Aniline leakage emergency treatment agent

A disposal agent, aniline technology, which is applied in the field of emergency disposal agents for hazardous chemicals, can solve the problems of limited aniline adsorption capacity, low aniline solubility, and increased aniline concentration, and achieve good fluidity, expanded pollution range, and small surface tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

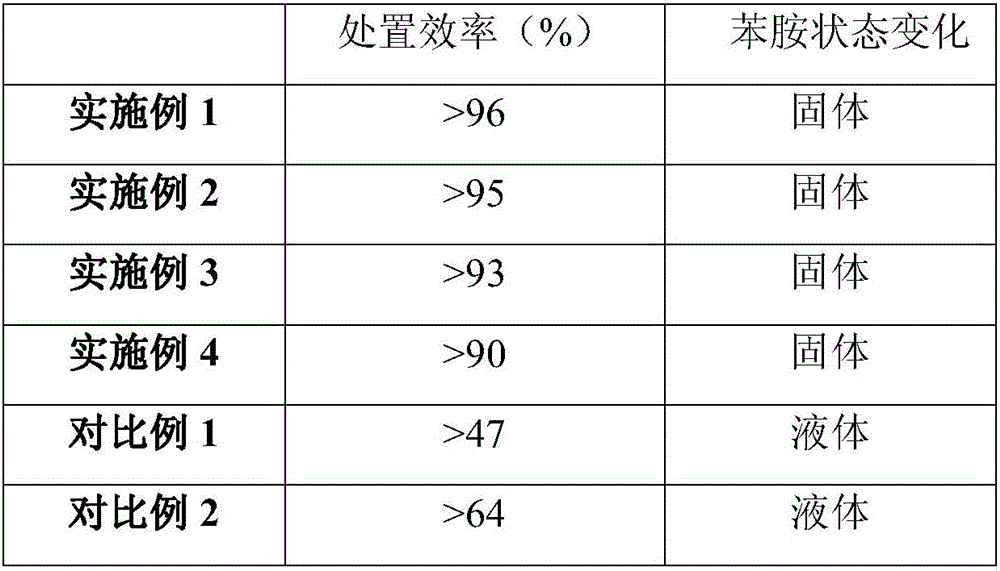

Embodiment 1

[0031] Measure 150mL of concentrated sulfuric acid (98%) and dissolve it in 480mL of water; then weigh 5.0g of sodium lauryl sulfate, 1.0g of sodium dodecyl sulfate, 20.0g of aluminum sulfate, and 30mL of hydrogen peroxide, and add them to the sulfuric acid solution. Stir until it is clear and colorless, and the emergency treatment agent for aniline leakage is obtained.

[0032] The prepared aniline leakage emergency treatment agent is packed in a storage tank and sprayed into a 125L simulated leakage box adding 250mL of aniline, wherein the initial concentration of aniline vapor is 198ppm. After the treatment agent is sprayed, the concentration of aniline vapor in the box can be When it drops below 7ppm, the decontamination rate is greater than 96%, aniline is transformed into solid salts, and the decontamination product presents a gel state.

Embodiment 2

[0034] Measure 400mL concentrated phosphoric acid (85%) and 30mL hydrogen peroxide to be dissolved in 950mL water, then take by weighing 8.0g cocamidopropyl sulfobetaine and 0.4g polyacrylic acid resin, join in the solution, stir until clear and colorless, That is, the emergency treatment agent for aniline leakage is obtained.

[0035] The prepared aniline leakage emergency treatment agent is packed in a storage tank and sprayed into a 125L simulated leakage box equipped with 500mL aniline, wherein the initial concentration of aniline vapor is 348ppm. After the treatment agent is sprayed, the aniline vapor in the box The concentration can be reduced to 14ppm, the decontamination rate is greater than 95%, the aniline is converted into solid salt substances, and the decontamination products are in a gel state. 30 minutes after the injection, the aniline vapor concentration in the box was measured to be 22ppm, and the decontamination rate remained above 94%, indicating that the d...

Embodiment 3

[0037] Measure 400mL of phosphoric acid and dissolve it in 750mL of water, then weigh 15.0g of sodium α-olefin sulfonate, 15.0g of aluminum sulfate hexahydrate, 12.0g of potassium permanganate and 1.0g of polyacrylic acid resin, add to the solution, stir until clear Colorless, that is, the emergency treatment agent for aniline leakage.

[0038] The prepared aniline leakage emergency disposal agent is packed in a storage tank and sprayed into a 125L simulated leakage space containing 500mL aniline, wherein the initial concentration of aniline vapor is 230ppm. After the disposal agent is sprayed, the aniline vapor in the leakage space The concentration can be reduced to 16ppm, the decontamination rate is greater than 93%, and aniline is converted into solid salt substances. 30 minutes after the end of spraying, the measured aniline vapor concentration was 20ppm, and the decontamination rate remained above 90%, indicating that the decontamination agent can effectively inhibit the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com