Modified high-purity magnesium aluminate spinel composite brick and preparation method thereof

A technology of pure magnesia-aluminum spinel and aluminum spinel, which is applied in the field of modified high-purity magnesia-alumina spinel composite bricks and its preparation, can solve the problems of inability to adapt to the working conditions of RH furnace, short service life and high price , to achieve low shrinkage, improved working conditions, and strong antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

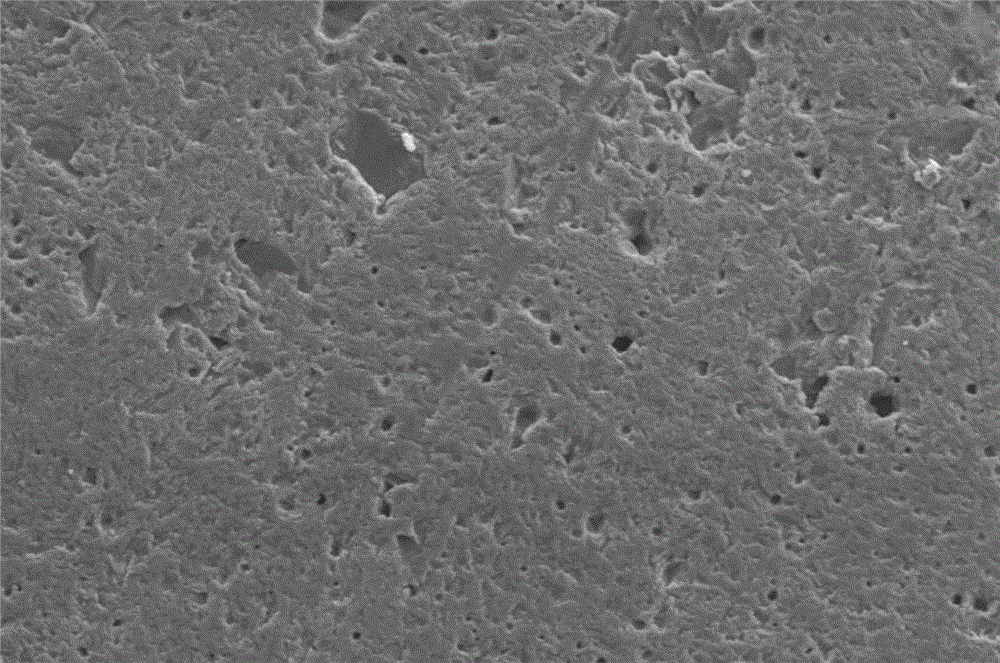

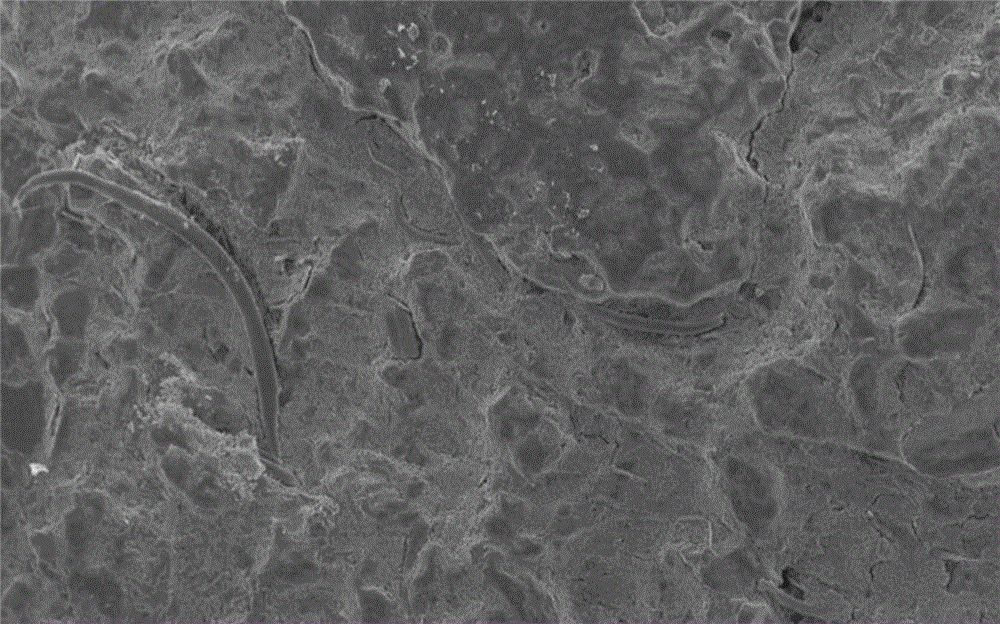

Image

Examples

Embodiment 1

[0032] The raw materials of the modified high-purity magnesia-aluminum spinel composite brick are prepared according to the following parts by weight.

[0033] Weigh high-purity sintered magnesia (model: MS99, MgO content 99.0%, SiO2 content 0.15%, Fe 2 O 3 Content 0.08%, CaO content 0.8%, AL 2 O 3 Content 0.09%) 53 parts, high-purity fused magnesia (model: DMS99, MgO≥99%) 22 parts, high-purity sintered magnesia-aluminum spinel (model: MAS76, MgO content 23%-24%, SiO 2 Content 0.12%, Fe2O3 content 0.05%, CaO content 0.30%, AL 2 O 3 Content 75%-76%) 10 parts and high-purity fused magnesia-aluminum spinel (model: MAS76, MgO content 23%-24%, SiO 2 Content 0.11%, Fe 2 O 3 Content 0.025%, CaO content 0.35%, AL 2 O 3 75%-76%), put it into a crusher for crushing, after crushing, add it to a ball mill for crushing, and then use a vibrating screen to screen out aggregates with a particle size of 5-150 mesh.

[0034] Weigh 3 parts of fused magnesia powder (model: DMS-97, MgO≥9...

Embodiment 2

[0042] The raw materials of the modified high-purity magnesia-aluminum spinel composite brick are prepared according to the following parts by weight.

[0043] Weigh high-purity sintered magnesia (Model: MS99, MgO content 99.0%, SiO 2 Content 0.15%, Fe2O3 content 0.08%, CaO content 0.8%, AL 2 O 3 Content 0.09%) 45 parts, high-purity fused magnesia (model: DMS99, MgO≥99%) 22 parts, high-purity sintered magnesia-aluminum spinel (model: MAS66, MgO content 33.5%, SiO 2 Content 0.3%, Fe 2 O 3 Content 0.15%, CaO content 0.62%, AL 2 O 3 Content 65.41%) 15 parts and high-purity fused magnesia-aluminum spinel (model: MAS76, MgO content 23%-24%, SiO 2 Content 0.11%, Fe 2 O 3 Content 0.025%, CaO content 0.35%, AL 2 O 3 75%-76%) 10 parts are put into a crusher for crushing, and after crushing, they are added to a ball mill for crushing.

[0044] Weigh 3 parts of fused magnesia powder (model: DMS-97, MgO≥97%, particle size 325 mesh), fused magnesia-aluminum spinel sand powder (m...

Embodiment 3

[0052] The raw materials of the modified high-purity magnesia-aluminum spinel composite brick are prepared according to the following parts by weight.

[0053] Weigh high-purity sintered magnesia (MgO content 99.0%, SiO 2 Content 0.15%, Fe 2 O 3 Content 0.08%, CaO content 0.8%, AL 2 O 3 Content 0.09%) 40 parts, high-purity fused magnesia (MgO≥99%) 22 parts, high-purity sintered magnesia-aluminum spinel (model: MAS76, MgO content 23%-24%, SiO 2 Content 0.12%, Fe 2 O 3 Content 0.05%, CaO content 0.30%, AL 2 O 3 Content 75%-76%) 23 parts and high-purity fused magnesia-aluminum spinel (model: MAS76, MgO content 23%-24%, SiO 2 Content 0.11%, Fe 2 O 3 Content 0.025%, CaO content 0.35%, AL 2 O 3 75%-76%) into the crusher for crushing, after crushing, add it to the ball mill for crushing, and then use a vibrating screen to screen out aggregates with a particle size of 5-150 mesh.

[0054] Weigh 3 parts of fused magnesia powder (model: DMS-97, MgO≥98%, particle size 325 me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com