High-toughness casting aluminum alloy and preparation method thereof

A technology for casting aluminum alloys and aluminum-silicon intermediate alloys, which is applied in the field of metal materials, can solve the problems of long production cycle, high requirements, and many processes, and achieve the effects of low production cost, large impact load, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

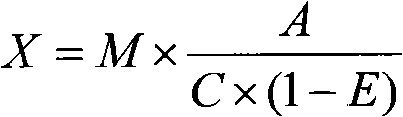

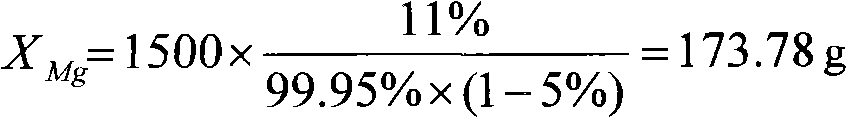

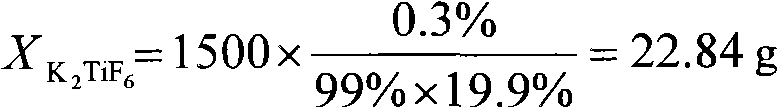

[0025] Prepare 1500g of the high-toughness cast aluminum alloy material of the present invention, the composition of the alloy material is Mg 11%, Ti0.3%, RE 0.2%, Si 0.15%, and the rest are aluminum and unavoidable trace impurities, wherein a single trace impurity The content of elements is <0.10%, and the total amount of trace impurities is <0.50%.

[0026] The preparation method is as follows:

[0027] (1) Raw material preparation aluminum block (aluminum ≥ 99.7%), magnesium block (magnesium ≥ 99.95%), K 2 TiF 6 (content ≥ 99%), aluminum-rare earth master alloy (aluminum 90% Al, rare earth 10%), aluminum-silicon master alloy (aluminum 88% Al, silicon 12%).

[0028] With reference to "Casting Handbook" (volume 3, casting non-ferrous alloys, 2nd edition, Machinery Industry Press, 2001, P187-188) and experience to determine the amount of burning loss of aluminum alloy elements of the present invention: aluminum: 1.0%, magnesium 5% ;Other materials have little change during ...

Embodiment 2

[0051] Prepare 1500g alloy material, the composition is Mg 10%, Ti 0.4%, RE 0.3%, Si 0.30%, the rest is aluminum and unavoidable trace impurities, wherein the individual impurities are <0.05%, and the total amount is <0.20%.

[0052] The preparation method is as follows:

[0053] (1) batching calculation method is the same as example 1.

[0054] (2) Using a resistance crucible furnace for melting, first sprinkle dehydrated carnallite-based flux in the graphite crucible, and then add pure aluminum and aluminum silicon preheated to 225 ° C; after melting, use the total amount of furnace charge 4 % covering agent protection; when the furnace temperature rises to 670°C, add pure magnesium block preheated to about 200°C and stir until it is completely melted; add aluminum rare earth master alloy preheated to about 200°C at 730°C, and stir quickly until mixed Evenly, alloy liquid is obtained.

[0055] (3) When the furnace temperature drops to 730°C, the drying refining agent (the ...

Embodiment 3

[0059] Prepare 1500g alloy material, the composition is Mg 9.5%, Ti 0.1%, RE 0.1%, Si 0.20%, the rest is aluminum and unavoidable trace impurities, wherein the individual impurities are <0.05%, and the total amount is <0.20%.

[0060] The preparation method is as follows:

[0061] (1) Batching calculation method is the same as Example 1. .

[0062] (2) Use a resistance crucible furnace to smelt, first sprinkle a dehydrated carnallite-based flux (moisture content ≤ 0.5%) into the graphite crucible, and then add preheated pure aluminum and aluminum-silicon in the middle; after clearing Use a covering agent covering 3% of the total charge for protection; add preheated pure magnesium block when the furnace temperature rises to 680°C, and stir while melting until it is completely melted; add preheated aluminum rare earth master alloy at 740°C, and stir quickly until mixed Uniform;

[0063] (3) When the furnace temperature drops to 730°C, the dried refining agent (the refining ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com