High wear resistant ceramic tool material and preparation method thereof

A ceramic tool, high wear resistance technology, applied in the field of ceramic materials, can solve the problems of brittleness and limited wear resistance, and achieve the effect of long service life, increased toughness and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

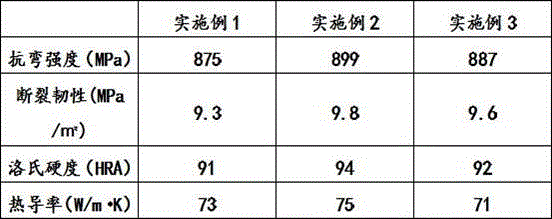

Examples

Embodiment 1

[0014] Example 1, a high wear-resistant ceramic cutting tool material, made of the following raw materials in parts by weight (kg): silicon oxide 55, waste glass scrap 7, serpentine tailings 10, blast furnace slag 5, copper oxide 1, steel slag powder 2. Tungsten boride 2, nano diamond 1, aluminum oxide 3, yttrium oxide 2, potassium magnesium titanate lamellae 1, glycerin 3, phenolic resin emulsion 2, polyvinyl alcohol 2, propylene glycol alginate 1, titanium dioxide 4, oblique Zircon 2, garnet 3, bauxite 12, iron sulfide 2.

[0015] A preparation method of a high wear-resistant ceramic cutting tool material, comprising the following steps:

[0016] (1) Silica, waste glass scrap, serpentine tailings, blast furnace slag, copper oxide, tungsten boride, aluminum oxide, yttrium oxide, potassium magnesium titanate lamellae, baddeleyite, garnet, bauxite After mixing, calcinate at 940°C for 3 hours, take it out, put it into a ball mill jar, add grinding balls, and carry out ball mill...

Embodiment 2

[0020] Example 2, a high wear-resistant ceramic tool material, made of the following raw materials in parts by weight (kg): silicon oxide 60, waste glass scrap 8, serpentine tailings 11, blast furnace slag 6, copper oxide 2, steel slag powder 3. Tungsten boride 3, nano diamond 2, alumina 4, yttrium oxide 3, potassium magnesium titanate lamellae 2, glycerin 4, phenolic resin emulsion 3, polyvinyl alcohol 3, propylene glycol alginate 2, titanium dioxide 5, oblique Zircon 3, garnet 4, bauxite 13, iron sulfide 2.

[0021] A preparation method of a high wear-resistant ceramic cutting tool material, comprising the following steps:

[0022] (1) Silica, waste glass scrap, serpentine tailings, blast furnace slag, copper oxide, tungsten boride, aluminum oxide, yttrium oxide, potassium magnesium titanate lamellae, baddeleyite, garnet, bauxite Calcined at 960°C for 2 hours after mixing, took it out, put it into a ball mill jar, added grinding balls, and carried out ball milling, the ball...

Embodiment 3

[0026] Example 3, a high wear-resistant ceramic tool material, made of the following raw materials in parts by weight (kg): silicon oxide 65, waste glass scrap 9, serpentine tailings 12, blast furnace slag 7, copper oxide 3, steel slag powder 4. Tungsten boride 4, nano diamond 3, aluminum oxide 5, yttrium oxide 4, potassium magnesium titanate lamellae 3, glycerin 5, phenolic resin emulsion 4, polyvinyl alcohol 4, propylene glycol alginate 3, titanium dioxide 6, oblique Zircon 4, garnet 5, bauxite 14, iron sulfide 3.

[0027] A preparation method of a high wear-resistant ceramic cutting tool material, comprising the following steps:

[0028] (1) Silica, waste glass scrap, serpentine tailings, blast furnace slag, copper oxide, tungsten boride, aluminum oxide, yttrium oxide, potassium magnesium titanate lamellae, baddeleyite, garnet, bauxite After mixing, calcining at 980° C. for 1 hour, take it out, put it into a ball mill jar, add grinding balls, and perform ball milling. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com