No-nickel flux-cored wire and preparation method and application thereof

A technology of flux-cored welding wire and powder, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problem of high production cost, and achieve the effect of high toughness and crack resistance and good crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

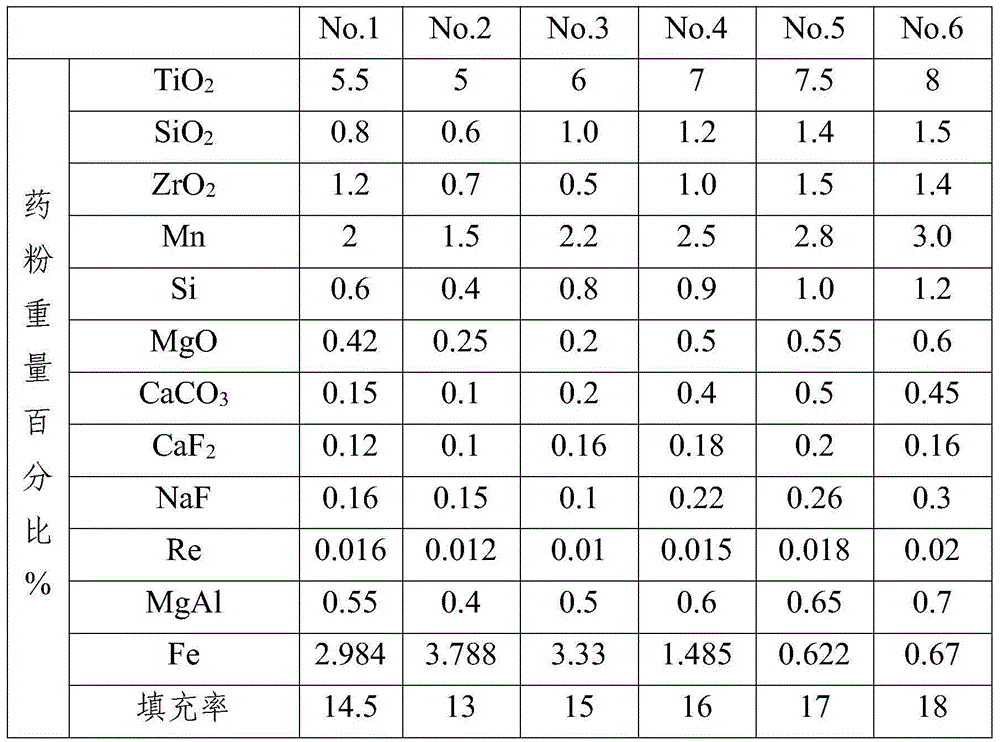

Embodiment 1

[0036] The flux-cored welding wire of the present embodiment, the composition of medicinal powder and the percentage content that accounts for described flux-cored welding wire gross mass are as follows: TiO 2 5.5%, SiO 2 0.8%, ZrO 2 1.2%, Mn 2.0%, Si 0.6%, MgO 0.42%, CaCO 3 0.15%, CaF 2 0.12%, NaF 0.16%, Fe2.884%, magnesium alloy 0.65, Re 0.016, filling rate 14.5%. Mild steel is used for the carbon steel skin.

[0037] The preparation method of the flux-cored welding wire in this embodiment: use the steel strip method to produce the flux-cored welding wire, O-shaped butt joint, fill the outer skin made of low-carbon steel strip with powder, the filling rate is 13-18%, and reduce the diameter after forming Finally, a finished welding wire with a diameter of 1.0-1.6mm is obtained.

[0038] Application of the flux-cored wire in this embodiment: the flux-cored wire of the present invention adopts CO 2 Gas protection, under the conditions of room temperature 25°C and relativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross section diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com