Foamed ceramic plate based on Muyu stone tailings and preparation method thereof

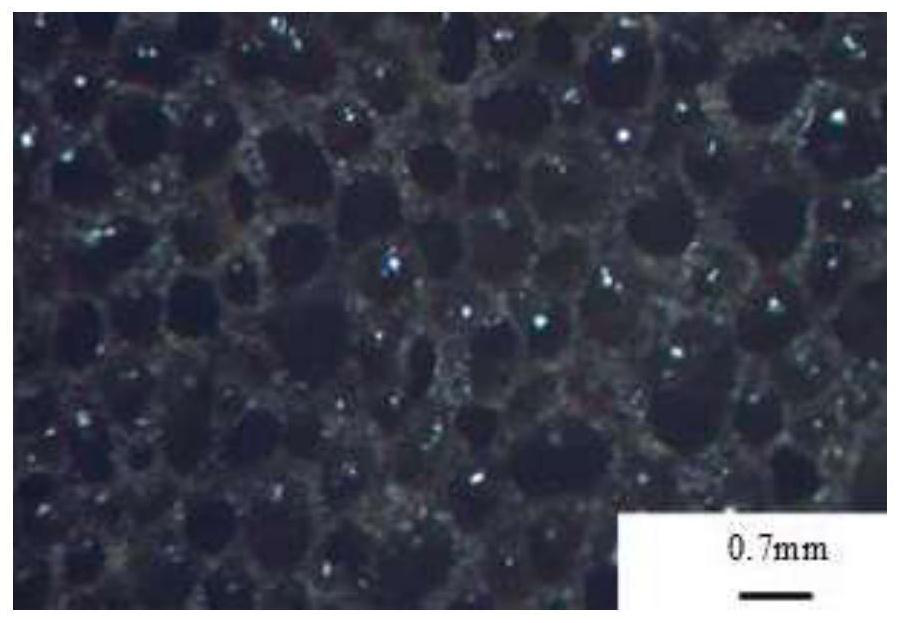

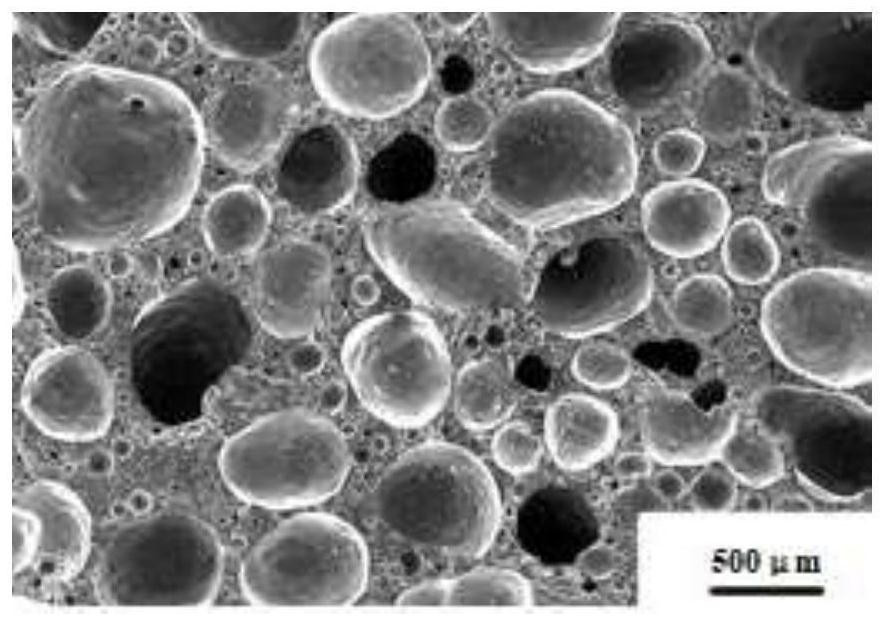

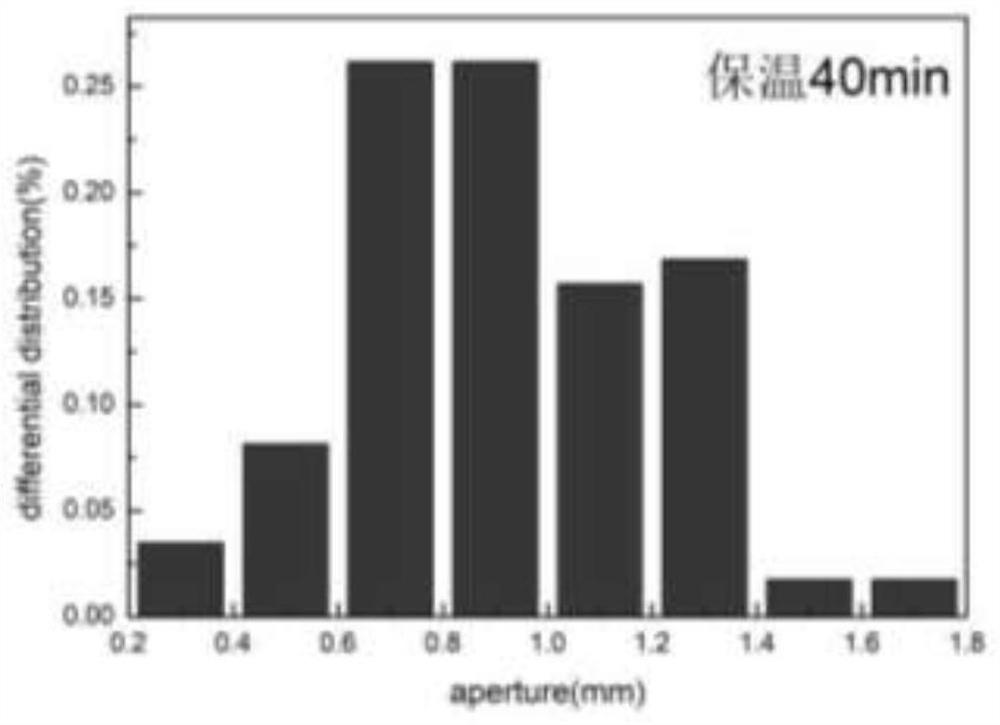

A technology of foamed ceramic plates and foamed ceramics, which is applied in the field of green building materials and building energy conservation, can solve problems such as limiting effective applications, and achieve the effects of eliminating adverse effects, good decorative effects, and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A foamed ceramic plate for architectural decoration based on Muyushi tailings, the preparation method of which comprises the following steps:

[0040] 1) Raw material ball milling: According to the ratio of material to ball of 1:2, ball mill Muyushi tailings, quartz, feldspar, and foaming agent for 2 hours respectively, and sieve to obtain the ball-milled raw materials; among them, Muyushi tailings are passed through a 270-mesh sieve, Quartz and feldspar pass through a 325-mesh sieve, and the foaming agent passes through a 500-mesh sieve;

[0041] 2) Mixing of raw materials: The raw materials are mixed according to mass percentage: 60% of Muyushi tailings, 20% of quartz, 19.7% of potassium feldspar, and 0.3% of silicon carbide, weighed, mixed with a ball mill for 1 hour, and the mixed material is obtained for later use;

[0042] 3) Body molding: Fill the mixed blank into a steel mold conforming to the predetermined shape of the product, and press it into a foamed cerami...

Embodiment 2

[0052] A foamed ceramic plate for architectural decoration based on Muyushi tailings, the preparation method of which comprises the following steps:

[0053] 1) Raw material ball milling: according to the ratio of material to ball of 1:2, ball mill Muyushi tailings, quartz, feldspar, and foaming agent for 1 hour respectively, and sieve to obtain the ball-milled raw materials; among them, Muyushi tailings are passed through a 200-mesh sieve, Quartz and feldspar pass through a 325-mesh sieve, and the foaming agent passes through a 600-mesh sieve;

[0054] 2) Mixing of raw materials: each raw material is mixed according to mass percentage: 85% of Muyushi tailings, 9% of quartz, 5.5% of albite, 0.5% of carbon black, weighed, and mixed with a ball mill for 0.5h to obtain the mixed material for later use;

[0055] 3) Body molding: Fill the mixed blank into a steel mold that conforms to the predetermined shape of the product, and press it into a foamed ceramic body with a molding pre...

Embodiment 3

[0062] A kind of foamed ceramic plate based on Muyushi tailings, its preparation method comprises the following steps:

[0063] 1) Ball milling of raw materials: According to the material-to-ball ratio of 1:2, ball mill Muyushi tailings, quartz, feldspar, and foaming agent for 1.5 hours respectively, and sieve to obtain ball-milled raw materials; among them, Muyushi tailings are passed through a 250-mesh sieve , quartz and feldspar pass through a 350-mesh sieve, and the foaming agent passes through a 500-mesh sieve;

[0064] 2) Mixing of raw materials: The raw materials are mixed according to mass percentage: 70% of Muyushi tailings, 9.6% of quartz, 20% of feldspar, and 0.4% of pulverized coal, weighed, and mixed with a ball mill for 0.8h to obtain the mixed material for later use. Wherein, feldspar is made up of potassium feldspar and albite by mass percentage 1:1;

[0065] 3) Body molding: Fill the mixed blank into a steel mold conforming to the predetermined shape of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com