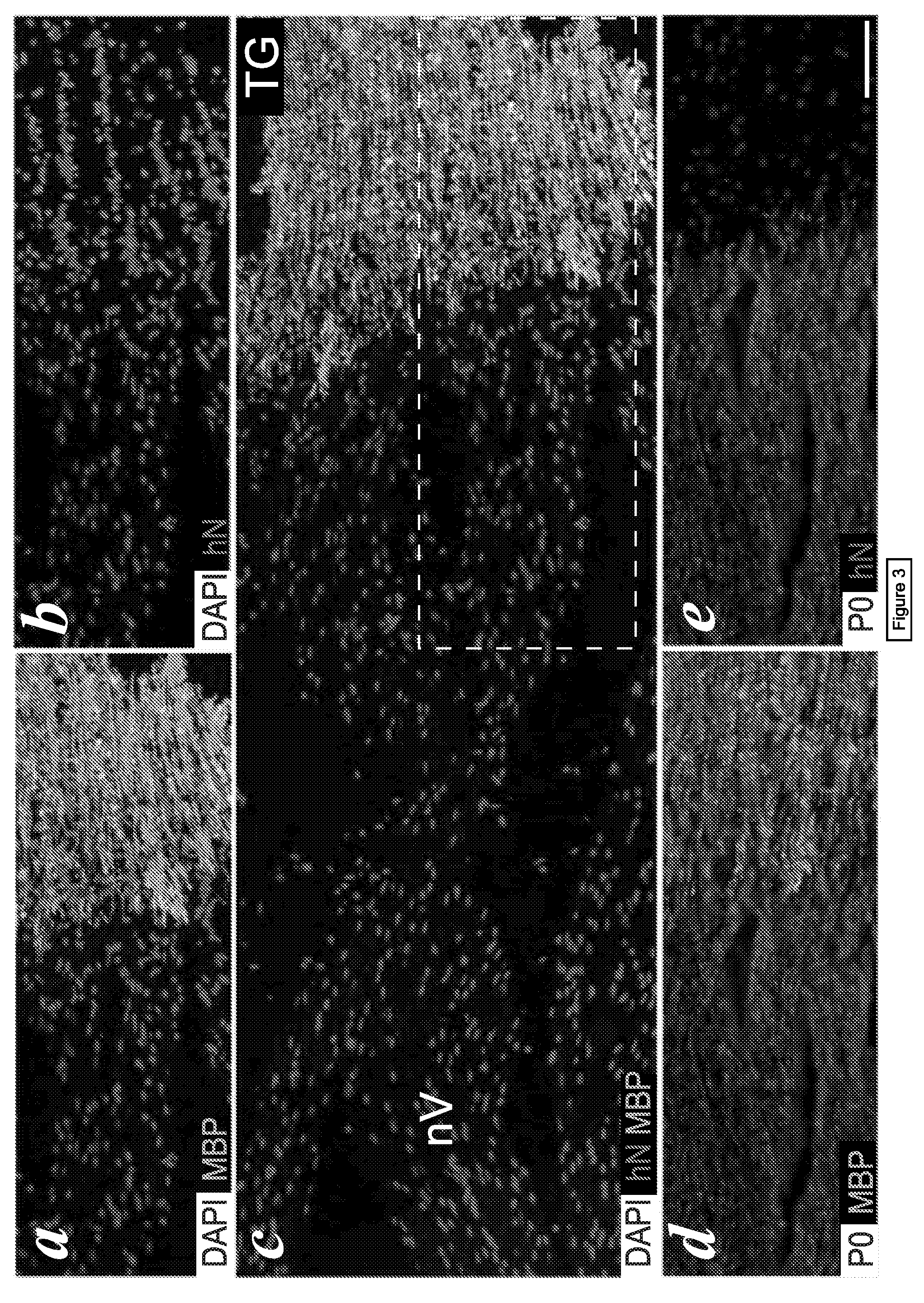

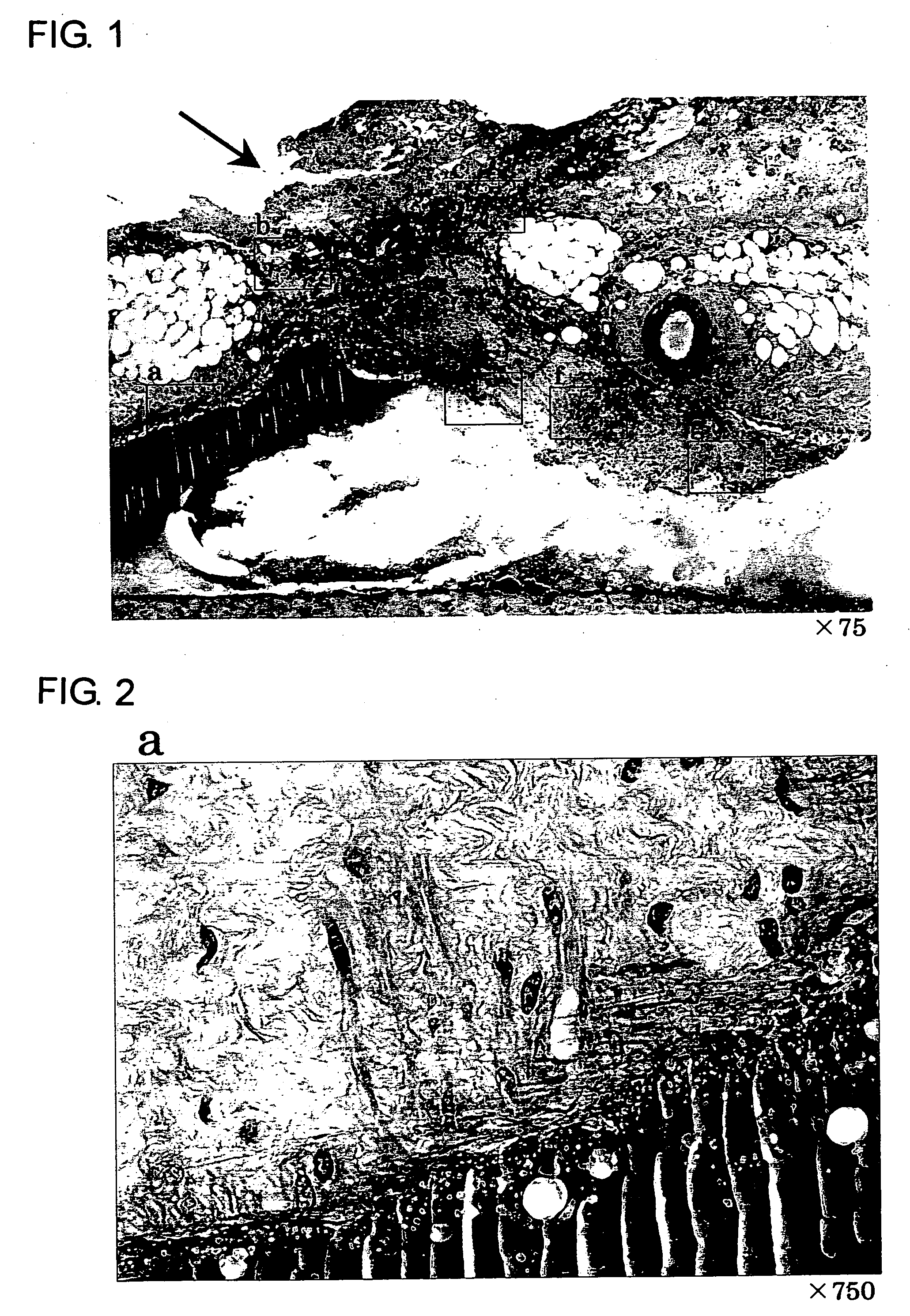

Non human animals with human-glial chimeric brains

The present invention is directed to a non-human mammal with at least 30% of all of its glial cells in its corpus callosum being human glial cells and / or at least 5% of all of its glial cells in the white matter of its brain and / or brain stem being human glial cells. Methods of producing and using the non-human mammal are also disclosed.

Owner:UNIVERSITY OF ROCHESTER

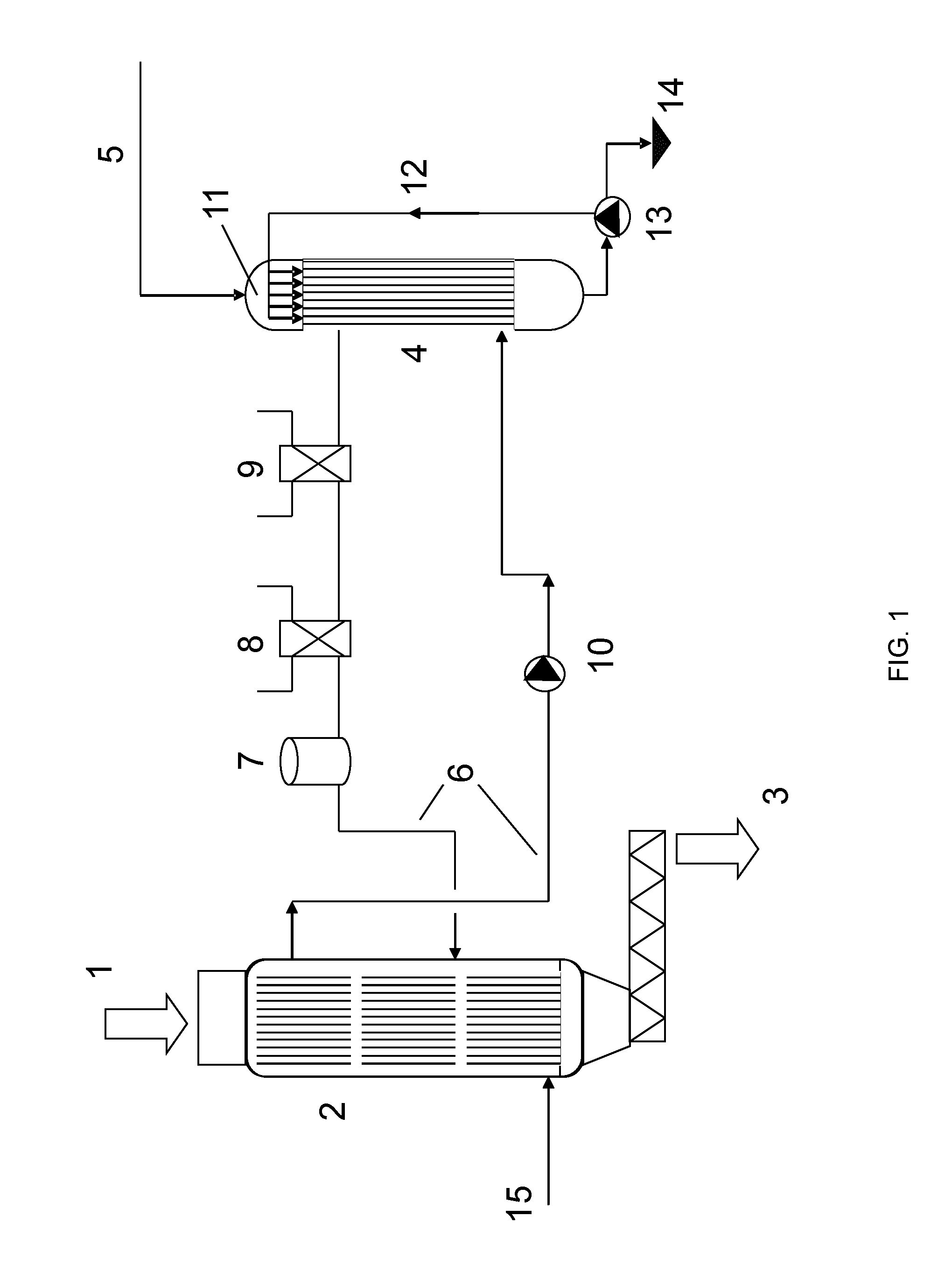

Recovery of Energy During the Production of Aromatic Carboxylic Acids

InactiveUS20080194865A1Maximum recoveryOrganic compound preparationChemical industryCarboxylic acidEnergy recovery

Energy is recovered during the production of aromatic carboxylic acids by liquid phase oxidation of aromatic hydrocarbons by performing a high efficiency separation on the reactor overhead vapor to form a high pressure gaseous overhead stream comprising water and organic impurities; recovering heat energy from the high pressure gaseous overhead stream by exchanging heat with a suitable heat sink material such that a condensate comprising from about 20 wt % to about 60 wt % of the water present in the high pressure gaseous overhead stream is formed and a high pressure off-gas is formed; and recovering energy in the form of work from the high pressure off-gas. Preferably such work is recovered using isentropic means for energy recovery, for example an expander. Apparatus for such process is also provided.

Owner:BP CORP NORTH AMERICA INC

Methods for obtaining paclitaxel from taxus plants

ActiveUS20060014968A1High purityMaximum recoveryOrganic chemistryChromatographic separationTaxus species

Methods for obtaining paclitaxel from plants containing paclitaxel are disclosed. Plant material is first obtained from plants containing paclitaxel. Paclitaxel is then extracted from the plant material. Subsequently, paclitaxel is separated from the paclitaxel extract using a series of column chromatography separation steps to obtain at least one fraction containing paclitaxel. The paclitaxel in a fraction that is obtained from the final chromatography step is crystallized. Using these methods, high purity paclitaxel may be efficiently obtained from plants containing paclitaxel.

Owner:INDENA SPA

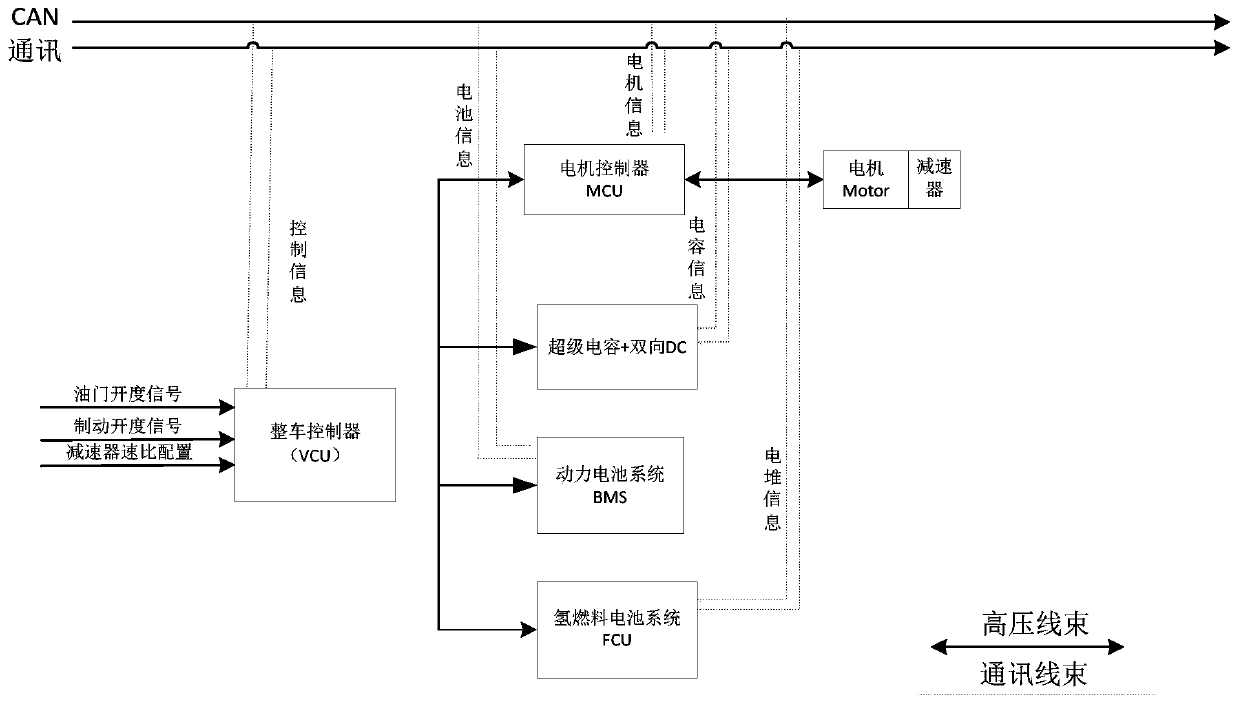

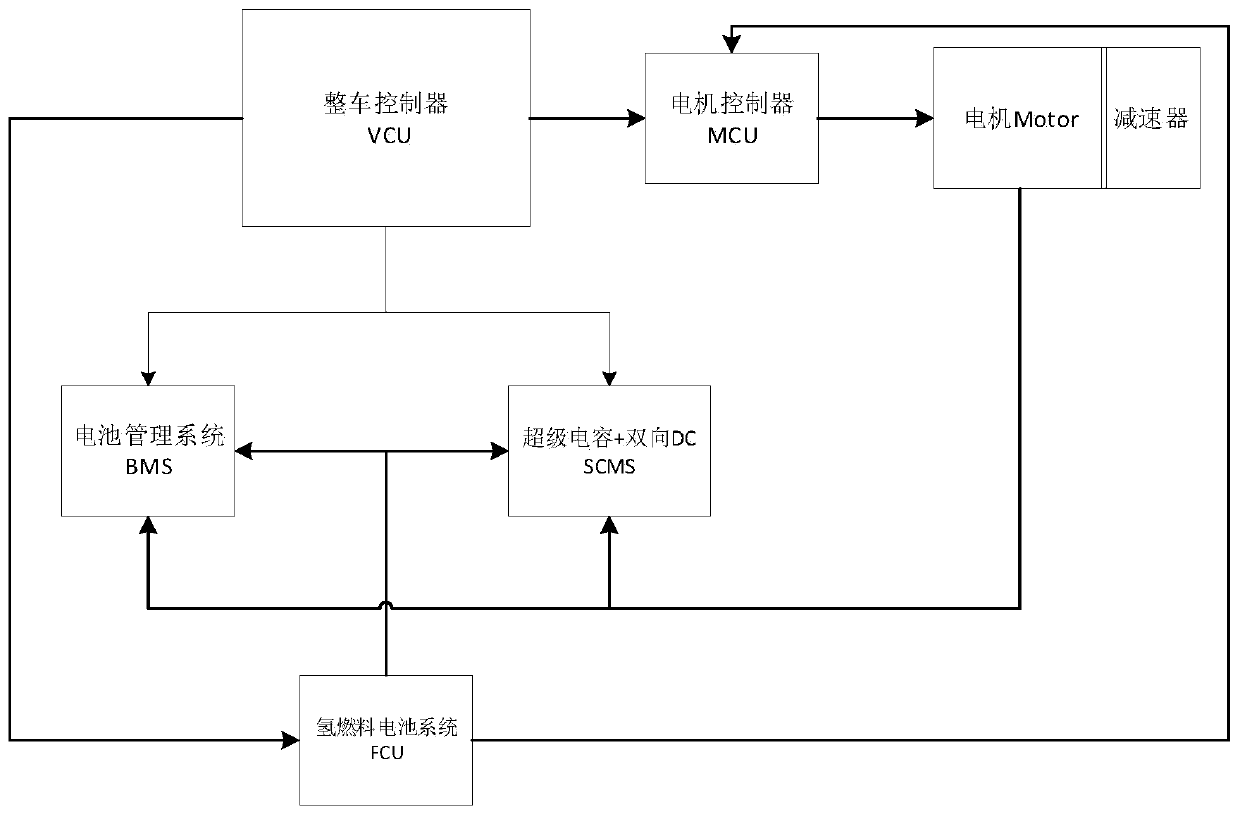

Hydrogen fuel-cell vehicle braking energy recovery system

PendingCN110576750AMeet the use characteristicsGuaranteed drivabilitySpeed controllerElectrodynamic brake systemsCapacitanceElectrical battery

The invention provides a hydrogen fuel-cell vehicle braking energy recovery system. The hydrogen fuel-cell vehicle braking energy recovery system comprises a vehicle control unit VCU, a motor controlunit MCU, a hydrogen fuel-cell sub system FCU, a battery management sub system BMS and a super-capacitor+bi-directional DC sub system SCMS; the VCU collects a motor rotation speed and speed reducer speed ratio information to obtain vehicle speed information, collects a throttle opening signal as an energy recovery triggering switch signal and collects an opening of a brake pedal as a judging basisof recovery power; and then, through the BMS, SOC and maximum rechargeable power of a power battery are obtained; through the SCMS, a capacitance, electric quantity and maximum rechargeable power ofa super-capacitor are obtained; and through the MCU, the motor rotation speed and a motor maximum feedback torque are obtained; and through an FCU, the working state of a fuel cell is obtained; and therefore, braking energy recovery is carried out.

Owner:中极氢能汽车(长治)有限公司

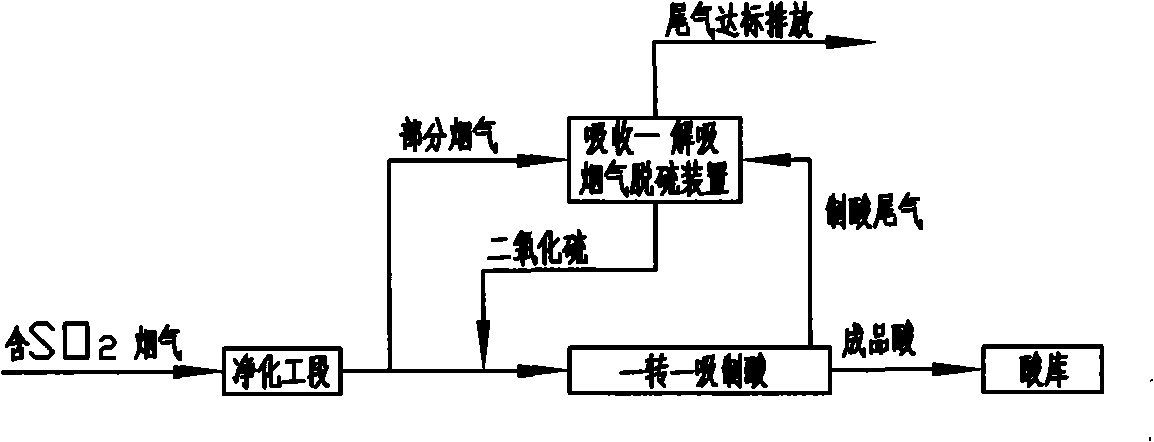

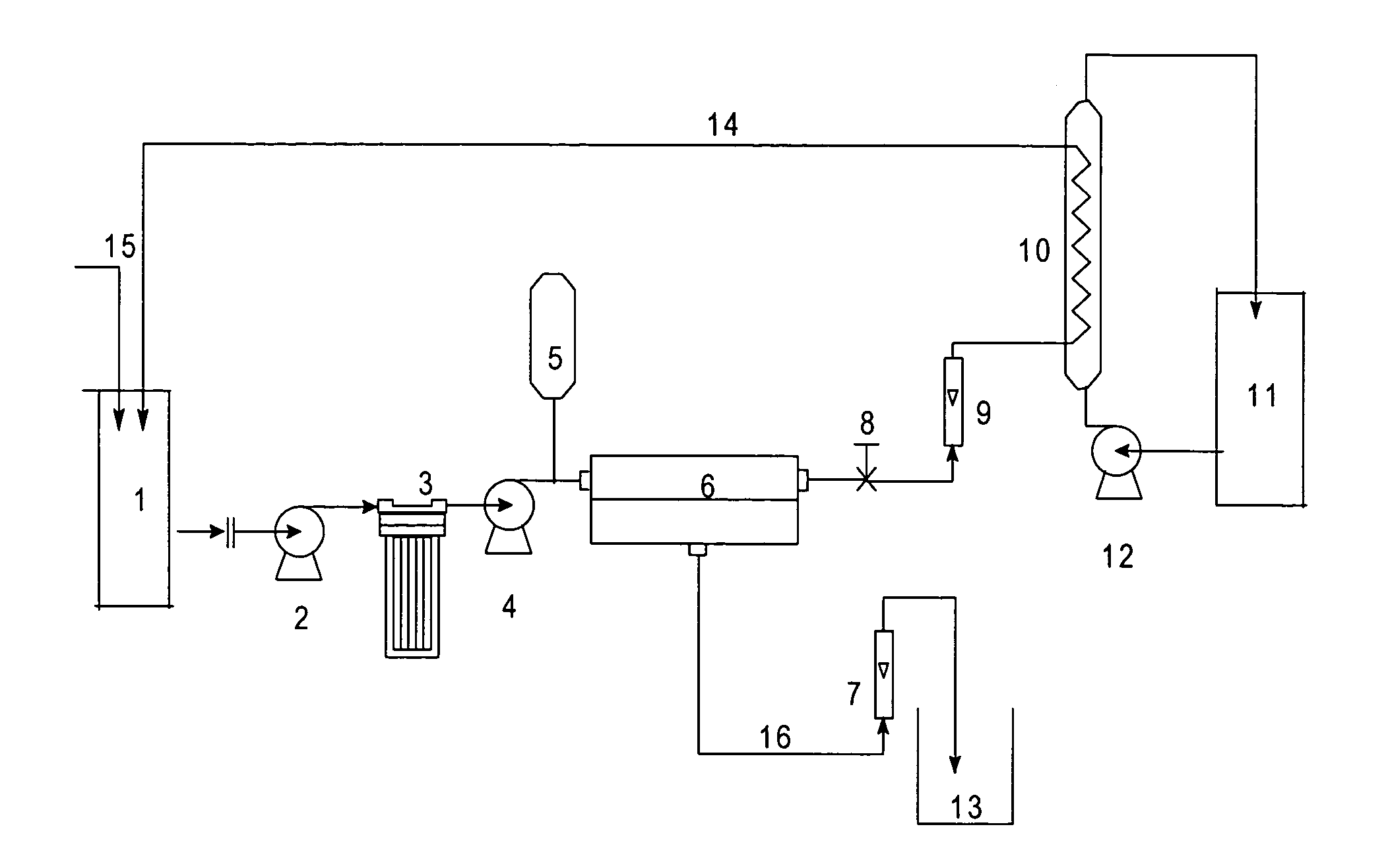

Method for economically recycling sulphur dioxide from low-concentration or non-continuity flue gas to produce sulphuric acid

ActiveCN101492154AMaximum recoveryReduce energy consumptionDispersed particle separationSulfur compoundsDesorptionEmission standard

The invention discloses a method for preparing sulphuric acid by economically recovering sulfur dioxide in low-concentration or noncontinuous flue gas, which comprises that: the flue gas containing the sulfur dioxide is subjected to purification, dust and impurity removal, temperature reduction, and acid mist removal, and then divided into two paths; one path of the flue gas is sent to a desulfurization working section, high-purity SO2 gas generated after absorption and desorption of the flue gas is evenly mixed into the other path of flue gas which is not subjected to desulfurization, the SO2 concentration of the mixed flue gas is improved to be more than 5 percent, and the mixed flue gas enters a single-conversion single-absorption acid preparation working section; and tail gas after acid preparation enters the desulfurization working section again for desulfurization, and is discharged after the SO2 content is far lower than the discharge standard. The process changes smelter off-gas which cannot meet the requirement of preparing acid by a contact method originally into the flue gas which can prepare the acid normally, and does not need desulfurizing all the flue gas, so the method greatly reduces energy consumption, running cost and investment, and the discharge amount of SO2 is far lower than that of a conventional flow so as to solve a difficult environmental protection problem for partial non-ferrous metallurgical plants and accord with the policy of national energy saving, energy consumption and pollution reduction.

Owner:CHINA NERIN ENG

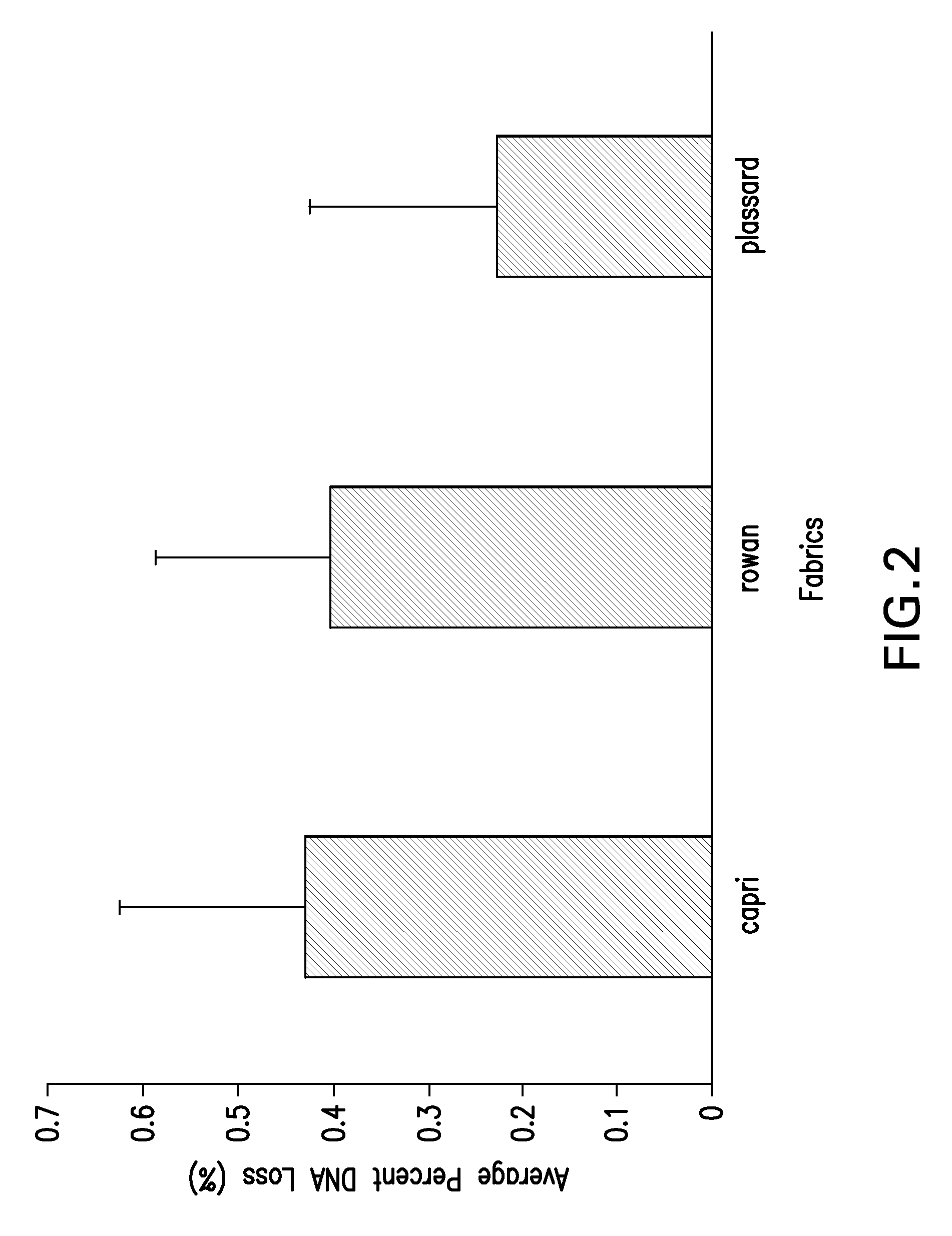

Forensic swab and kit

InactiveUS20090098559A1Efficient releaseEasy to collectAnalysis using chemical indicatorsMicrobiological testing/measurementForensic dnaDna recovery

The present invention relates to a high sensitivity crime scene swab device for maximal recovery of trace forensic DNA evidence left at a crime scene for DNA PCR analysis. More particularly, DNA recovery is obtained from fingerprints lifted from surfaces at the crime scene. The invention also relates to a high sensitivity method for DNA analysis of trace DNA obtained by generating small tandem repeat (STR) profiles using a polymerase chain reaction protocol.

Owner:CITY OF NEW YORK

Braking control mechanism of compound electromechanical braking system

InactiveCN103085785AMaximum recoveryReduce power consumptionElectrodynamic brake systemsFoot actuated initiationsElectricityControl theory

The invention discloses a braking control mechanism of a compound electromechanical braking system. The braking control mechanism of the compound electromechanical braking system aims to overcome the problem that in the prior art, electric braking can not function alone when a driver steps on a braking pedal. The braking control mechanism of the compound electromechanical braking system comprises a braking pedal, a sensor, a return spring, a motor shell, a motor rotor, a motor stator and a rotary translation transmission mechanism, wherein the motor stator is fixed in an inner cavity of the motor shell, the motor rotor which is inserted into an inner hole of the motor stator is installed in the inner cavity of the motor shell through a first bearing and a second bearing in a rotary connection mode, the motor rotor is sleeved on the rotary translation transmission mechanism in a spline pair connected mode, the left end of the rotary translation transmission mechanism is connected with the right end of an input force push rod in a sliding mode, the return spring is sleeved at the left end of the rotary translation transmission mechanism located between the input force push rod and the motor shell, the left end of the input force push rod is hinged with the middle of the braking pedal, and one end, fixing a rotary shaft end, of the upper end of the braking pedal is fixedly connected with a rotary end of the sensor.

Owner:JILIN UNIV

Method and device for particle removal and droplet preparation for qualitative and quantitative bioanalysis

InactiveUS20110041591A1High yieldMinimal useAnalysis using chemical indicatorsSamplingBiomedical engineeringPlunger

This disclosure provides a method and device for particle removal and droplet preparation for qualitative and quantitative bioanalysis. In one embodiment, the disclosed device includes a lateral flow filter through which the sample is filtered such that the filtrate fluid is collected in the distal end of the filter matrix. The filtered fluid is made to eject from the matrix to form a droplet by pressing / squeezing the distal end of the filter only, with the help of a suitably shaped plunger means.

Owner:ADVANCED MICRODEVICES PVT

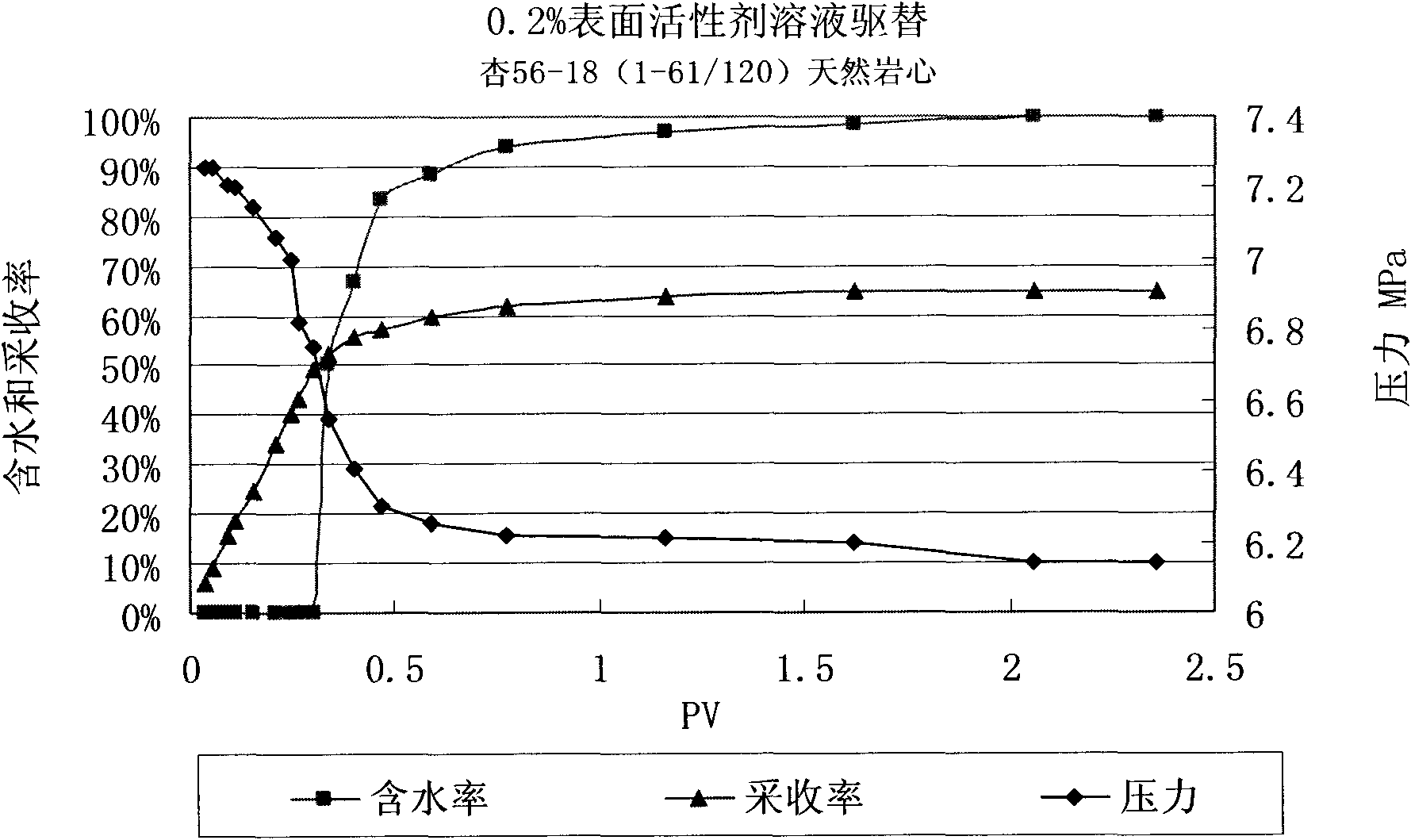

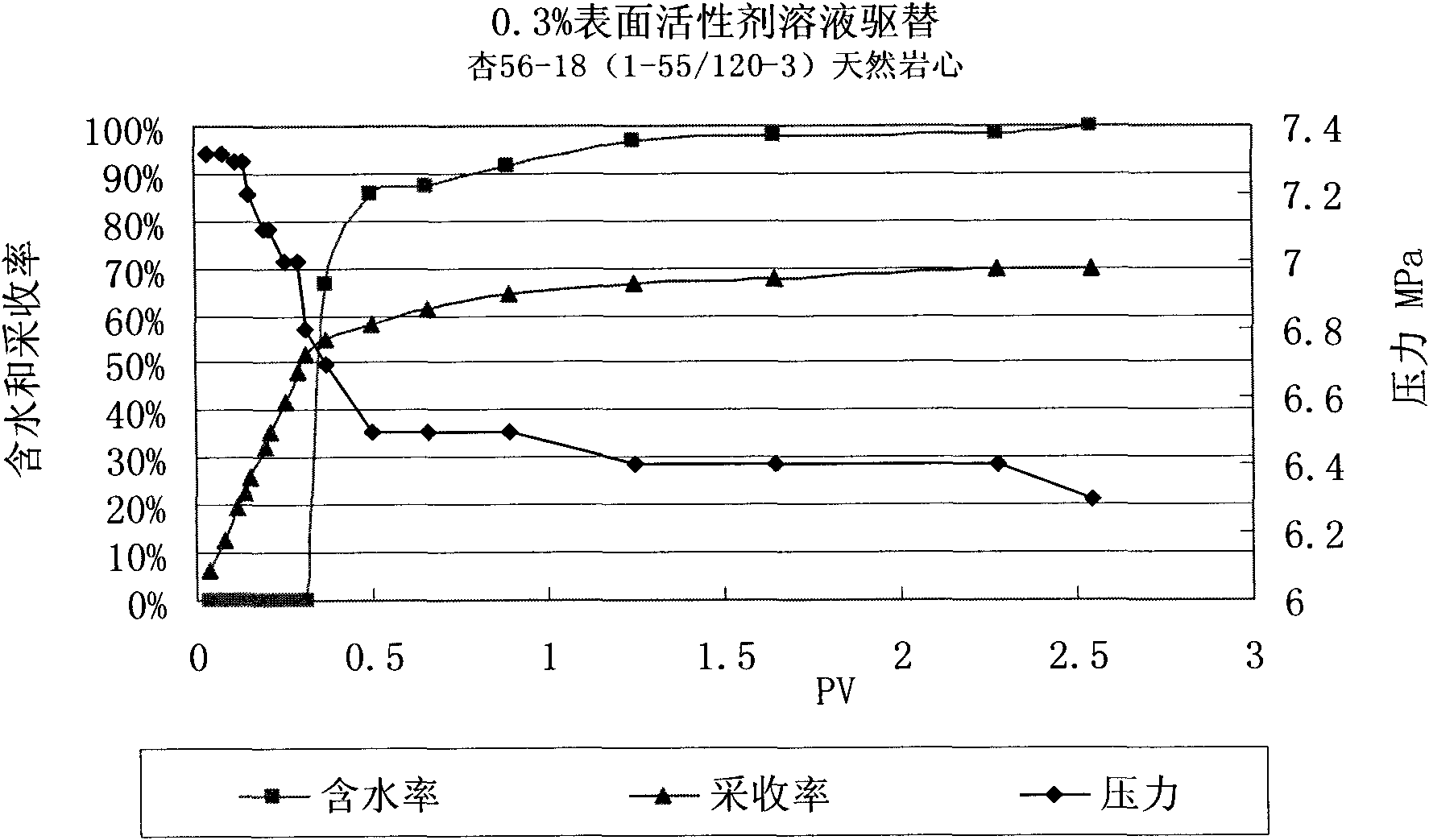

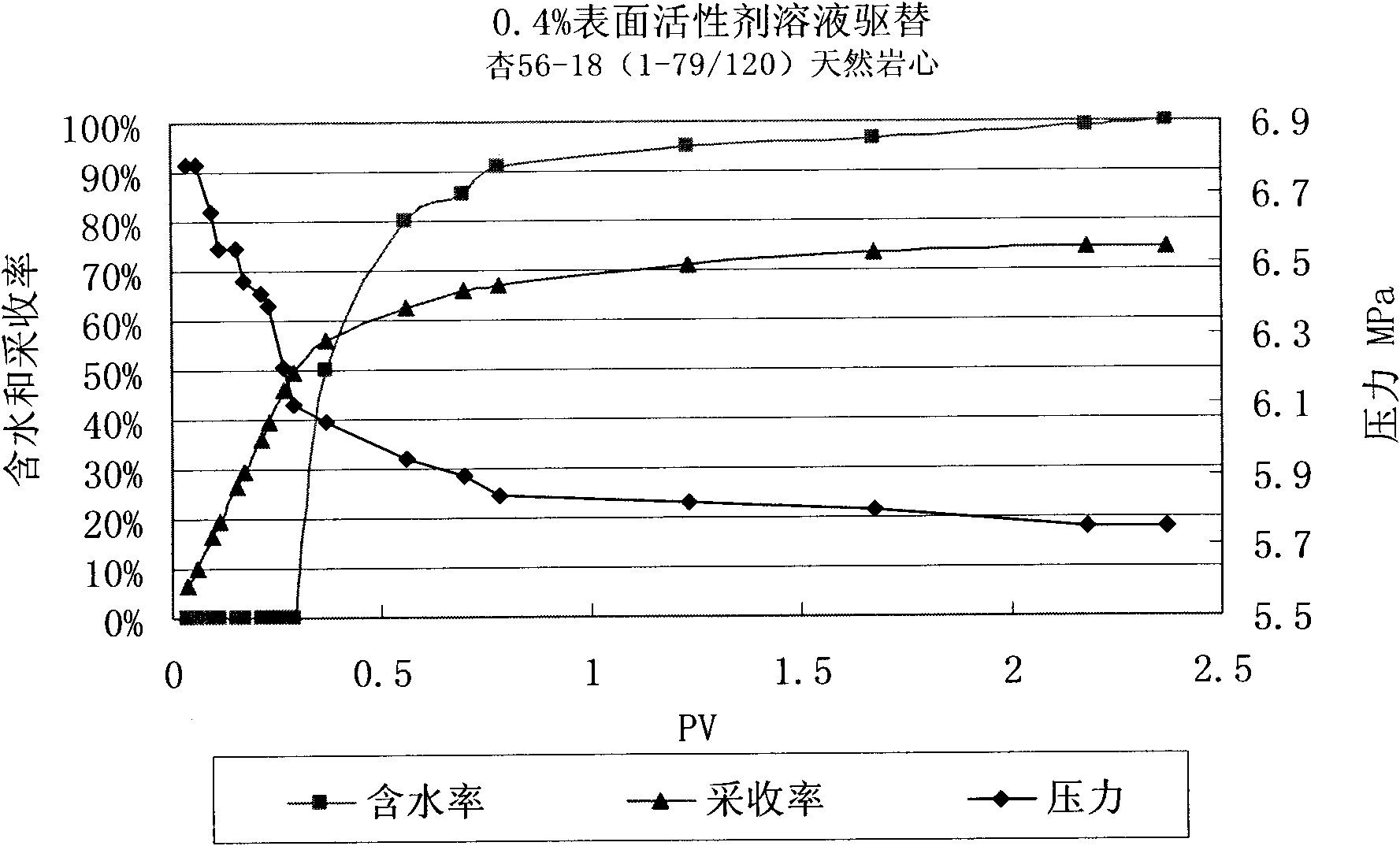

Oil-field largest swept volume chemical-flooding oil production method

The invention relates to an oil-field largest swept volume chemical-flooding oil production method, which is applied to the technical field of oil production in oil fields. The method is applicable to all reservoirs which can be exploited by water flooding but are not exploited by water flooding. When oil is exploited, the self energy of the strata of a reservoir is first utilized to carry out flowing production or swabbing production; when an oil field adopting flowing production or swabbing production reaches the economic benefit limit of production, flowing production or swabbing production is ended, subsequent water-flooding production is not carried out any more, but chemical flooding injecting surfactant as main agent is directly adopted to intensify oil production. The method has the following advantages that: at the moment, the swept volume of the displacement of the chemical displacing fluid is the largest, which is best favorable for the exertion of the oil-washing effect ofthe surfactant, and thereby the yield of oil production can be increased to the max.

Fluid flow control for cool, efficient fuel cell operation

InactiveUS20030049506A1Improve air utilizationReduce the maximum temperatureFuel cell heat exchangeFuel cells groupingFuel cellsCoolant flow

A fuel cell stack (7) has a two-pass fuel flow field (11, 14) extending from a fuel inlet (8) around a fuel turnaround manifold (12) to a fuel outlet (15). The stack has two air flow fields (37, 40) extending from an air inlet (32) through an air turnaround manifold (38) to an air outlet (41), the air outlet (41) being adjacent to the fuel outlet (15). The stack includes a coolant flow field (23, 25, 27) which extends from a coolant inlet (21) to a coolant outlet (28), the coolant inlet being adjacent to both the fuel outlet and the air outlet. The fluid flow configuration provides lower temperature, a more even temperature profile, a higher coolant exit temperature, and permits operation with higher air utilization and lower coolant flow.

Owner:AUDI AG

Process for recovery of iron from copper slag

InactiveUS20070283785A1Avoid reactionEfficient use ofSteel manufacturing process aspectsRecycling and recovery technologiesValue added productPyrometallurgy

The present invention relates to a process for recovery of iron from copper slag. This invention particularly relates to a process for recovery of iron from a waste like granulated copper slag generated during the production of copper from its ores by a pyrometallurgical method. The present invention will be useful for solving the ecological and environmental issues with an added economic advantage of utilising the dump slag generated in the copper plants. Novelty of the present invention is process for the preparation of value added products viz grinding grade cast iron using copper slag generated during the processing of copper concentrate which otherwise is considered as a waste. Other novel features of the inventions are creating a homogeneous mixture of slag, reductant and flux so that reaction kinetics is more than conventional process. The reductant is used in such a way so that maximum recovery of iron can take place.

Owner:COUNCIL OF SCI & IND RES

Hollow Needle and Indwelling Needle Using the Hollow Needle

InactiveUS20070282265A1Reduce harmKeep for a long timeInfusion syringesSurgical needlesFluorocarbonSurgery

[PROBLEMS] A non tissue-destructive hollow needle not damaging the tissue of a needle inserting portion and an indwelling needle using the hollow needle. [MEANS FOR SOLVING PROBLEMS] A hollow needle is made from ceramic, has an outer diameter of 1-5 mm, and a wall thickness of 0.6-1.8 mm, and gives less damage to the tissue of a needle inserting portion. Worth noting is that the ceramic is zirconium and its oxide. The non tissue-destructive hollow needle can be used as a indwelling needle. The indwelling needle is constructed by inserting a resin straight fine needle, with chemical resistant and corrosion resistant properties, into the ceramic hollow needle, inserting the hollow needle, installed on the straight fine needle, into a hollow needle outer tube, and providing a connection tube, adapted for connection to an external extension tube, on the hollow needle outer tube. The connection tube is connected to the external extension tube through a connection ring. A fluorocarbon resin is suitably used as the chemical resistant, corrosion resistant resin.

Owner:INST OF WHOLE BODY METABOLISM

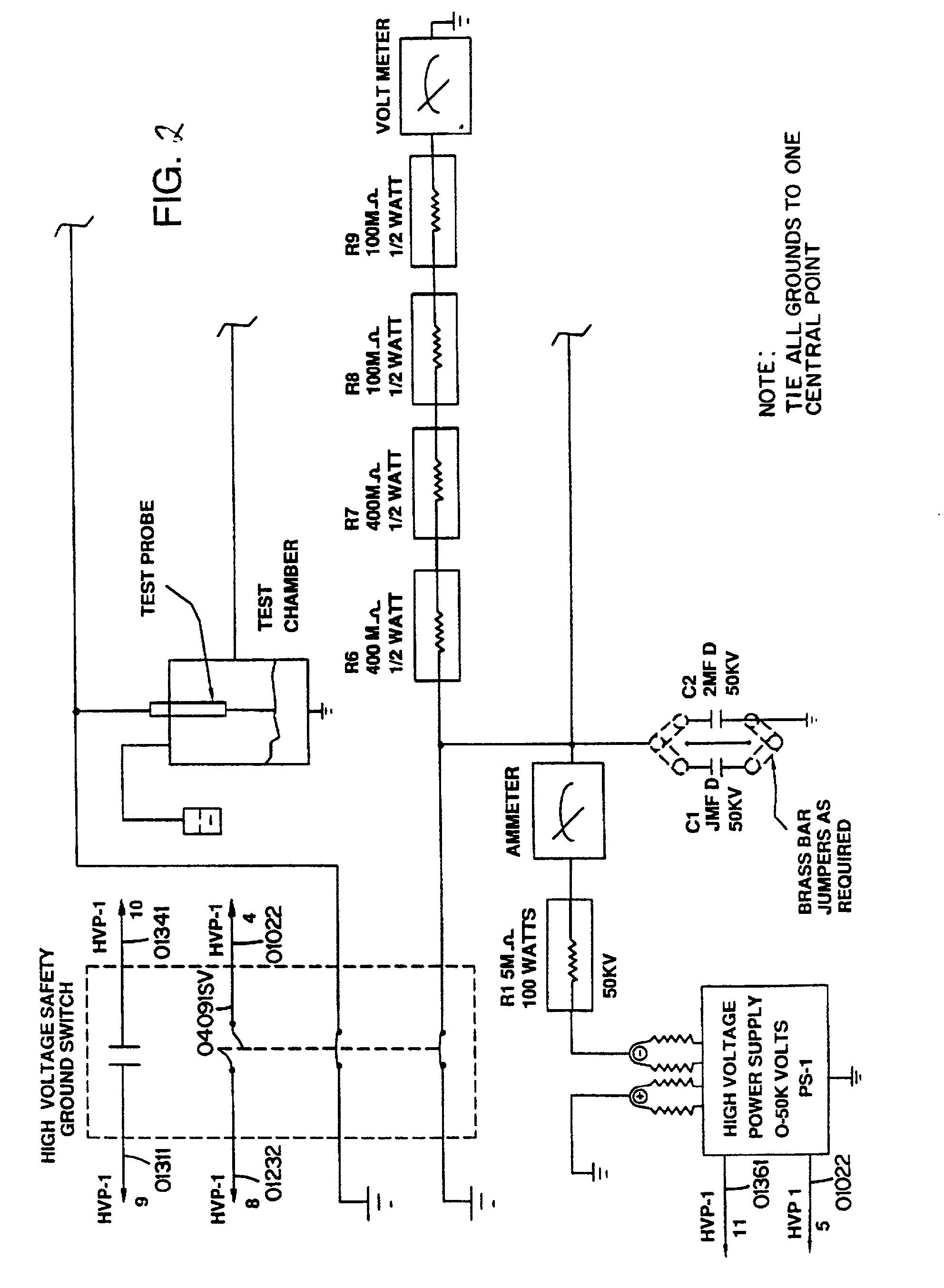

Method and apparatus for extracting hydrocarbons from tar sands using electro plasma

InactiveUS20020005346A1Maximum recoveryEasy to sitFluid removalLiquid hydrocarbon mixture productionElectricityTar

An in-situ method and apparatus for recovering hydrocarbons from hydrocarbon-bearing material by dissociation includes sinking a well casing into a deposit of the hydrocarbon-bearing material. A probe is inserted into the well casing until the probe end is adjacent the deposit of material. An electrical charge is released into the deposit via the probe end to dissociate the hydrocarbon-bearing material and produce a hydrocarbon rich product which can be recovered for fuel value.

Owner:EP TECH

Oilseed crushing heat recovery system

An oilseed crushing process wherein the oilseeds are preheated to generate warm, soft oilseeds, then flakes are generated by flaking the warm, soft oilseeds. The flakes are then cooked by generating a hot vapour stream and hot flakes. The hot flakes are then prepressed to generate oil and a partially de-oiled cake. The partially de-oiled cake is solvent extracted to generate solvent laden oil and solvent laden meal. The hot, wet meal is then dried to generate oilseed meal and an additional hot vapour stream. The at least part of the preheating step to generate warm, soft oilseeds is accomplished using a hot liquid medium. The hot liquid medium is heated by a heat transfer mechanism that condenses at least one of the hot vapour streams generated during the flake-cooking step or the meal-drying step.

Owner:DESMET BELGIUM

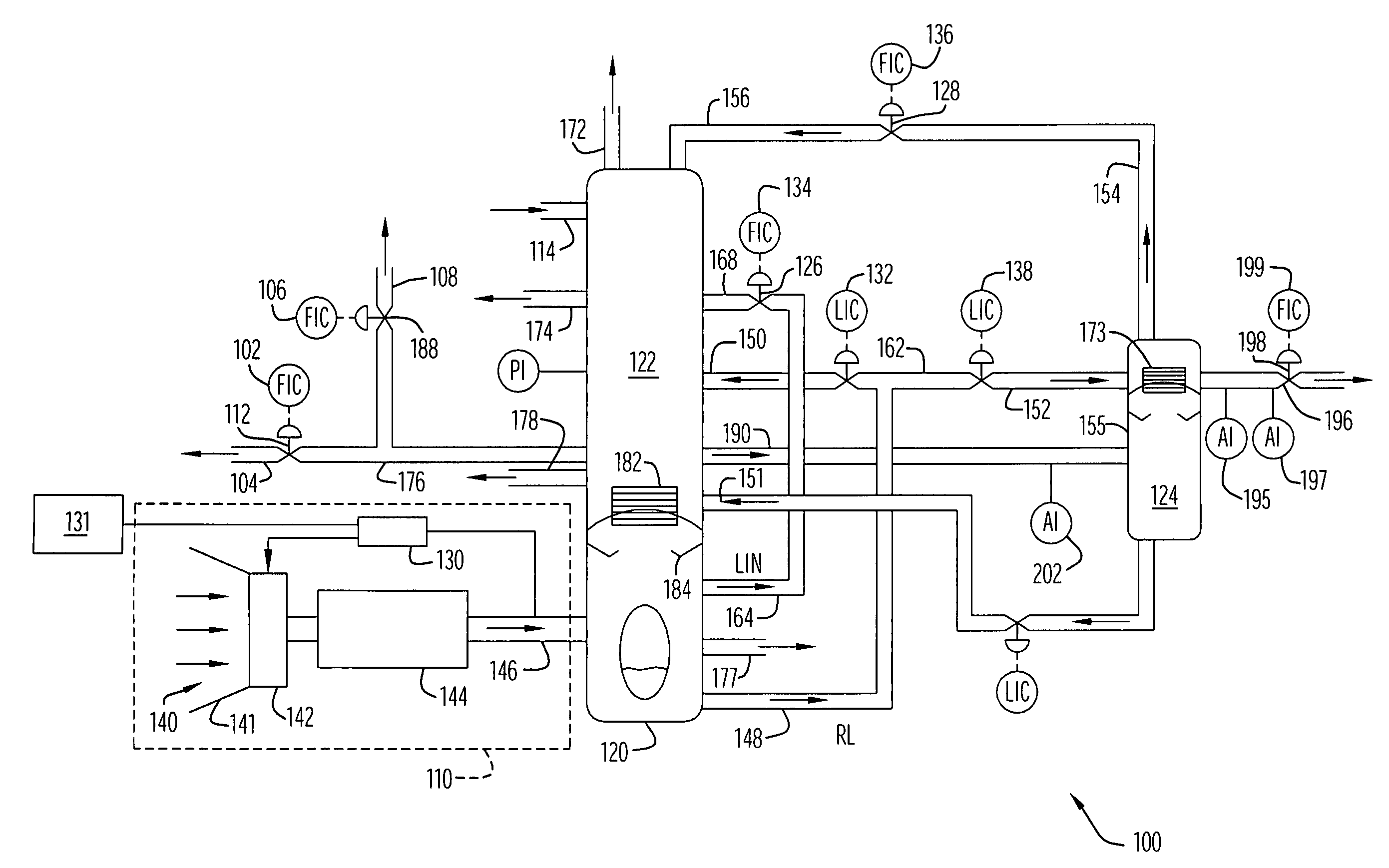

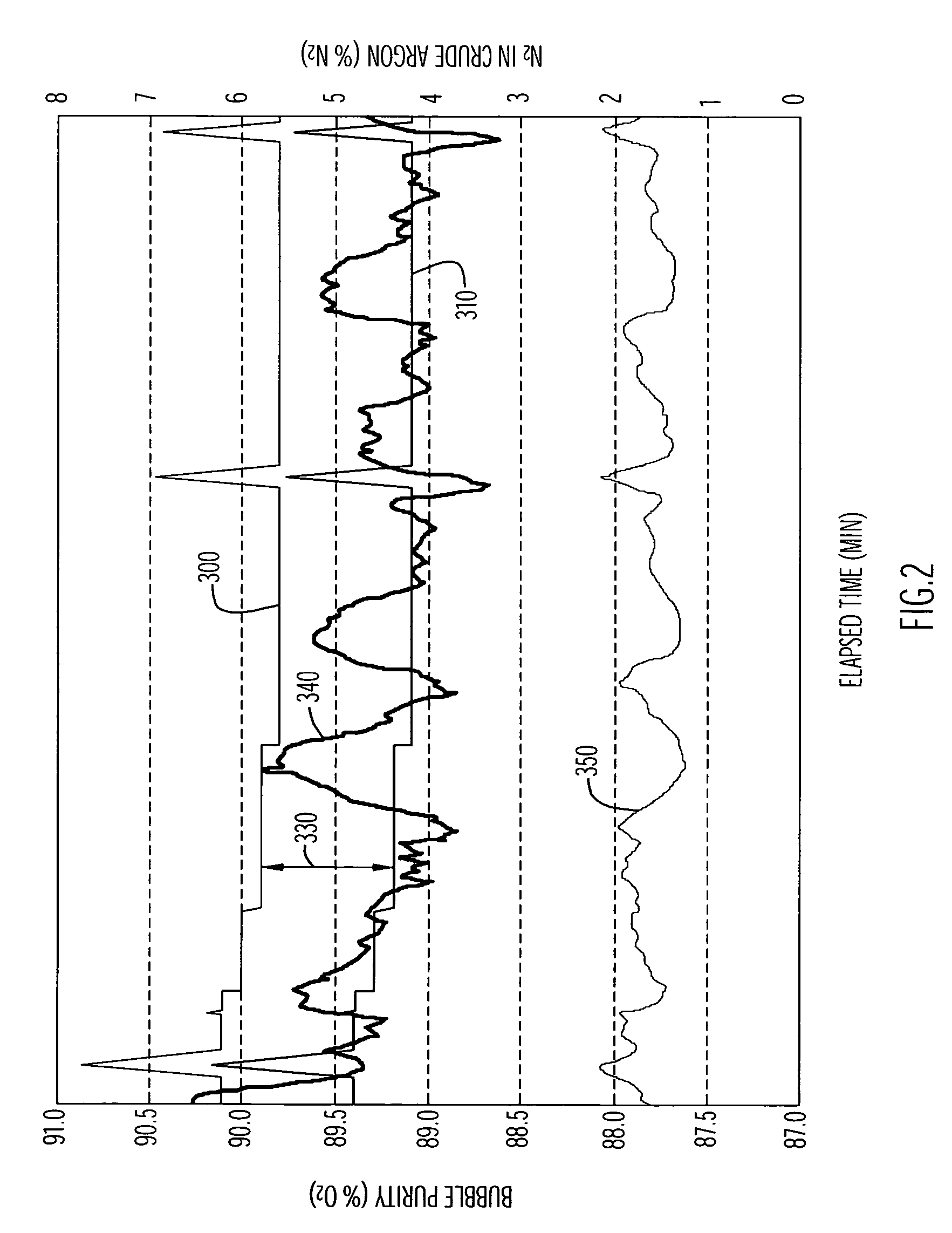

Methods and systems for optimizing argon recovery in an air separation unit

ActiveUS20050072187A1Maximum argon recoveryMaximize flowSolidificationLiquefactionDistillationNitrogen

A cryogenic air separation system that optimizes the recovery of argon includes an air intake, a high-pressure distillation column, a low-pressure distillation column, a crude argon distillation column, and a controller that automatically controls the composition of the raw argon stream to decrease the concentration of oxygen in the stream while preventing the concentration of nitrogen in the crude argon stream from exceeding a selected value. In addition, the controller also controls the composition of the crude argon stream until an oxygen concentration of the crude argon stream reaches a selected value. The controller may include a multivariable predictive controller.

Owner:AIR LIQUIDE LARGE INDS U S LP

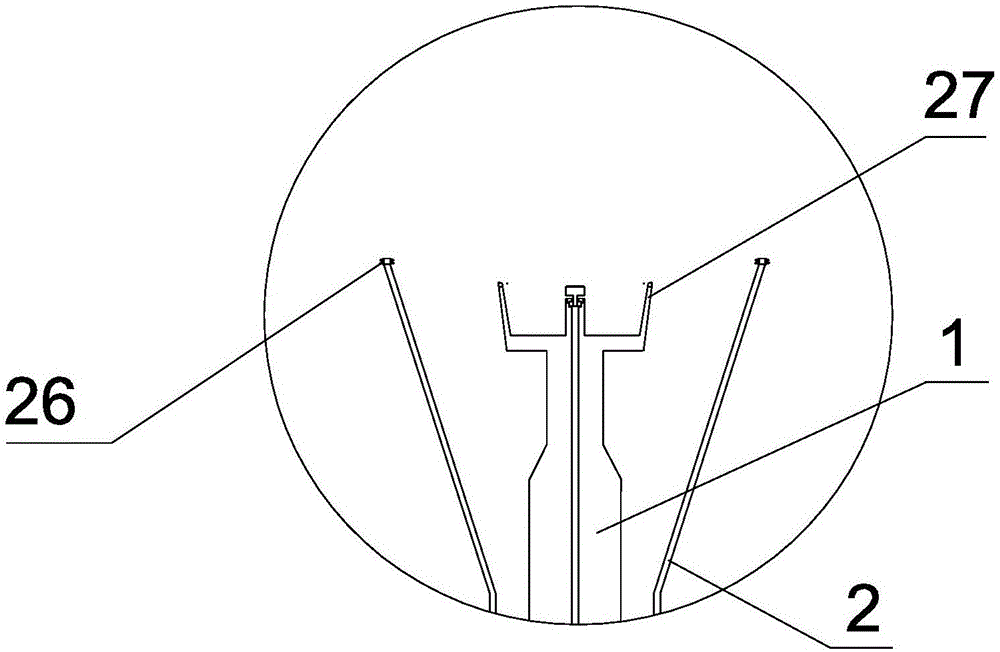

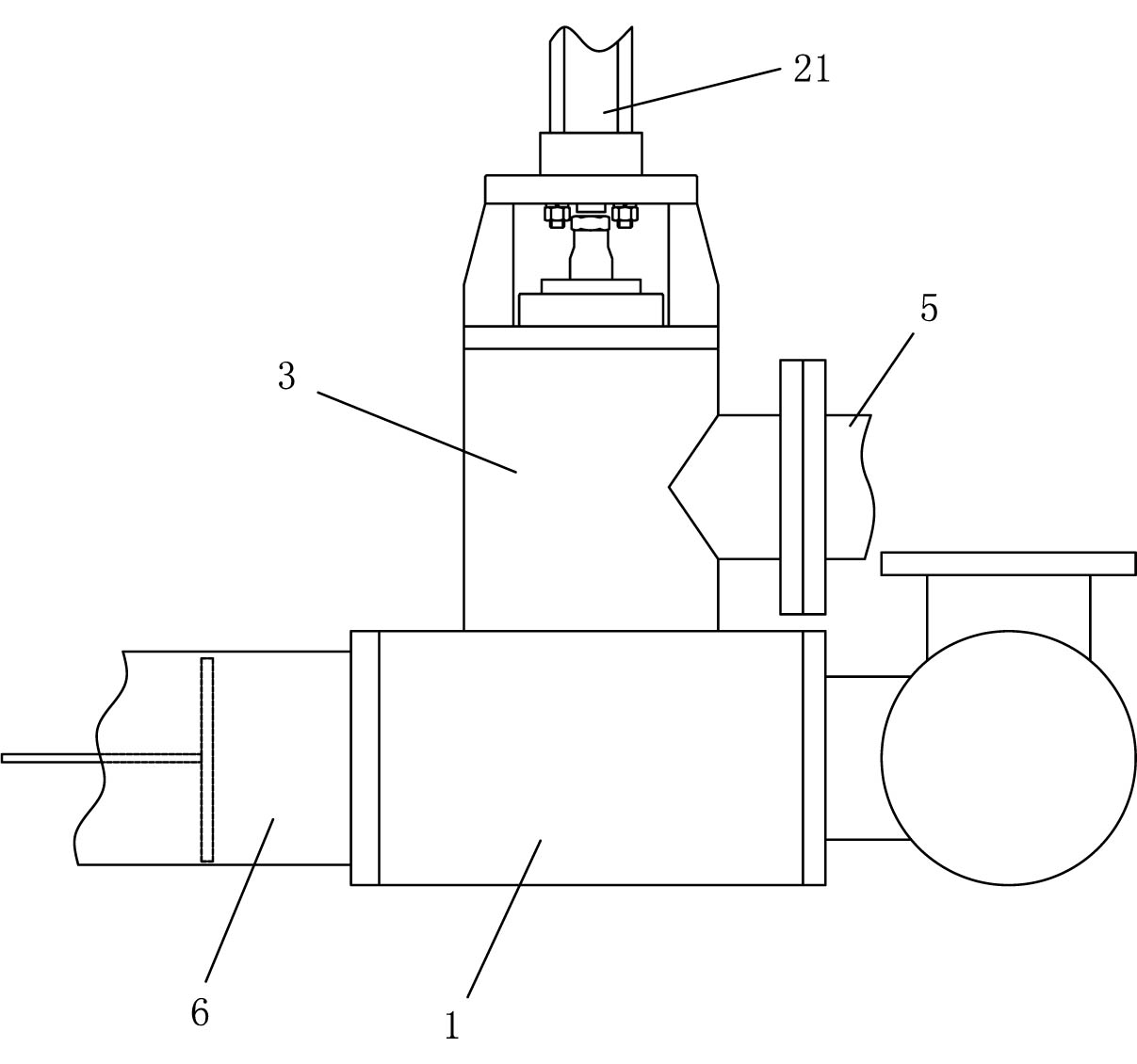

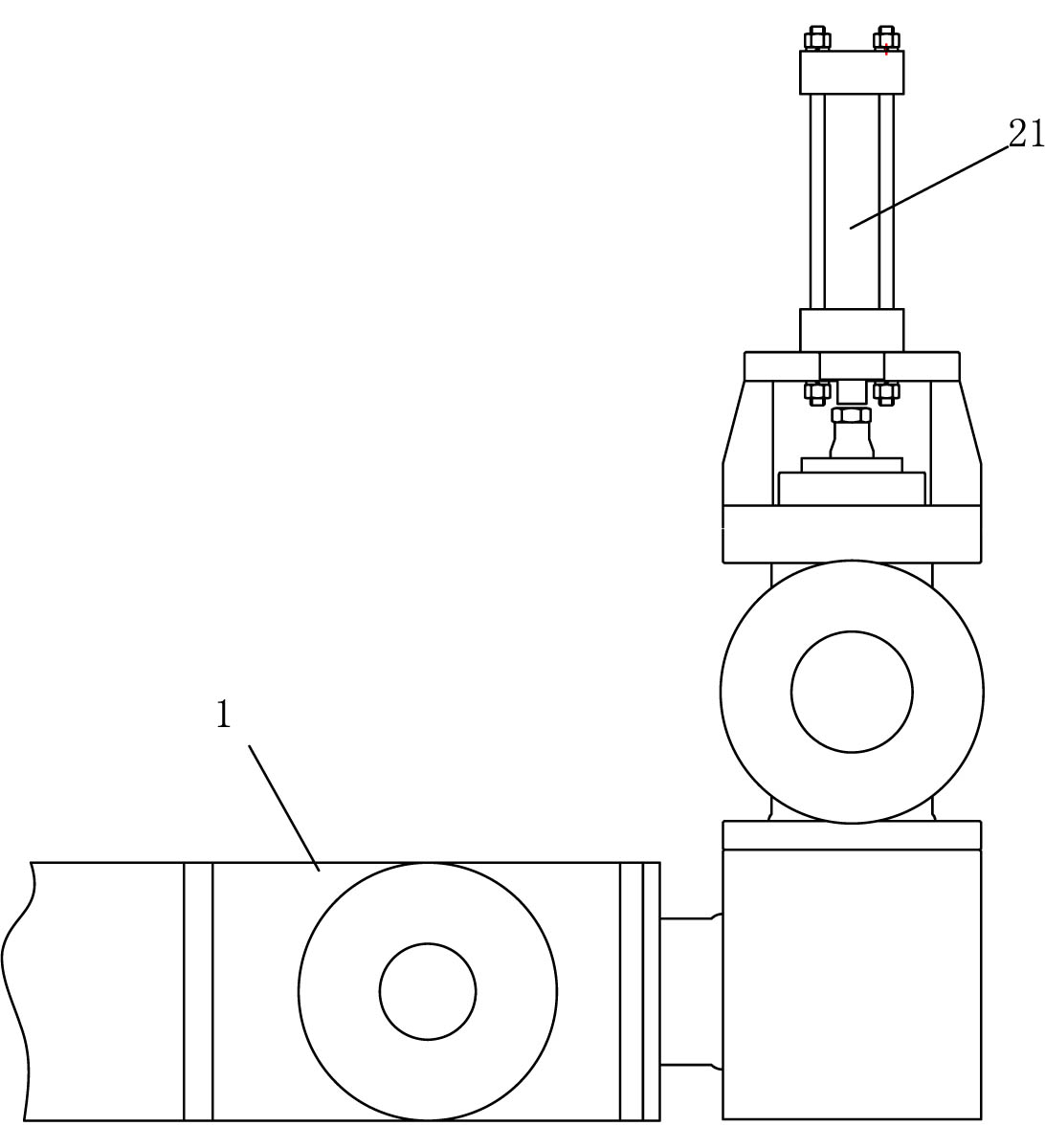

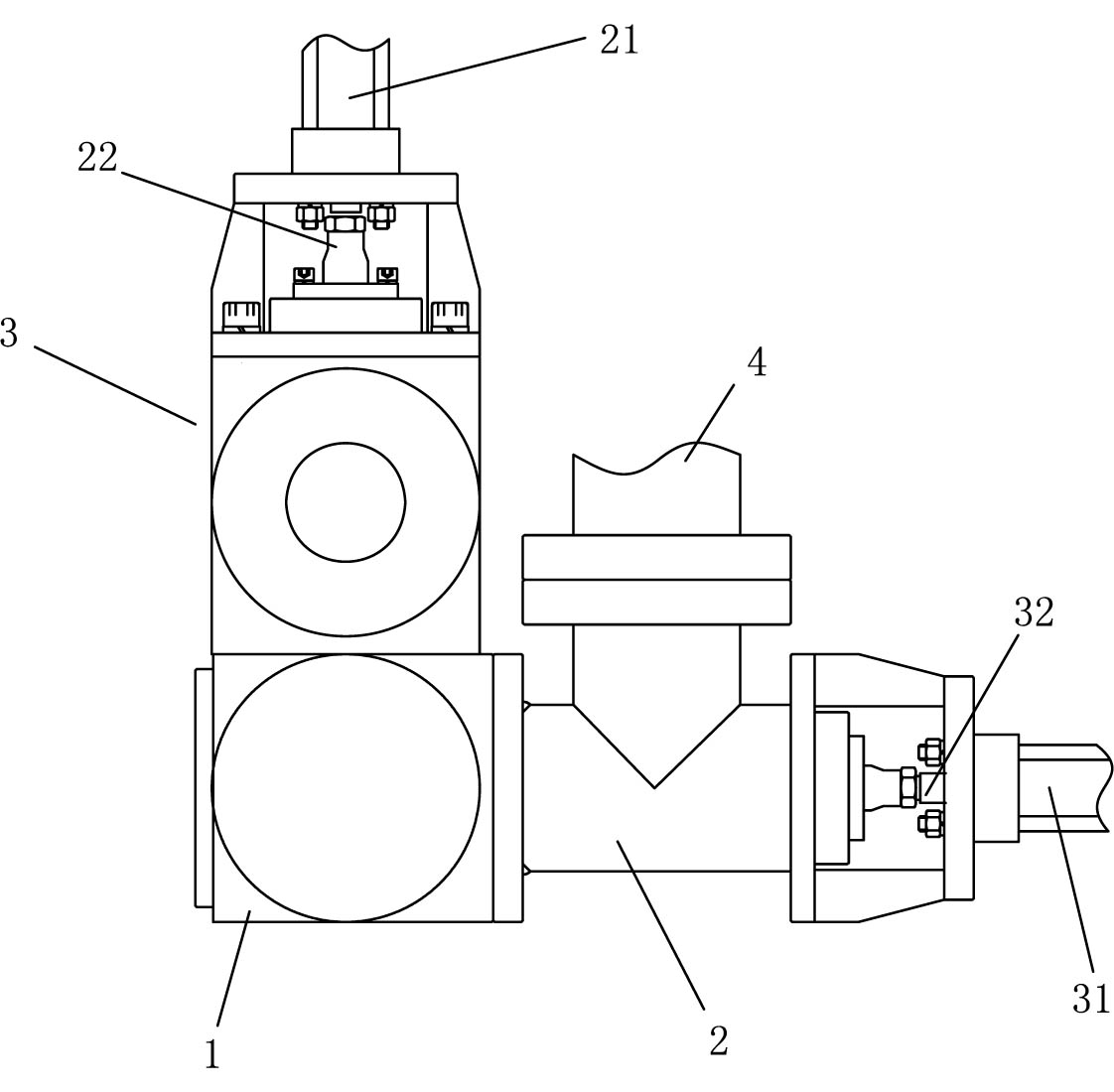

Remaining fuel recovery system for fuel tank of scraped car and working method of remaining fuel recovery system

ActiveCN106523216AMaximum recoveryEasy exitUnderstructuresMachines/enginesControl systemDrilling system

The invention relates to the field of dismantling recovery of scraped cars, in particular to a remaining fuel recovery system for a fuel tank of a scraped car and a working method of the remaining fuel recovery system. The remaining fuel recovery system comprises a recovery system and a running system which drives the recover system to move, wherein the recovery system comprises a drilling system used for drilling at the bottom of the fuel tank of the scraped car, a fuel receiving system used for receiving fuel flowing out of a hole in the bottom of the fuel tank, a fuel vapor recovery system used for absorbing fuel vapor and a controlling system used for comprehensively controlling the whole recovery system. The remaining fuel recovery system can be used for recovering remaining fuel of the fuel tank of the scraped car, is safe and environment-friendly and can recover fuel remaining in the fuel tank of the scraped car to the greatest extent.

Owner:JIANGSU UNIV OF TECH

Isolated nucleic acid molecule encoding a regulator of fungal gene expression

InactiveUS6806082B2Increase productionHigh copy numberSugar derivativesMicroorganismsFungal gene expressionFungal gene

The invention relates to regulators of fungal gene expression and their use in commercial and medical applications. More particularly, the invention relates to regulators of fungal genes involved in production of enzymes, secondary metabolites and other useful products, as well as to regulators of genes involved in fungal invasion. The invention provides novel regulators of fungal gene expression, and methods for using regulator genes in commercial and medical applications.

Owner:DSM IP ASSETS BV

Recovery of sodium thiocyanate from industrial process solution using nanofiltration technique

InactiveUS7314606B2Promote recoveryLittle or no impuritiesNitrosyl chlorideThiocyanic acidSodium thiocyanateNanofiltration

Owner:COUNCIL OF SCI & IND RES

Powder slurry delivering device

The invention relates to a powder slurry delivering device comprising a slurry cavity. An inlet of the slurry cavity is provided with a feed interlock valve; an outlet of the slurry cavity is provided with a discharge interlock valve; the feed interlock valve is connected with a feed pipe; the discharge interlock valve is connected with a discharge pipe; and the slurry cavity is further connected with a delivering pump. During operation, the slurry from the feed pipe is sucked into the slurry cavity through the feed interlock valve under the action of the delivering pump and is then output to the discharge pipe through the discharge interlock valve, and materials are supplied for multiple slurry production devices. The device has the advantages of high automation degree, no pollution, no need of manual transportation during production of powder slurry and high working efficiency.

Owner:江门市正曦输送机械设备有限公司

Device and kit for collecting forensic DNA from surfaces including fingerprints

InactiveUS9200321B2Efficient releaseEasy to collectMicrobiological testing/measurementWithdrawing sample devicesForensic dnaDna recovery

The present invention relates to a high sensitivity crime scene swab device for maximal recovery of trace forensic DNA evidence left at a crime scene for DNA PCR analysis. More particularly, DNA recovery is obtained from fingerprints lifted from surfaces at the crime scene. The invention also relates to a high sensitivity method for DNA analysis of trace DNA obtained by generating small tandem repeat (STR) profiles using a polymerase chain reaction protocol.

Owner:CITY OF NEW YORK

Methods and systems for optimizing argon recovery in an air separation unit

A cryogenic air separation system that optimizes the recovery of argon includes an air intake, a high-pressure distillation column, a low-pressure distillation column, a crude argon distillation column, and a controller that automatically controls the composition of the raw argon stream to decrease the concentration of oxygen in the stream while preventing the concentration of nitrogen in the crude argon stream from exceeding a selected value. In addition, the controller also controls the composition of the crude argon stream until an oxygen concentration of the crude argon stream reaches a selected value. The controller may include a multivariable predictive controller.

Owner:AIR LIQUIDE LARGE INDS U S LP

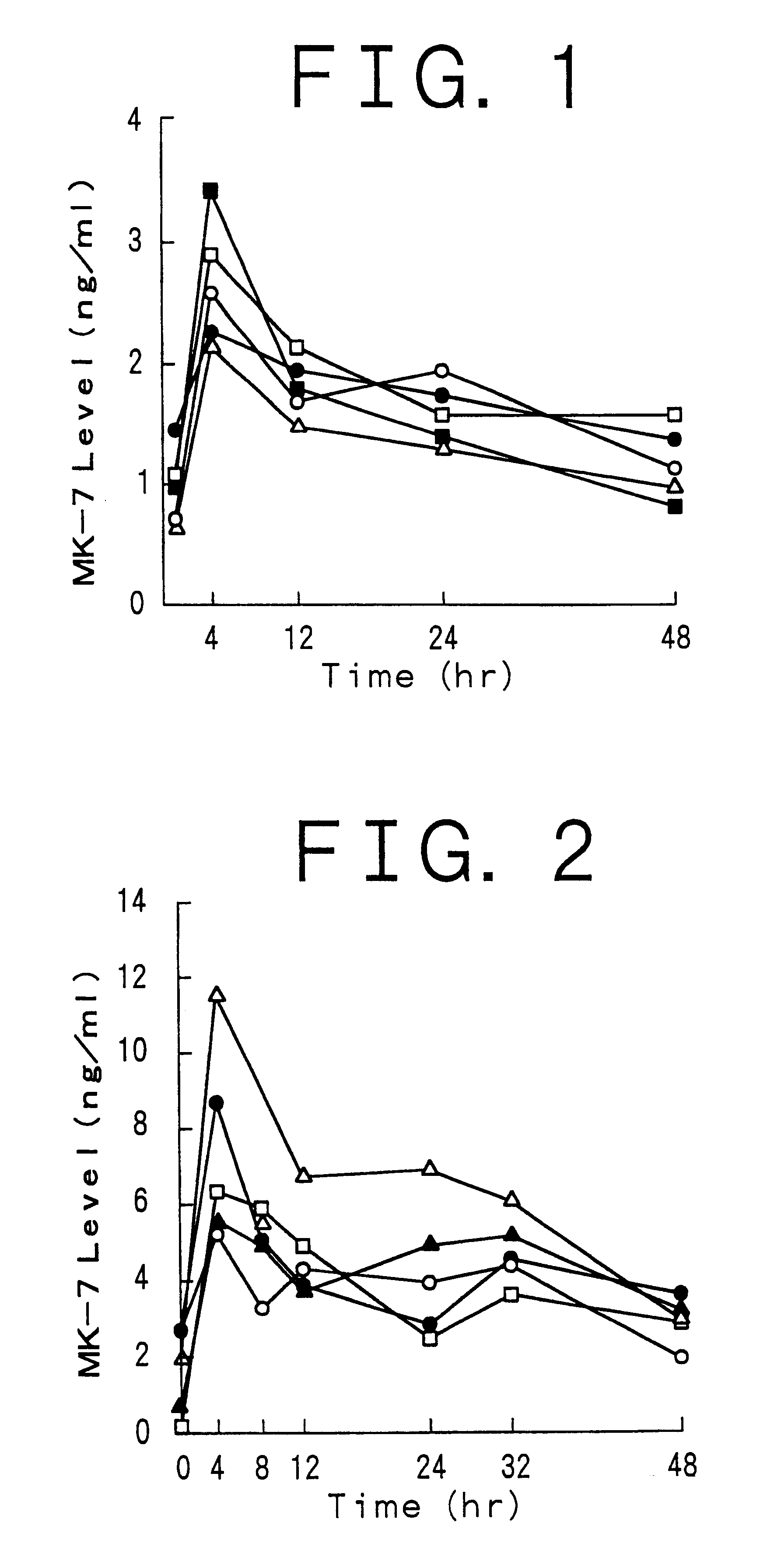

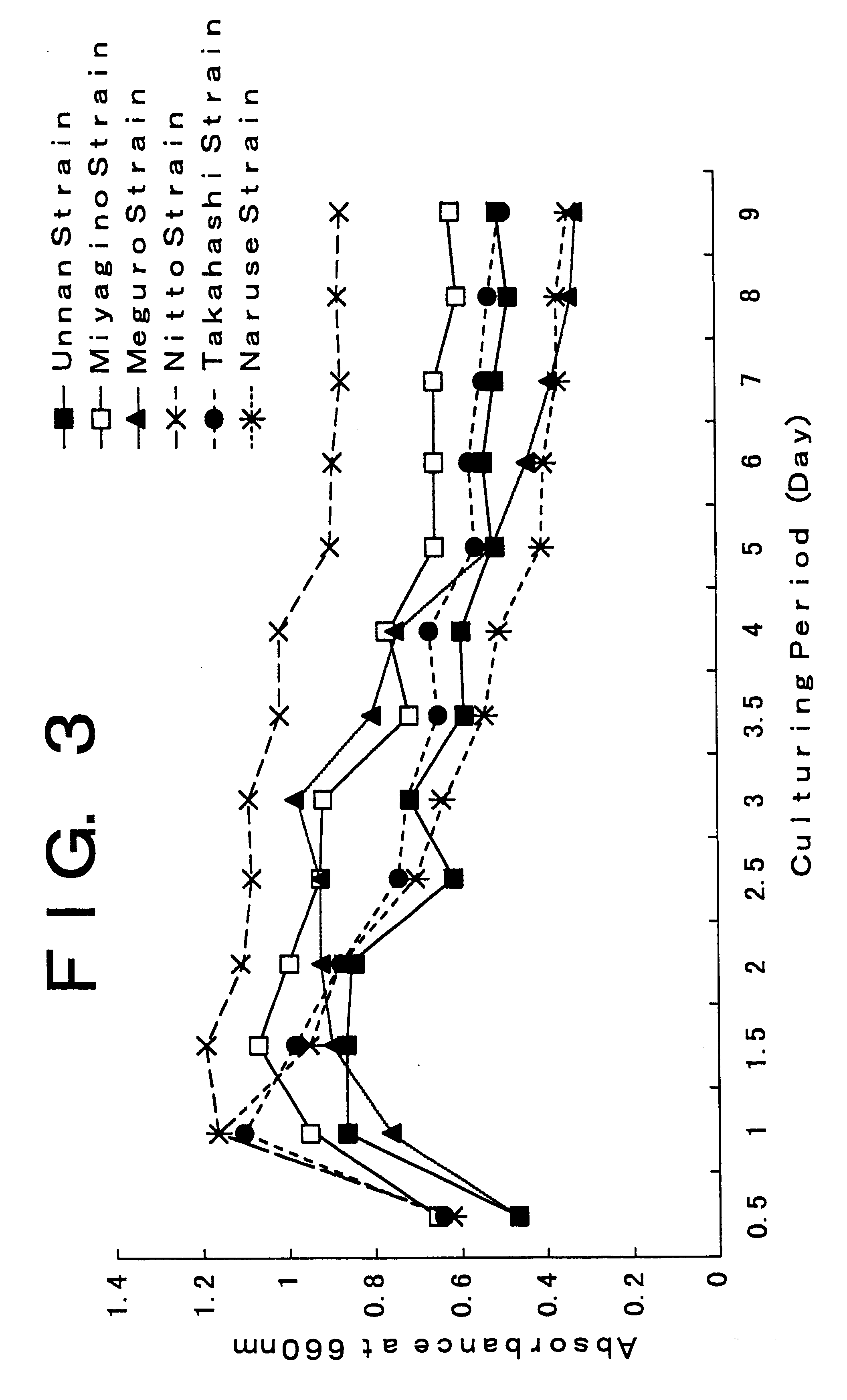

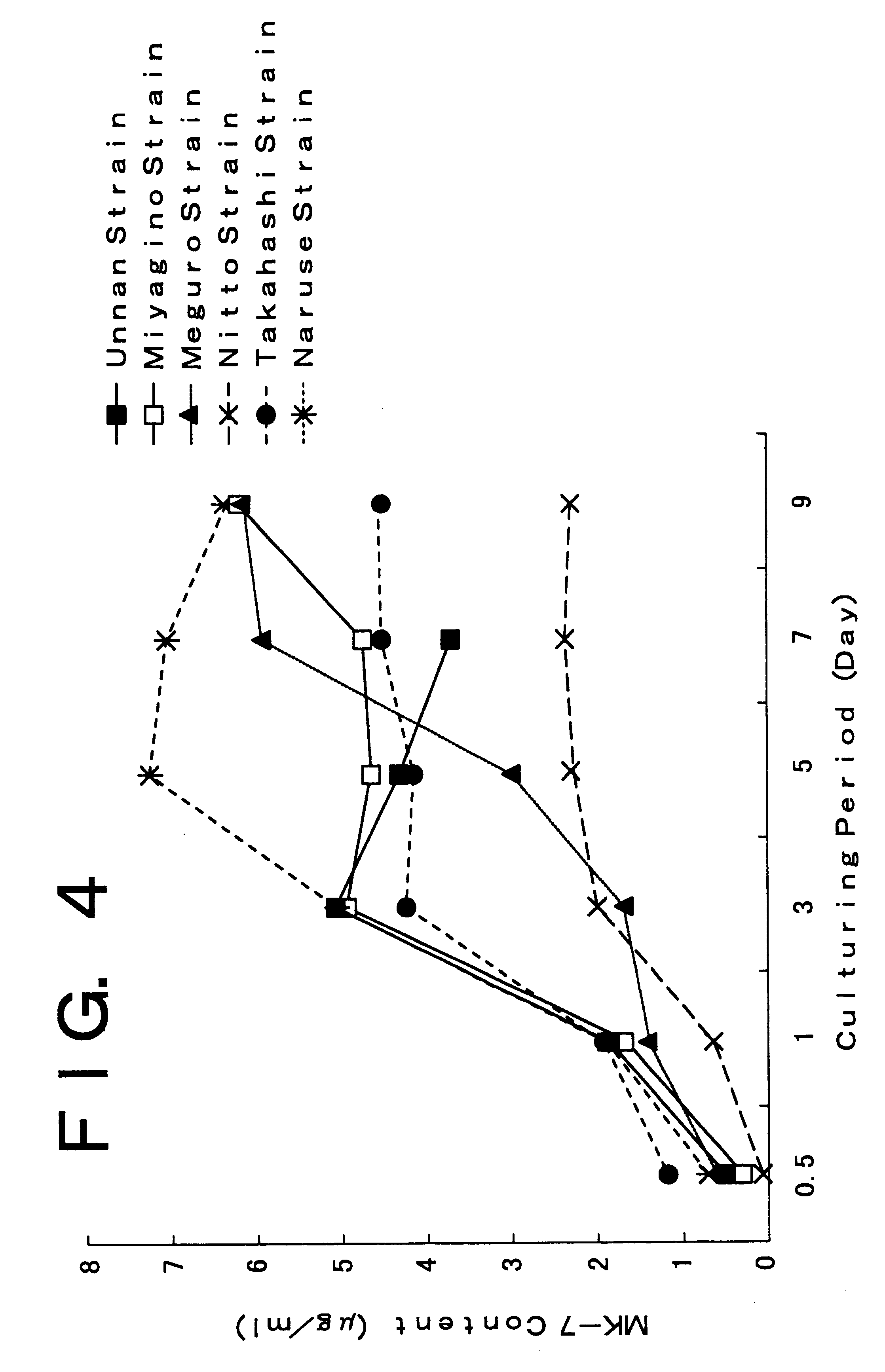

Method for culturing Bacillus subtilis natto to produce water-soluble vitamin K and food product, beverage, or feed containing the cultured microorganism or the vitamin K derivative

InactiveUS6677143B2Improve the level ofMaximum recoveryMilk preparationBiocideMicroorganismMicrobiology

A method for culturing Bacillus subtilis in such a manner that a vitamin K derivative is accumulated in the largest amount in the cells of the microorganism. A method for the culture of Bacillus subtilis, which comprises culturing Bacillus subtilis and recovering the cells of the microorganism before the vitamin K produced within the cells of the microorganism is released from the cells is disclosed, as well as the cultured product of Bacillus subtilis cultured by this method, a water-soluble vitamin K derivative originating in the cultured product, a food product, beverage, or feed containing the cultured product and / or the water-soluble vitamin K derivative, and a method for extracting vitamin K.

Owner:SUMI HIROYUKI

Method of recycling lithium battery cathode material lithium iron phosphate

InactiveCN109485027AMaximum recoveryWaste accumulators reclaimingPhosphorus compoundsLithium iron phosphateLithium hydroxide

The invention discloses a method of recycling lithium battery cathode material lithium iron phosphate. The method includes the steps of allowing a waste lithium iron phosphate battery to discharge, disassembling the waste lithium iron phosphate battery to obtain a cathode, crushing the cathode, and screening; adding the crushed and screened particles into an acid liquid for soaking so that metals,such as lithium and iron, in the particles are present in a solution in ion form; soaking, and filtering to obtain solution a; adding immobilized residue into an acid solution for soaking, stirring,and filtering to obtain solution b; adding an alkaline liquid, and stirring until no solid separates out; adding an aluminum salt into the solution with the solid separated so that lithium hydroxide separates out; dissolving crude lithium hydroxide and deionized water in a mass ratio of (0.01-0.1):1, stirring well, filtering, and separating to obtain filtrate c; heating the filtrate c, concentrating, cooling, filtering, washing the separated precipitate from filtering, and drying to obtain finished lithium hydroxide. The method herein allows lithium sources to be maximally recycled when applied to the recycle of lithium battery cathode materials.

Owner:新疆舰目摩托车有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com