Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

149results about How to "Increase the addition ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for preparing formed sludge fuel

InactiveCN102212403AImprove dehydration effectImplement resourcesSludge treatment by de-watering/drying/thickeningBiofuelsSludgeSolid fuel

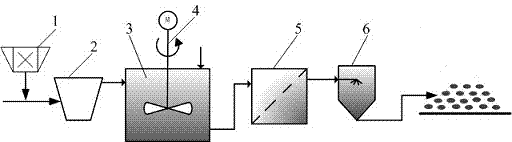

The invention discloses a process method for preparing a derived solid fuel by using sludge, and the method comprises the following steps: feeding dehydrated wet sludge with the moisture content of 70-85% and biomass at a weight ratio of 50:(1-10) into a tempering kettle, introducing less water, evenly stirring, adding a tempering agent the mass of which is 0-20% of that of dried solid sludge, stirring for 2-10 minutes continuously, removing most of water by a dehydrator, forming, and naturally drying for 24 hours, thus obtaining the derived sludge solid fuel. The invention also discloses a device for preparing a formed sludge fuel. The device comprises a straw crusher, a feeder, the tempering kettle, the stirrer, the fuel hydrator and a fuel forming machine, wherein the stirrer is positioned at the top of the tempering kettle, a stirring shaft is coincident with the axis of the tempering kettle and inserted into the tempering kettle, the outlet of the straw crusher is connected with the inlet of the feeder, the outlet of the feeder is connected with the inlet of the tempering kettle, the outlet of the tempering kettle is connected with the inlet of the fuel dehydrator, and the outlet of the fuel dehydrator is connected with the inlet of the fuel forming machine.

Owner:JIANGSU XINFA ENVIRONMENTAL PROTECTION TECHCO

Wear-resistant glaze for preparing sanitary ceramics and method for preparing sanitary ceramics

The invention discloses a wear-resistant glaze for preparing sanitary ceramics, which comprises the following components in percentage by mass: 24-28% of Quartz, 20-32% of feldspar, 6-13% of wollastonite, 8-12% of zirconium silicate, 5-10% of Suzhou soil, 5-10% of calcite, 2-5% of zinc oxide, 2-5% of corundum, 2-5% of clinker, 2-5% of dolomite, 2-5% of calcined talc and 0.2-0.5% of methyl cellulose. According to the wear-resistant glaze for preparing sanitary ceramics provided by the technical scheme, the usage amount of the feldspar and the wollastonite is adjusted to improve the Al / Si ratioof formula components, and the addition ratio of the raw materials of the zinc oxide, calcined talc and zirconium silicate for improving wear resistance is increased, so that the glaze wear amount ofthe sanitary ceramics is reduced as a whole, and the glossiness is improved. Furthermore, the preparation method for preparing the sanitary ceramics by using the wear-resistant glaze for preparing sanitary ceramics is proposed, so that the surface of the prepared sanitary ceramics is smooth and fine, the average wear amount of the glaze surface is reduced to 70-80 mg, the wear resistance is high,the service life is long, and the glossiness is as high as 95-105 GU.

Owner:FOSHAN DONGPENG CERAMIC +3

Polyvinylchloride (PVC) plastic wood plank and preparation method thereof

The invention provides a polyvinylchloride (PVC) plastic wood plank and a preparation method thereof. The PVC plastic wood plank consists of the following ingredients: PVC, calcium carbonate, wood flour, azodicarbonamide (AC) foaming agents, stabilizing agents, coupling agents, acrylicester (ACR), paraffin wax, stearic acid and fire retardants. By means of the PVC plastic wood plank, appending proportion of the calcium carbonate is enhanced by reducing the amount of the wood flour, and at the same time, by adjusting the amount of the PVC, and the type and amount of other additives, not only can hardness of the plank be greatly enhanced, but also appropriate toughness can be possessed. Therefore, the plank is guaranteed to be not only possess enough hardness when used as wood floors in public places so that damage and sinking of the surface of the plank are not prone to occurring, but also meet requirements of the wood floors due to the toughness of the plank so that the plank can be ensured to be not easy to crack.

Owner:江西铁木真装饰材料有限公司

High-filler paper and production method thereof

InactiveCN102433796AHigh whitenessIncrease the addition ratioInorganic compound additionPulp material addition processesCalcium silicatePlant fibre

The invention discloses high-filler paper and a production method thereof. The high-filler paper contains 30 to 60 mass percent of filler, and the filler is active calcium silicate; in the step of adding the filler, after the active calcium silicate in an amount which is 40 to 70 percent of the total mass of the active calcium silicate and the pulp is fully stirred and dissolved to form emulsion,the emulsion is guided into a covered pulp storage tank or a pre-making pulp storage tank and fully stirred and mixed with plant fibers; the filler adding proportion of the high-filler paper is improved, so that the consumption of the plant fibers is greatly reduced at the same time of improving the performance of the paper; and according to the production method for the high-filler paper, the adding process of the papermaking filler is simplified, the filler and the plant fibers can be fully mixed uniformly, and the internal bonding force is increased, so that the performance of the paper isimproved.

Owner:GUONENG PAPER IND

Microencapsulation peptide-containing fat powder feed additive and production method thereof

ActiveCN101791048ANot easily oxidizedLow moisture absorptionAnimal feeding stuffFood additiveMonoglyceride

The invention discloses a microencapsulation peptide-containing fat powder feed additive and a production method thereof, and the microencapsulation peptide-containing fat powder feed additive contains core material and wall material, wherein the core material comprises 20-50 percent of grease; and the wall material comprises 20-50 percent of peptide powder, 3-5 percent of casein, 1-5 percent of monoglyceride, 1-5 percent of sucrose ester, 1-3 percent of carrageenan and 10-30 percent of maltodextrin. The production method of the feed additive comprises the steps of: mixing and stirring water phase and oil phase according to the formulation, and then carrying out high pressure homogenization and spray drying for completing primary embedding; and carrying out secondary embedding on the obtained microcapsule fat powder by using 5-10 percent of HPMC with the embedding rate reaching up to more than 95%. The obtained peptide-containing fat powder can be easily added into feed and has extremely high nutritional value, so that the feed additive is excellent in quality.

Owner:泰安肽普德蛋白有限公司

Method for culturing microalgae by utilizing aquaculture wastewater

InactiveCN107629961ADefense against microbial attackNo need for sterilization or disinfectionUnicellular algaeMicroorganism based processesEcologyCulture mediums

The invention relates to a method for culturing microalgae by utilizing aquaculture wastewater. The method comprises the following steps: 1) domesticating microalgae: inoculating microalgae into a culture medium for culturing, adding unsterilized aquaculture wastewater in a culture process and gradually increasing the adding rate of the aquaculture wastewater according to the growing number of themicroalgae; 2) activating the microalgae: adding the unsterilized aquaculture wastewater into the culture medium and then inoculating the domesticated microalgae into culture medium for performing amplification culture; and 3) culturing the microalgae: inoculating the activated microalgae into an unsterilized aquaculture wastewater solution and culturing under an outdoor condition, thereby realizing aquaculture wastewater purification and microalgae grease production. According to the method for culturing the microalgae by utilizing the aquaculture wastewater provided by the invention, the unsterilized aquaculture wastewater is adopted for culturing the microalgae under the outdoor condition, the aquaculture wastewater purification and the microalgae grease production can be realized at the same time and the method has the advantages of low cost and suitability for large-scale production.

Owner:SHAOGUAN COLLEGE

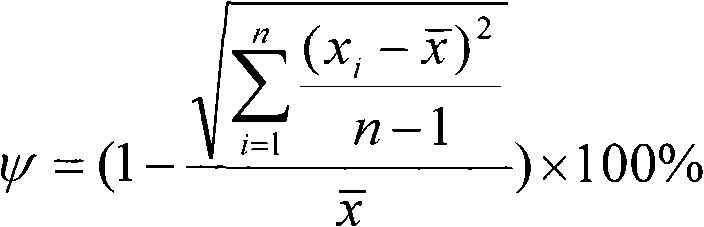

Method for determining feed liquid application uniformity in cigarette charging process

ActiveCN101718758AQuality improvementImprove stabilityComponent separationStatistical analysisProcess engineering

The invention relates to a method for determining the feed liquid application uniformity in a cigarette charging process, which is characterized by comprising the following steps: taking 1,2-propanediol in a feed liquid as a label, representing the distribution of the feed liquid in the tobacco flake by utilizing the content of the 1,2-propanediol in a tobacco flake after charging, and determining the uniformity degree of the charging through detection, calculation and statistical analysis. The invention provides an integral and objective method for the quantitative evaluation of the feed liquid application uniformity in the cigarette charging process, and the method has very important meanings for improving charging equipment and the charging process, and promoting the quality and the stability of cigarette products.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Bioanalysis preparation technique of biological organic fertilizer by chicken manure

InactiveCN107857689AIncrease the addition ratioNot volatileBio-organic fraction processingMagnesium fertilisersBiotechnologyBacillus licheniformis

The invention discloses a bioanalysis preparation technique of a biological organic fertilizer by chicken manure. High-efficient and green chicken mature fermenting biological organic fertilizer is developed through a mixed bacteria aerobiotic two-step fermenting technique, wherein an one-step fermenting flora comprises aspergillus, thermophilic sporotrichum, saccharomycetes, bacillus subtilis, thermophilic heterotrophism ammonia oxidizing bacteria; a two-step aerobiotic fermenting flora comprises EM fungicide, azotobacter chroococcum, and bacillus licheniformis. The technique adopts multi-bacterium mixing fermentation; through combination of metabolic capabilities, the complex metabolism which is hard to complete by single culture is completed; through synergic fermentation between microorganisms, the chicken mature is effectively transformed, the hygienic index reaches the national standard, and the product decomposition and growth promoting index are significantly promoted. The fermenting technique is simple and high-efficient, the deodorization and sterilizing effects are good; besides, the production cost is low, and the technique is easy to carry out industrial scale production.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

Emulsion stabilizer for the production of plant protein milk

InactiveCN101095475AImprove stabilityImprove emulsifying abilityFood preparationMilk substitutesEmulsionChemistry

The invention relates to an emulsion stabilizer for plant protein milk production. The comprised components and weight proportion are as follows: mono-fatty glycerin ester 10-20%, poly-glycerin fatty ester 4-8%, sodium alginate 3-6%, microcrystalline cellulose 60-75%, and sodium pyrophosphate 4-10%. The invention is characterized by increased floating stability, emulsifying ability and raw material usage rate. There is no deposition in preservative period, no apparent floating fatty circle when the product is used for plant protein milk production such as peanut milk, walnut milk and soybean milk, and the product quality is improved.

Owner:MASSON GROUP

Asphalt mixture stirring equipment and technology for adding reclaimed materials in high proportions

The invention discloses asphalt mixture stirring equipment and technology for adding reclaimed materials in high proportions. The technology comprises the following steps: (1) native aggregates and reclaimed fine materials are delivered into a reclaimed mixture drying drum so as to be dried, wrapped and mixed, the hot mixture is delivered into a hot aggregate vibrating screen classifier through ahot material elevator so as to be screened, and all levels of screened hot aggregates respectively fall into corresponding compartments of a hot aggregate temporary storage bin; (2) reclaimed coarse materials are delivered into a reclaimed coarse material drying drum through a cold material elevator so as to be dried, and the dried reclaimed coarse materials vertically fall into a reclaimed hot material temporary storage bin directly; (3) reclaimed hot materials vertically fall into a reclaimed hot material metering bin so as to be metered, and the metered reclaimed hot materials vertically fall into a stirrer; all levels of hot aggregates vertically fall into a hot aggregate metering bin respectively so as to be accurately metered, and all levels of metered hot aggregates are obliquely delivered into the stirrer through an oblique chute; and all materials are fully stirred and mixed through the stirrer. The equipment and the technology disclosed by the invention increase the adding proportions of the reclaimed materials.

Owner:FUJIAN QUANCHENG MACHINERY

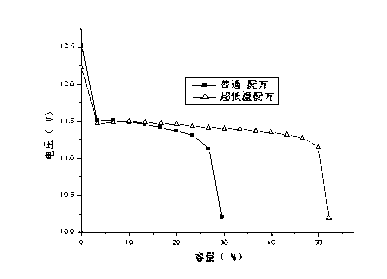

Valve-controlled type lead-acid storage battery

ActiveCN103280582AFacilitate penetrationImprove low temperature discharge performanceCell electrodesFinal product manufactureFiberEngineering

The invention discloses a valve-controlled type lead-acid storage battery. Lead plaster in a positive plate of the valve-controlled type lead-acid storage battery comprises the following active substances in percentage by weight: 68%-81% of lead powder, 3%-12% of red lead, 0.05%-0.15% of short fiber, 7%-11% of deionized water, 5%-10% of sulphuric acid with the density of 1.4g / mL and 0.2%-1% of additive; and the lead plaster in a negative plate of the valve-controlled type lead-acid storage battery comprises the following active substances in percentage by weight: 68%-82% of lead powder, 0.1%-0.3% of short fiber, 6%-15% of deionized water, 5%-15% of sulphuric acid with the density of 1.4g / mL, 0.1%-0.5% of acetylene black, 0.1%-1% of humic acid, 0.1%-1% of lignin and 0.5%-0.8% of barium sulfate. The valve-controlled type lead-acid storage battery produced according to the formulas of a positive electrode and a negative electrode has the advantages that the low-temperature discharge performance is substantially improved, and the discharge capacity at -40 DEG C reaches above 50% of the normal capacity.

Owner:武汉长光电源有限公司

Coarse cereal flour and manufacture method and application thereof

ActiveCN103053637AChange processing characteristicsIncrease the addition ratioDough treatmentBiotechnologyCereal grain

The invention discloses coarse cereal flour and a manufacture method and an application thereof. The method comprises processing coarse cereal grain through physical and chemical methods of smashing, texture recombination, drying and the like to obtain the coarse cereal flour. When the coarse cereal flour is used for processing fine dried cereal noodles, the cereal adding proportion is improved apparently, the cereal adding proportion can reach 20%, and a fine dried noodle processing technological process is not changed obviously. Manufactured fine dried noodles are heavy in cereal flavor after being boiled, tastes of the fine dried noodles have no apparent difference with tastes of ordinary fine dried noodles, the appearance is easy to accept by consumers, the consumer satisfaction degree is improved, and good commodity is provided.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Palm-kernel meal with effect of removing antinutritional factors, preparation method and application thereof

The invention discloses palm-kernel meal with the effect of removing antinutritional factors, a preparation method and an application thereof. The palm-kernel meal is prepared by the following steps: physically crushing unprocessed palm-kernel meal materials, simulating the digestion of the gastrointestinal tract environment of a single-stomach animal and carrying out aerobic fermentation and low-temperature drying. The product indexes of the palm-kernel meal with the effect of removing antinutritional factors are as follows: the crude protein is more than or equal to 20 percent, the crude fat is less than or equal to 9 percent, pH is less than or equal to 4.8, the number of active bacteria is more than or equal to 20 times 10<10> cfu per g. The palm-kernel meal with the effect of removing antinutritional factors disclosed by the invention has the advantages that the palatability is good, the digestion and absorption rate of the palm-kernel meal in the digestive tracts of livestock and poultry is increased, so that the adding ratio of the palm-kernel meal in diet formula of the livestock and the poultry is increased, corns can be replaced in the livestock and poultry feed by 30 to 50 percent, a new feed source is provided, the contradiction of fighting for food ration between the livestock and the poultry and human is solved, the production cost of all feed factories and farmers is greatly reduced, and the social benefit and the economic benefit are very high.

Owner:黄石市佳兴生物科技有限公司

Modified full acrylic ester emulsion

The acrylate emulsion modified with acrylic acid monomer containing amino ester and seed emulsion containing epoxy group has improved cohesion to base material and thus greatly raised water resistance and wash fastness. Using the anionic and non-ionic emulsifier with olefine group makes the emulsion possess greatly raised electrolyte stability and low temperature stability and further raised water resistance. Furthermore, the emulsion with raised flowability and low temperature stability makes it possible to reduce the amount of glycol, propylene glycol and other water soluble solvent and thus reduce VOC in preparing emulsion paint, and this is favorable to protecting environment and saving energy. The emulsion is used in emulsion paint for outer wall.

Owner:江苏日出化工有限公司

Biodegradation-based sludge brick-making technology

InactiveCN102390913AIncrease the addition ratioReduce moisture contentSludge treatment by de-watering/drying/thickeningSolid waste managementBrickFilter press

The invention relates to a biodegradation-based sludge brick-making technology. Compared with a traditional technology, the biodegradation-based sludge brick-making technology is characterized in that a step of anaerobic treatment is added. Fermentation is carried out and then filter-pressing dehydration treatment is performed, so that the content of organic matters in sludge is reduced to below 10% and the content of water is reduced to 20%-30%, thereby obtaining brick-making sludge suitable for being added to a brick-making material, such as shale and the like. According to the traditional technology, the filter-pressing dehydration treatment is directly performed, so that the content of water in the sludge is only reduced to about 80% and the content of organic volatile matters is above 20%. Generally, the total added weight of the sludge, which contains 80% of water and more than 20% of organic matters and is added for making a brick, is only 30% of the weight of the brick-making material. In the brick-making sludge which is suitable for being added to the brick-making material and is obtained according to the biodegradation-based sludge brick-making technology, the content of organic matters is reduced to below 10% and the content of water is reduced to 20%-30%, and the total added weight of the sludge used for making the brick can be 40%-60% of the weight of the brick-making material, thereby saving raw materials, lowering cost and greatly promoting the capacity for treating the sludge.

Owner:CHONGQING JUKANG BUILDING MATERIAL

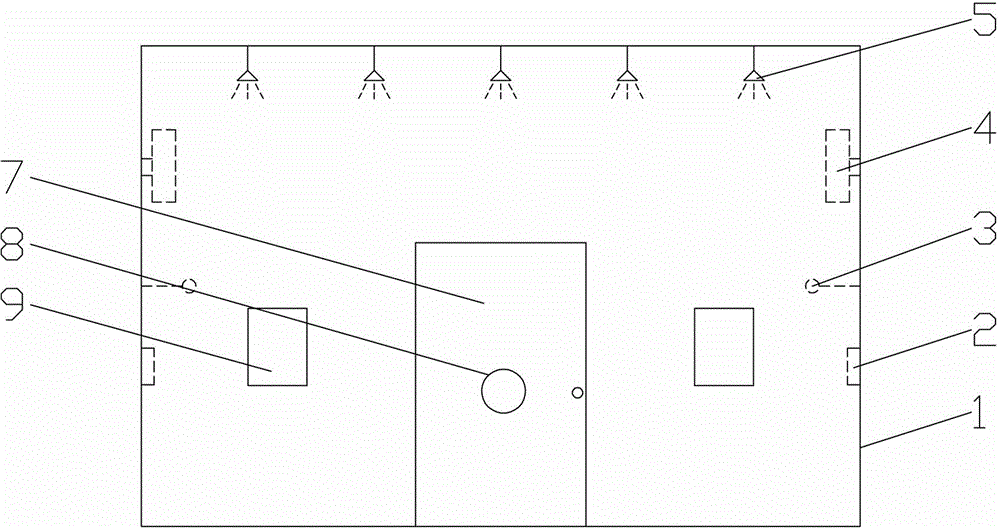

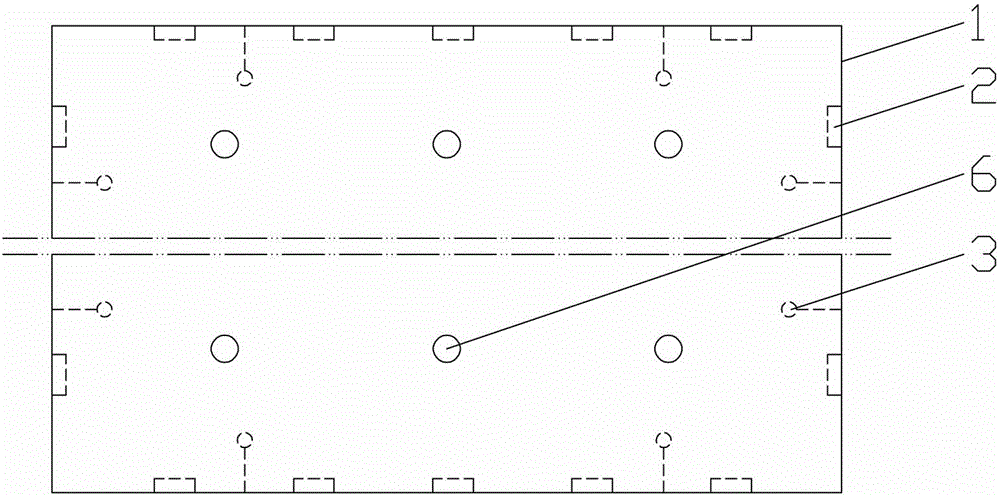

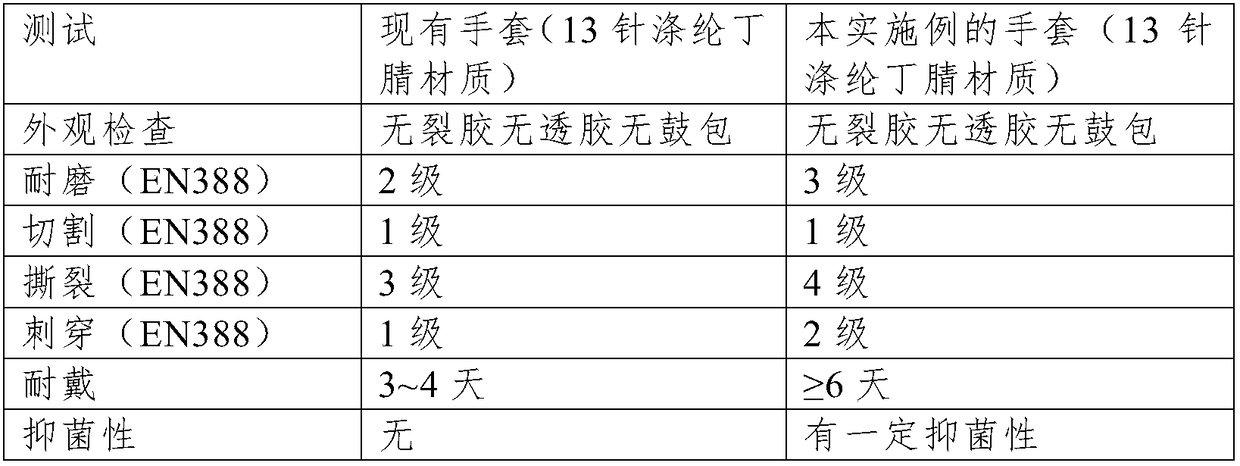

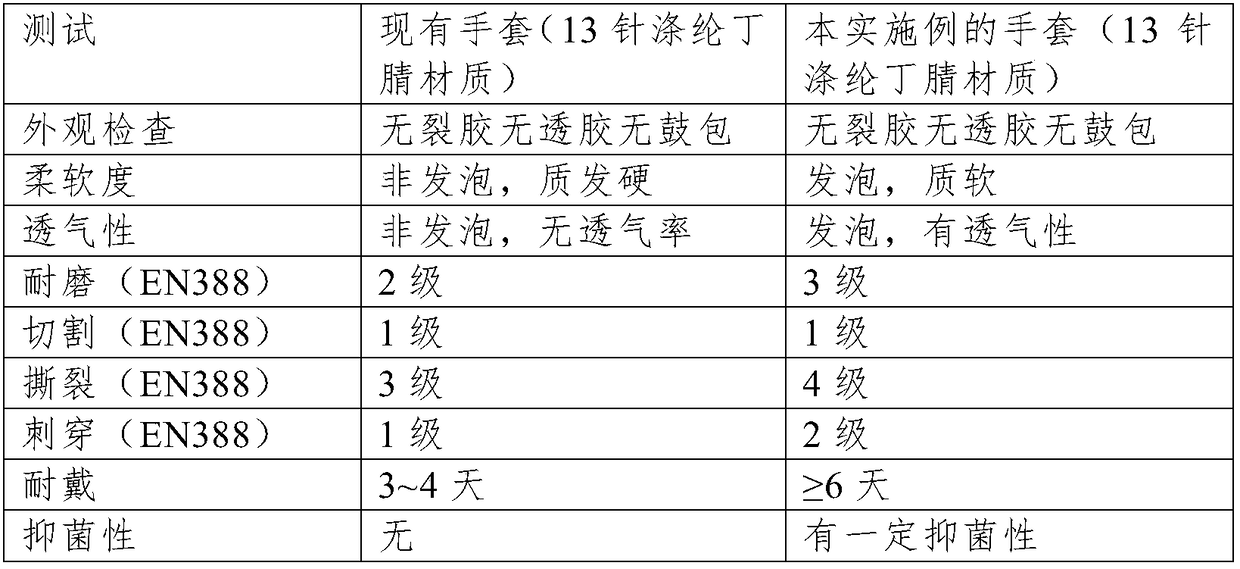

Graphene laminated rubber glove and preparation method thereof

ActiveCN108486902AImproved cut and tear resistanceBacteriostaticGlovesConjugated diene hydrocarbon coatingsPolymer scienceVulcanization

The invention relates to a graphene laminated rubber glove which comprises a glove blank, a rubber layer and a graphene membrane layer, wherein the rubber layer is adhered to the outer surface of theglove blank; the graphene membrane layer covers the outer surface of the rubber layer; the rubber layer is made of graphene-free foamed rubber or non-foamed rubber. A preparation method of the glove comprises the following steps: preparing graphene-free rubber slurry, and soaking a knitted glove blank into the rubber slurry; preparing a graphene-latex dispersion, and further soaking the glove blank soaked into the rubber slurry into the graphene-latex dispersion; performing vulcanization drying, thereby obtaining the graphene laminated rubber glove. Due to secondary soaking, the rubber slurryof primary soaking is cured to form a rubber body structure part of the glove, and then the quality of the main body structure can meet related standards (EN388) and ensure basic working protection functions of gloves; due to secondary soaking, a graphene laminated membrane can be formed, so that a rubber surface formed by primary soaking can be protected, and various overall properties of a gloveproduct can be improved.

Owner:SHANDONG XINGYU GLOVES

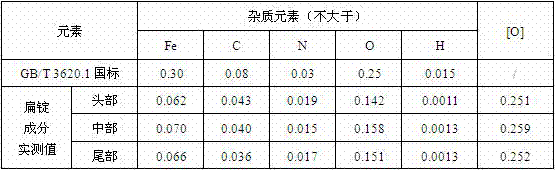

Method for obtaining TA2 slab ingot from chip-shaped and plate-shaped pure-titanium residual materials through smelting and recycling

ActiveCN107502751AShort production processLow costProcess efficiency improvementTitaniumChemical composition

The invention discloses a method for obtaining a TA2 slab ingot from chip-shaped and plate-shaped pure-titanium residual materials through smelting and recycling. The adding proportion of the chip-shaped titanium residual materials can be obviously improved, in addition, sponge titanium does not need to be added, 100% pure-titanium residual material adding, smelting and recycling can be achieved through the chip-shaped and plate-shaped pure-titanium residual materials, and the TA2 slab ingot with qualified components is produced. A component compounding method is provided, the components of the smelted and recycled TA2 slab ingot are designed, the components of the slab ingot meet the standard requirements of GB / T 3620.1 Titanium and Titanium alloy Mark and Chemical Component, meanwhile, the mechanical performance of a titanium plate produced through the method meets and is superior to the standard requirements of GB / T 3621 Titanium and Titanium Alloy Plate, and component performance is good.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

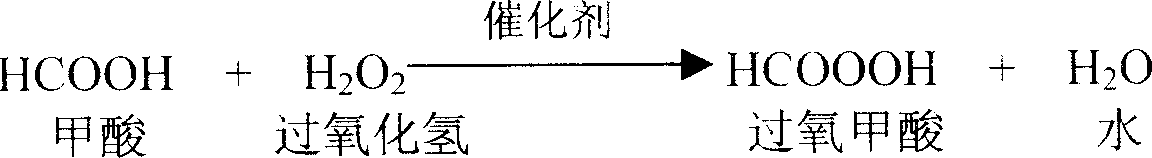

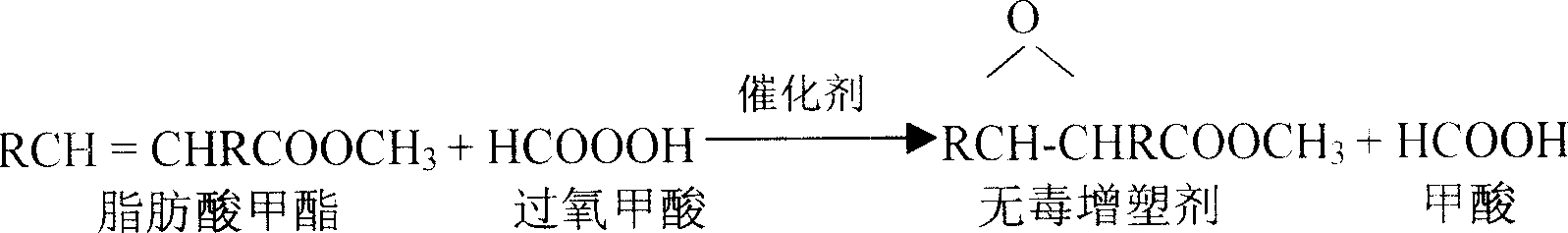

Preparation method of nontoxic plasticizer

The invention discloses a nontoxic plasticizer preparing method, which is characterized by the following: using fatty acid formic ester as raw material; using peroxide as oxygen giver; using organic acid as oxygen carrier; using acid as catalyst; using complex compound as stabilizing agent; treating by epoxidation. The invention has good compatibility and low volatility, which has no toxicity.

Owner:罗春妹

High-temperature processed wood-plastic composite and preparation method thereof

InactiveCN106752011AImprove interface strengthHigh mechanical strength and modulusThermoplasticHot pressing

The invention provides a high-temperature molded wood-plastic composite and a preparation method thereof and belongs to the technical field of wood-plastic composites and preparation methods thereof. The invention aims at solving a problem that the wood-plastic composite is hard to prepare at high temperature. The high-temperature molded wood-plastic composite contains a modified plant material, a general-purpose plastic, a coupling agent or an interface compatibilizer, a lubricating agent, a heat stabilizer and a mineral filler; and the modified plant material is a plant material modified by a modifying agent. The preparation method for the high-temperature molded wood-plastic composite comprises the steps: 1, modifying the plant material with the modifying agent; 2, mixing the modified plant material together with the thermoplastic plastic, the coupling agent, the lubricating agent, the heat stabilizer and the mineral filler; 3, melting and blending a mixture obtained in the step 2 by using a double screw; and 4, adding a blend to an extruder for extrusion molding; and carrying out injection molding by using an injection molding machine or carrying out hot press molding by using a hot press; or directly carrying out operations of the steps 2, 3 and 4 on the modifying agent solid and other solids.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method for preparing light porous sintered material from aluminum ash

ActiveCN112430124AIncrease the addition ratioLower sintering temperatureCeramicwareMetallic aluminumFluoride

The invention provides a method for preparing a light porous sintering material from aluminum ash. The method comprises the following steps: (1) carrying out graded grinding and crushing treatment onwaste aluminum ash to remove large-particle components such as metal aluminum and the like in the waste aluminum ash to obtain fine aluminum ash; (2) fully grinding a silicon source to prepare a finesilicon source material; (3) compounding the fine aluminum ash and the fine silicon source material according to a mass ratio of 1-4:1, and fully mixing; (4) adding the mixture into a mold, and carrying out pressure molding to prepare a dry blank; (5) putting the dry blank into a high-temperature furnace, and carrying out calcining treatment to obtain a sintered blank; and (6) cutting and shapingthe sintered blank to prepare a porous material product. According to the invention, the raw materials are wide in source, only a high-silicon material is adopted as an additive, the whole preparationprocess is a dry method, and the environmental problems that aluminum nitride is hydrolyzed when encountering water to generate ammonia gas, fluoride is dissolved out to pollute a water body and thelike are solved.

Owner:郑州中科新兴产业技术研究院 +2

Novel absorbing articles and manufacturing method thereof

ActiveCN101317800AImprove integrityIncrease the addition ratioAbsorbent padsBaby linensWoven fabricEngineering

The invention provides a novel absorption article and a method for manufacturing the absorption article. A plurality of bosses are arranged in a shaping socket of the building drum of a publicly-known absorption core. The demoulded absorption core is wrapped by non-woven fabric. The absorption cores are fixedly connected with each other by the upper and lower layers of the non-woven fabric at a though hole formed by the bosses. The absorption article made by the method comprises a liquid permeable surface with an integral circumference, a liquid-tight bottom layer and an absorber arranged between the liquid permeable surface and the liquid-tight bottom layer. The absorber consists of the absorption cores wrapped by the non-woven fabrics. A plurality of through holes are arranged on the absorption cores. The through hole goes through the upper and the lower surfaces of the absorption core. The non-woven fabrics of the upper and the lower surfaces of the absorption cores are fixedly connected with each other at the through holes of the absorption cores. The absorption article is provided with a thin or an ultra-thin absorber. And the adverse conditions, such as clot and breakdown, and the like, do not happen after the absorber absorbs liquid.

Owner:CHIAUS FUJIAN IND DEV

Purification treatment method of cast superalloy return scraps and superalloy

The embodiment of the invention provides a purification treatment method of cast superalloy return scraps and a superalloy and relates to the field of return scrap purification and remelting. The purification treatment method of the cast superalloy return scraps mainly comprises the steps of mixing the treated return scraps with a new material, conducting high-temperature refining; adding coveringslag on the surface of molten steel to conduct deslagging treatment in the high-temperature refining process, wherein the covering slag comprises CaO-Al2O3-CaF2-MgO, and the weight ratio of CaO to Al2O3 to CaF2 to MgO is 4-6:2-3:1-3:0-1; and conducting vacuum horizontal continuous casting and billet discharge on the molten steel subjected to deslagging treatment to obtain a purified master alloycast rod. The purification treatment method of the cast superalloy return scraps, provided by the embodiment of the invention is simple in process, low in cost and high in purification effect.

Owner:BEIJING CISRI GAONA TECH

Interpenetrating polymer network core-shell emulsion and preparation method thereof

InactiveCN103936939AGood scrub resistanceIncrease the addition ratioPhosphoric Acid EstersSodium bicarbonate

The invention discloses an interpenetrating polymer network core-shell emulsion and a preparation method thereof. The core-shell emulsion is prepared from a monomer, emulsifiers, an initiator, a PH regulating agent and water. The core-shell emulsion is characterized in that the monomer consists of a functional monomer and a mixed monomer, wherein the mixed monomer consists of a vinyl monomer and butyl acrylate, and the functional monomer consists of diacetone acrylamide, adipic dihydrazide, divinyl benzene and a reactive type silicon monomer; the emulsifiers refer to a nonylphenol-free reactive type emulsifier SR-10, a fatty phosphoric acid ester emulsifier and an exclusive non-ion reactive type emulsifier; the initiator refers to sodium persulfate; the PH regulating agent refers to sodium hydrogen carbonate; water refers to deionized water. The preparation method comprises the following steps: (1) in a raw material ratio, preparing a monomer mixed liquid for later use, preparing deionized water and an initiator and stirring to form an initiator mixed liquid for later use; and (2) polymerizing the emulsion. The core-shell emulsion and the method have the beneficial effects of being environmental-friendly and safe, the technology is simple, the scrubbing-resisting capability and the pigment filler bearing capability are strong and the stability of electrolyte and freeze thawing is high.

Owner:HEBEI SUNRISING CHEM CORP

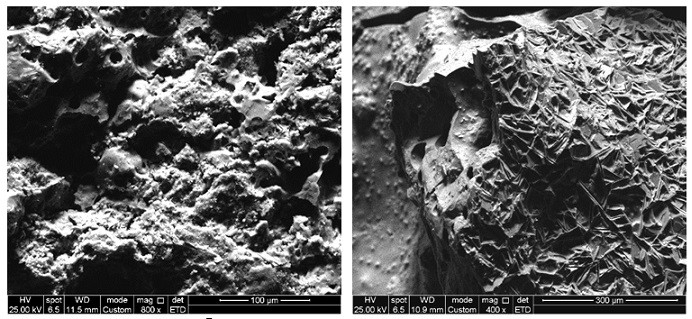

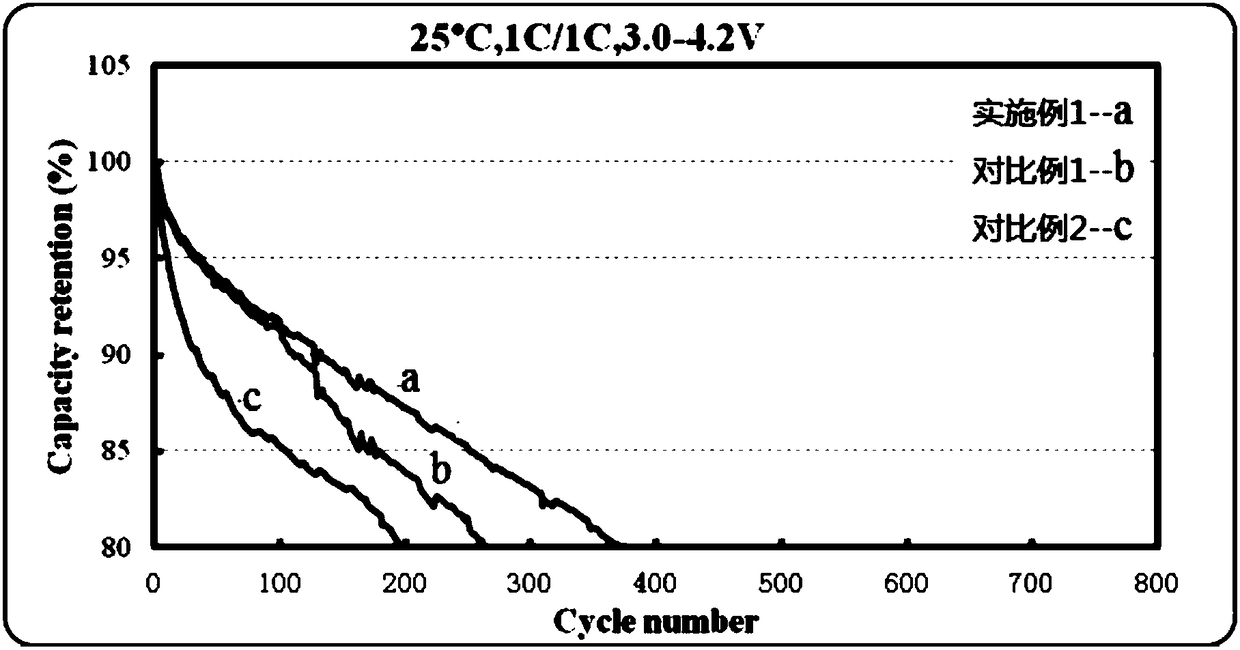

Carbon black modified water-based SBR lithium ion battery binder and preparation method thereof

InactiveCN108598482AHigh cycle capacityImprove cycle lifeCell electrodesSecondary cellsWater basedSodium stearate

The invention discloses a carbon black modified water-based SBR lithium ion battery binder and a preparation method thereof, and relates to the technical field of a lithium ion battery binder, whereinthe binder is prepared through the following steps: using styrene and butadiene as raw materials; bonding the conductive carbon black on an SBR molecular chain through an in-situ emulsion polymerization method, wherein the preparation method comprises adding an aqueous solution of sodium stearate to an aqueous surfactant solution to obtain an emulsified solution; then adding carbon black to disperse to obtain a carbon black emulsion system; dissolving an reducibility initiator and electrolyte in deionized water to obtain a reducing solution; adding the deionized water, the reducing solution,a molecular weight regulator SD-12 and styrene to the carbon black emulsion system, vacuumizing to the negative pressure, and then adding butadiene, cooling, and adding an oxidizing initiator to initiate a polymerization reaction. The binder of the present invention is used for battery preparation. In the case that no conductive carbon black is additionally added, the battery has a high cycle capacity, thereby increasing the additive proportion of the active material, and indirectly increasing the energy density of the battery system.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Modified acrylic acid emulsion

A kind of modified propenoic acid latex is involved in this invention, whose modification lines in modifying latex polymer by use of wet adhesion monomer containing siloxany and ureid, so as to change adhesion capability of latex polymer and carrying capability to paint, especially increase evidently initial adhesion ofrce to abio-matrix, founder and adhesion force in rigot condition, and so waterproof and washproof capabilities of latex paint are increased geminatly. On the other side, by adopting lunar nonionic magma replacing emulsification system of intrinsic magma and protection glue and reaction magma having alkena bonds at the same time, advances electrolyte and freeze-thaw stability to a great extent, and waterproof capability is advanced accordingly.

Owner:江苏日出化工有限公司

PPM environment-friendly material and preparation method thereof

The invention discloses a PPM environment-friendly material and a preparation method thereof. The PPM environment-friendly material comprises the following components in percentage by weight: 80%-85% of calcium carbonate, 15%-20% of carrier resin, 0.5%-10% of a dispersing agent, 0.5%-10% of a lubricating agent, 0.5%-10% of a coupling agent and 0.1%-3% of an antioxidant. The preparation method of the PPM environment-friendly material comprises the following steps: coating and modifying the calcium carbonate; banburying and mixing the modified calcium carbonate with the carrier resin, lubricating agent and antioxidant; carrying out extruding granulation and finishing air cooling, screening and packaging until finishing the whole preparation process. The PPM environment-friendly material has easily available preparation raw materials, low cost, high quality, mature process, convenience for popularization and obvious effects. The PPM environment-friendly material can be extensively applied to the fields of processing of plastic products, particularly to the industries of plastic packaging, agricultural plastics and plastic construction materials.

Owner:广东碧盛环球环保材料有限公司

Method for extracting and separating tungsten molybdenum

ActiveCN104120257ALow costIncrease the addition ratioProcess efficiency improvementIsooctyl alcoholAlcohol

The invention discloses a method for extracting and separating tungsten molybdenum. N263-sec-octyl alcohol-kerosene system is used for extracting and separating ammonium tungstate solutions, an organic phase is composed of 20 percent of N263, 20 percent of isooctyl alcohol and 60 percent of kerosene, and O / A is 1:1. According to the method, firstly, the organic phase is vulcanized, the organic phase and vulcanizing agents are mixed and are in sufficient contact for standing so as to achieve phase splitting, and the vulcanized organic phase is obtained; molybdenum is extracted and removed, high-molybdenum ammonium tungstate is doped into the vulcanized organic phase for treatment, and through extraction and separation of more than two levels, a qualified low-molybdenum ammonium tungstate solution is obtained. According to the method, the organic phase configuration process, the sulfidation process and the reverse extraction process are carried out, the technology is innovated and improved, the problems that in the traditional ammonium tungstate extraction and molybdenum removing process, the efficiency is low, and the cost is high are solved, and the method becomes possible in the industrial application aspect.

Owner:XIAMEN TUNGSTEN

Method for smelting, recycling and preparing TA2 pure titanium by adopting TA1 scrap-like pure titanium residual material

ActiveCN107893164AAvoid pollutionAdd lessProcess efficiency improvementChemical compositionAdditive ingredient

The invention belongs to the technical field of processing of titanium materials and particularly relates to a method for smelting, recycling and preparing TA2 pure titanium by adopting a TA1 scrap-like pure titanium residual material. According to the method, a dry-type milled TA1 pure titanium plate blank is adopted to obtain the TA1 scrap-like titanium residual material, and the TA1 scrap-liketitanium residual material is subjected to magnetic separation deironing, caking and drying to obtain titanium scrap press cakes; and the titanium scrap press cakes are reasonably dosed by an ingredient dosing method and are smelt and recycled to obtain the TA2 pure titanium. The smelting and recycling flow for the scrap-like titanium residual material can be greatly reduced, the smelting and recycling quality is improved, no sponge titanium is needed to be added, the smelting and recycling of the TA1 scrap-like titanium residual material can be realized one hundred percent, and the additive proportion of the scrap-like titanium residual material is greatly improved. The method has good effect of removing high and low density inclusions, the obtained TA2 pure titanium meets the standard requirements of GB / T 3620.1 Titanium and Titanium Alloy Brand Number and Chemical Components, and the mechanical property of a produced titanium plate is superior to the standard requirements of GB / T 3621 Titanium and Titanium Alloy Plate.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Environment-friendly and energy-saving type fully-recycled asphalt mixture stirring equipment

InactiveCN109706821AReduce asphalt smoke concentrationReduced asphalt smoke concentrationRoads maintainenceProcess engineeringAsphalt

The invention discloses environment-friendly and energy-saving type fully-recycled asphalt mixture stirring equipment, which belongs to the field of asphalt mixture stirring equipment and comprises acold material metering and conveying mechanism, an asphalt storage pumping and metering mechanism, a raw material drying mechanism, a regenerated material drying mechanism, a dust removal mechanism, amineral powder storage metering mechanism, a hot material storage mechanism and a stirring mechanism; and the cold material metering and conveying mechanism comprises a raw material metering and conveying assembly and a regenerated material metering and conveying assembly. According to the invention, the regenerated material heating mode is changed; the asphalt smoke concentration of the regenerated material is reduced; asphalt flue gas generated during full-regeneration of the mixture is reduced from the source, the service life of a cloth bag in a bag-type dust collector is prolonged, the maintenance strength of equipment is reduced, the influence of water vapor flue gas on the equipment, combustion and environment is reduced, and the equipment is designed in an environment-friendly manner and is compatible with a production conventional proportion, namely, the regenerated asphalt mixture with the regenerated material additive proportion of 10-60% and the 100% raw asphalt mixture with no regenerated material.

Owner:江苏人杰筑路机械科技有限公司

Full solid waste dry-mixed mortar and preparation method thereof

The invention provides a full solid waste dry-mixed mortar which is formed by mixing various raw materials. The raw materials comprise flying ash, steel slag, mineral slag, gypsum, ceramic waste material and furnace slag. The invention also provides a preparation method of the full solid waste dry-mixed mortar. Through three approaches of optimizing the varieties and content of solid wastes insidethe solid waste mortar, reasonably carrying out mixing and matching according to grain composition and optimizing the preparation method, formula optimization is combined with process optimization, the preparation of the full solid waste dry-mixed mortar is realized, practice indicates that the full solid waste dry-mixed mortar improves the addition proportion of solid wastes inside the mortar, and also solves the problem that the mortar is non-uniform caused by low consistency, high shrinkage, easy cracking, hollowing and material separation existing in the solid waste mortar prepared by adding water into the full solid waste dry-mixed mortar, so that the application range of the solid waste inside the mortar is enlarged.

Owner:山东生态环境研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com