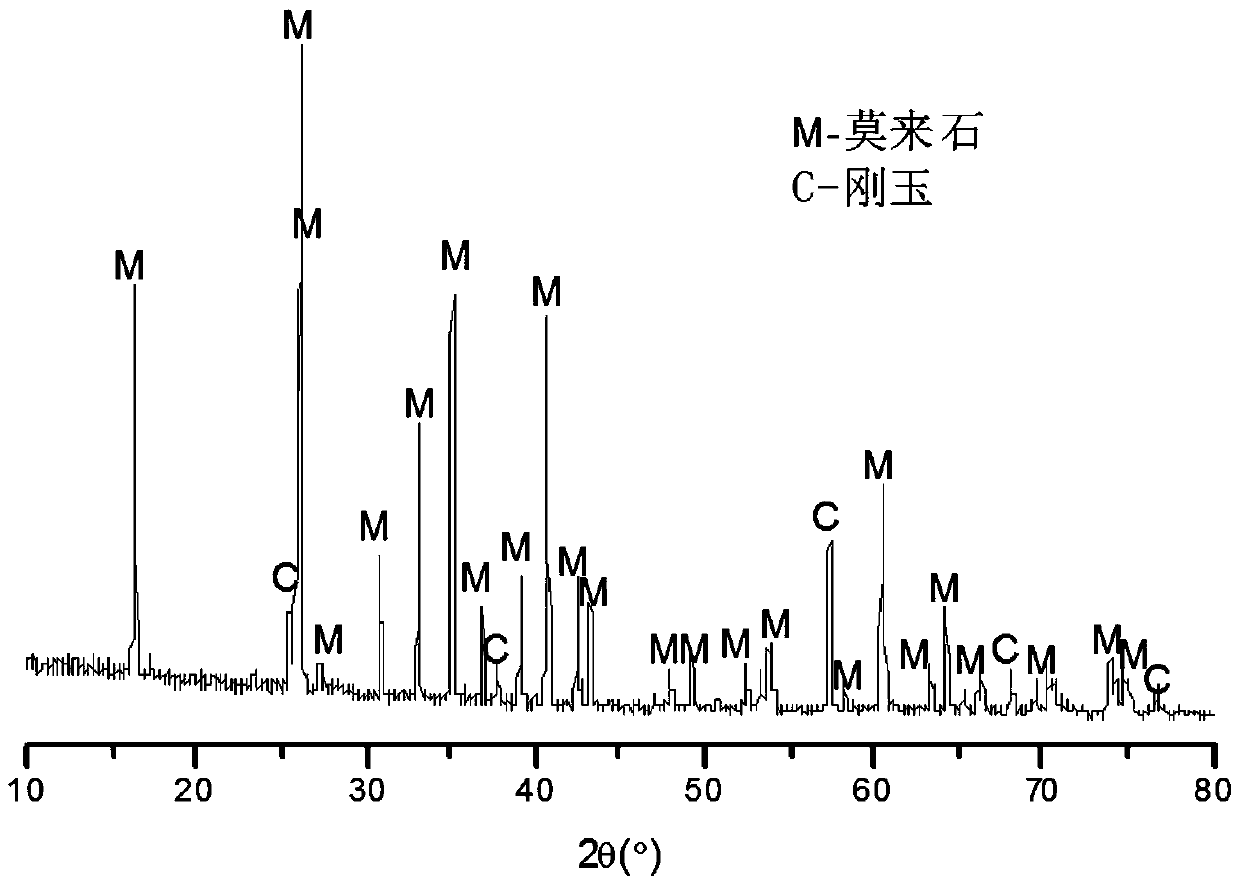

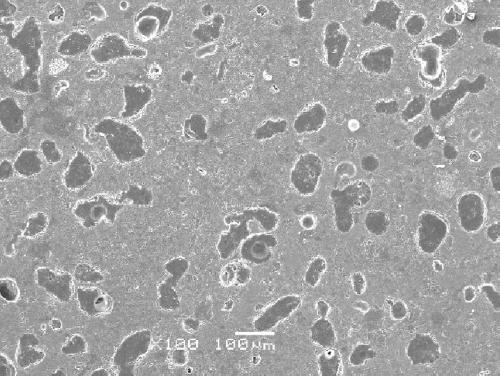

A closed-cell alumina-based mullite material and its preparation method

A mullite and closed-cell technology, which is applied in the field of closed-cell bauxite-based mullite material and its preparation, can solve the problems of high preparation temperature, complicated process and high product price, and achieves high closed porosity and volume. The effect of low density and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Mix 70wt% bauxite raw mineral powder and 30wt% siliceous raw material according to mass percentage, add the starch of the sum of the above-mentioned raw material mass percentages and 6wt% as additive, stir to obtain mixed mud; pour the mud Put it into a mold and shape it under a pressure of 100MPa to obtain a green body; bake the green body at a temperature of 120°C for 8 hours, and then put it into a high-temperature furnace and calcinate it at 1650-1680°C for 5 hours to obtain a closed-cell type. Alumina-based mullite material.

[0021] Al in the bauxite raw ore powder described in this embodiment 2 o 3 The mass percentage is 70-75wt%, and the particle size is ≤0.074mm; the silicon dioxide raw material is fused quartz, and the SiO2 in the raw material 2 Mass percentage content ≥ 98.0wt%, particle size: 0.01 ~ 0.1mm.

[0022] The technical indicators of the closed-cell alumina-based mullite material prepared in this example are: the closed porosity is 22% to 28%, an...

Embodiment 2

[0024] Mix 60wt% bauxite raw mineral powder and 40wt% siliceous raw material uniformly by mass percentage, add polyethylene glycol of the sum of the above-mentioned raw material mass percentages and 4wt% as an additive, and stir to obtain a mixed sludge; Pour the mud into the mold and shape it under a pressure of 120MPa to obtain a green body; bake the green body at a temperature of 120°C for 6 hours, and then put it into a high-temperature furnace for calcination at a temperature of 1550-1600°C for 6 hours to obtain Closed-cell alumina-based mullite material.

[0025] Al in the bauxite raw ore powder described in this embodiment 2 o 3 The mass percentage is 75-80wt%, and the particle size is ≤0.074mm; the silicon dioxide raw material is waste silica brick, and the SiO2 in the raw material 2 Mass percentage content ≥ 94.0wt%, particle size: 0.02 ~ 0.15mm.

[0026] The technical indicators of the closed-cell alumina-based mullite material prepared in this example are: the cl...

Embodiment 3

[0028] Mix 68wt% bauxite raw mineral powder and 32wt% siliceous raw material according to mass percentage, add the sum of 4wt% dextrin of above-mentioned raw material mass percentage as additive, stir to obtain mixed mud; mud Pour it into a mold and shape it under a pressure of 100MPa to obtain a green body; bake the green body at a temperature of 110°C for 10 hours, and then put it into a high-temperature furnace and calcinate it at 1580-1620°C for 3 hours to obtain a closed cell. Alumina-based mullite material.

[0029] Al in the bauxite raw ore powder described in this embodiment 2 o 3 The mass percentage is 55-60wt%, and the particle size is ≤0.074mm; the silicon dioxide raw material is waste silica brick, and the SiO2 in the raw material 2 Mass percentage content ≥ 94.0wt%, particle size: 0.02 ~ 0.2mm. The technical indicators of the closed-cell alumina-based mullite material prepared in this example are: the closed porosity is 25% to 32%, and the bulk density is 1.8 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com