Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Completely transformed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

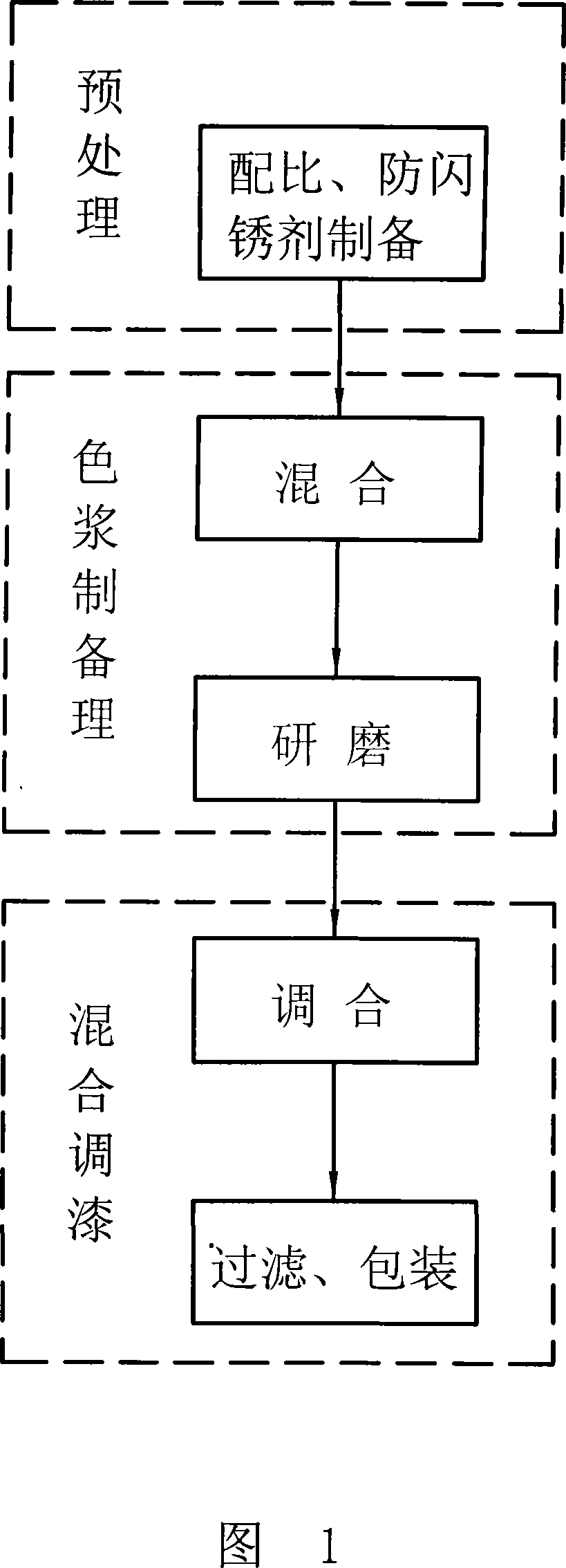

Water industrial antirust paint and preparation method thereof

InactiveCN101045843AHigh hardnessStrong adhesionAnti-corrosive paintsEmulsion paintsEpoxyALUMINUM PHOSPHATE

This invention relates to a aquosity industry anti-rust paint and its preparation method. According to weight it includes 8 to 11% aquosity acroleic acid modified epoxy, 33 to 40% acroleic acid latices, 0.1 to 0.3% defoamer, 0.05 to 0.15% wetting agent, 0.3 to 0.5% dispersant, 0.3 to 0.5% rust-resistant agent, 7.5 to 9% iron oxide red, 6 to 8% French chalk, 5 to 10% modified zinc phosphate, 2.5 to 10% trimerization aluminum phosphate, 3 to 3.5% precipitated baryte , 0.5 to 1% zinc oxide, 3 to 5% mica ferric oxide, alcohol ester twelve 1 to 2%, triethanolamine 1 to 2%, thickening agent 0.3 to 0.6%, preservative 0.05 to 0.1%, 5 to 20% de-ionized water, through pretreatment, color paste preparation and blending and adjusting to gain product.

Owner:邹磊

Aqueous rust-conversion rust-inhibiting primer

The invention relates to a water-based rust conversion antirust primer which is characterized in that: the primer comprises the following components with the corresponding percentage by weight : main conversion agent 5-35, auxiliary conversion agents 2-15, film forming material 40-55, penetrant 0.2-1.0, humectant 1-10, anti-forming agent 0.1-0.5, corrosion inhibitor 0.2-0.5 and solvent 0.5-8; the process is as follows: adding deionized water to a charging basket and heating the water to 60-80 DEG C with aliphatic alcohol polyethenoxy ether added, adding propylene glycol and starting a high-speed dispersion machine for agitation, later on adding tributyl phosphate, potassium sorbate, tannic acid and one of the auxiliary conversion agents and cooling down to 20-33 DEG C after agitating for 30-55 minutes, and adding vinyl chloride-modified acrylic resin latex and discharging material after agitating for 10-20 minutes. The invention has the advantages of direct application to steel surfaces with rust, thorough conversion of rust, excellent adhesive force of a conversion film, good flexibility, adaptation to various forms, and good compatibility with various top coatings.

Owner:安泰能(上海)高分子材料有限公司

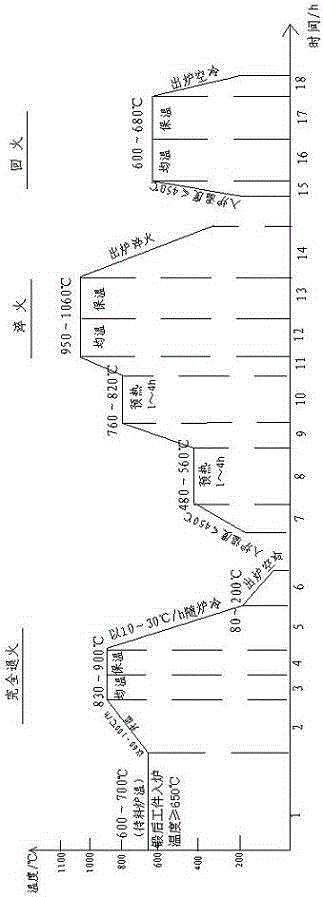

Heat treatment method of high-chromium martensitic stainless steel

ActiveCN102719627ASufficient quenching and cooling intensityAvoid crackingMartensitic stainless steelQuenching

The invention relates to a stainless-steel heat treatment technology, in particular to a heat treatment method of high-chromium martensitic stainless steel. The heat treatment method comprises the following steps of: 1) annealing; 2) preheating; 3) quenching; and 4) tempering. The heat treatment method has the following advantages that 4Cr16Mo stainless steel heat treatment process comprises the following procedures of: (1) complete annealing, controlling the furnace entering temperature after forging, the heating speed, the heating temperature, the insulating time and the furnace cooling speed; (2) quenching heating, controlling the preheating temperature, the heating speed, the heating temperature and the insulating time; (3) quenching cooling, adopting a gap-cooling mode of air-liquid-air-liquid-air-liquid, the quenching stress is furthest reduced while ensuring that a workpiece obtains enough quenching cooling severity and obtains a martensitic structure, and the cracking of the workpiece caused by excessive stress is avoided; and (4) tempering, strictly controlling the tempering furnace-entering time, tempering heating temperature and the insulating time, the structure transformation is complete, the quenching stress is eliminated, and fine and uniform tempering sorbite is obtained.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Thermal treatment technology for improving low-temperature impact toughness of 25Cr2Ni4MoV steel forging

The invention belongs to the technical field of production of steel forging products used at low temperature, relating to a thermal treatment technology requiring higher low-temperature impact toughness, and particularly relating to a thermal treatment technology for improving the low-temperature impact toughness of a 25Cr2Ni4MoV steel forging. The thermal treatment technology comprises the following steps of: (1) normalizing heating; (2) normalizing cooling; (3) quenching heating; and (4) quenching cooling. The thermal treatment technology provided by the invention effectively improves the low-temperature impact toughness and prolongs the service life of a product while guaranteeing the material strength.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Production process for changkou hawthorn dry red wine

InactiveCN102373137APreserve the flavorImprove stabilityAlcoholic beverage preparationMicroorganism based processesPectinaseVitamin C

The invention discloses a production process for changkou hawthorn dry red wine. The production process comprises the following steps of: adding purified water into high-quality changkou hawthorn serving as a raw material in an amount which is the same as the weight of the hawthorn, boiling and pulping; adding purified water containing 6-12 percent of alcohol in an amount of a quarter based on the weight of the hawthorn; adding 60-80 mg / L of SO2 based on the amount of hawthorn pulp; adding 0.6-0.8 ml / kg of pectinase based on the amount of the hawthorn, and treating for 20-30 hours; adding sugar into a stainless steel fermentation tank; adding a yeast liquid for brewing the wine; performing main fermentation at the temperature 20-28 DEG C for 7-10 day; performing post fermentation at the temperature 17-20 DEG C for 25-30 days; transferring into a pool, separating and deacidifying to obtain raw wine; and adding gelatin for clarifying, ageing, separating and filtering to obtain the hawthorn dry red wine. The hawthorn dry red wine has hawthorn flavor, is tartish, astringent, clear and transparent, is in a rubine color, is rich in amino acid, crataegolic acid, flavone, vitamin C, trace elements and the like, and has a good health-care function.

Owner:WEIFANG ENG VOCATIONAL COLLEGE

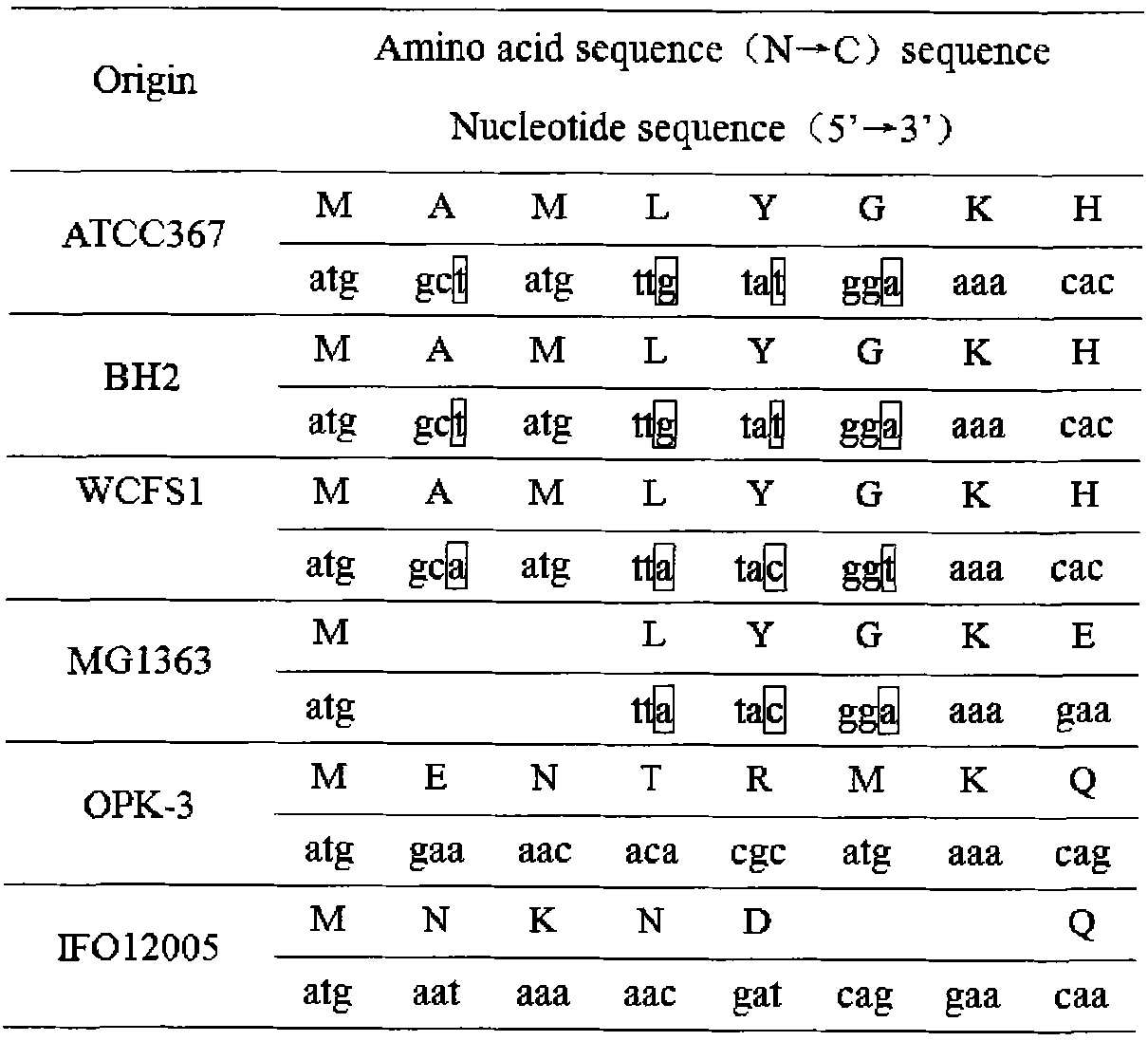

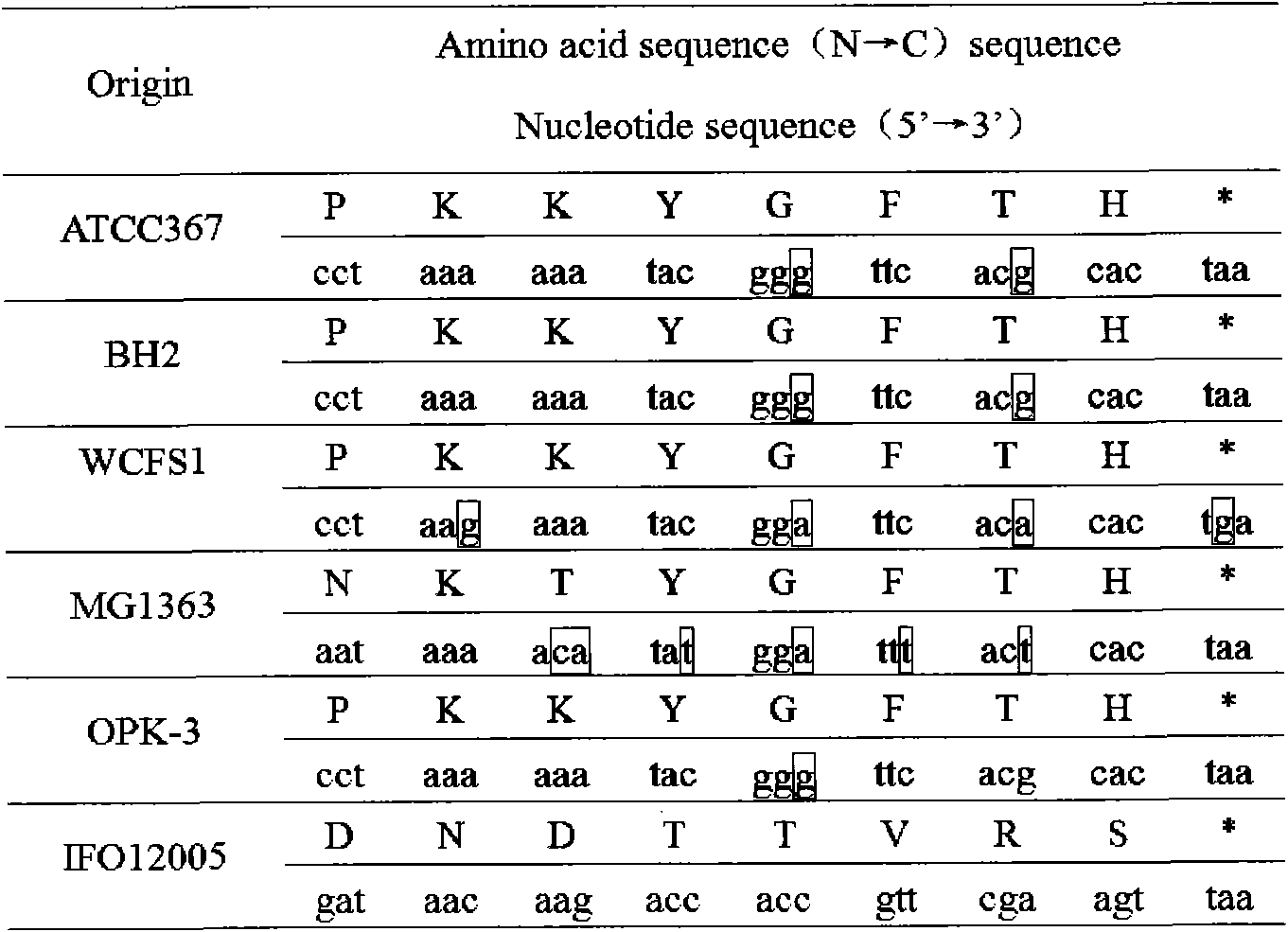

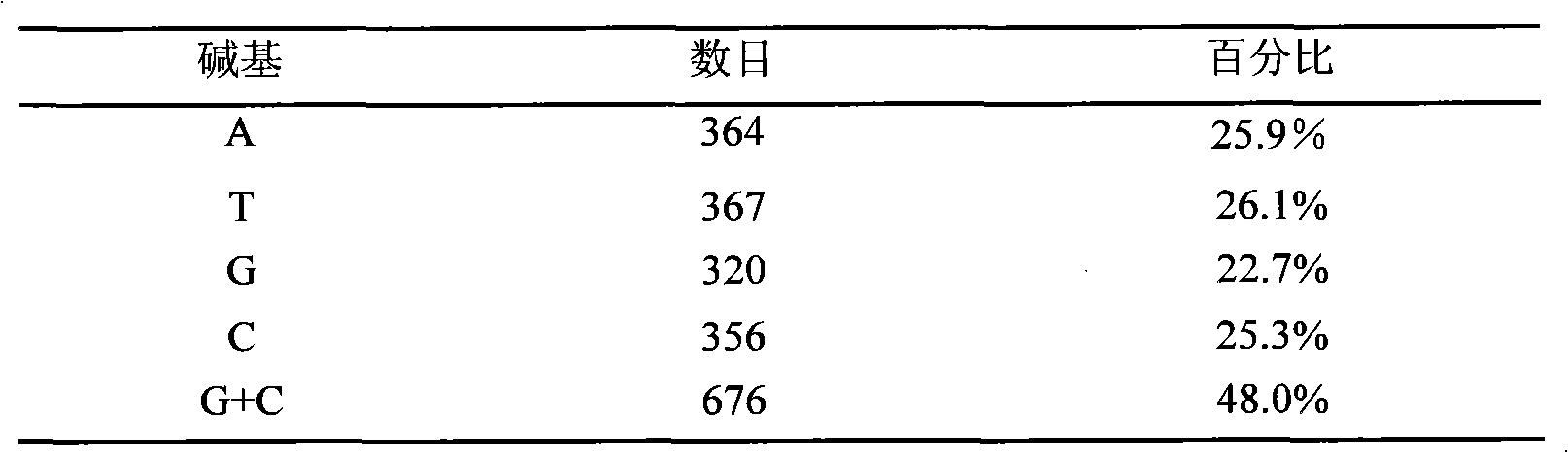

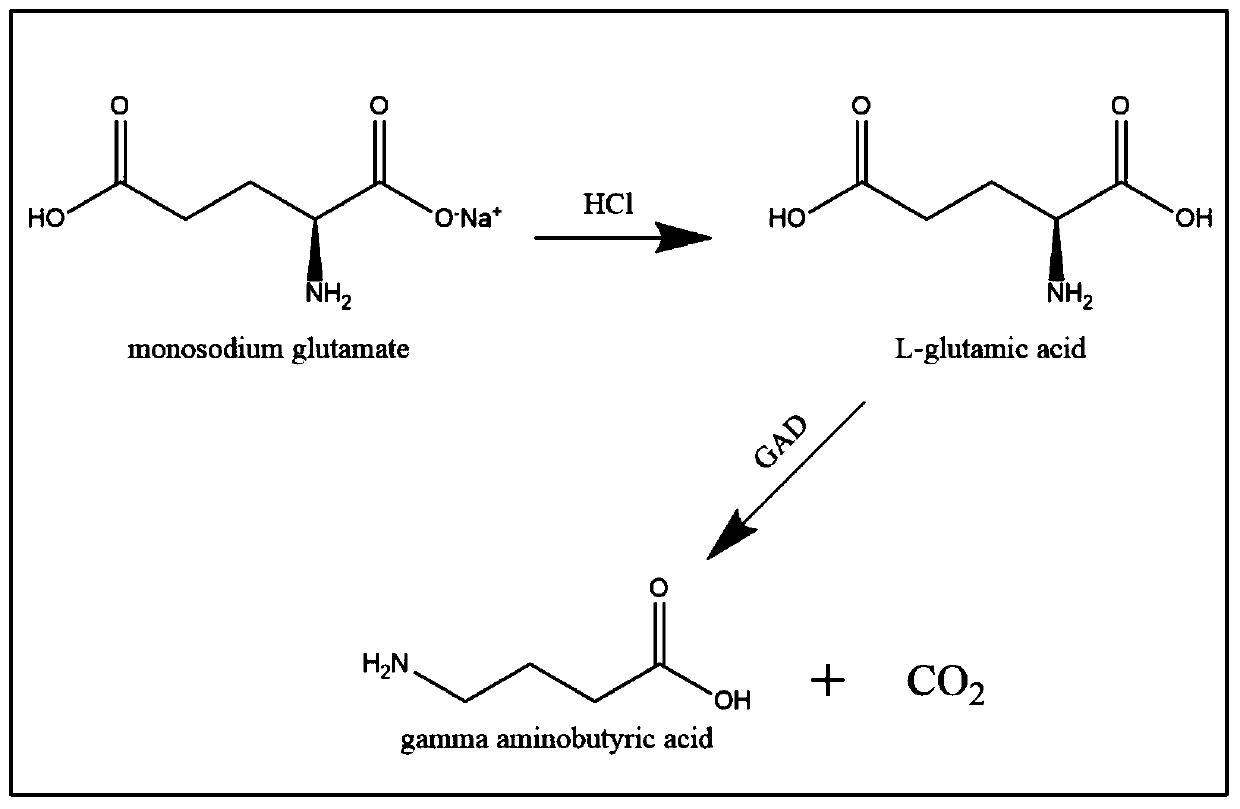

Cloning, expression and application of Lactobacillus brevis glutamate decarboxylase gene

InactiveCN102080090AOvercoming rateOvercome the cycleFermentationLyasesEscherichia coliRestriction enzyme digestion

The invention discloses cloning, expression and application of a Lactobacillus brevis glutamate decarboxylase gene. The gene is derived from Lactobacillus brevis CGMCC No.1306, and is obtained by amplifying a Lactobacillus brevis genome DNA through PCR (polymerase chain reaction); and the full length of the gene is 1407bp. BamH I and EcoRI restriction enzyme recognition sequences are respectively added to both ends of the gene; and the gene is connected with pET-28a(+) which is digested by the same restriction enzymes, and is converted into colibacillus expression host bacteria BL21 (DE3), thereby realizing the recombinant expression in the colibacillus; and the molecular weight of the expression product glutamate decarboxylase is 53538.6Da. The recombinant glutamate decarboxylase, or the engineering bacteria for expressing the recombinant glutamate decarboxylase can convert L-glutamic acid or salt thereof into gamma-aminobutyric acid by decarboxylation, and has the advantages of high conversion efficiency, high product purity and high production efficiency.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

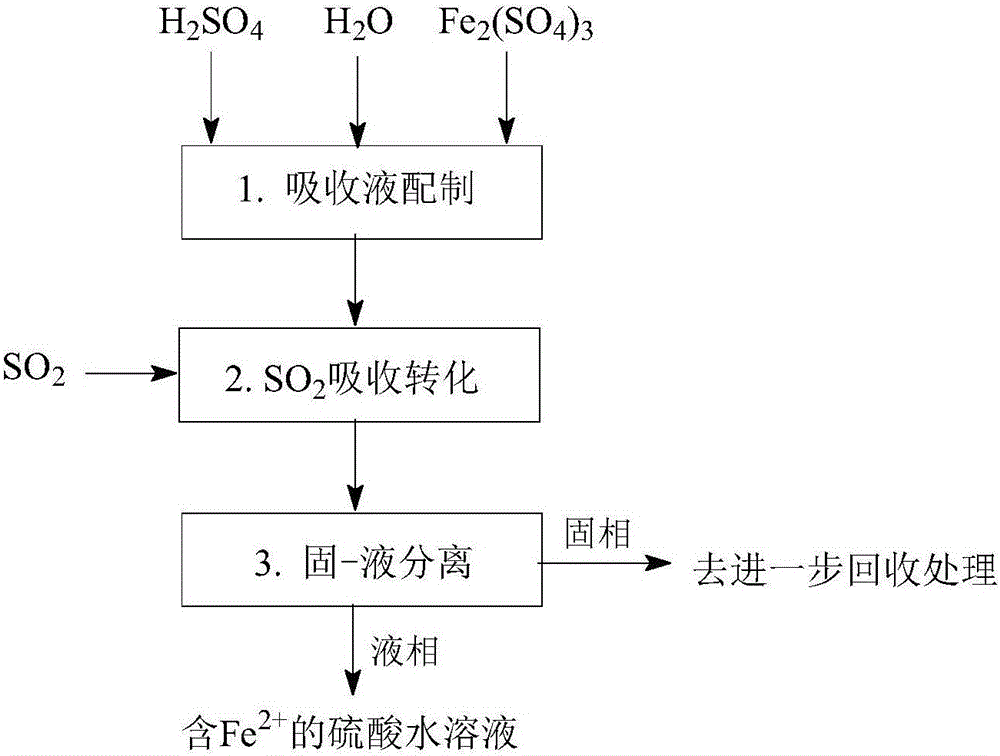

SO2 absorbing and converting technological method

InactiveCN105964127AAchieve recyclingOvercoming the fatal flawSulfur compoundsDispersed particle separationAqueous solutionOxidizing agent

The present invention provides a SO 2 The processing method of absorption conversion, the method is based on Fe 3+ Aqueous sulfuric acid solution as absorbent, Fe 3+ As an oxidizing agent, the SO 2 Absorb dissolved in sulfuric acid aqueous solution, absorb dissolved SO 2 with Fe 3+ The reaction converts to H 2 SO 4 , while Fe 3+ is reduced to Fe 2+ ; The obtained Fe 2+ Aqueous sulfuric acid can convert Fe 2+ Oxidation regeneration to Fe 3+ Afterwards, it can be recycled as an absorbent, or to remove Fe 2+ Preparation of sulfuric acid products. The present invention uses Fe 3+ is the oxidizing agent, SO 2 The absorption and conversion of SO 2 The removal efficiency is high, the conversion is thorough, and the operating conditions are mild. While realizing wet desulfurization, sulfuric acid can be co-produced, and through Fe 3+ / Fe 2+ The pair realizes Fe 3+ cyclic use; the utilization rate of atoms is high, the process is safe and reliable, and it is conducive to large-scale industrialization. is a SO 2 An effective method for removal and recycling of resources.

Owner:YANGZHOU UNIV

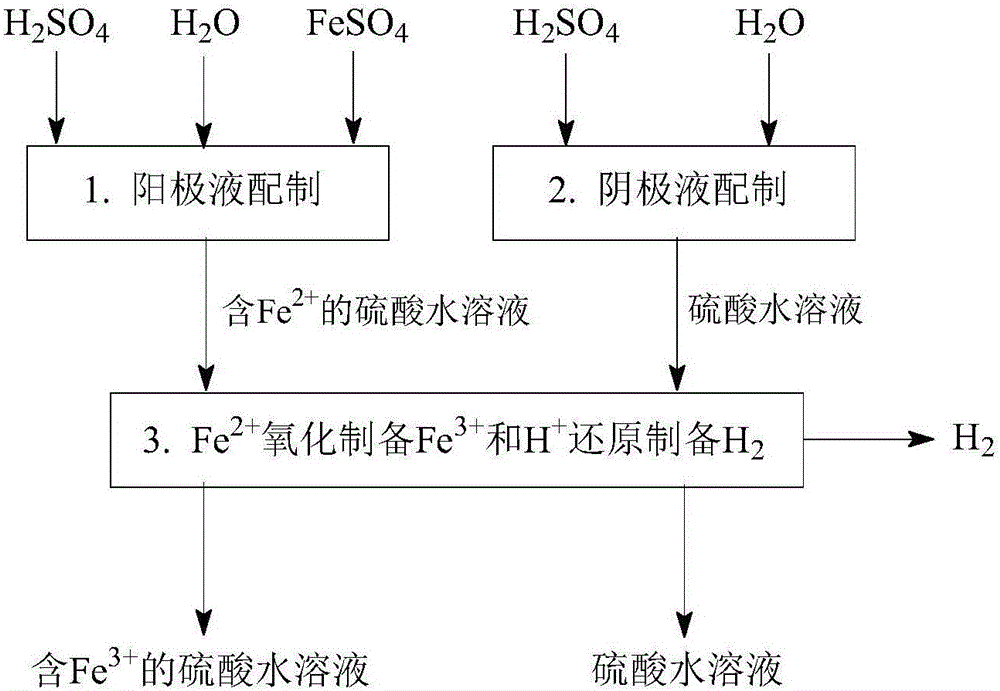

Method for desulfurization cogenerating of hydrogen and sulfuric acid

ActiveCN106039964AAchieve regenerationOvercoming the fatal flawElectrolysis componentsDispersed particle separationHydrogenGas phase

The invention discloses a method for desulfurization cogenerating of hydrogen and sulfuric acid. The method includes three main steps, namely SO2 absorption and conversion, Fe3+regeneration and H2 cogeneration and F2+removal and H2 cogeneration. In the method, a Fe3+ / F2+ electrochemical pair is adopted as a process catalyst, indirect electrochemical oxidation is realized, sulfur dioxide in a gas phase is removed by using a sulfuric acid water solution wet method, and hydrogen and sulfuric acid can be cogenerated at the same time. The method is high in process efficiency and energy utilization rate, low in equipment investment and production cost, safe and reliable in process and conducive to large-scale industrialization, and is an environment-friendly technology for desulfurization, comprehensive utilization of sulfur dioxide and cogeneration of hydrogen and sulfuric acid.

Owner:YANGZHOU UNIV

Overlay welding process for deep holes on valve body sealing surface

InactiveCN102518853AGuaranteed hardnessGuaranteed tightnessFurnace typesValve housingsEngineeringAlloy

The invention relates to an overlay welding process for deep holes on a valve body sealing surface. The innovation point of the overlay welding process is that the steps are as follows: drilling out a valve body middle hole extending to the valve body sealing surface from the position of a valve rod hole of the valve body on valve body blank; drilling out concentric process holes, diameter of which is smaller than that of the valve body middle hole, on the bottom part of the valve body middle hole of the valve body blank; carrying out overlay welding of hard alloy on a shaft shoulder surface between the process holes and the valve body middle hole; carrying out thermal treatment to the valve body blank; and finally, machining the sealing surface of the valve body blank; the bottom part of the valve body middle hole is drilled with process holes, so that the hole diameter of the process holes ensures that the welding area achieves the processing width of the overlay welding on the sealing surface; overlay welding is carried out to the annular shaft shoulder surface between the process holes and the valve body middle hole, so that compound stress is reduced to be within a safe range to avoid crackles. The inner wall of the overlay welding layer does not contact with the mother material, so that fusion phenomenon does not exist, and the hardness of the overlay welding layer is ensured, and the sealing performance is ensured. Besides, overlay welding materials on the positions of the process holes are saved, so that welding rods are saved.

Owner:NANTONG POWER STATION VALVE

Comprehensive utilization method of acidic and alkaline waste etching solution

InactiveCN101654275ALarge amount of processingMeet the requirements of cleaner productionPhotography auxillary processesCopper oxides/halidesEtchingEconomic benefits

The invention provides a comprehensive treatment method of acidic and alkaline waste etching solution of circuit boards, belonging to the technology in the field of environmental protection. The method is characterized by neutralizing and precipitating the acidic waste etching solution and the alkaline waste etching solution under the condition that the pH value is 5-6.5, pulping and then mixing the precipitates and quicklime, dehydrating and then roasting the mixtures at 400-600 DEG C, dissolving calcium chloride in the roasted product by water, separating and removing the residual lime by gravity separating to obtain the copper oxide products with purity being over 98%, or taking the generated copper oxide as the raw material to produce other products. The calcium chloride and ammonia generated in the process are also subjected to concentration, crystallization, ammonia evaporation and absorption to obtain the calcium chloride and ammonia products. The comprehensive treatment methodhas the advantages of total recycle, zero discharge, large treatment capacity, low treatment cost, high product quality, diverse product categories and the like, can not only eliminate environmental pollution radically but also create higher economic benefits.

Owner:广州市白云区南溪化工厂

Method for producing organic fertilizer by using sugar refining filter mud and bagasse

ActiveCN104529578ASolve the problem of secondary environmental pollutionGood fermentation air permeabilityBio-organic fraction processingClimate change adaptationNutrientOrganic manure

The invention provides a method for producing an organic fertilizer by using sugar refining filter mud and bagasse. The method comprises the steps of blending the sugar refining filter mud, of which the weight ratio is 90.01-99.9%, and the bagasse, of which the weight ratio is 0.1-9.99%, so as to form a filter mud fermentation material, then, putting the filter mud fermentation material on three-dimensional fermentation equipment, of which the vertical direction comprises 2-40 layers and the horizontal direction comprises 2-40 belt conveyors, carrying out aerobic fermentation, carrying out composting and dehydrating, so as to obtain well-composted organic raw materials, then, applying the well-composted organic raw materials directly as an organic fertilizer, or producing various organic fertilizer products in a manner that the well-composted organic raw materials are matched with macro-, medium- and micro- nutrient elements essential to plants. The method provided by the invention can be used for effectively utilizing the sugar refining filter mud and the bagasse and is good in fermentation effect and small in floor area, meanwhile, secondary pollution resulting from bad smell can be avoided, and the aims of high efficiency and environment-friendliness are achieved.

Owner:GUANGXI LIYUANBAO SCI & TECH

Method for quickly preparing low-heat-conduction mullite heat-insulation brick on basis of foam processes

The invention discloses a method for quickly preparing a low-heat-conduction mullite heat-insulation bricks on the basis of foam processes. The method includes adding auxiliary materials including setting accelerators, water reducing agents, structural propping agents and water into raw materials including aluminum oxide fine powder, corundum fine powder, expansive agents, gel powder, clay, mullite powder and binding agents and mixing the auxiliary materials and the raw materials with one another to obtain first mixtures; adding foaming agents into the first mixtures and uniformly mixing the foaming agents and the first mixtures with one another to obtain second mixtures; calcining the second mixtures to obtain the low-heat-conduction mullite heat-insulation bricks. The invention further discloses the low-heat-conduction mullite heat-insulation brick prepared by the aid of the method. The method and the low-heat-conduction mullite heat-insulation brick have the advantages that the method includes simple preparation technologies and is free of environmental hazards, low in production cost and short in production cycle; good heat-insulation effects can be realized by the low-heat-conduction mullite heat-insulation brick prepared by the aid of the method, the low-heat-conduction mullite heat-insulation brick is high in thermal shock resistance, long in service life and wide in service range, and the like.

Owner:YIXING MORGAN THERMAL CERAMICS CO LTD

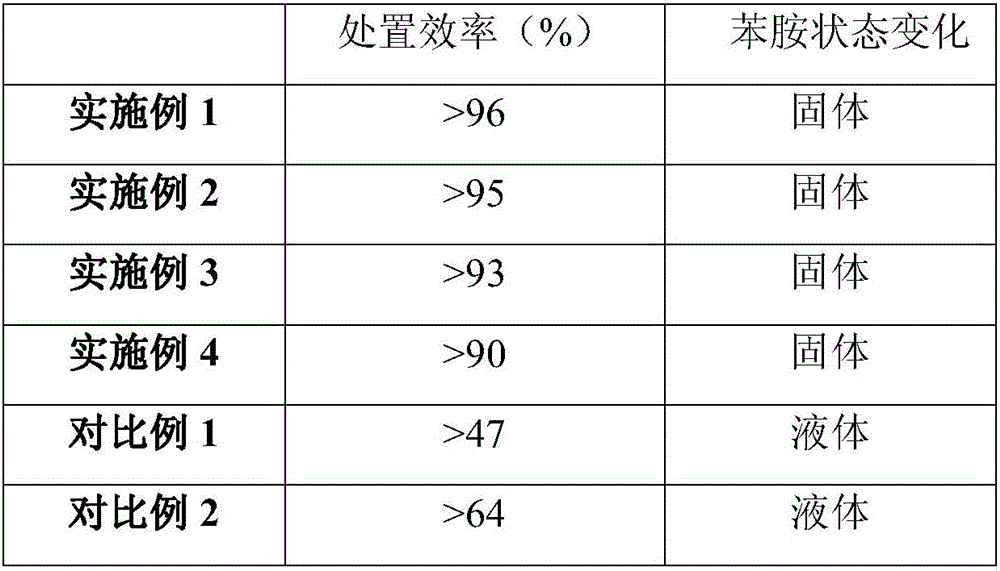

Aniline leakage emergency treatment agent

ActiveCN105709363ACompletely transformedCompletely curedChemical protectionEmergency treatmentLiquid state

The invention discloses an aniline leakage emergency treatment agent. The aniline leakage emergency treatment agent consists of the following components in parts by weight: 0.5-10.0 parts of a surfactant, 5.0-40.0 parts of a transforming agent, 0-4.0 parts of a flocculating agent, 0-8.0 parts of an oxidant, 0-0.2 part of a curing agent and 50.0-95.0 parts of water. When in use, the aniline leakage emergency treatment agent is sprayed to an aniline leakage site in an atomizing manner, so that aniline vapor concentration in air can be quickly reduced, liquid-state aniline is quickly converted and solidified, and re-volatilization of the aniline vapor can be restrained within a relatively long time, so that necessary conditions are provided for subsequent rescue.

Owner:UNIV OF SCI & TECH OF CHINA

SiO2 doped Sb nano phase change film material, and preparation method and application of film material

InactiveCN106953006AEasy to prepareProcess parameters are easy to control effectivelyMaterial nanotechnologyElectrical apparatusChemical compositionRandom access memory

The invention discloses an SiO2 doped Sb nano phase change film material, and a preparation method and an application of the film material. A chemical composition of the SiO2 doped Sb nano phase change film material is (SiO2)xSb1-x, wherein x is greater than or equal to 0.22 and less than or equal to 0.40; and the film material is deposited by a magnetron sputtering method. The prepared SiO2 doped Sb nano phase change film material has a high crystallization temperature, can effectively improve thermal stability of a PCRAM (Phase Change Random Access Memory), has a high crystallization speed, and can greatly increase a memory speed of the PCRAM.

Owner:JIANGSU UNIV OF TECH

Method for producing well-composted organic raw materials by using sugar refining filter mud and bagasse

InactiveCN104529579AImprove permeabilityGood aerobic fermentation stateBio-organic fraction processingClimate change adaptationOrganic manureSugar refining

The invention provides a method for producing well-composted organic raw materials by using sugar refining filter mud and bagasse. The method comprises the steps of blending the sugar refining filter mud, of which the weight ratio is 90.01-99.9%, and the bagasse, of which the weight ratio is 0.1-9.99%, so as to form a filter mud fermentation material, then, putting the filter mud fermentation material in a fermentation tank or stacking the filter mud fermentation material into window shapes on the ground surface, carrying out aerobic fermentation, stirring with fermentation equipment during fermentation, carrying out fermentation composting, and dehydrating, so as to obtain the well-composted organic raw materials. The method provided by the invention can be used for effectively utilizing the sugar refining filter mud and the bagasse and is good in fermentation effect and small in floor area, meanwhile, secondary pollution resulting from bad smell can be avoided, and the aims of high efficiency and environment-friendliness are achieved.

Owner:GUANGXI LIYUANBAO SCI & TECH

Production method of low-hardness 20CrMnTi round steel

ActiveCN110129653AIncrease phase transition timePromote formationTemperature control deviceThree stageManganese

The embodiment of the invention provides a production method of low-hardness 20CrMnTi round steel. The production method is characterized by comprising the following steps that a round steel blank isdesigned and controlled to comprise the components of 0.18 percent to 0.22 percent of carbon, 0.20 percent to 0.30 percent of silicon, 0.85 percent to 1.05 percent of manganese, 1.05 percent to 1.25 percent of chromium, 0.050 percent to 0.070 percent of titanium, 0.020 to 0.040 percent of aluminum and less than or equal to 0.0020 percent of oxygen; the round steel blank is smelted into molten steel through a steel furnace, and the molten steel is subjected to LF refining, RH vacuum treatment and continuous casting to form a continuous casting billet; the continuous casting billet is heated ina furnace in a three-stage manner, and after being heated, the continuous casting billet is rolled into rolled round steel through rough rolling, medium rolling and finish rolling mill units; the rolled round steel is subjected to controlled cooling through a water-passing cooler; and the rolled round steel enters a cooling bed for natural cooling after passing through water, wherein the temperature of the cooling bed when the round steel enters is controlled to be 930+ / -30 DEG C .

Owner:LIUZHOU IRON & STEEL

Coupling process for preparing biodiesel and enriching polyunsaturated fatty acid esters

InactiveCN106399406AImprove applicabilityHigh yieldBiofuelsFermentationSaturated fatty acid esterOil phase

The invention relates to a coupling process for preparing biodiesel and enriching polyunsaturated fatty acid esters. The coupling process comprises the following steps: reacting grease, short-chain alcohol, water and liquid lipase in a reactor, and then dividing reaction liquid into a heavy phase and a light phase; recycling and reusing enzyme in the heavy phase; and distilling the light phase so as to separate out a C14-C18 fatty acid ester which serves as the biodiesel. A tower oil phase is applied to subsequent immobilized enzyme transformation, and meanwhile, online dehydration is introduced to a reaction course. The process, without conducting pre-treatment on the grease raw material in a previous reaction process of liquid enzyme catalysis, can achieve the effective transformation of the grease, which is C14-C18 in fatty acid carbon-chain length, into corresponding fatty acid ester, with a transformation rate reaching 90% or above; and tower liquid is applied to immobilized lipase catalysis in the second stage, and polyunsaturated fatty acid esters higher than C19 are effectively transformed into corresponding fatty acid ester, with a transformation rate reaching 98% or above. The process has the advantages of being strong in grease raw material adaptability, environment-friendly and clean in process, high in product yield and the like.

Owner:北京启迪德清生物能源科技有限公司

Iron-cobalt alloy and preparation method of magnetizing pole head of iron-cobalt alloy

ActiveCN103834862AImprove magnetic propertiesImprove mechanical propertiesMagnetic bodiesQuenching agentsDry iceIngot

The invention discloses an iron-cobalt alloy and a preparation method of a magnetizing pole head of the iron-cobalt alloy. The iron-cobalt alloy comprises the following substances in percentage by weight: 29-34.5% of Co, 0.05-0.15% of rare earth, 0.15-0.40% of Nb, 0.10-0.25% of Zr and the balance of Fe. The preparation method of the magnetizing pole head of the iron-cobalt alloy comprises the following steps: 1) smelting the alloy by virtue of a vacuum furnace and casting the alloy into alloy ingot; 2) after forging and molding, directly quenching in a mixed solution of dry ice and water; 3) processing the forge piece into the magnetizing pole head; 4) subsequently carrying out three times of treatment containing pre-heating treatment and multiplex heat treatment by using a protective atmosphere heat treatment furnace and a vacuum heat treatment furnace so as to ensure excellent comprehensive properties of a finished product. The magnetizing pole head produced by virtue of the preparation method has the advantages of strong saturation flux density, low coercive force, small residual magnetism, good mechanical property, high compressive strength, long service life and good quality stability and can meet operating requirements on high property of the magnetizing pole head in the electron industry.

Owner:梅州市嘉晟工贸有限公司

Application of electromagnetic field for improving life of metallic material

The invention discloses an application of electromagnetic field to improve the lifetime of metal material, which comprises the following steps: fixing disposed element on the chuck; placing fixed element in the high-frequency electromagnetic inductive coil; placing high-frequency coil with element and chuck in the low-frequency exciting coil; making the disposed working piece receive magnet, power and mechanical energy; fitting for disposing kinds of metal material such as electronic profession, mechanic manufacturing profession, mining industry, building industry and automobile industry; improving the using lifetime of working piece effectively.

Owner:WUHAN JINGTAI TECH CO LTD

Biological preparation method of gamma-aminobutyric acid

ActiveCN109735559ALow costSuitable for industrial productionFermentationVector-based foreign material introductionMonosodium glutamateGlutamate decarboxylase

The invention provides a biological preparation method of gamma-aminobutyric acid, which comprises the following steps of: 1) preparing glutamic acid decarboxylase whole cell thallus by using an E. coli engineering strain capable of expressing glutamic acid decarboxylase; 2) using monosodium glutamate and concentrated hydrochloric acid to prepare L-glutamic acid; 3) dissolving L-glutamic acid as asubstrate in water, adding glutamic acid decarboxylase whole cell thallus and pyridoxal phosphate, stirring and reacting to obtain gamma-aminobutyric acid. The method uses water to replace buffer salt solution to form a water-phase reaction system, uses monosodium glutamate to replace high-purity glutamic acid, so that the purity of the gamma-aminobutyric acid is up to 97.7 percent, and the costof raw materials is reduced; whole cells used for catalysis can be produced in a large scale by microbial fermentation, the cost is low, and the source is wide; the biological enzyme-promoted catalytic reaction is a water-phase reaction, the enzymatic conversion condition is mild, the raw material conversion is thorough, the post-treatment is simple, the product is separated by adopting a method of evaporation concentration and natural crystallization, the cost is low, the process is environment-friendly, and the method is suitable for industrial production of gamma-aminobutyric acid.

Owner:HUBEI UNIV

Technique of manufacturing steel spade in environment protechion type

InactiveCN1518856ASolve the problem of black smoke polluting the environmentSolve the pollution of the environmentHand equipmentsMetallurgySewage

An environmental protection type technology for manufacturing the steel spade includes heating the raw steel plate in roller furnace, die pressing by mechanical press, rolling its tubular part by a rolling machine, quenching in hardening medium, tempering in tempering furnace, washing in water washing apparatus, heating the sewage by the afterheat of roller furnace for evaporating and concentrating, and recovering the hardening medium. Its advantages are high quality of product, no environmental pollution.

Owner:付长智

Quenching device for support roller path part of oversized excavator and quenching process

ActiveCN106011440AFine grainUniform tissueFurnace typesIncreasing energy efficiencyEngineeringInduction hardening

The invention belongs to the technical field of metal process quenching, and relates to a quenching device for a support roller path part of an oversized excavator and a quenching process. The device comprises a vertical induction quenching machine tool, a supporting wheel support roller path quenching water spraying device and a supporting wheel support roller path induction quenching heating tool. The process comprises the following steps: fixedly placing a workpiece in the induction quenching machine tool, heating the workpiece at a frequency of 300 to 600Hz by virtue of the supporting wheel support roller path induction quenching heating tool, and spraying water to a the support roller path part of the heated supporting wheel for quenching by taking clear water as a cooling medium by virtue of the supporting wheel support roller path quenching water spraying device. According to the device and the system, a deep induction heating link for quenching treatment of the support roller path part of a supporting wheel of the excavator and an adjacent shaft shoulder surface can be implemented, energy resources can be saved, and the working efficiency can be improved.

Owner:石家庄新莱特机械轧辊有限公司

Tea processing technology

InactiveCN105076505AFully fermentedReduce bitternessPre-extraction tea treatmentCarbon dioxideAgroforestry

The invention belongs to a tea processing technology. The technology scheme comprises the following steps: refreshing leaves, sunning leaves, rolling leaves, placing leaves in a certain condition, frying leaves, twisting leaves, baking leaves with charcoal, allowing leaves to stand, baking leaves with machine and producing the finished products. The technology scheme is characterized in that: the step for placing leaves in a certain condition is a process for placing leaves for 6-10 hours in the condition that the temperature is 15-25 DEG C, the humidity is 60-70% and the carbon dioxide concentration is 700-800PPM; the step for baking leaves with charcoal is a process for baking leaves for 4.5-5.5 hours in the condition that the temperature is 45-55 DEG C, the humidity is 60-80% and the carbon dioxide concentration is 700-800PPM; the step for allowing leaves to stand is a process for placing leaves for 30-40 hours in the condition that the temperature is 15-25 DEG C, the humidity is 60-70% and the carbon dioxide concentration is 700-800PPM; the step for baking leaves with machine is a process for baking leaves at 95-105 DEG C for 9-11 hours and then at 75-85 DEG C for 45-55 hours.

Owner:漳州辰和茶业有限公司

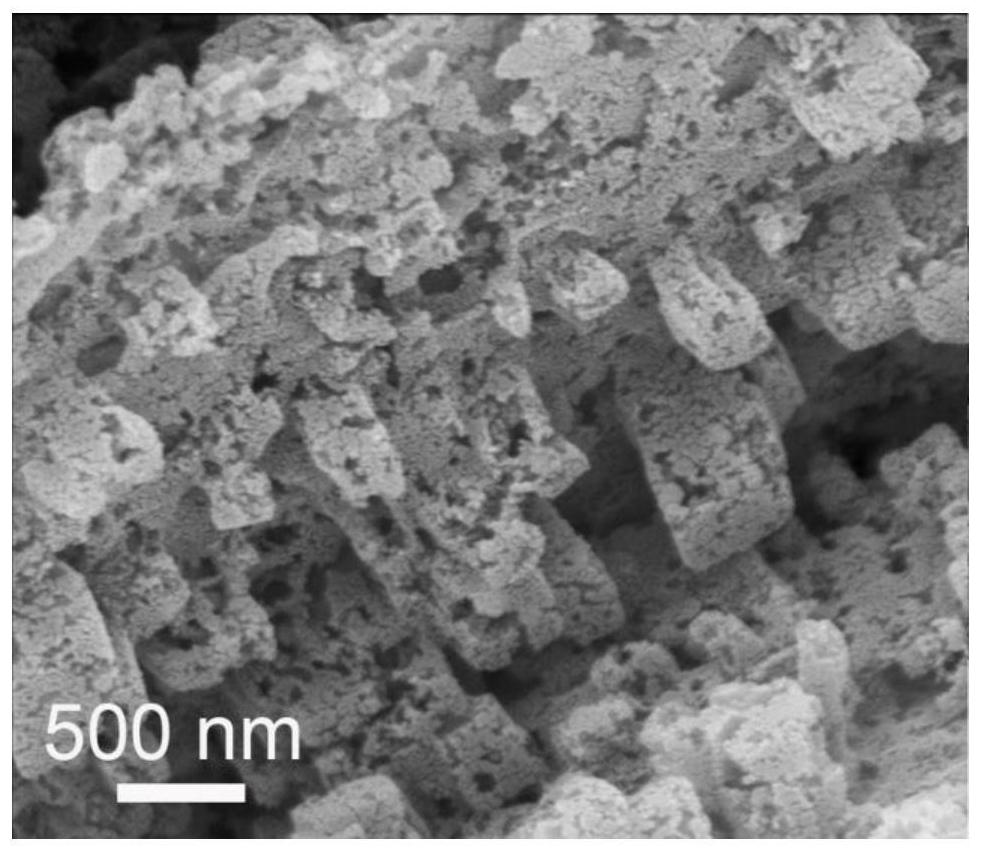

Fullerene-based Fe and N-doped porous carbon material as well as preparation method and application thereof

ActiveCN112018400AGood uniformityGood regularityFuel and primary cellsCell electrodesSelf-assemblyNitrogen doping

The invention belongs to the field of carbon composite materials, and discloses a fullerene-based Fe and N-doped porous carbon material as well as a preparation method and application thereof. The method comprises the following steps of: dissolving a fullerene derivative by taking a benzene solvent as a good solvent, then mixing the dissolved fullerene derivative with an alcohol solvent as a poorsolvent, making the mixture standing still at room temperature for a preset time, filtering to obtain a precipitate, and drying the precipitate under a vacuum condition for a preset time to obtain a precursor; and calcining the precursor in an ammonia atmosphere for a preset time to finally prepare the fullerene-based Fe and N-doped porous carbon material. According to the method provided by the invention, a micro-nano structure with three-dimensional graded growth can be formed through intermolecular self-assembly of the fullerene; and fullerene molecules contain N and Fe, and the micro-nanostructure subjected to high-temperature annealing treatment in an ammonia atmosphere has a pore structure in graded distribution, short-range ordered nano graphene sheets and high-content nitrogen doping, so that the N and Fe co-doped three-dimensional graded carbon composite material is prepared.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing nicotinamide mononucleotide

The invention provides a method for preparing nicotinamide mononucleotide. The method is characterized by using hypoxanthic acid and / or guanylic acid, ATP and nicotinamide as raw materials, carrying out combined catalytic reaction by using ribosidase, ribose pyrophosphate kinase and nicotinamide ribose phosphate transferase, and synthesizing by using a one-pot method to obtain nicotinamide mononucleotide. The method opens up a new way for synthesizing nicotinamide mononucleotide by an enzyme method, and significantly reduces the production cost.

Owner:湖州颐盛生物科技有限公司

Method for preparing 3,4-dichloroaniline by using o-dichlorobenzene through nitration and hydrogenation

InactiveCN109651157ASimple processComplete conversion of raw materialsOrganic compound preparationAmino compound preparationChemistryPalladium on carbon

The invention discloses a method for preparing 3,4-dichloroaniline by using o-dichlorobenzene through nitration and hydrogenation, the method comprises the following steps: materials of o-dichloroaniline, sulfuric acid, recycled acid, and nitric acid in a ratio of 2.34: 1.6: 1.1: 1.3 are added into a nitration kettle for nitration reaction so as to obtain a 3,4-dichloronitrobenzene and 2,3-dichloronitrobenzene mixed solution; the mixed solution enters a main rectifying tower to be subjected to reduced pressure rectification and crystallization separation to obtain more than 99.5% of 3, 4-dichloronitrobenzene and 2,3-dichloronitrobenzene; and 3, 4-dichloronitrobenzene, a palladium-carbon catalyst and ethanol are added into a hydrogenation kettle, hydrogen is introduced while stirring, desolventizing is performed after the reaction is ended, and reduced pressure rectification is performed to obtain a finished product of 3,4-dichloroaniline with the purity of more than 99.5%. The method is simple in process and wide in temperature and pressure range and is easy to control, so that the environment is protected, the cost is saved, and the yield is improved.

Owner:HULUDAO TIANQI SHENGYE CHEM

High-manganese CADI and heat treatment method thereof

ActiveCN110964973AHigh hardnessImprove wear resistanceQuenching agentsChemical compositionNitrate salts

The invention discloses high-manganese CADI (Carbidic Austempered Ductile Iron) and a heat treatment method thereof, and belongs to the technical field of wear-resistant materials. Nodular cast iron (mass fraction, %) with the following chemical components is prepared by adopting a medium-frequency smelting electric furnace: 3.10-3.35 parts of C, 3.03-3.25 parts of Mn, 2.52-2.77 parts of Si, 1.02-1.10 parts of Cr, 0.21-0.24 part of Al, 0.05-0.08 parts of Sb, less than or equal to 0.035 parts of P, less than or equal to 0.030 parts of S and the balance of Fe. The obtained casting is heated to atemperature of 860-870 DEG C, then is subjected to heat preservation for 100-120 minutes, is taken out to be rapidly put into a nitrate solution with the temperature of 280-290 DEG C for heat preservation for 120-150 minutes, then is taken out to be rapidly put into liquid nitrogen with the temperature of -195 DEG C to -200 DEG C for cooling for 100-120 minutes, and is taken out to be put into the air for recovering to room temperature to obtain the high-manganese CADI.

Owner:BEIJING UNIV OF TECH

Alloy steel and integrated brake beam frame and manufacturing method thereof

ActiveCN107130170AImprove mechanical propertiesExceed the basic mechanical performance requirementsRail brake actuationNiobiumManganese

The invention provides alloy steel and an integrated brake beam frame and a manufacturing method thereof. The alloy steel comprises the following components in percentage by mass: 0.12-0.18% of carbon, 0.25-0.35% of silicon, 1.20-1.50% of manganese, 0.001-0.015% of phosphorus, 0.001-0.010% of sulfur, 0.01-0.08% of niobium, 0.01-0.45% of nickel, 0.20-0.30% of chromium, 0.015-0.050% of aluminum, 0.01-0.15% of copper, 0.08-0.14% of vanadium, 0.01-0.20% of molybdenum, 0.06-0.10% of titanium, and the balance of iron. Through coordinative cooperation among chemical components of the alloy steel, the alloy steel is excellent in process adaptability, and can serve as raw materials of the integrated brake beam frame, the prepared integrated brake beam frame is excellent and stable in performances, and the once pass percent of products is prominently increased.

Owner:CRRC QIQIHAR ROLLING CO LTD

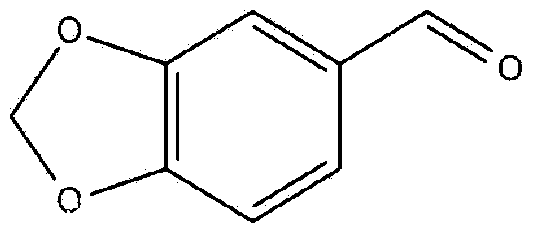

Synthetic method of 3, 4-methylene dioxybenzaldehyde

The invention discloses a synthetic method of 3, 4-methylene dioxybenzaldehyde and relates to the field of chemical organic synthesis, and particularly relates to a synthetic method in which an intermediate generated in a process of preparing 3, 4-methylene dioxybenzaldehyde by taking catechol methylene ether as a raw material is oxidized by suing a nitryl-free oxidizing agent to generate the final product. According to the synthetic method of 3, 4-methylene dioxybenzaldehyde, oxidative decarboxylation is carried out on the intermediate piperonyl mandelic acid (prepared from catechol methylene ether) as an initial reactant in the presence of at least one catalyst selected from metal chloride Lewis acid and at least one oxidizing agent selected from oxygen and peroxides in an acidic environment so as to synthesize 3, 4-methylene dioxybenzaldehyde. The synthetic method provided by the invention is simple in technical step, thorough in conversion of the raw materials, high in finished product yield and short in technical time, and the product does not contain color-changing impurities and is stable in technical quality.

Owner:成都建中香料香精有限公司

Preparation method of radix puerariae beverage and radix puerariae beverage

PendingCN110353139AHigh nutritional valueCompletely transformedYeast food ingredientsNatural extract food ingredientsFlavorRhizopus oryzae

The invention relates to the field of health-care beverages, in particular to a preparation method of a radix puerariae beverage and the radix puerariae beverage. The preparation method of the radix puerariae beverage comprises the following steps of adding rhizopus oryzae powder into cooked radix puerariae, performing saccharifying at 25-30 DEG C, adding hot water into the saccharified radix puerariae for heating until the temperature reaches 80-100 DEG C, and maintaining the temperature for 30-60 minutes to obtain a radix puerariae material; then, performing lactobacillus fementation, yeastfermentation and acetic acid bacteria fermentation on the radix puerariae material in sequence to ensure that the final acidity of the radix puerariae material is higher than or equal to 15 g / L; afterthe fermentation is finished, obtaining a supernatant for blending, filtering and sterilizing to obtain the radix puerariae beverage. According to the provided preparation method, the extraction of radix puerariae and flavone is enhanced, the nutritional value of the radix puerariae beverage is increased, and meanwhile, flavor substances generated by different strains can thoroughly convert the smell of radix puerariae and generate a pleasant fragrance; the commercial value of a product is increased.

Owner:江西仁仁健康微生态科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com