Compound Sialon-corundum fire brick series and its production process

A technology of composite corundum and refractory bricks, which is applied in ceramic molding machines and manufacturing tools, can solve the problems of difficult large-scale practical application and high production costs, and achieve the effects of excellent corrosion resistance, low production costs, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is an example to illustrate the production method of Sialon composite corundum series refractory bricks

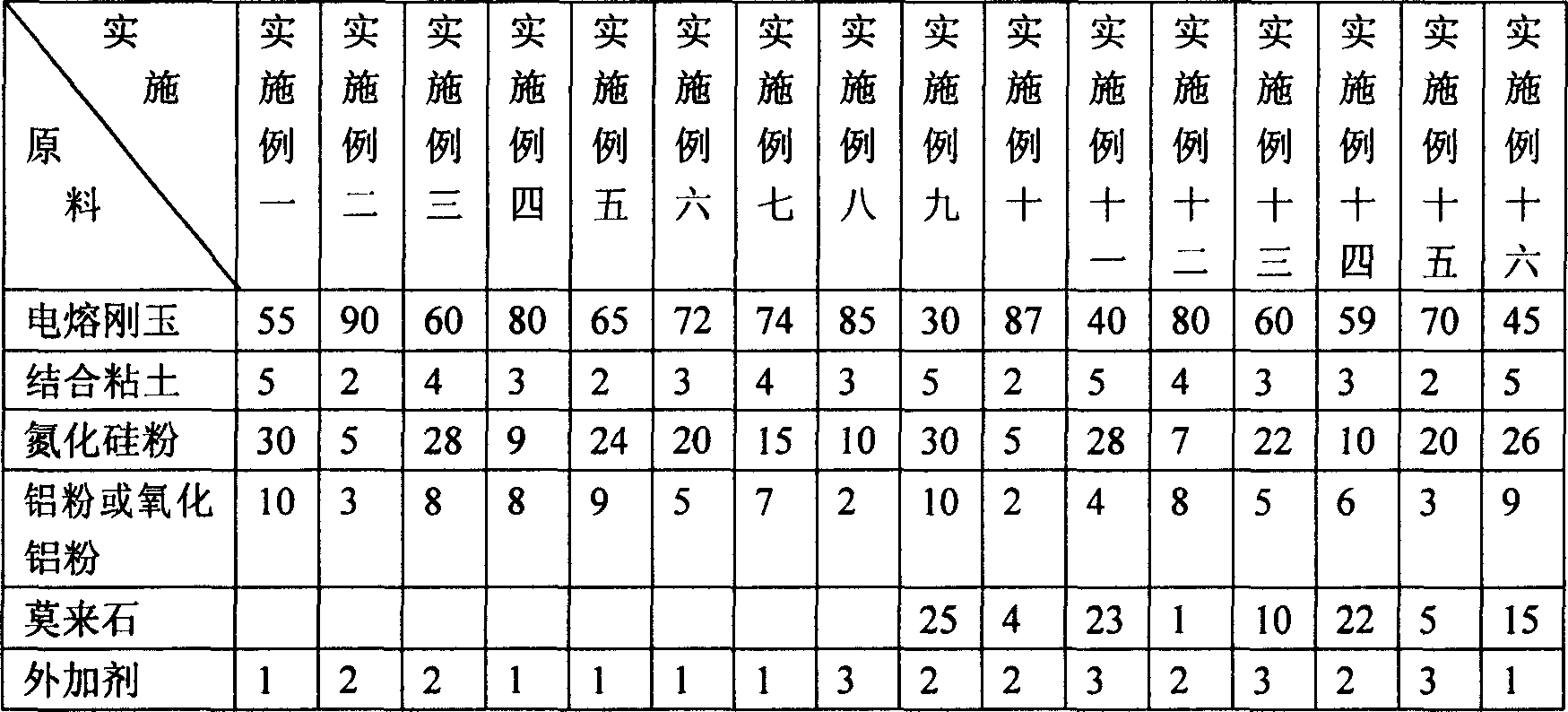

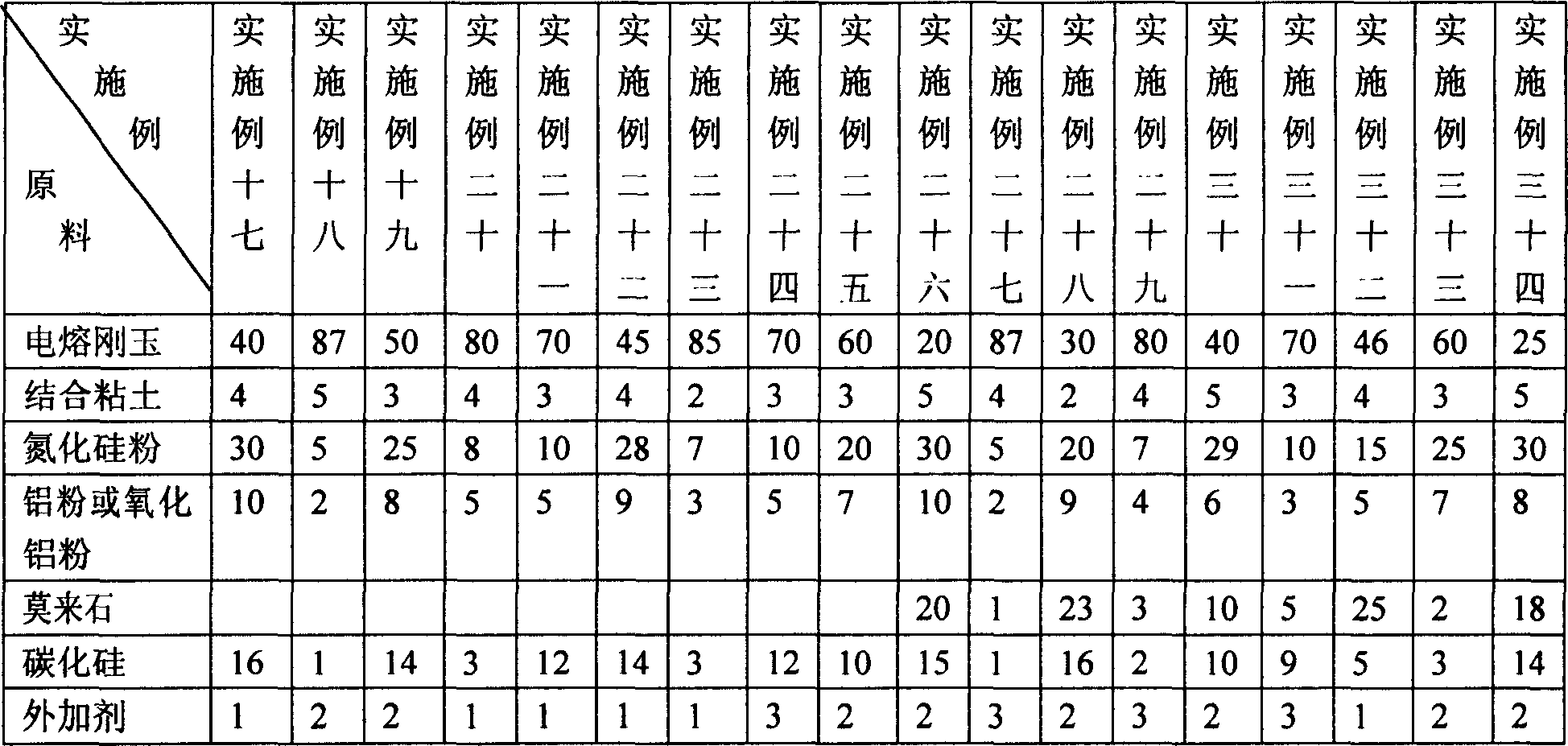

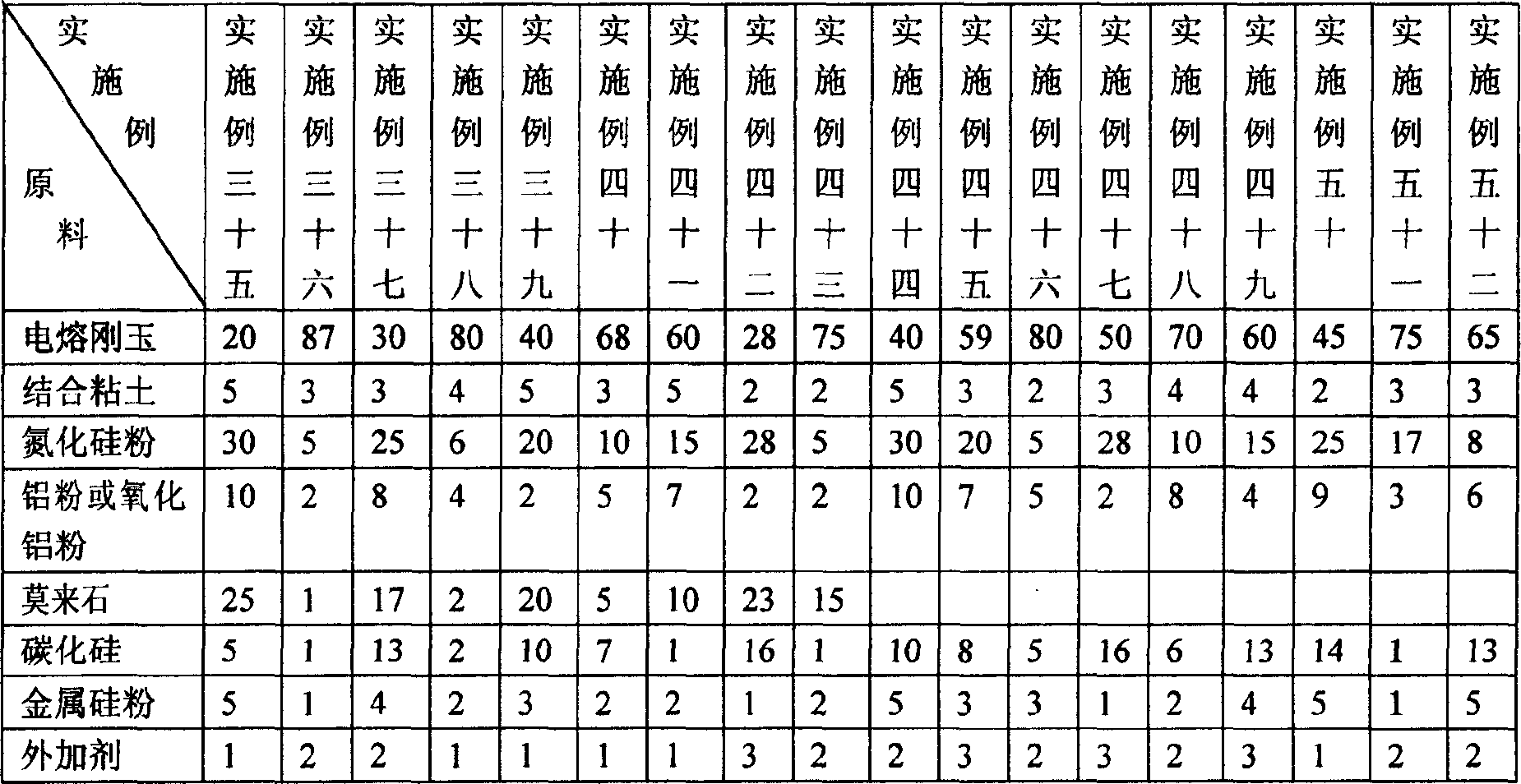

[0034] Embodiments one to ten take the raw materials according to the weight percentage of each component specified in Table 1, and all produce according to the following methods:

[0035] The weighed raw materials are mixed, pressed and formed, dried and put into the kiln. The firing temperature is 1400°C, kept for 20 hours, and cooled with the furnace to leave the kiln.

[0036] After the product leaves the kiln, inspect its physical and chemical properties, surface quality and external dimensions; process the qualified Sialon composite corundum refractory bricks according to the size standards or contract requirements; then carry out pre-assembly and inspection, and draw the pre-assembly after passing the inspection Diagrams, numbered in layers; assembly diagrams are archived by users and technical departments. Finally, the products are stored in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com