Method for obtaining TA2 slab ingot from chip-shaped and plate-shaped pure-titanium residual materials through smelting and recycling

A technology of residual material and pure titanium, which is applied in the direction of improving process efficiency, etc., can solve the problems of difficult quality assurance, difficult removal of high and low density inclusions of titanium residual material, high recycling cost, etc., and achieves low cost, excellent composition and performance, and production process short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further elaborated below in combination with specific embodiments.

[0032] The invention adopts the smelting and recycling of chip-like and plate-like pure titanium residues, and the goal is to obtain 190*1055*5700mm flat ingots.

[0033] Step 1, surface treatment: cleaning, drying and magnetic separation of pure titanium shavings and titanium residues to remove surface oil and iron filings impurities to obtain clean and dry titanium shavings; use shot blasting pickling method to clean the plate Remove impurities such as oxide scales and oil stains on the surface of pure titanium residues and dry them to make the surface clean and dry;

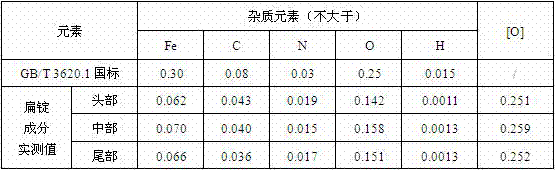

[0034] Step 2, ingredient calculation: use chemical analysis method to detect and calibrate the composition of chip-shaped and plate-shaped pure titanium residues, and the results are shown in Table 1. According to the strength requirements of the plate, the target [O]% of smelting and recycling TA2 slabs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com