Low-porosity periclase-magnesium aluminate spinel-zirconia sintered composite refractory material and production process thereof

A magnesia-aluminum spinel and refractory technology, which is applied in the field of periclase-magnesium-aluminum spinel-zirconia sintered composite refractory materials, can solve the problems of increasing the purchase cost of refractory materials and being unacceptable to glass manufacturers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

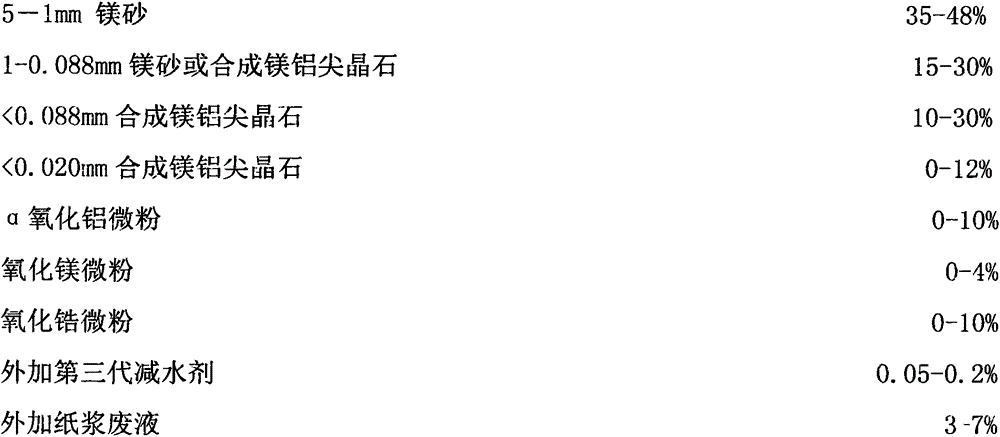

Embodiment 1

[0016] Sintered magnesia with 97% MgO content and synthetic magnesia-alumina spinel with 66% alumina content and 34% magnesium oxide content are used as main materials, and the proportion is: 5-1mm sintered magnesia 45%, 1-0.088mm sintered Magnesia 22%, 3 , apparent porosity 14.2%, load softening temperature T 0.6 = 1680°C, thermal shock stability 1100°C water cooling ≥ 8 times, a refractory material with good high temperature resistance, thermal shock resistance, low porosity physics and ideal chemical mineral composition has been produced.

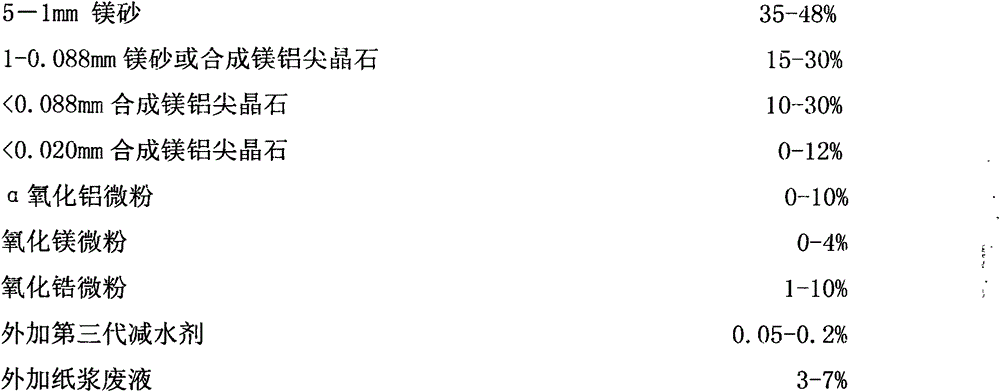

Embodiment 2

[0018] Fused magnesia with 97% MgO content and synthetic magnesia-alumina spinel with 66% alumina content and 34% magnesia content are used as main materials, and the ratio is: 5-1mm fused magnesia 40%, 1-0.088 mm synthetic magnesium aluminum spinel 25%, 3 , apparent porosity 12.8%, load softening temperature T 0.6 >1700°C, thermal shock stability 1100°C water cooling = 2 times, a refractory material with good physical and chemical properties and ideal chemical mineral composition was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com