Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Large impact load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

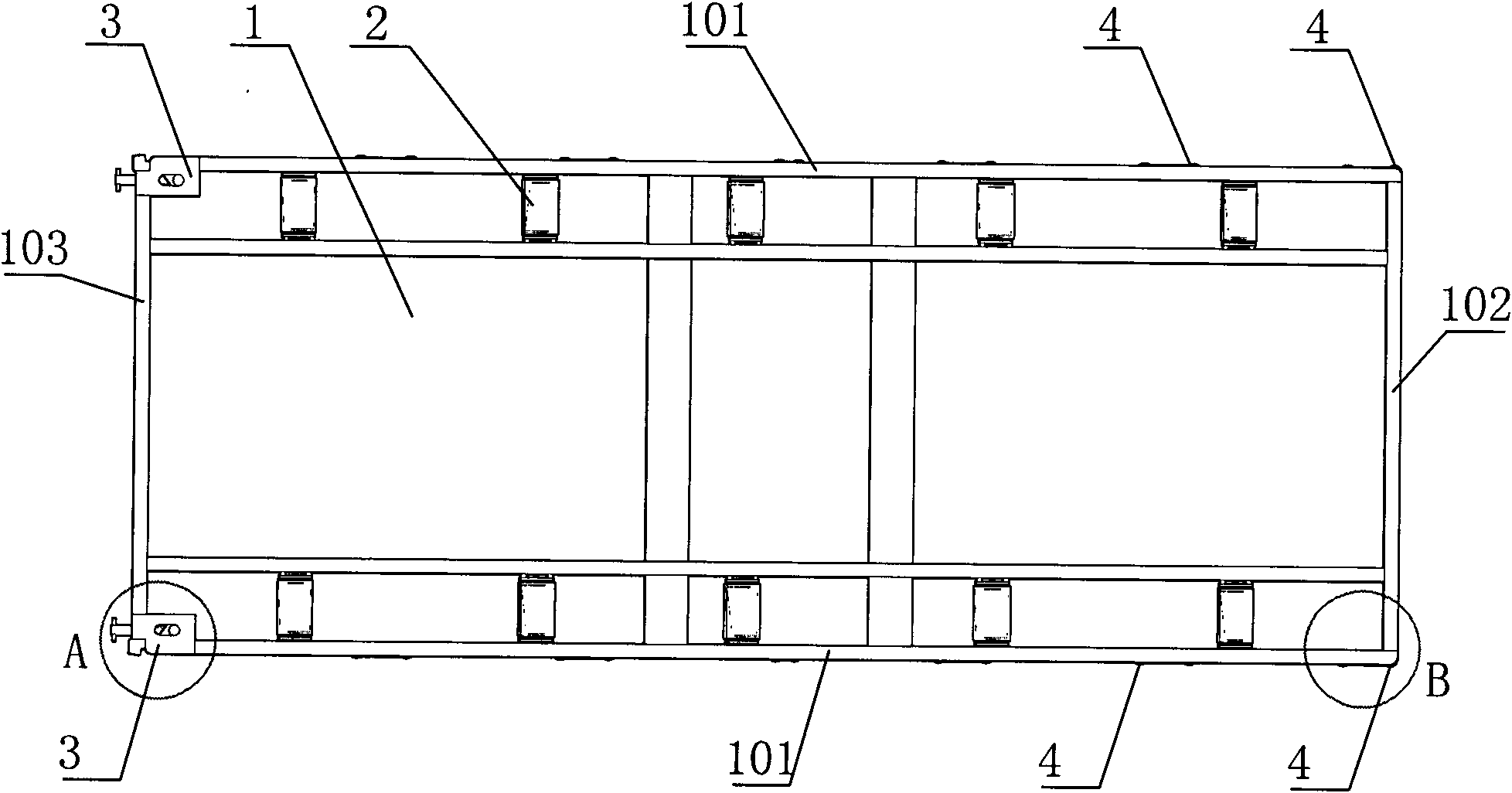

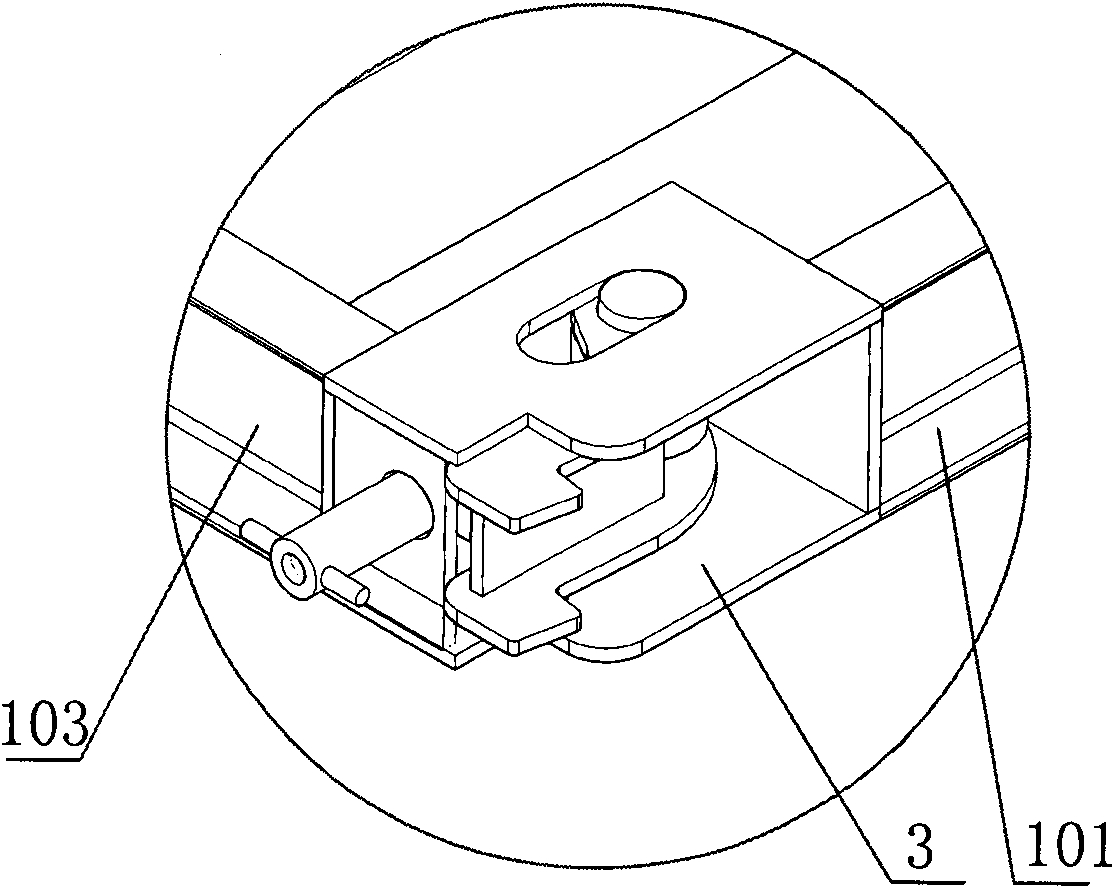

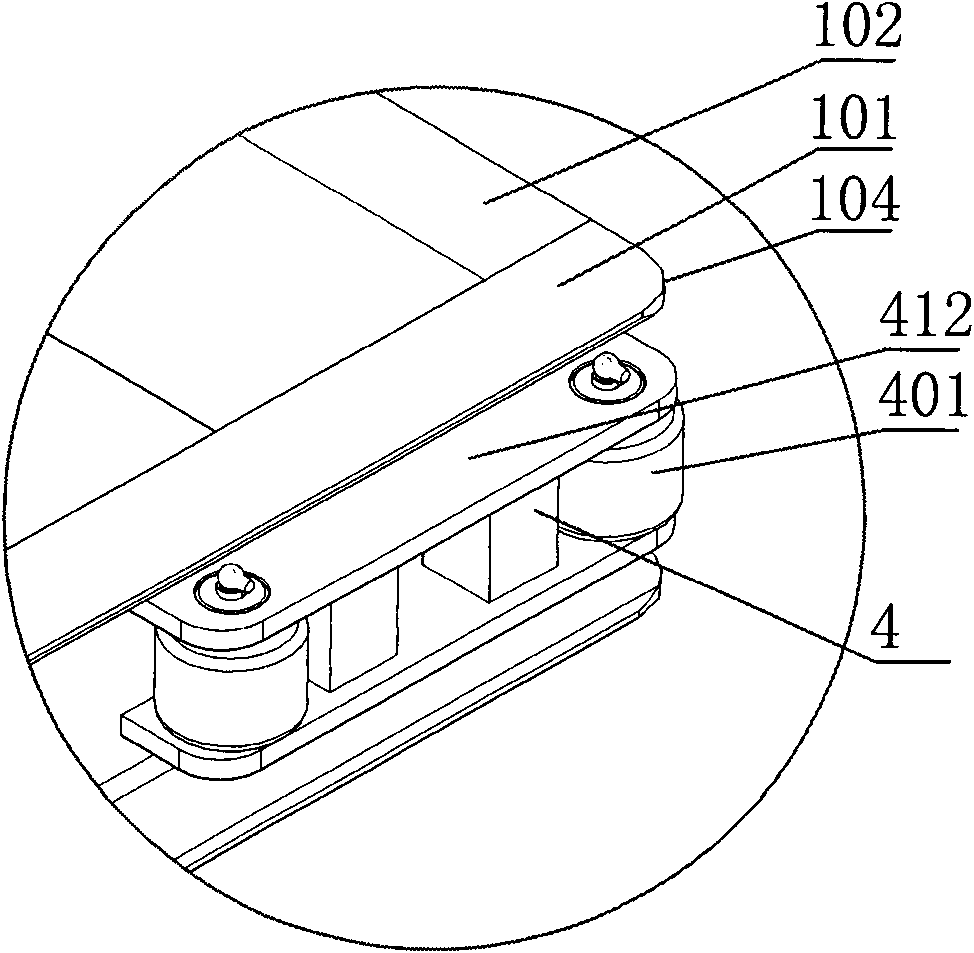

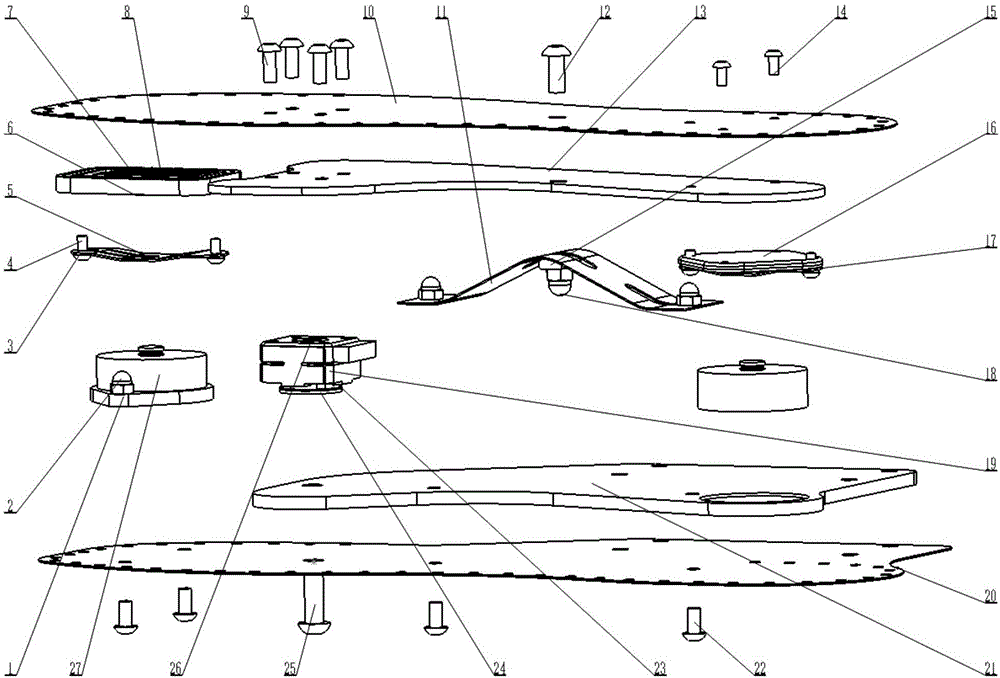

Built-in mobile pallet of container

InactiveCN101891046AEffective protectionAvoid cutsLarge containersRigid containersRolling resistanceFront edge

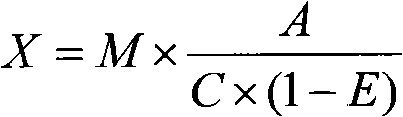

The invention relates to a built-in mobile pallet of a container, comprising a rectangular chassis with rolling wheels at the bottom, wherein a plurality of guide devices are arranged at two lateral parts and the edge corner parts of the chassis; the guide devices are of guide wheel structures, and the peripheral surface of each guide wheel protrudes out of the lateral side of the chassis; and locking devices are arranged at two corner parts of the rear edge of the chassis. In the invention, the guide wheels are arranged at the lateral parts and the edge corner parts of the chassis, which converts sliding friction with larger resistance into rolling friction with smaller resistance; the peripheral surface of each guide wheel at the edge corner part is firstly in contact with a firm door frame of the container in the loading process, therefore, the relatively parallel position between the pallet and the container is well regulated basically; in addition, the guide wheels at the lateral parts can self-adaptively regulate the relative position between the pallet and the container in the continuous conveying process, thereby preventing the wall of the container from being crashed, even lacerated and effectively protecting the container; and locking hooks arranged at the rear edge corner parts are reasonable in structure, convenient to use and reliable to lock.

Owner:WUXI CLS MASCH CO LTD

High-toughness casting aluminum alloy and preparation method thereof

Owner:宁波旭润铝业有限公司 +1

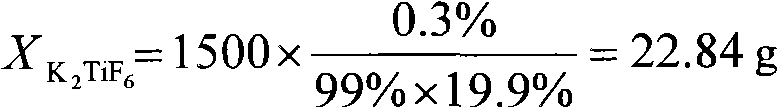

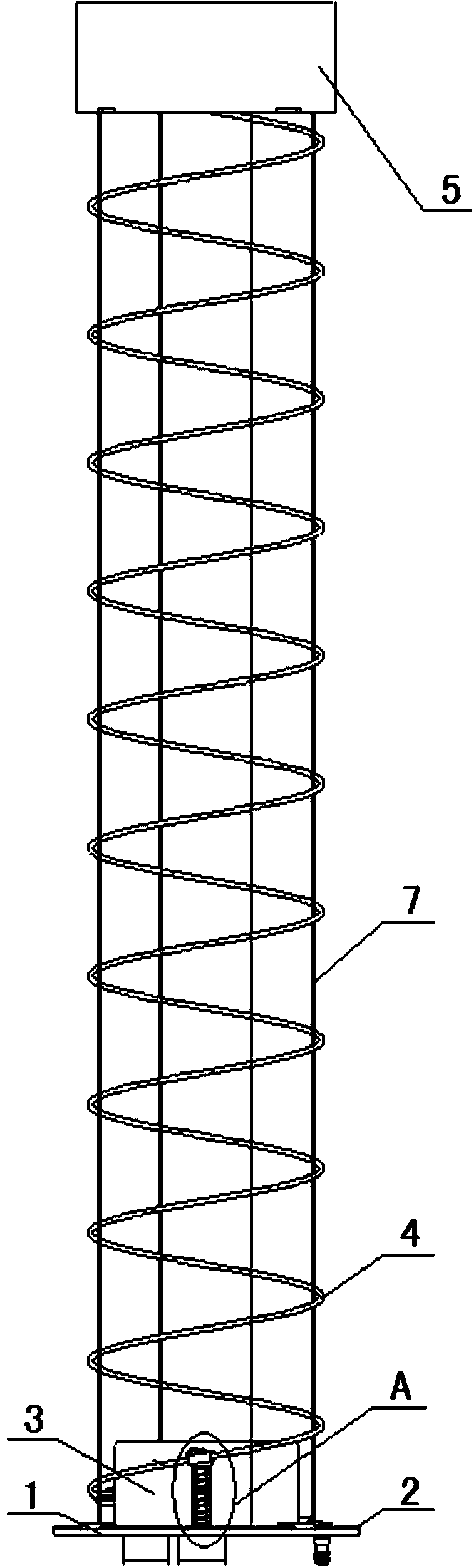

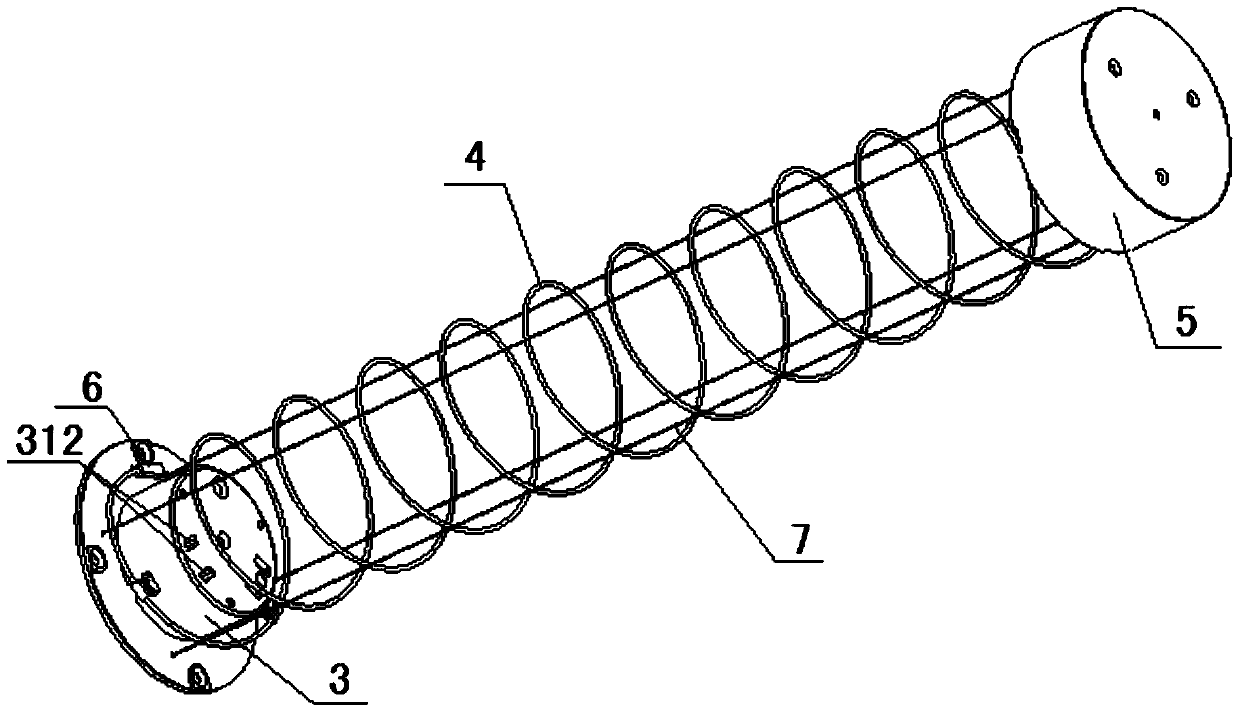

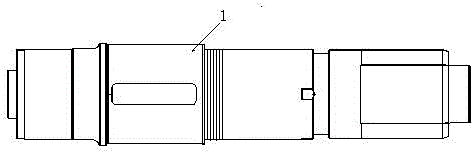

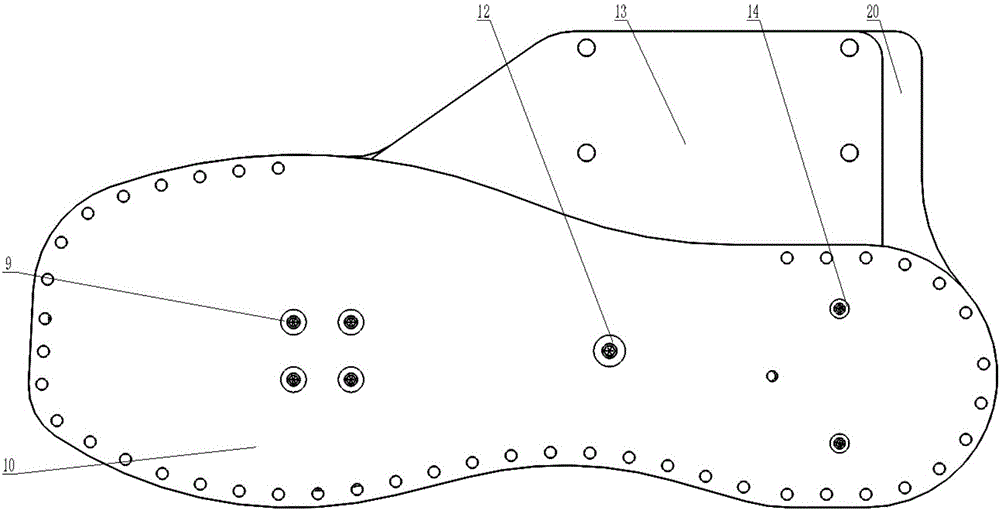

Satellite-based helical antenna

ActiveCN104836011AEasy to storeEasy to installRadiating elements structural formsRadiating element housingsEngineeringHelix

The invention provides a satellite-based helical antenna. The antenna comprises a baffle board, an insulating board, a base, a helical antenna body and a protective cover. The baffle board, the base and the insulating board are fixed through screws. The insulating board is pressed between the baffle board and the base. The baffle board, the base and the insulating board are fixed as a whole. The lower end of a helical antenna body is fixed on the insulating board and the upper end thereof is fixed in the protective cover. When the helical antenna body is compressed to the greatest extent, the protective cover fully covers the base and the helical antenna body and is connected and fixed with the base through the screw. The helical antenna can be folded into a small size and has high compression ratio, the compressed antenna is convenient to store and install, has strong strength, and can bear large impact load; and the compressed antenna has no irreversible deformation, and can rapidly recover to the virgin state after being released.

Owner:四川九洲空管科技有限责任公司

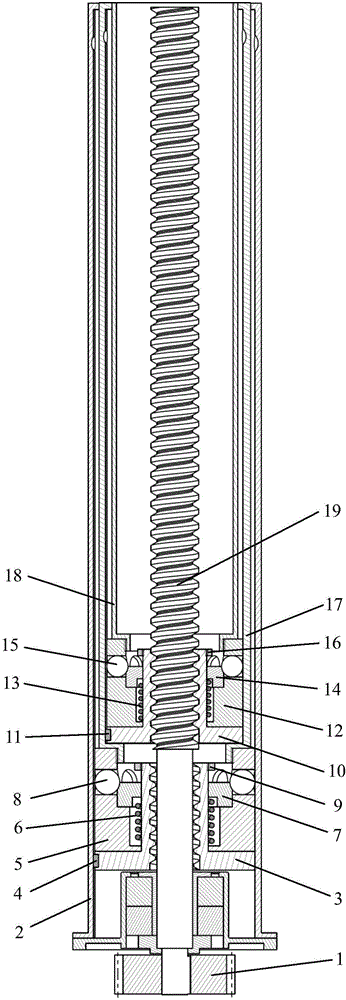

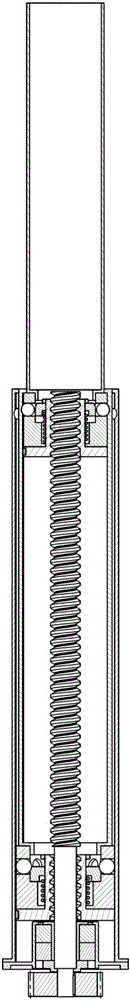

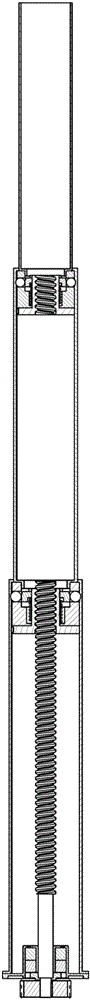

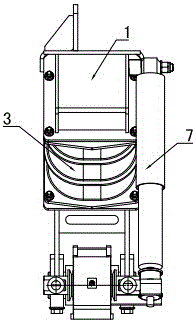

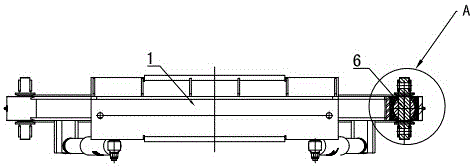

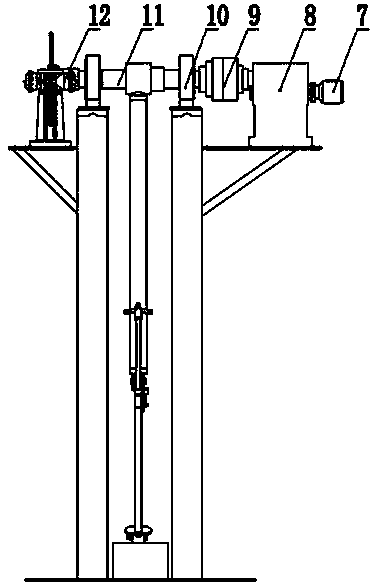

Electric multistage actuating cylinder retracting and releasing locking device

The invention provides an electric multistage actuating cylinder retracting and releasing locking device which comprises an outer cylinder, a middle cylinder, an inner cylinder, a screw and a two-stage steel ball lock mechanism mounted on the outer side of the screw. The outer cylinder, the middle cylinder and the inner cylinder are three coaxial sleeves which are sequentially embedded mutually, the middle cylinder and the inner cylinder are fixedly connected with the two-stage steel ball lock mechanism respectively, and the steel ball locking mechanism drives relative motion of upper and lower locking sliders and upper and lower sliding sleeve through joint action of the screw and upper and lower elastic elements so as to realize locking and unlocking of upper and lower steel balls; a steel ball lock is a mechanical lock, so that the device can bear high impact load in a locked state; an internal thread of the lower sliding sleeve does not be meshed with an external thread of the screw when a multistage actuating cylinder is at a fully-retracted position, and after the middle cylinder and the inner cylinder complete locking through an upper-stage steel ball lock mechanism, the inner cylinder drives the lower sliding sleeve to move upwards so as to be meshed with the screw to complete unfolding of the middle cylinder, so that due to this stage-by-stage unfolding mode, the multistage actuating cylinder is long in unfolding stroke and needless of manual operation in the process of retracting and releasing.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

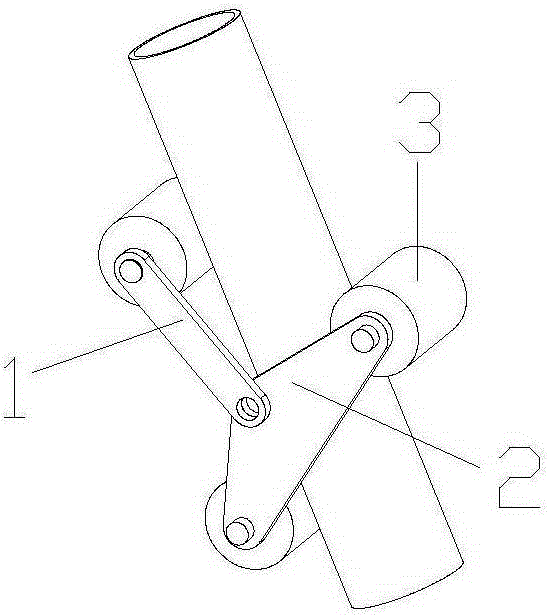

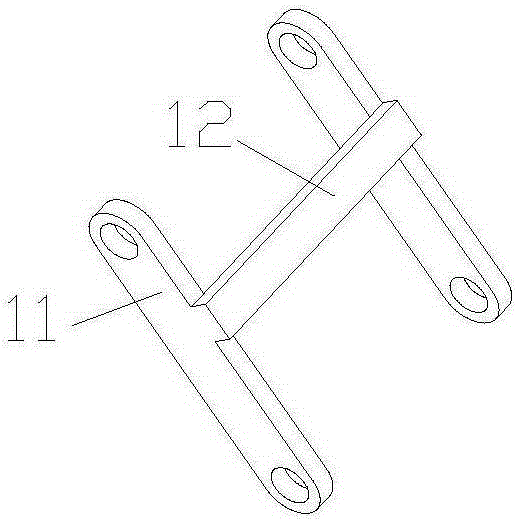

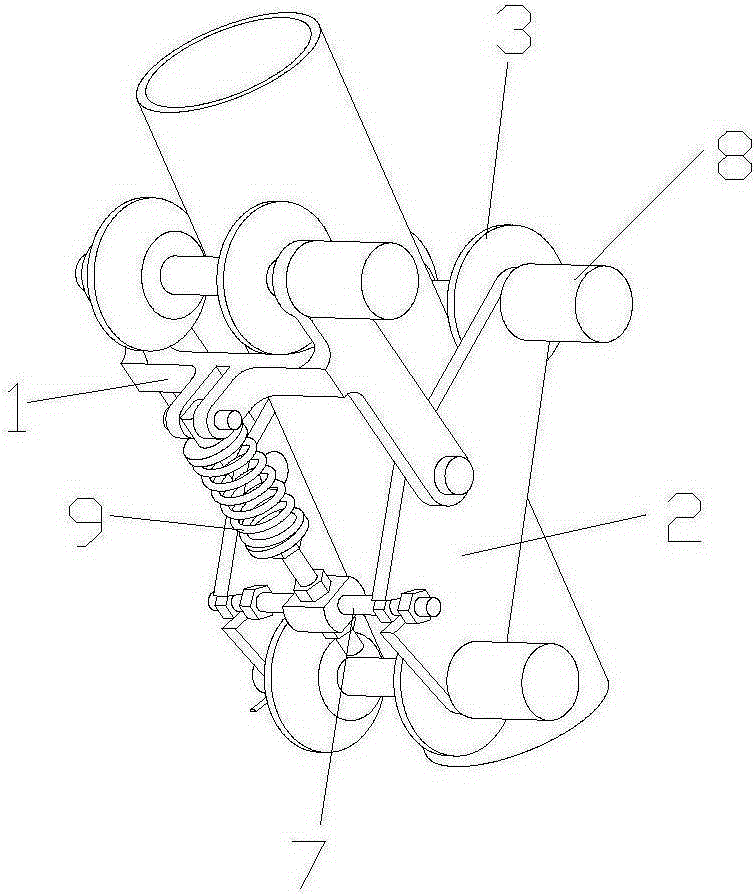

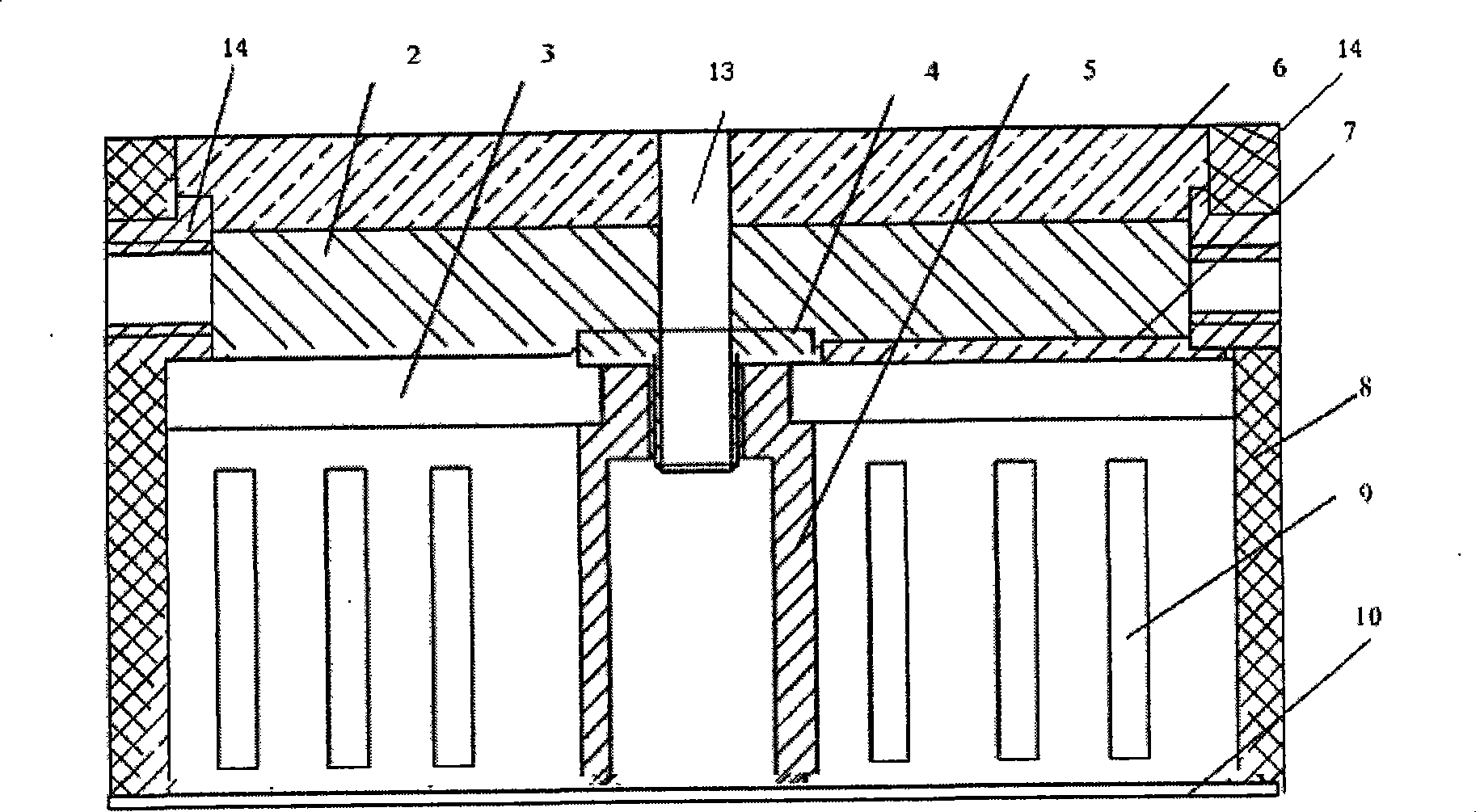

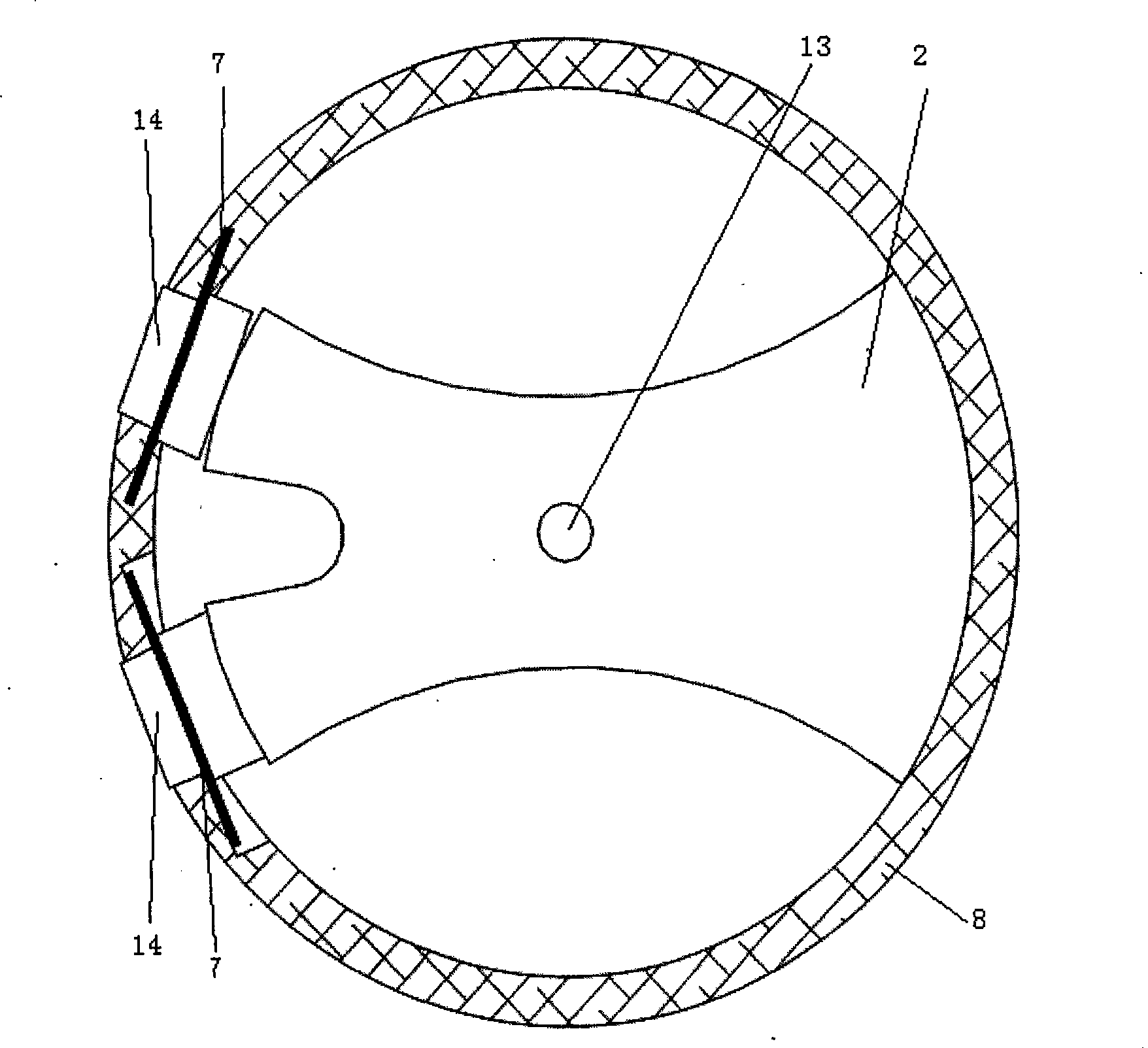

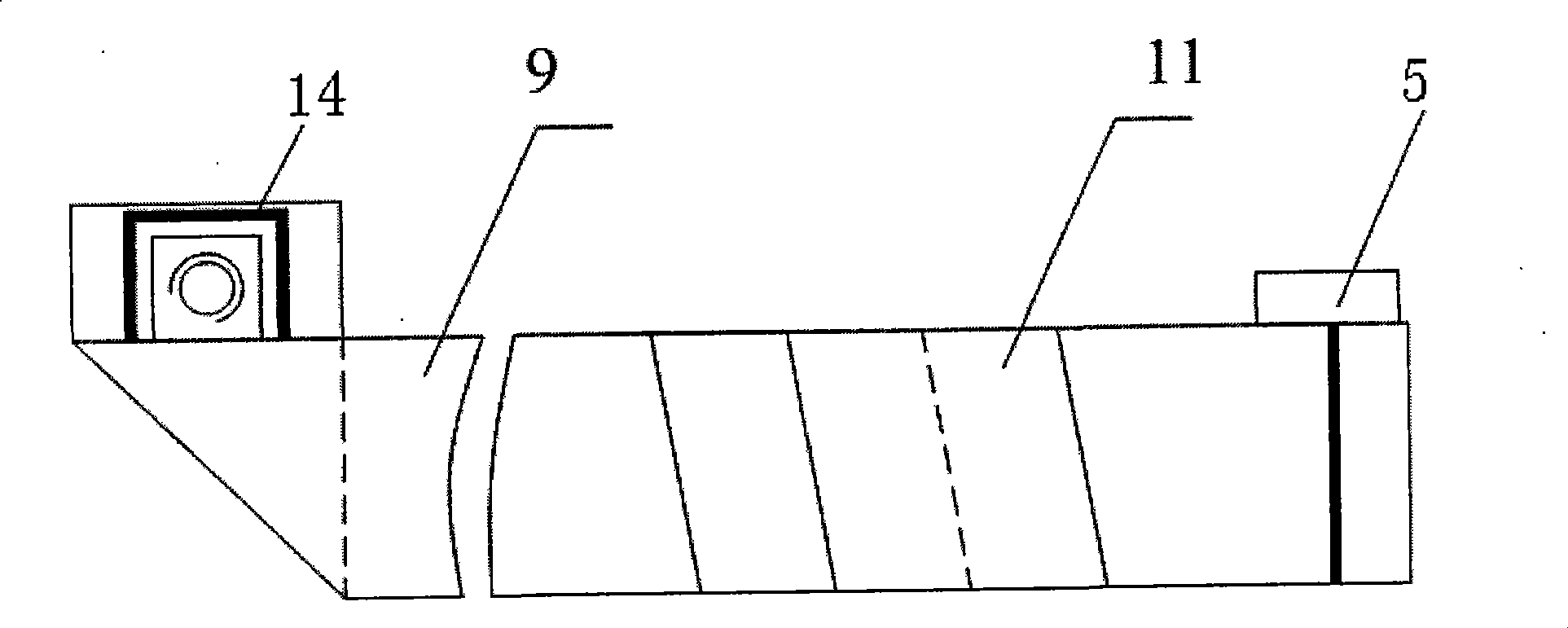

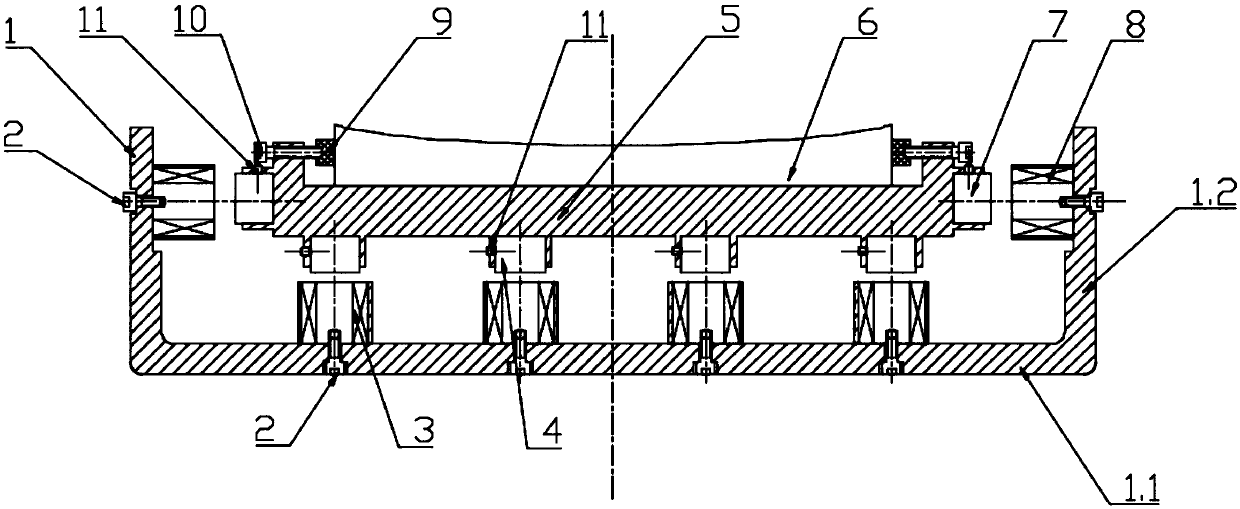

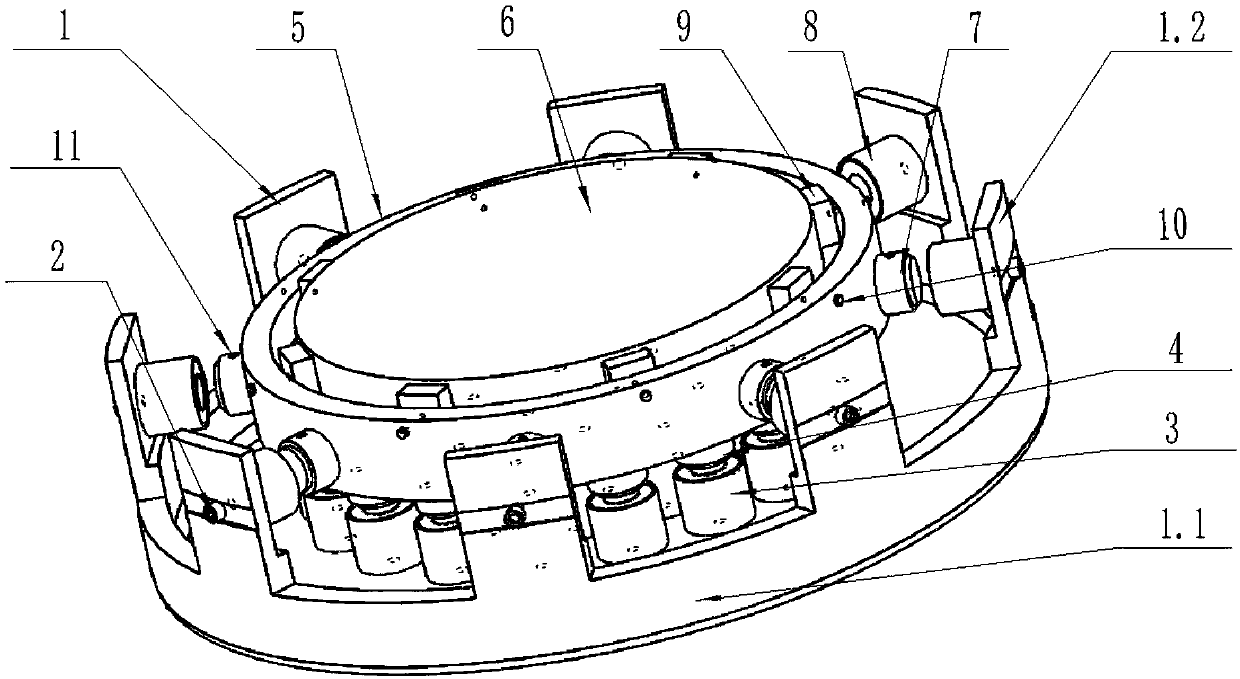

Device and method for machining composite energy absorption tube

The invention discloses a composite energy absorption tube machining device which comprises a rectifier (1), a resistor (2), a switch (3), a capacitor (4), a boosting transformer (5), an upper fixing plate (6), a fixing bolt (7), a pressing block (8), a mould frame (9), a constraint mould (11), a coil (12), a lower fixing plate (13), a T-shaped platform (14), an exhaust vent (16), a fixing groove (17) and a wire hole (18). Compared with a hydraulic forming method and a mechanical bulging method, a composite metal energy absorption forming method based on the electromagnetic forming principle and used in the composite energy absorption tube machining device is high in machining efficiency and high in the pipe fitting forming speed and enables composite metal tubes to be formed under the high strain rate; due to the fact that the high strain deformation process can be used for forming metal materials which are deformed difficultly through a conventional method, the plasticity of the metal materials is greatly improved, and the yield strength of the materials is greatly improved. Different wave forms and reinforcing ribs can be formed by changing the shape of the constraint mould in a mould body, and the machining flexibility is high.

Owner:HUNAN UNIV

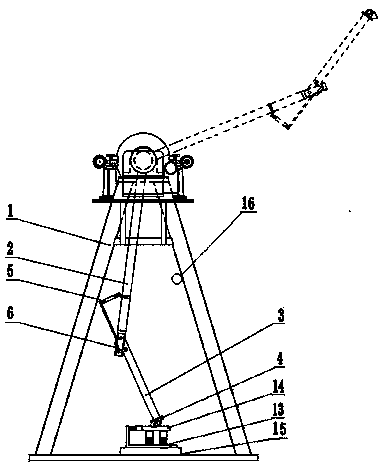

Closed high-altitude cable rope climbing robot

ActiveCN105346615AExtended service lifeNot much internal strengthVehiclesDrive wheelDamping function

The invention discloses a closed high-altitude cable rope climbing robot which comprises three idler wheel sets, side supports, a descent speed limiting device and obstacle induction devices. The side supports are symmetrically arranged on the two sides of the three idler wheel sets and a closed structure is formed by the three idler wheel sets through the side supports. Each idler wheel set comprises at least one idler wheel and can serve as a drive wheel set. By the adoption of the structure, the whole robot is an elastic mechanism, the situation that each wheel is independently and elastically suspended is avoided, and therefore the robot obstacle crossing function is facilitated greatly. The descending speed can be adjusted through the descent speed limiting device, and when the robot climbs cable ropes at different inclination angles, the actual significance is higher. The fluid damping function is achieved, and compared with mechanical friction braking, thermal stability is good, the robot is suitable for being braked for a long time at a long distance, and braking force cannot be attenuated. Meanwhile, the braking force is increased along with the increase of the descending speed, the descending speed and the braking force are in a dynamic balanced process, and the robot can descend at a constant speed or nearly a constant speed.

Owner:NANJING UNIV OF POSTS & TELECOMM

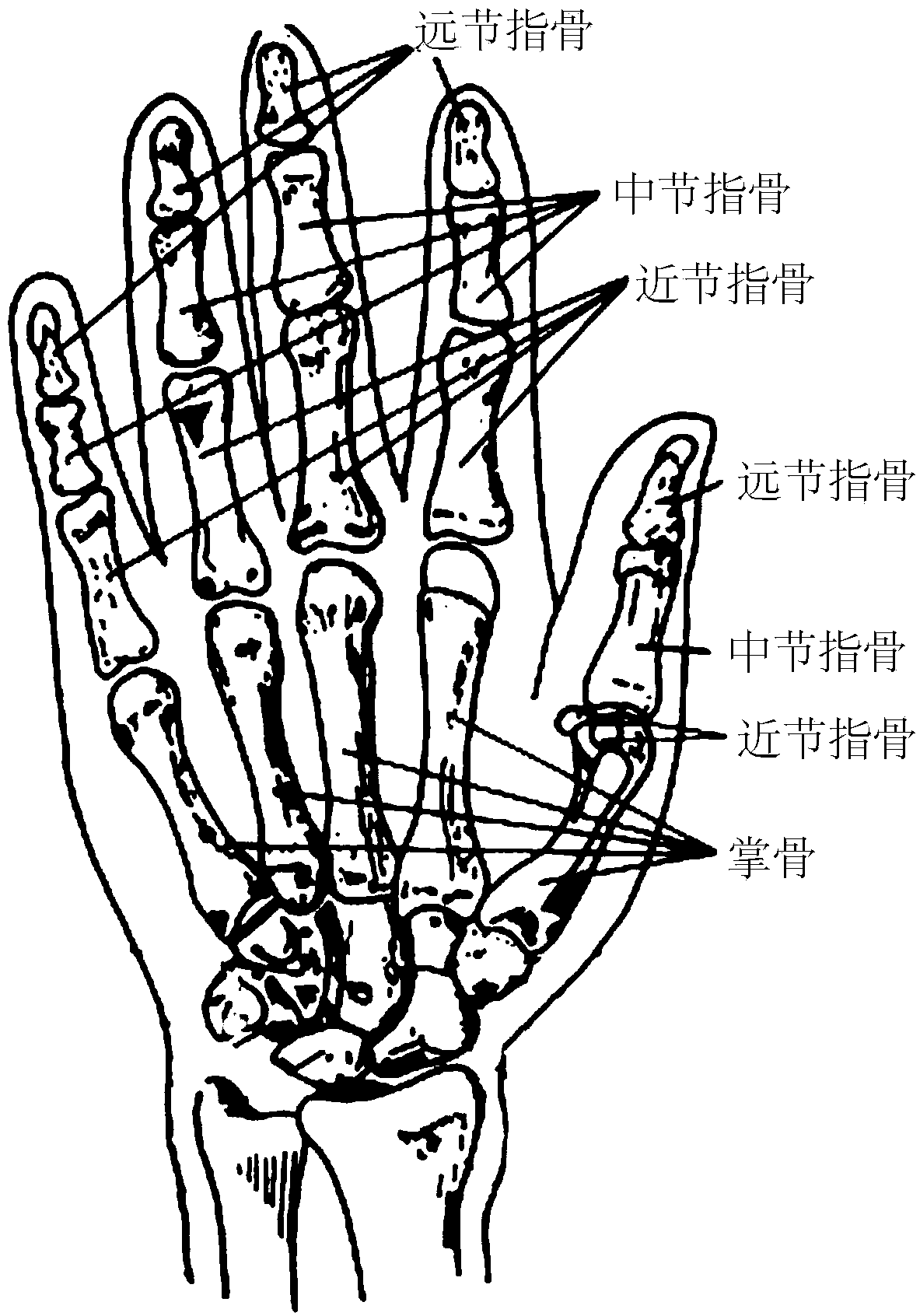

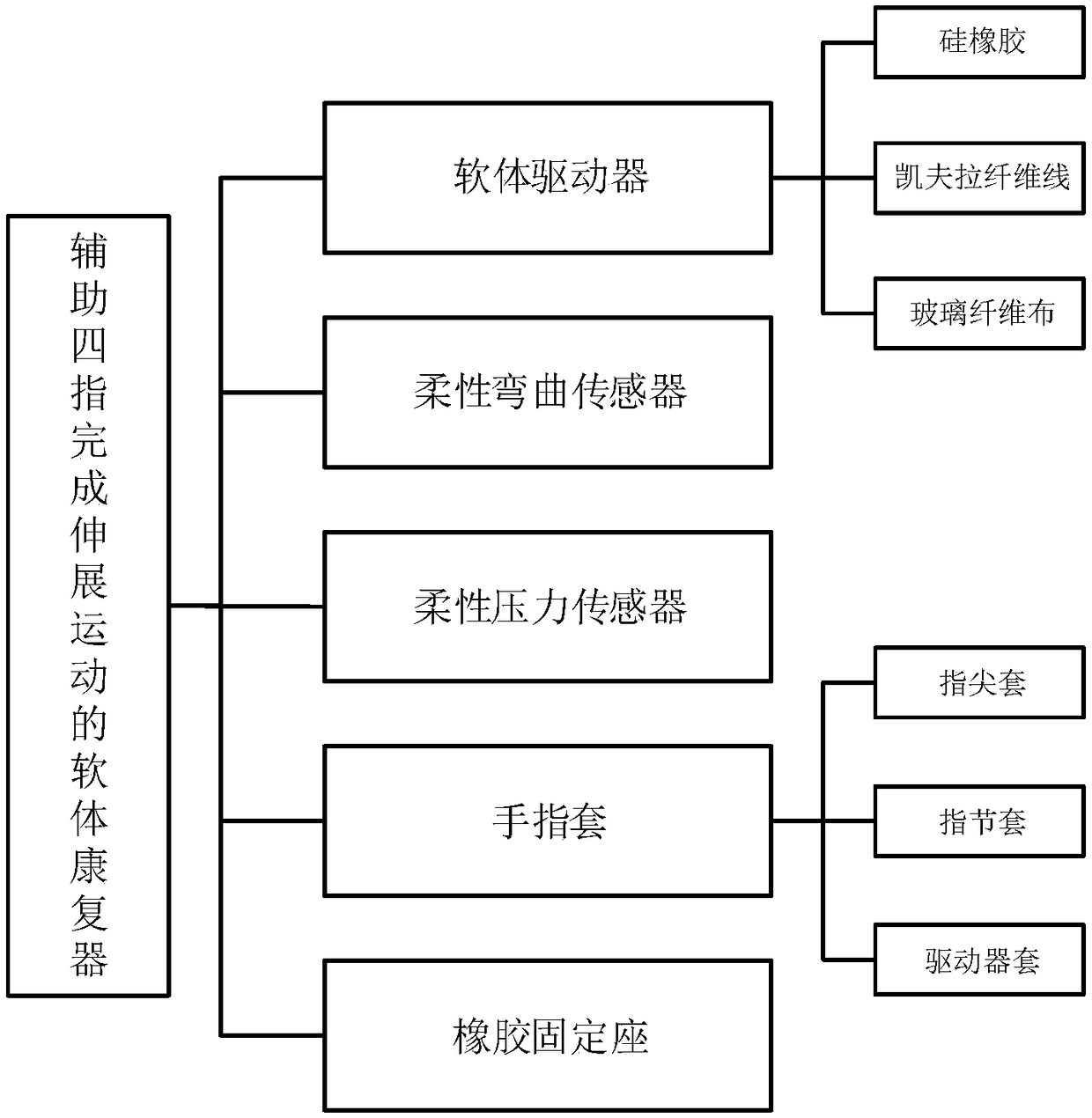

Software driver for assisting four-finger stretching of human hand

The invention discloses a software driver for assisting four-finger stretching of a human hand. The software driver includes an inner layer silicone tube, an outer layer silicone tube, a Kevlar fiberline and three-section glass fiber cloths. The front end of the inner layer silicone tube is closed, the rear end of the inner layer silicone tube is provided with an opening which is used for being connected with an air pressure or hydraulic driving device, the Kevlar fiber line is wound around a portion of the outer wall of the inner layer silicone tube corresponding to four-finger phalanges ina double helix mode, the three-section glass fiber cloths are attached to the side of the inner layer silicone tube deviated from the fingers, the positions respectively correspond to a connecting joint for the four-finger phalanges and proximal phalanges, a connecting joint for the proximal phalanges and intermediate phalanges and a connecting joint for the intermediate phalanges and distal phalanges; the outer layer silicone tube sleeves the inner layer silicone tube and is closely combined with the inner layer silicone tube, and the Kevlar fiber line and the glass fiber cloths are fixed onthe outer wall of the inner layer silicone tube. By loading the drive, a glove achieves simulation of four-finger stretching exercise and assists the four fingers in stretching training.

Owner:HUAZHONG UNIV OF SCI & TECH +1

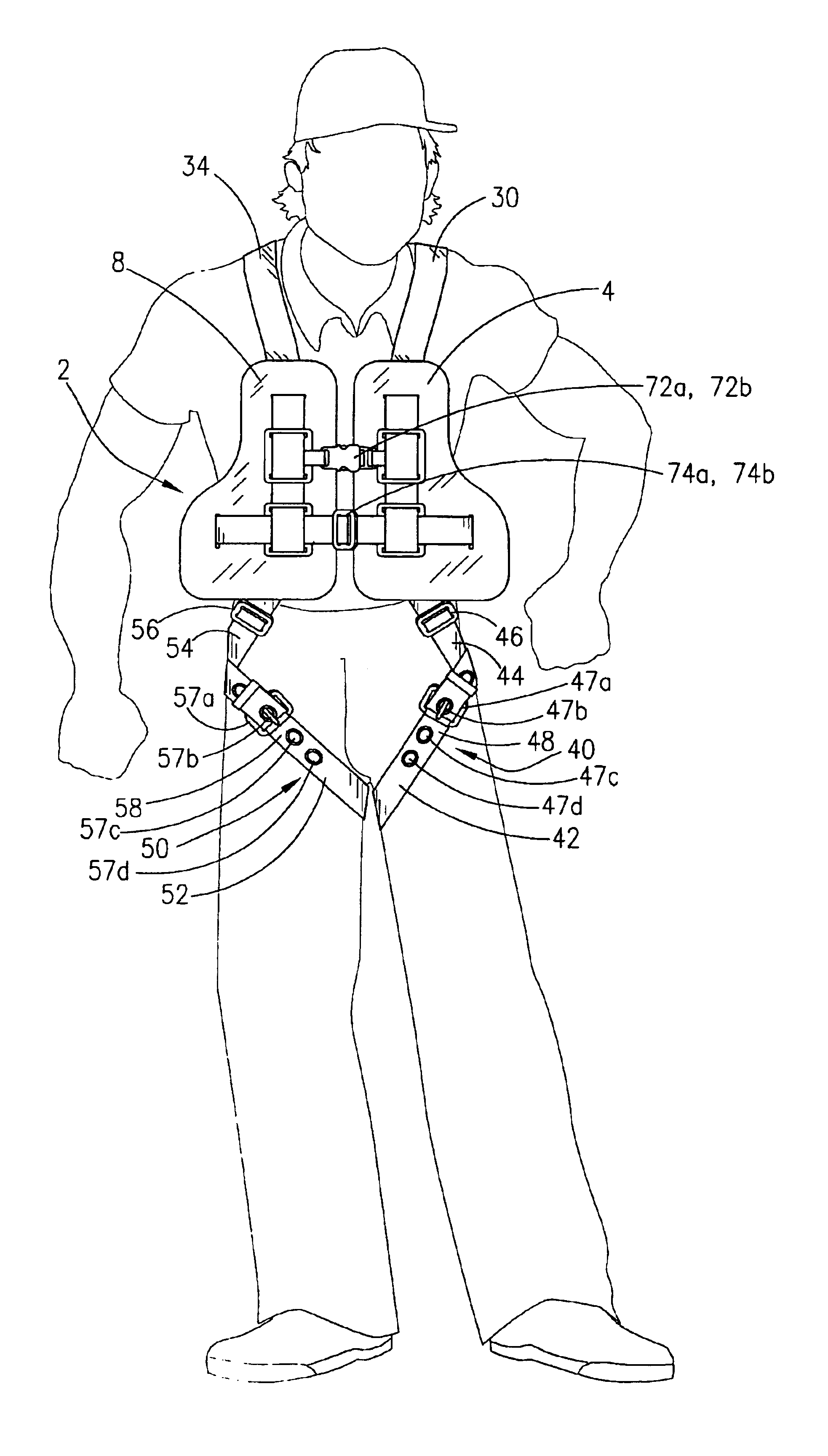

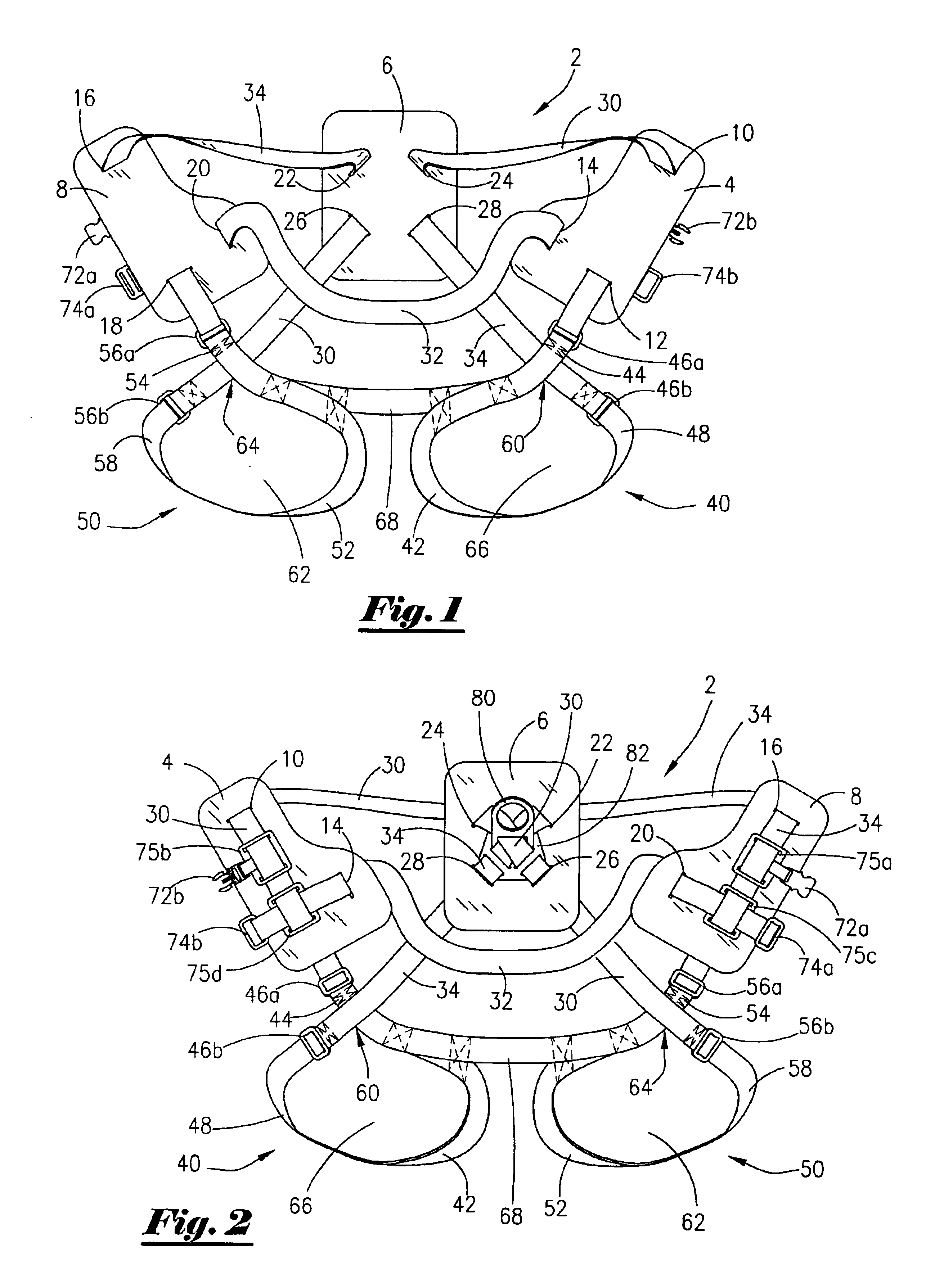

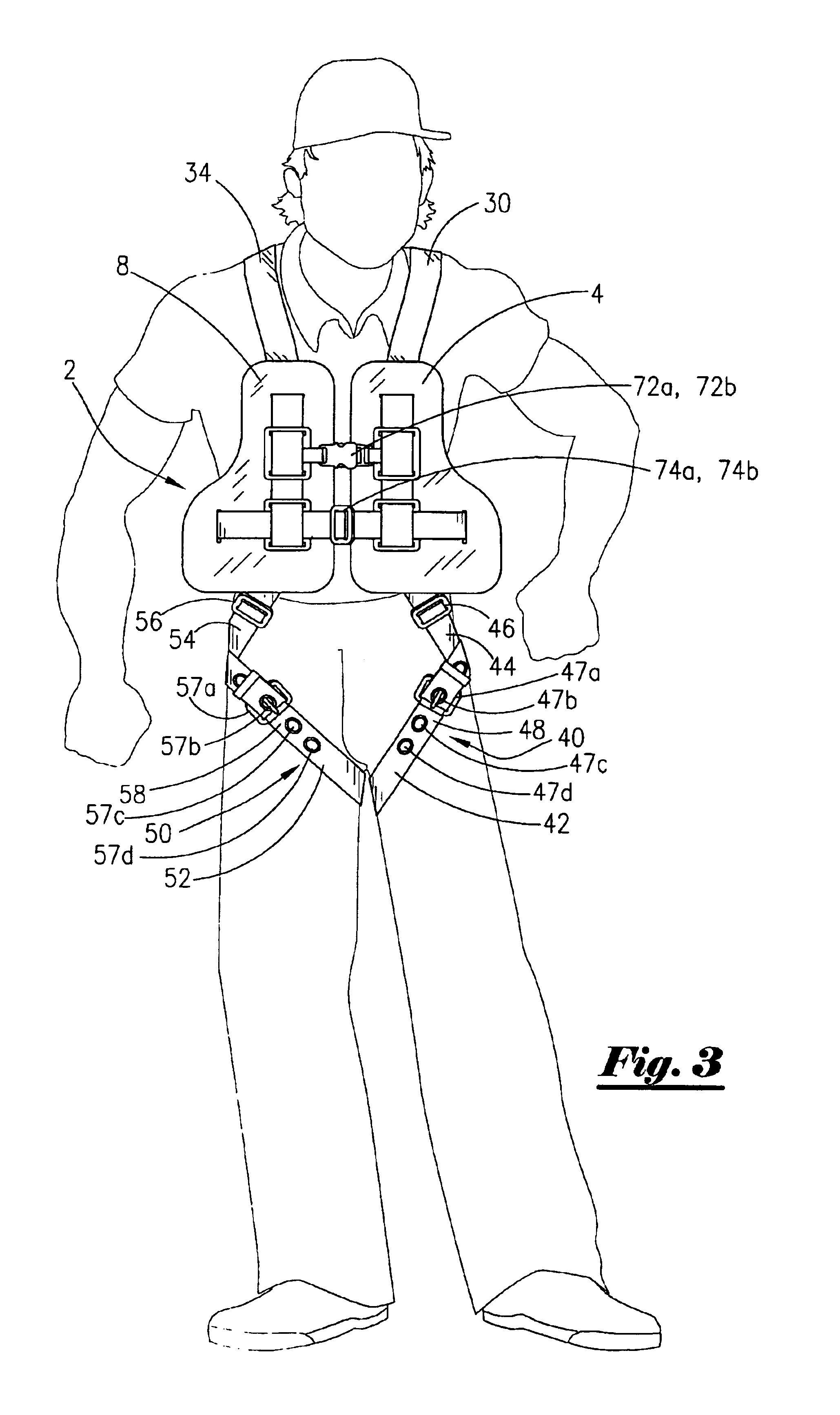

Safety vest and lanyard C-I-P

A safety vest device. The device comprising a right buoyant pad, a center buoyant pad being connected by a first shoulder strap and a left buoyant pad being connected by a second shoulder strap. The device also comprises a right leg strap having an end connected to the right buoyant pad and another end that is connected to the center buoyant pad. Also included is the left leg strap having an end connected to the left buoyant pad and another end that is connected to the center buoyant pad. Also included may be an attaching device that attaches the right buoyant pad to the left buoyant pad. Further, the device may include a ring member attached to the center buoyant pad, and wherein the ring member is configured to attach to a safety lanyard that includes a dielectric component. The device may further comprise a lower strap attached at a first end to the right foam pad and attached at a second end to the left buoyant pad. The lower strap is configured to be inserted through an eyelet in the second end of the left leg strap and through an eyelet in the second end of the right leg strap.

Owner:MILLER DONALD M

Cast steel and method for preparing same

The invention discloses a cast steel and making method, which comprises the following parts: 0.18-0.22% C, 0.30-0.60% Si, 0.90-1.25% Mn, 0.48-0.55% Ni, 0.10-0.25% Cr, not more than 0.10% Mo, not more than 0.040% P, not more than 0.040% S and Fe (0.42-0.48% C). The making method comprises the following steps: 1. allocating; 2. fusing; 3. casting; 4. normalizing. The invention possesses high-strength and high-extending rate, which is fit for casting steel case.

Owner:CHINA NATIONAL HEAVY DUTY TRUCK GROUP

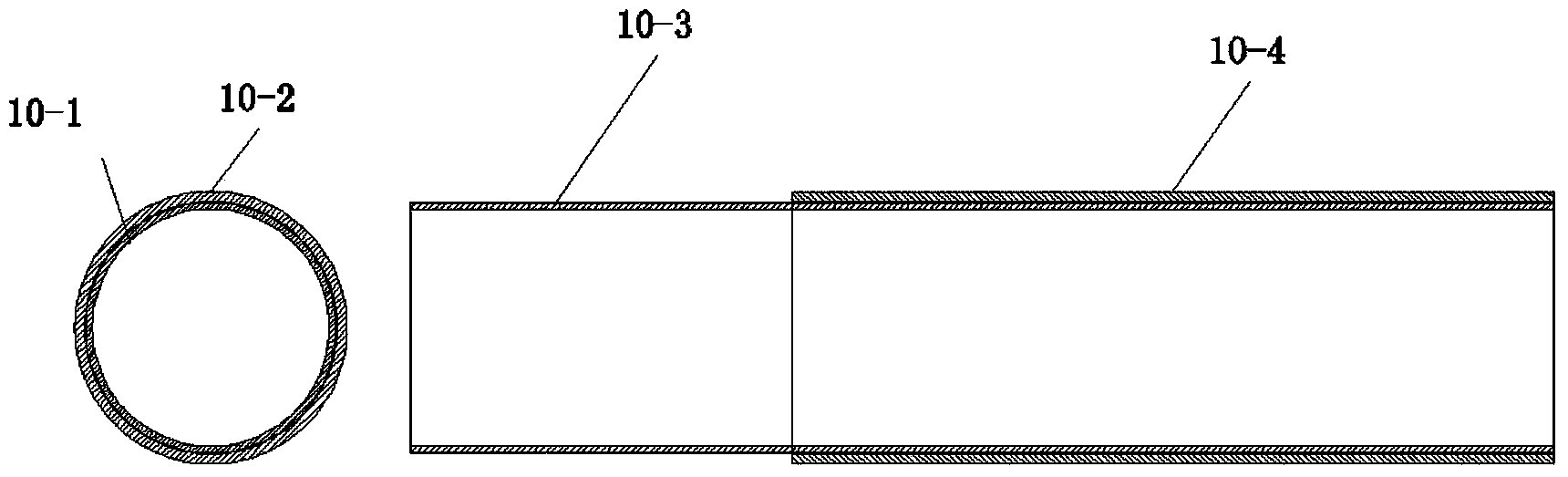

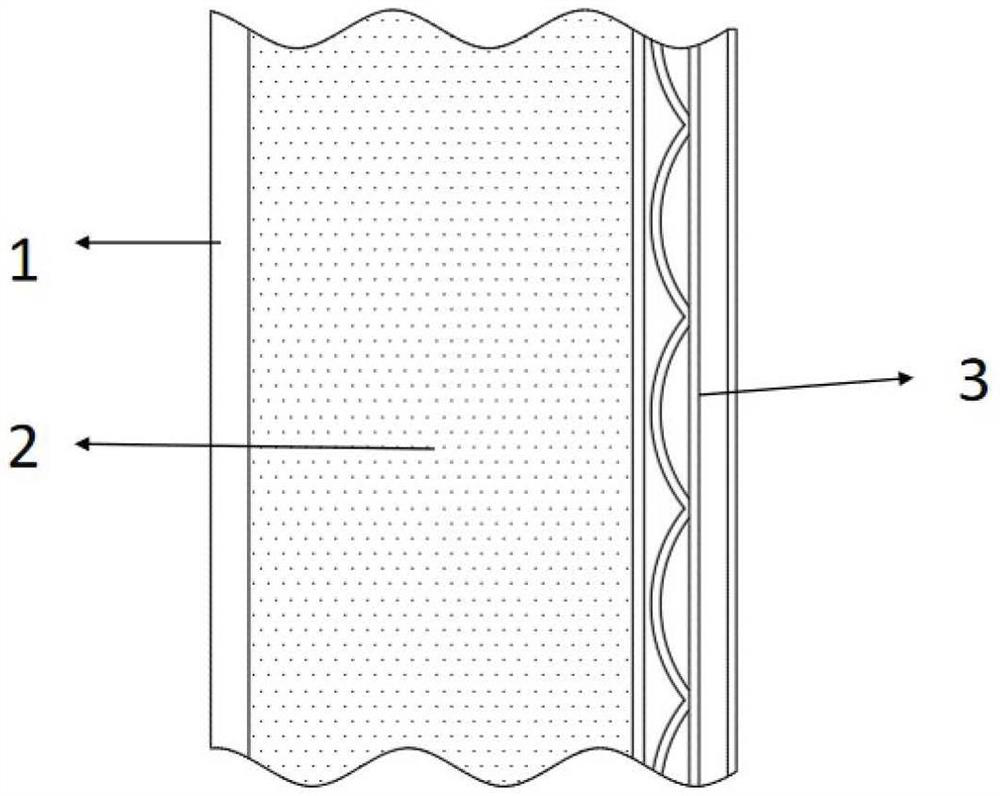

Space debris protection structure

ActiveCN110155375AGuaranteed stabilityLarge impact loadCosmonautic safety/emergency devicesStress concentrationInter layer

The embodiment of the invention provides a space debris protection structure. The protection structure comprises an inner supporting layer, an intermediate layer and an outer protection layer. The inner supporting layer is used for fixing the intermediate layer and provided with a cavity with two open ends, and the cavity is used for accommodating a to-be-protected piece; the intermediate layer isarranged between the inner supporting layer and the outer protection layer and at least composed of cellular structures, the cellular structures are circumferentially arranged on the outer surface ofthe inner supporting layer, and the intermediate layer is at least used for absorbing energy of space debris; and the outer protection layer is circumferentially arranged on the outer surface of theintermediate layer, a smooth transition layer is further arranged on the outer surface of the outer protection layer, and the outer protection layer is used for crushing the space debris. By means ofthe space debris protection structure provided by the embodiment of the invention, the technical problems that an existing space debris protection structure is large in stress concentration, fails toprotect a space cabin comprehensively and fails to meet larger-diameter debris protection requirements can be solved.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

Key-connection combined vertical roll

InactiveCN106694559AOvercome the problem of high production costReduce manufacturing costRollsMetal rolling arrangementsMechanical engineeringBearing capacity

The invention discloses a key-connection combined vertical roll and belongs to the technical field of rolls. The key-connection combined vertical roll comprises a roll shaft and a roll sleeve. The roll sleeve is connected to the outer circumference of the middle of the roll shaft through a key in a matched mode. By adoption of the key-connection combined vertical roll, the problem that the difference between the diameter of a roll body and the diameter of a roll neck of the vertical roll is large, the overall casting gross-to-net ratio is large, and consequentially the production cost is high is solved, the production cost is greatly lowered, the centring performance is good, and the bearing capacity is high.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

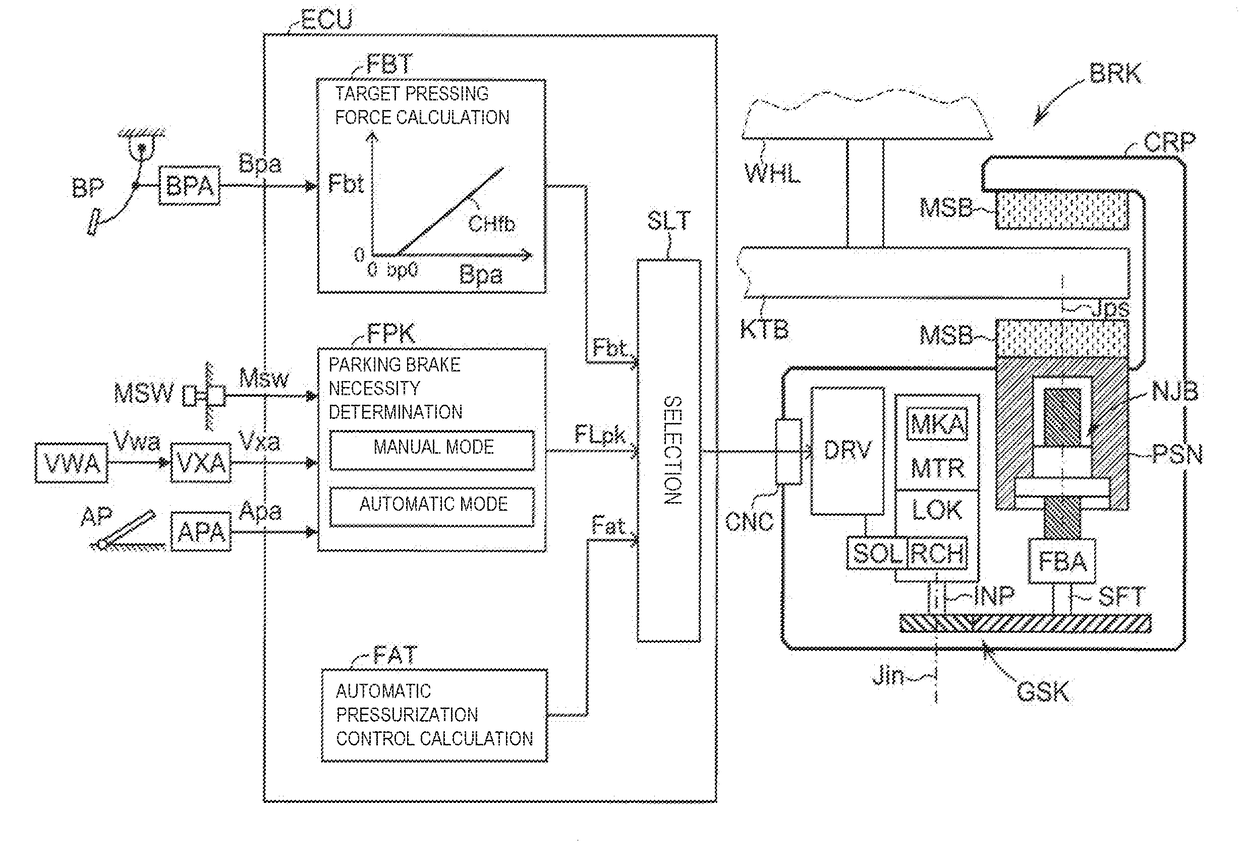

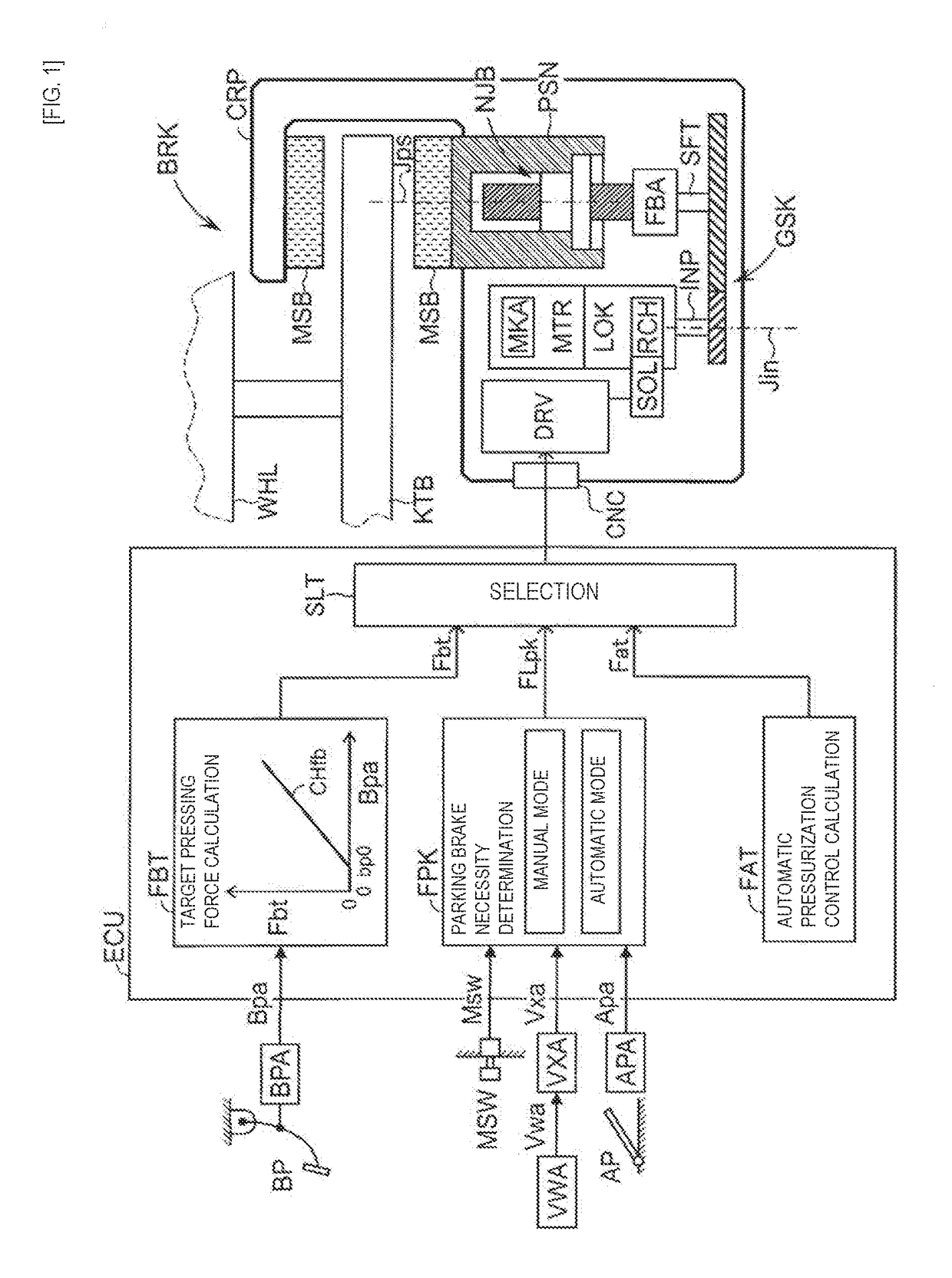

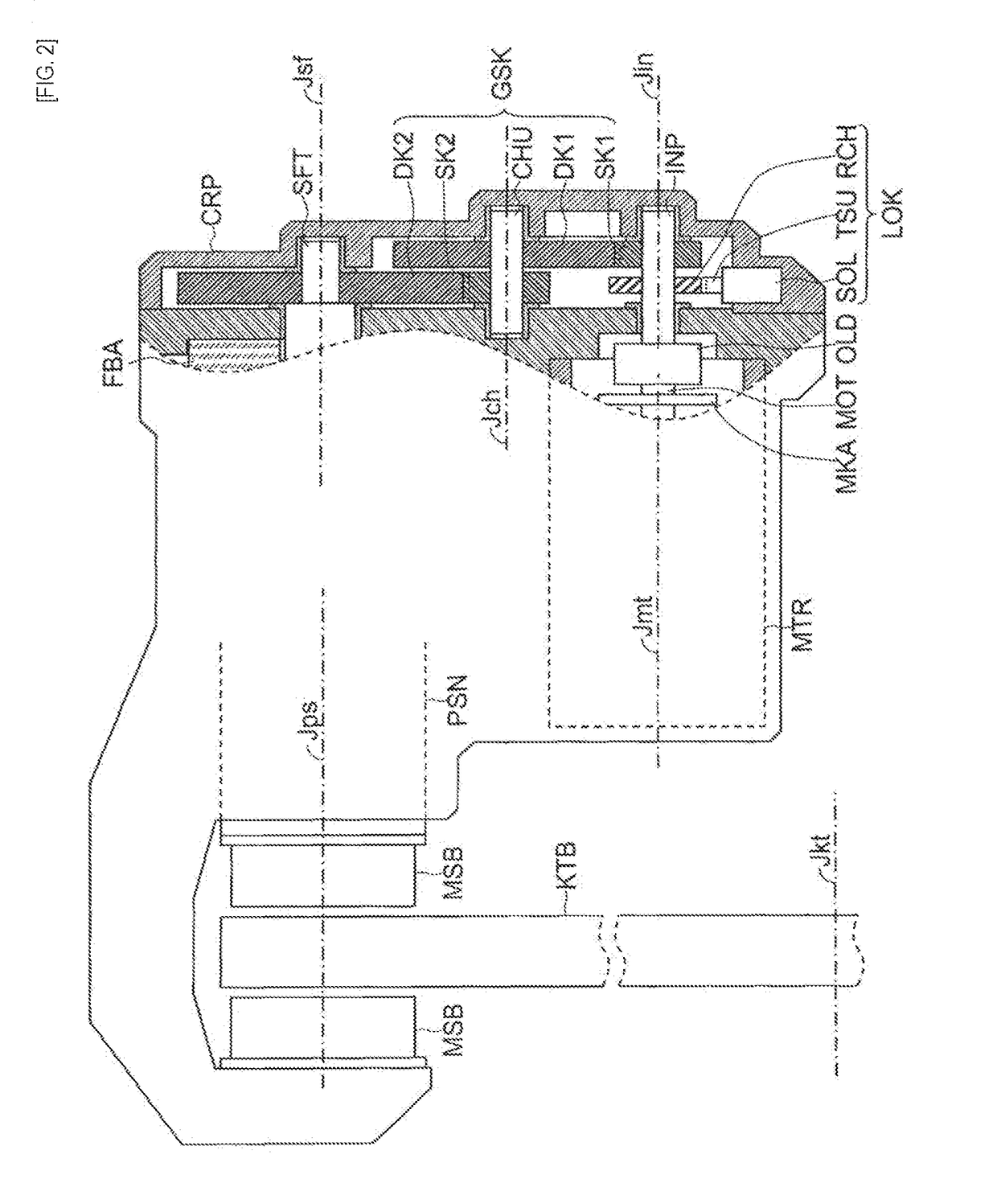

Electric braking device for vehicle

ActiveUS20180215369A1Reduce supplyLarge impact loadBraking action transmissionAutomatic initiationsLocking mechanismTransmitted power

This electric braking device transmits power generated by an electric motor to a pressing member and causes pressing force to be generated by the pressing member with respect to a friction member. The electric braking device includes a lock mechanism. A locked state (in which movement of a locked section in a direction in which pressing force decreases is impossible) is achieved in the lock mechanism by: performing “supplied power amount reduction control” in which the amount of power supplied to the electric motor is reduced while a locking member is maintained in a lockable position; causing the locked section to move in the direction in which pressing force decreases; and causing the locking member and the locked section to engage. When performing supplied power amount reduction control, the amount of power supplied is first reduced by a large reduction gradient and then reduced by a small reduction gradient.

Owner:ADVICS CO LTD

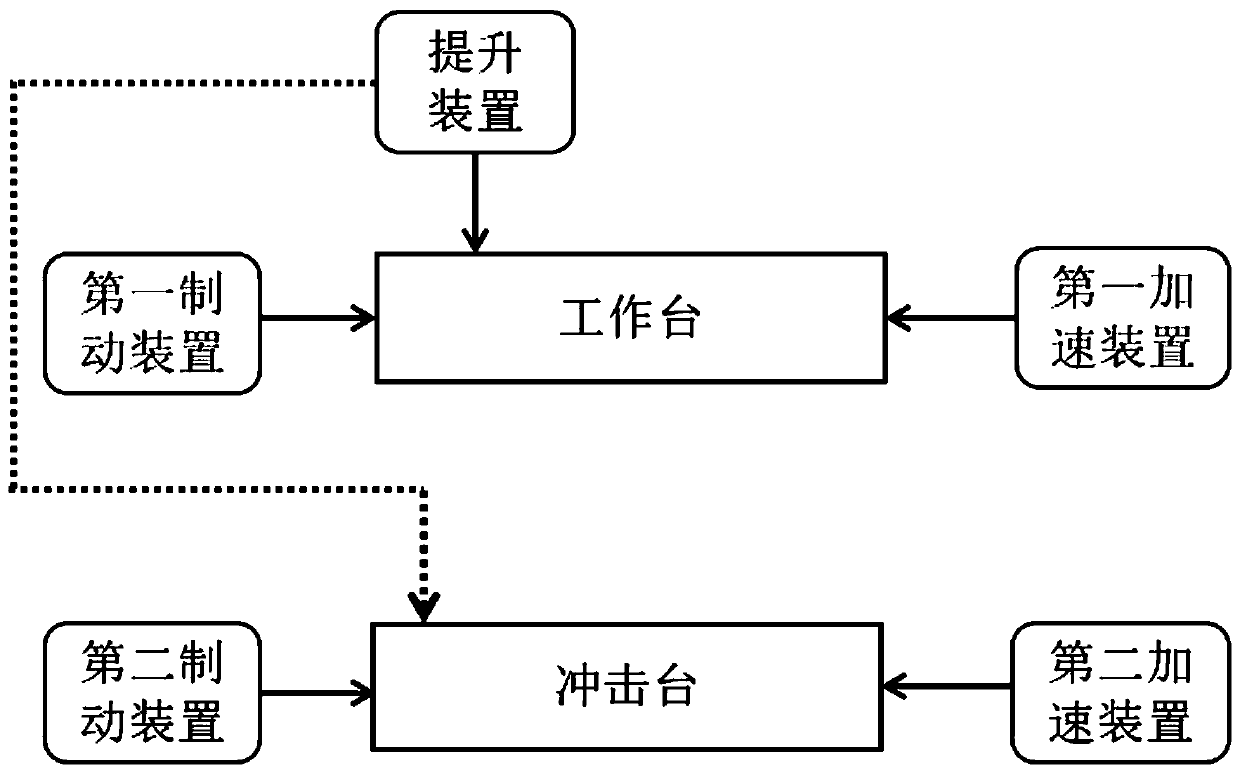

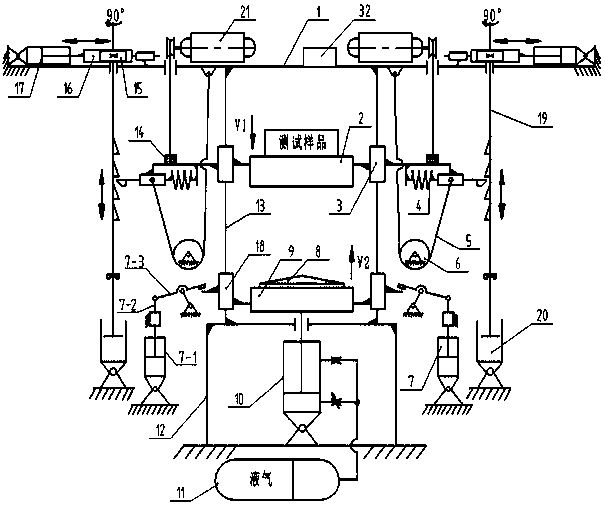

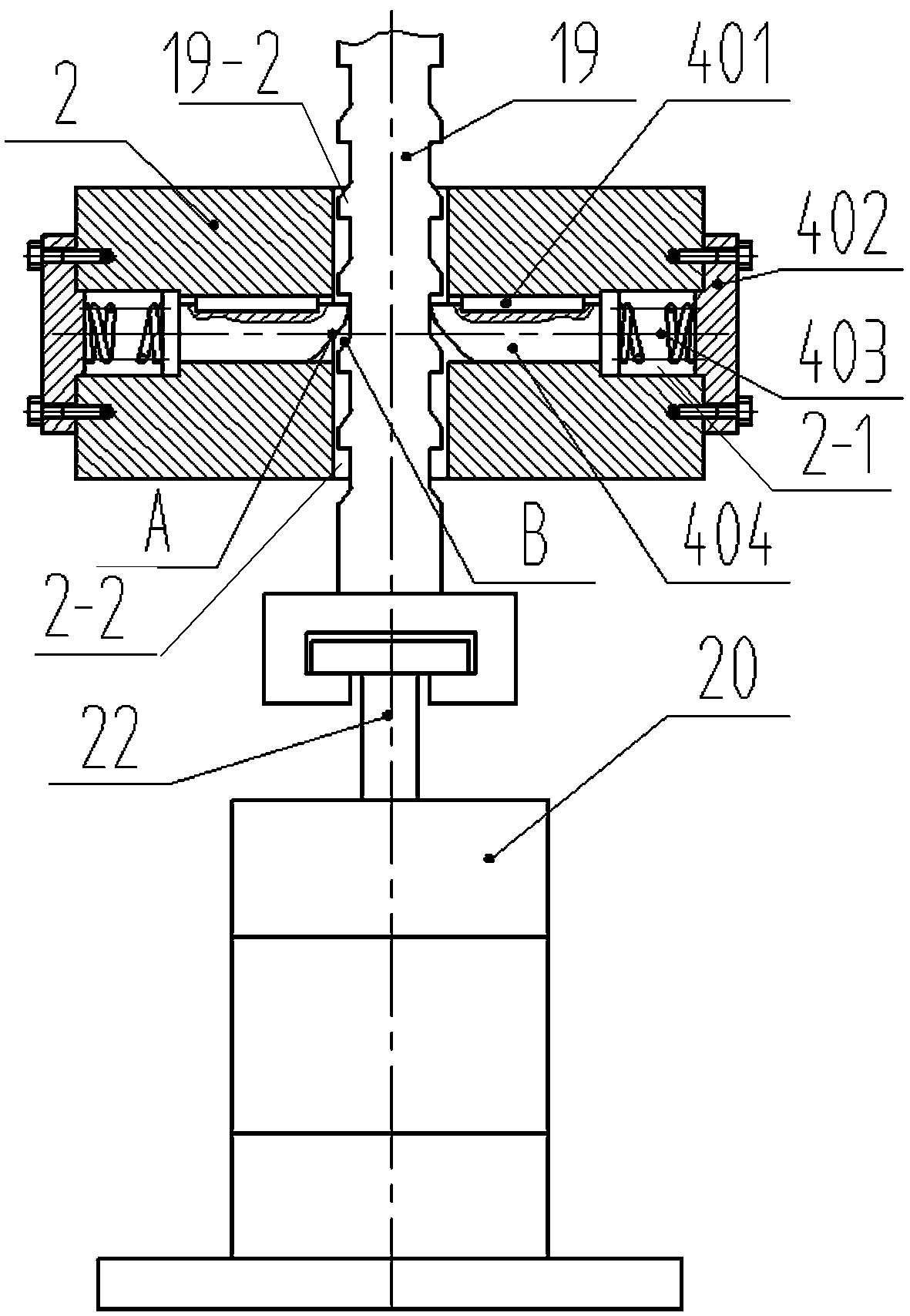

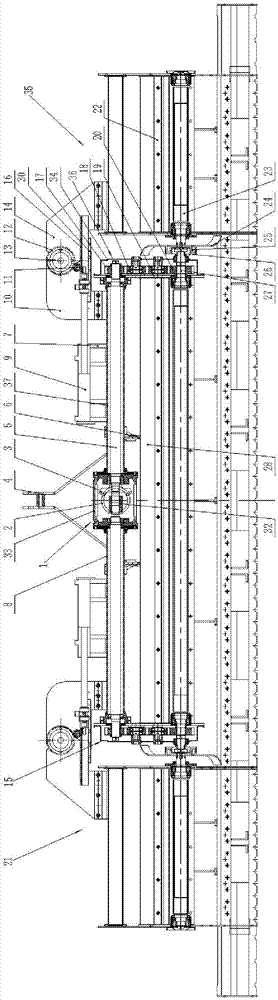

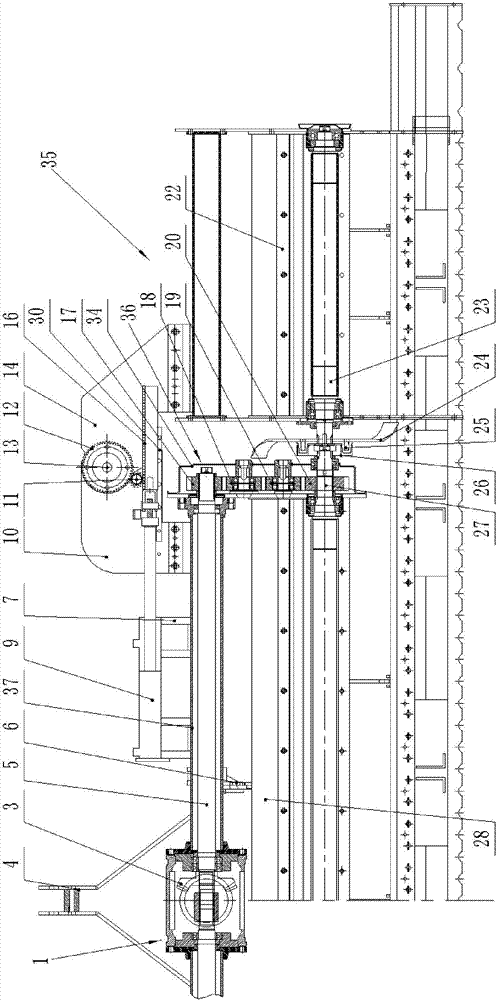

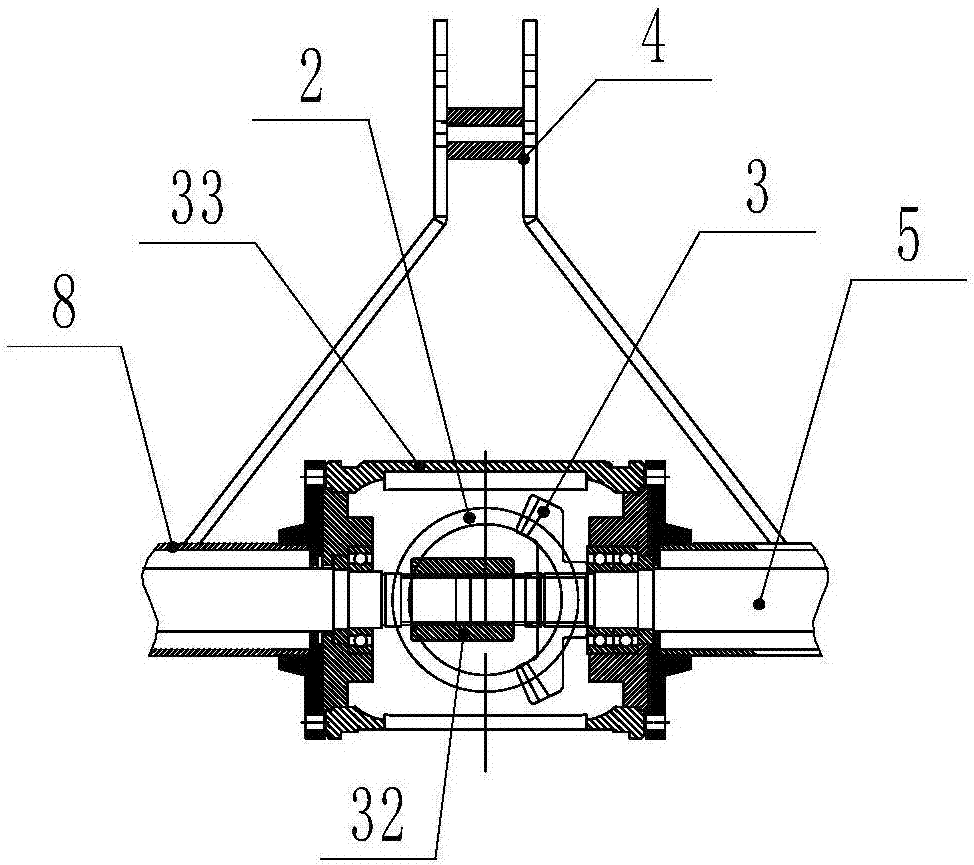

High-speed strong impact testing machine

The invention relates to a high-speed strong impact testing machine which comprises a workbench, an impact table, a lifting device, a rack, a top plate, a first acceleration device and a second acceleration device, the rack and the top plate are connected through a guide column. The guide column is further connected with a workbench and an impact table. One end of the lifting device is arranged onthe top plate; the other end of the lifting device can be connected with or make contact with or be separated from the workbench, one end of the first acceleration device is arranged on the top plate, the other end of the first acceleration device can be connected with or be separated from the workbench, one end of the second acceleration device is arranged on the rack, and the other end of the second acceleration device can make contact with or be separated from the impact table. Three impact effects of light impact, medium impact and high-strength impact can be achieved.

Owner:SHENYANG POLYTECHNIC UNIV

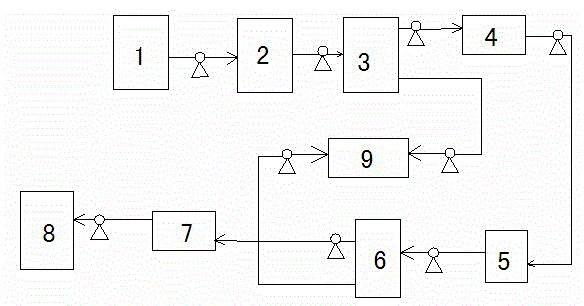

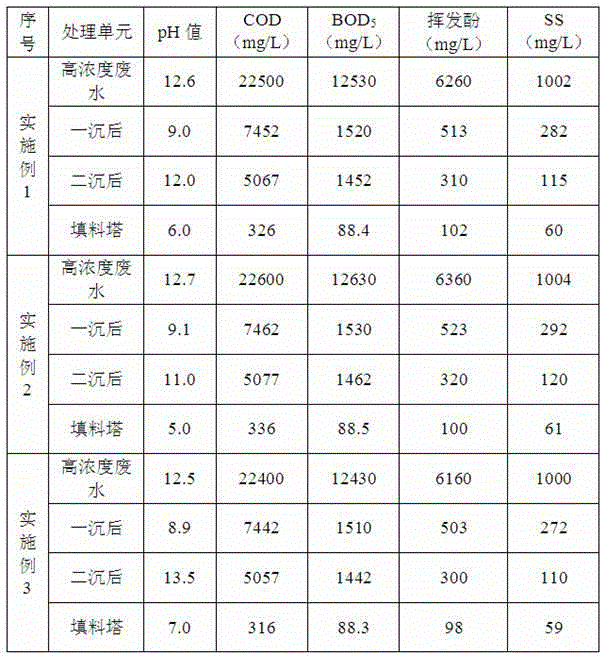

Coking wastewater pretreatment method and coking wastewater pretreatment system

ActiveCN103979712ALarge impact loadPromote improvementMultistage water/sewage treatmentHigh concentrationPretreatment method

The invention relates to a coking wastewater pretreatment method and a coking wastewater pretreatment system and belongs to the technical field of wastewater treatment. The method comprises the following steps: (1) adding a FeSO4 solution into coking wastewater and performing aeration stirring; (2) stirring while adding polyacrylamide until mud and water are layered; (3) adding hydrogen peroxide into an upper-layer solution and stirring; (4) adding Ca(OH)2 for adjusting the pH value to be 11-13.5, and after aerating and stirring to be uniform, stirring while adding polyacrylamide until mud and water are layered; (5) separating out the upper-layer solution, adjusting the pH value to be 5.0-7.0, feeding the upper-layer solution into a filled tower, and adding an active carbon catalyst for performing catalytic reaction for 2-4 hours. The method is safe, simple, efficient and very low in operating cost, and has wide application prospect in treatment of high-concentration wastewater generated in coal chemical industry.

Owner:郑新伟

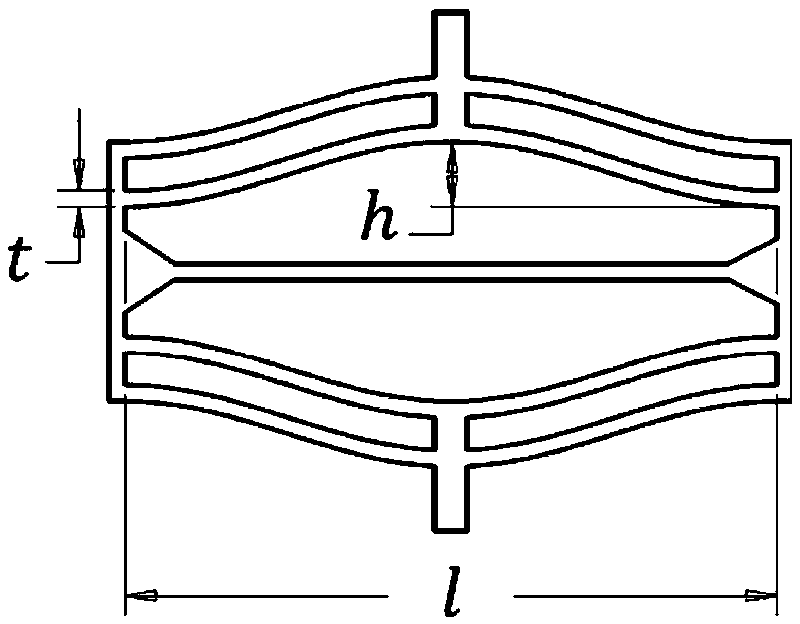

Discharge coil for electromagnetic riveter and production method thereof

The invention discloses a discharge coil for an electromagnetic riveter, wherein the center of the coil is a core tube, an initial end of a copper strip is welded with the core tube, the core tube is The invention discloses a discharge coil for an electromagnetic riveter, wherein the center of the coil is a core tube, an initial end of a copper strip is welded with the core tube, the core tube issiating hole at the center of the coil improves heat dissipation conditions of the coil and reduces the temperature rise speed of the coil; the whole coil is packaged in the shell so as to ensure thatdiating hole at the center of the coil improves heat dissipation conditions of the coil and reduces the temperature rise speed of the coil; the whole coil is packaged in the shell so as to ensure thatthe coil can bear larger impact load; and the design of a partition improves the insulating property of the coil. the coil can bear larger impact load; and the design of a partition improves the insulating property of the coil.urrounded by layers of the copper strip wrapped by glass fabric, the continuous copper strip forms a cake-shaped disc in a shell, a round insulating board is arranged on the cake-shaped disc, the censurrounded by layers of the copper strip wrapped by glass fabric, the continuous copper strip forms a cake-shaped disc in a shell, a round insulating board is arranged on the cake-shaped disc, the center of the insulating board is a through hole matched with the upper end of the core tube, a supporting plate is arranged on the insulating board, an insulating layer is arranged on the supporting plater of the insulating board is a through hole matched with the upper end of the core tube, a supporting plate is arranged on the insulating board, an insulating layer is arranged on the supporting plate, a connecting line is fixedly connected with a countersunk nut on the shell, and the supporting plate is supported against two countersunk square nuts. The invention also discloses a method for prote, a connecting line is fixedly connected with a countersunk nut on the shell, and the supporting plate is supported against two countersunk square nuts. The invention also discloses a method for producing the discharge coil. The countersunk nuts are adopted, so the external dimension of the coil is reduced and the coil can be conveniently arranged into a small-scale electromagnetic riveter; a raducing the discharge coil. The countersunk nuts are adopted, so the external dimension of the coil is reduced and the coil can be conveniently arranged into a small-scale electromagnetic riveter; a rad

Owner:NORTHWESTERN POLYTECHNICAL UNIV

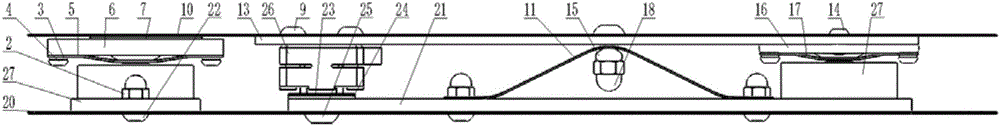

Device for measuring contact force of foot of human body

ActiveCN106473743AEfficient measurementReduce lossesDiagnostic recording/measuringSensorsHuman bodyMeasurement device

The invention relates to a measuring device, particularly to a device for measuring a contact force of a foot of a human body. With the measuring device, problems that costs for manufacturing the existing force-measuring platform and force-measuring shoes are high and the pressure sensor can not measure contact force information effectively in different motion states can be solved. A three-dimensional force sensor and two one-dimensional force sensors are arranged between a bottom steel plate and a top steel plate; a roller pin row structure is arranged right above one of the two one-dimensional force sensors and below the top steel plate; and a roller row gasket is arranged between the roller pin row and the top steel plate. The other one of the two one-dimensional force sensors is arranged below calcaneus, is installed in a circular groove of a bottom carbon plate and is fixedly connected with the bottom steel plate. A rear CM clamp groove is fixedly installed on a lower end surface of the top steel plate by a CM cover plate and is arranged right above one of the two one-dimensional force sensors. A tightening reed is arranged below a foot arch. The device provided by the invention is used for measuring the contact force of the foot of the human body.

Owner:HARBIN INST OF TECH

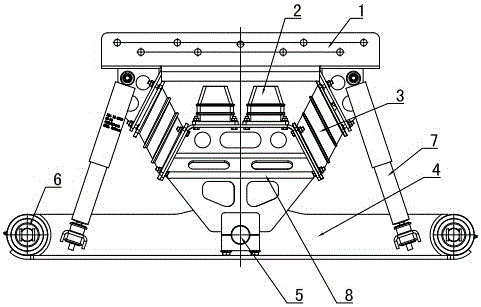

Novel rubber suspension assembly

ActiveCN105109296AHigh hardnessImprove integrityResilient suspensionsManufacturing technologyEngineering

The invention discloses a novel rubber suspension assembly, and belongs to the technical field of manufacture of vehicle parts. The novel rubber suspension assembly is characterized by comprising a rubber suspension fixing and welding plate (1) and a rubber suspension main welding and balancing beam (4) which are mutually arranged in parallel, wherein a rubber suspension main spring (3) is mounted between the rubber suspension fixing and welding plate (1) and the rubber suspension main welding and balancing beam (4); a supporting frame is arranged on the left side of the upper part of the rubber suspension main spring (3), a supporting frame is arranged on the right side of the upper part of the rubber suspension main spring (3), the two supporting frames are connected with two end parts of the rubber suspension fixing and welding plate (1) respectively, and a rubber suspension auxiliary spring (2) is vertically arranged at the middle position of the corresponding supporting frame; the lower part of the rubber suspension main spring (3) is connected to the middle position of the rubber suspension main welding and balancing beam (4).The novel rubber suspension assembly is light in structure, long in service life and convenient to maintain and preserve, and the novel rubber suspension assembly conforms to light weight requirements.

Owner:山东安博机械科技股份有限公司

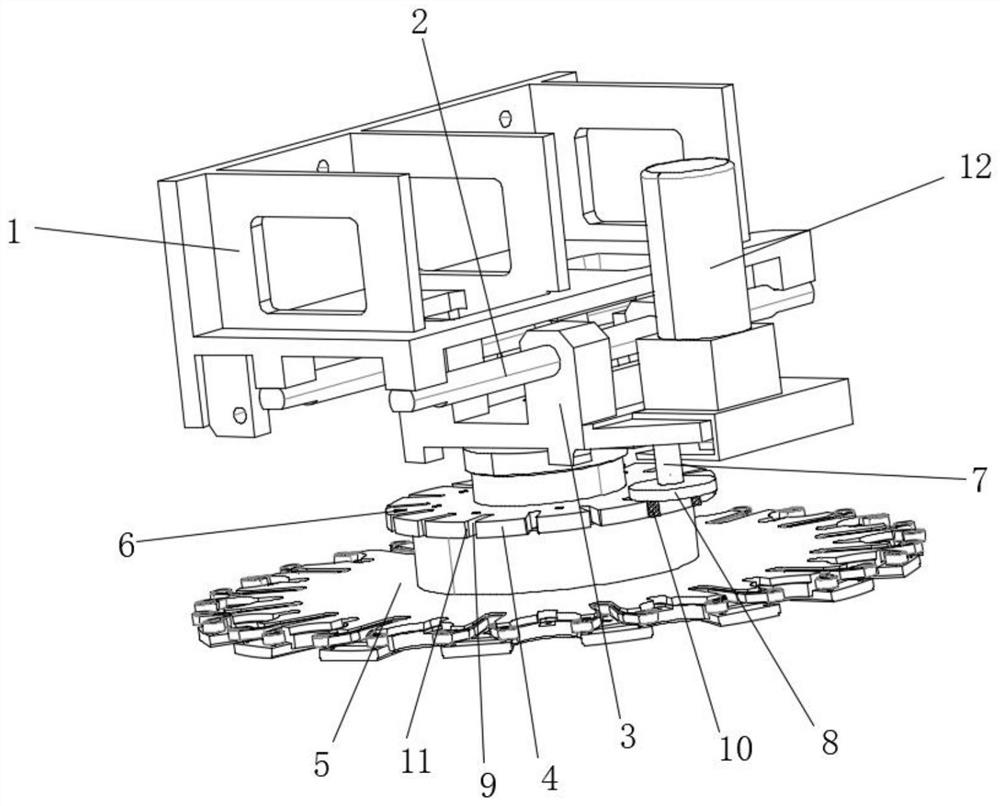

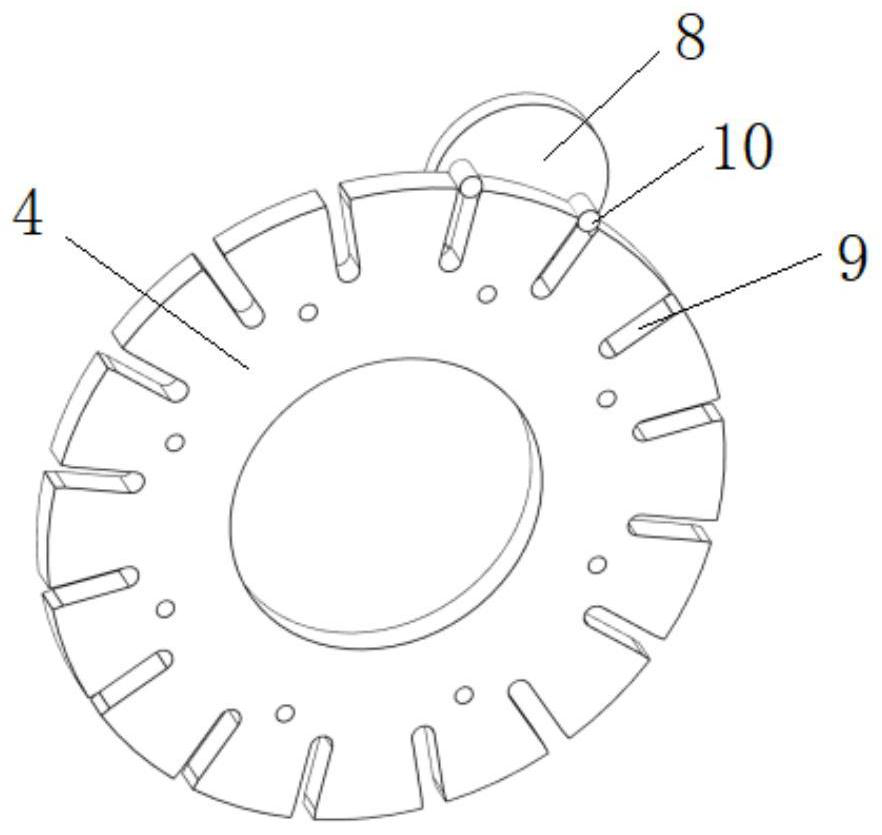

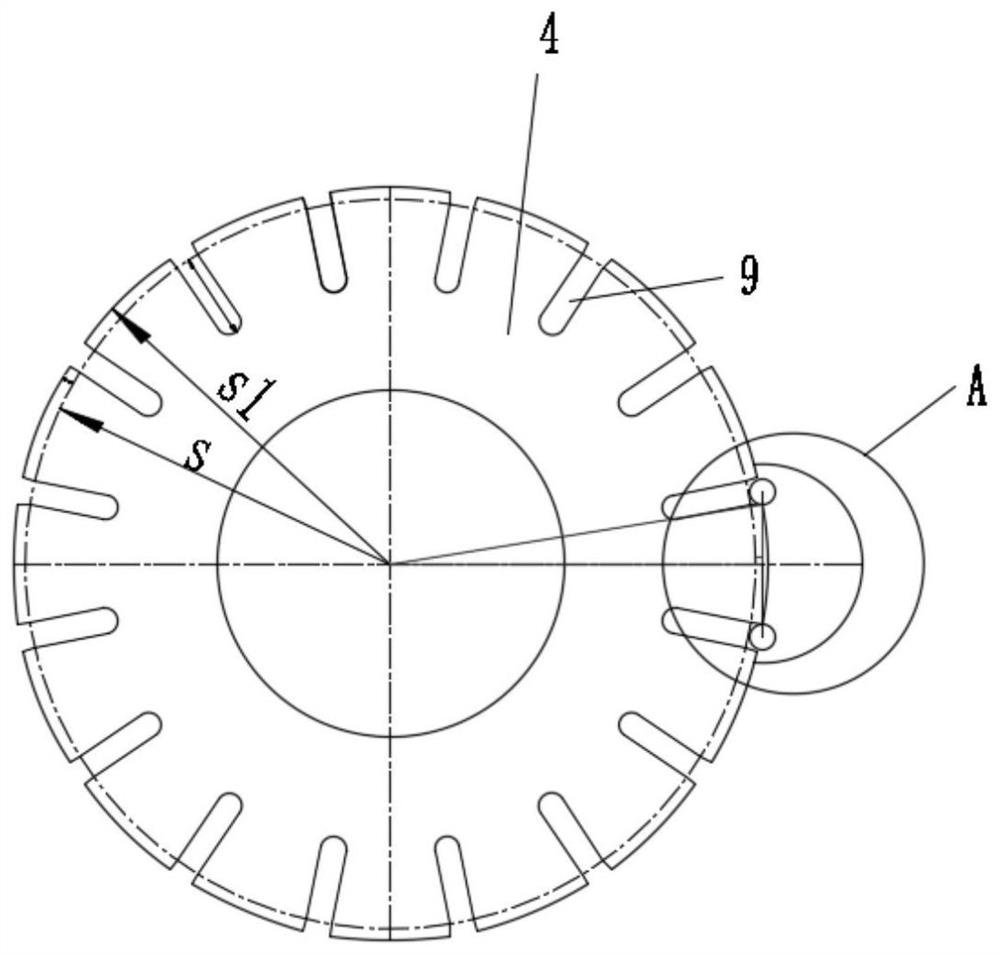

High-stability tool changer rotating indexing mechanism

InactiveCN111975425AFast tool changeReduce shock loadPositioning apparatusMetal-working holdersEngineeringStructural engineering

The invention discloses a high-stability tool changer rotating indexing mechanism. The mechanism comprises a substrate; a pair of slide rails is arranged at the bottom of the substrate; a moving seatis arranged between the slide rails; a rotating indexing disc is arranged at the bottom of the moving seat; a tool changer disc is fixed at the bottom of the rotating indexing disc; an indexing inversion mechanism is arranged on the moving seat and drives the rotating indexing disc to rotate; the indexing inversion mechanism comprises a stirring disc which is arranged at the bottom of the moving seat via a rotating shaft; n concave grooves are equidistantly formed in the rotating indexing disc and n > 8; two symmetrically arranged round pins which are engaged with the concave grooves are arranged on the stirring disc; and transition circular arcs are formed in the outer end parts of the concave grooves, so the concave grooves extend outwardly to form modifying grooves. Through the arrangement that the transition circular arcs are formed in the outer end parts of the concave grooves and that the concave grooves extend outwardly to form modifying grooves, the impact load of engagement between the round pins and the concave grooves is effectively lowered, so abrasion is lowered and durability is improved.

Owner:ZHEJIANG UNIV CITY COLLEGE

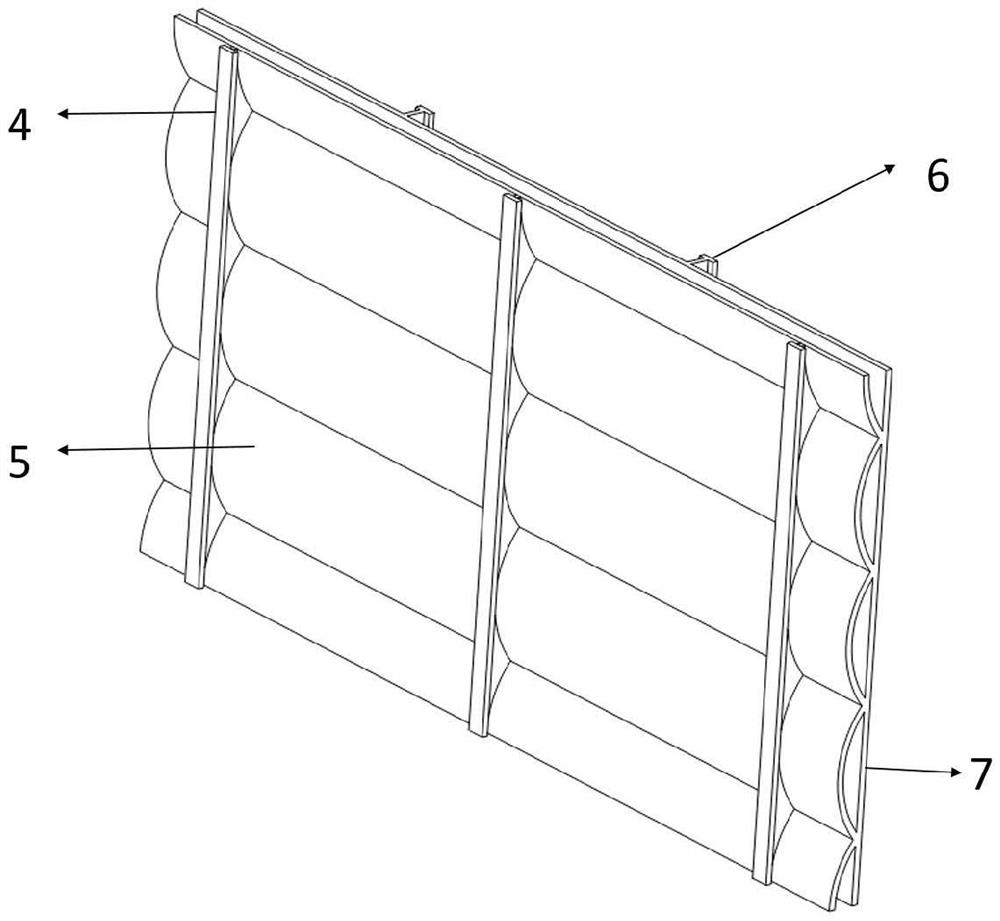

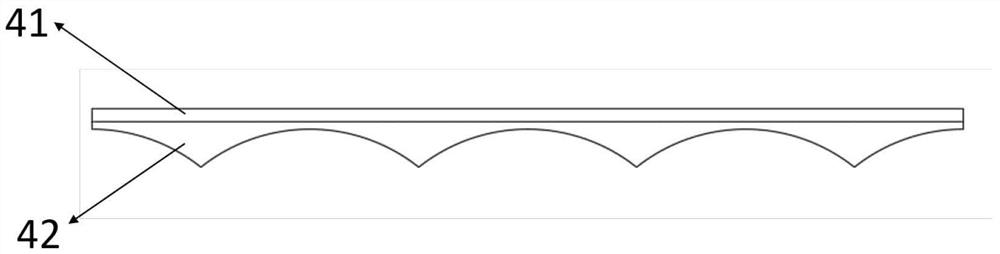

Arc-shaped reinforced pressure-resistant bulkhead structure capable of resisting underwater explosion impact bending

ActiveCN114212186AImprove water tightnessShock resistanceHull bulkheadsUnderwater explosionDetonation

The invention discloses an arc-shaped reinforced pressure-resistant bulkhead structure capable of resisting underwater explosion impact bending, and belongs to the technical field of ship structure protection. The problem that an existing liquid tank inner plate is poor in protection force is solved. The protective structure is fixedly arranged on one side, close to a protective liquid tank, of the inner panel, the first reinforcing ribs are located on the side of the protective structure, the second reinforcing ribs are located on the side of the inner panel, and the protective structure comprises a plurality of arc-shaped supporting plates which are horizontally arranged and are in butt joint side by side from top to bottom; the first reinforcing rib and the protection structure are fixedly connected in a gapless mode, and the second reinforcing rib and the inner panel are fixedly connected in a gapless mode. According to the reinforced pressure-resistant bulkhead structure with the arc-shaped supporting plates, shock waves and bubble loads generated in the detonation process and fragment penetration can be more efficiently resisted, in addition, the reinforced pressure-resistant bulkhead structure is provided with a two-layer structure, and for fragments with higher quality and higher speed, the reinforced pressure-resistant bulkhead structure is equivalent to a two-layer bulkhead barrier, so that the service life of the bulkhead structure is prolonged, and the service life of the bulkhead structure is prolonged. And fragment energy is absorbed by the arc-shaped supporting plate and the inner panel in sequence, so that the water tightness of the liquid tank is enhanced.

Owner:HARBIN ENG UNIV

Composite material for accelerating formation of aerobic granular sludge as well as preparation method and application of composite material

PendingCN114368831AReduce incubation timeEasy to passSustainable biological treatmentBiological water/sewage treatmentAeration ratePorous carbon

The invention provides a composite material for accelerating formation of aerobic granular sludge as well as a preparation method and application of the composite material. According to the invention, an aerobic granular sludge rapid construction system based on the porous carbon and iron-based material composite nanomaterial is constructed, and the porous carbon and the iron-based material are added to prepare the composite nanomaterial, so that the forming speed of the aerobic granular sludge is remarkably increased; compared with the composite nano material which is added with an inert material and is not added with the material, the time of the composite nano material prepared by the invention is shortened by 30-50%. The prepared aerobic granular sludge is good in stability after being mature and can resist large impact loads, the quality of treated sewage reaches the first-grade A standard, the treatment capacity on conventional pollutants is improved by 10%-30%, and compared with a conventional aerobic granular sludge technology, the aeration rate and occupied land are saved, and energy consumption is reduced by 10%-30%.

Owner:SHIHEZI UNIVERSITY

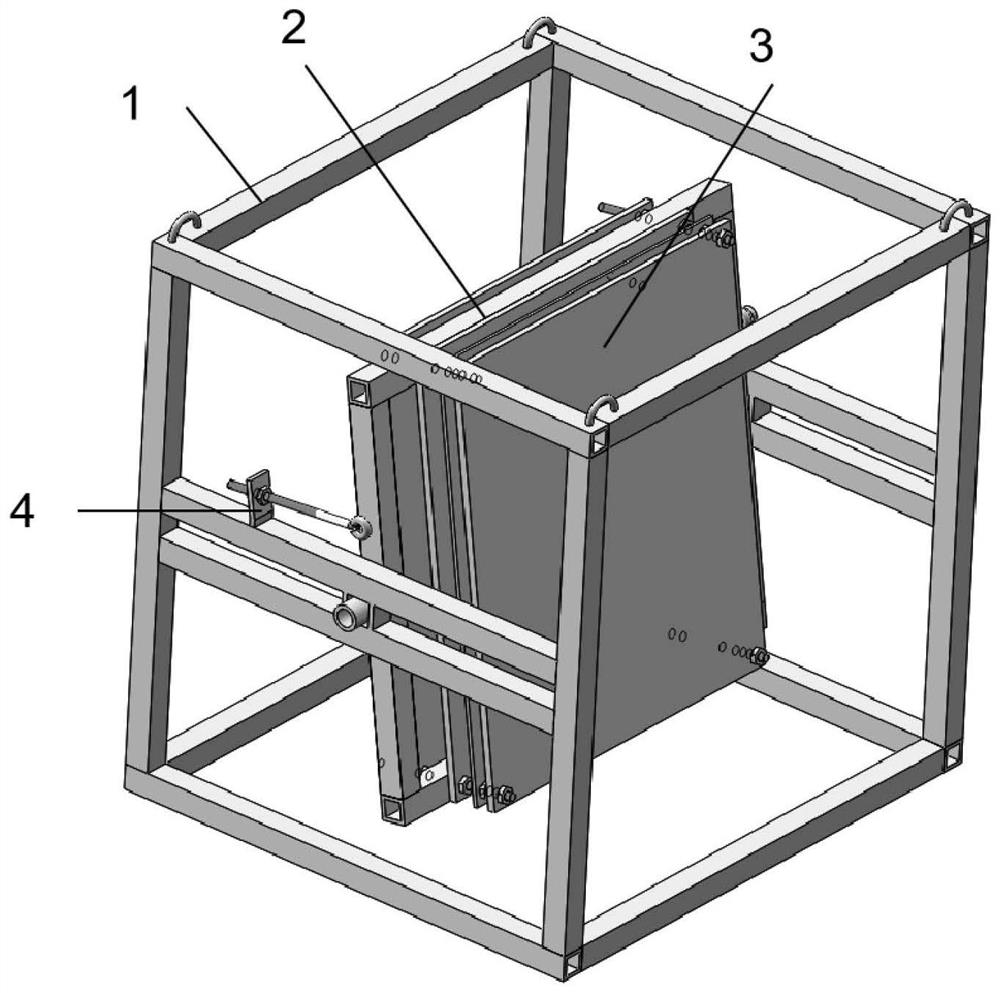

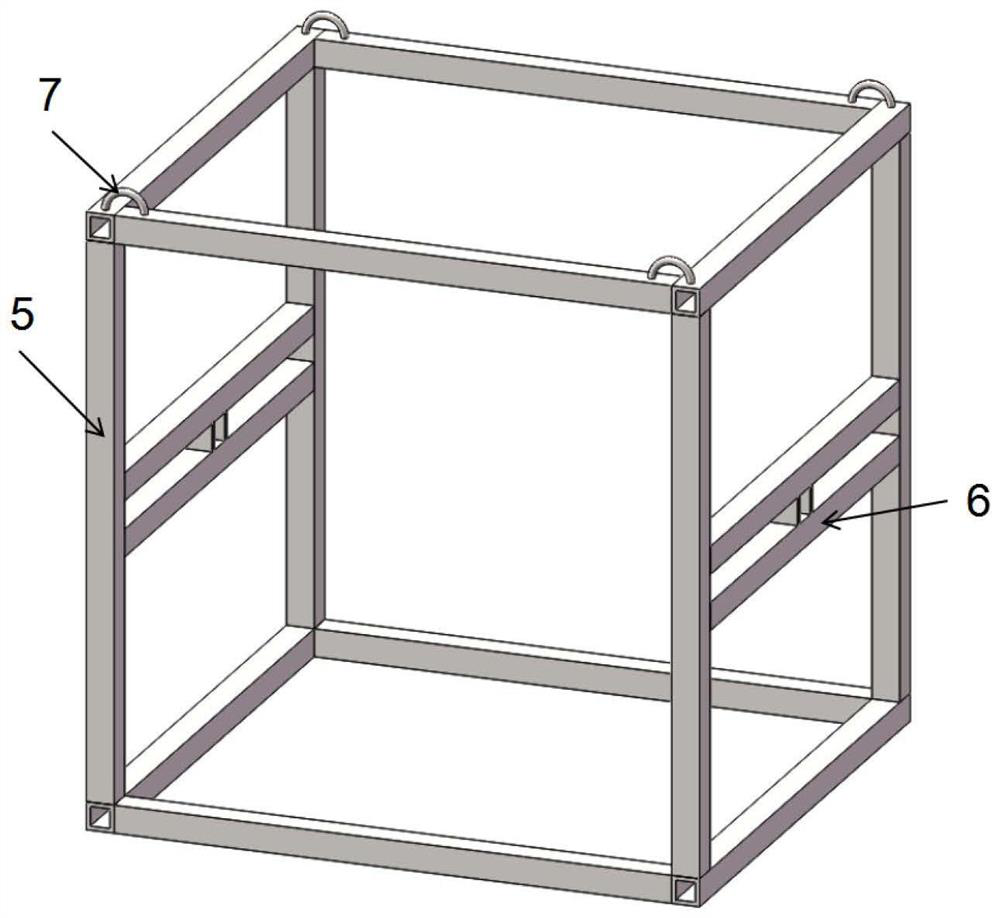

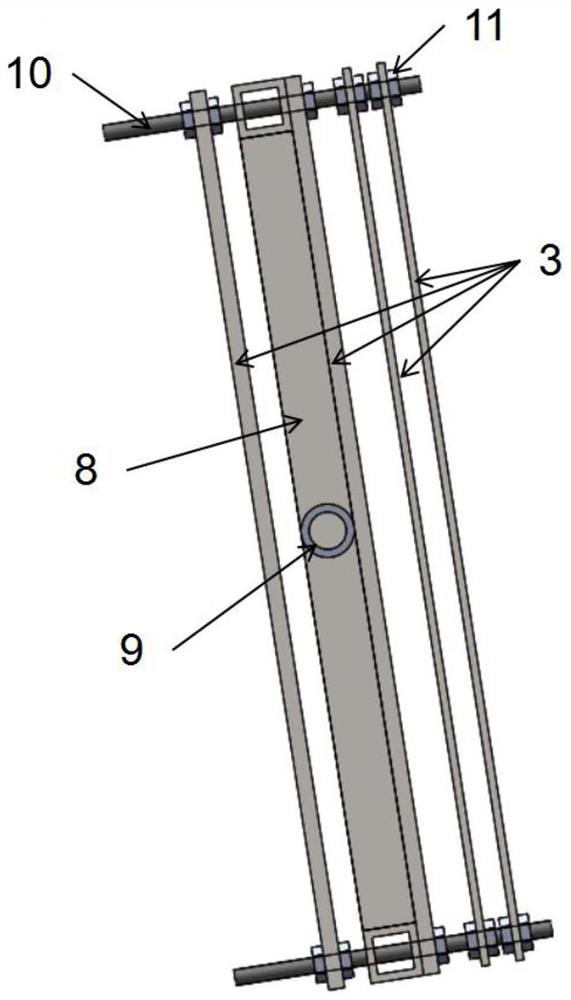

Intercepting and recycling device for high-speed water entry model test

PendingCN114112294AReduce shock loadEasy to take outHydrodynamic testingWater entryUnderwater vehicle

The invention discloses an intercepting and recycling device for a high-speed water entry model test, and belongs to the technical field of high-speed water entry tests of underwater vehicles. Comprising an intercepting frame, an intercepting plate frame, an intercepting plate and an intercepting plate angle adjusting device. The intercepting frame is of a frame structure, the intercepting plate frame is a rectangular frame, the two ends of the intercepting plate frame are connected into the intercepting frame through intercepting plate angle adjusting devices and rotating round pipes and can rotate relatively, an intercepting plate is embedded in the intercepting plate frame, two layers of intercepting plates are fixed right in front of the front side end face of the intercepting plate frame in parallel, and a layer of intercepting plate is fixed right behind the rear side end face of the intercepting plate frame in parallel. The two rotating circular pipes are vertically fixed to the middles of the two sides of the intercepting plate frame correspondingly; the angle of the intercepting frame is adjusted by adjusting the screwing-in length of an angle adjusting rod in the intercepting plate angle adjusting device. According to the device, the underwater model can be effectively intercepted and recycled, it is guaranteed that the main body structure of the model is not damaged, and the device is simple in structure and easy to use.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

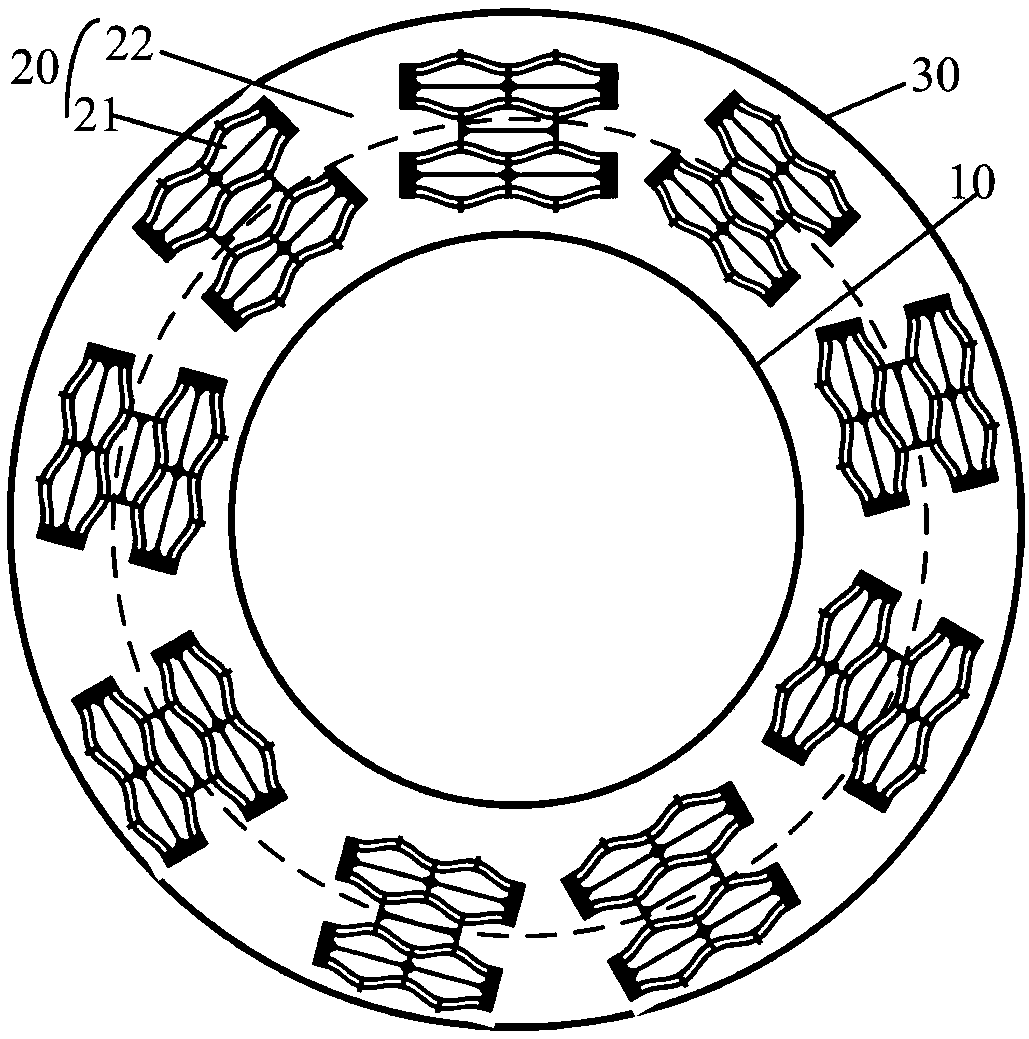

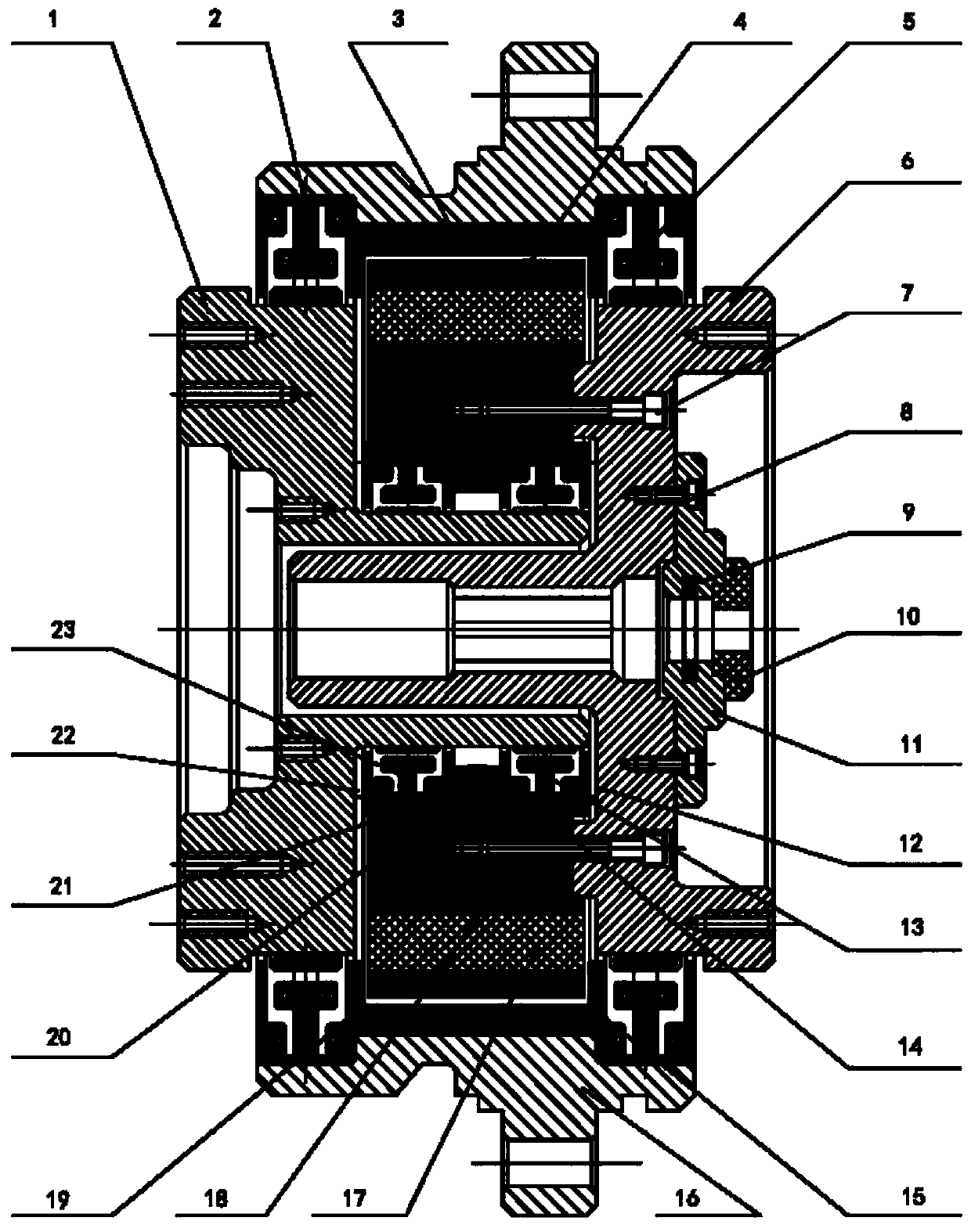

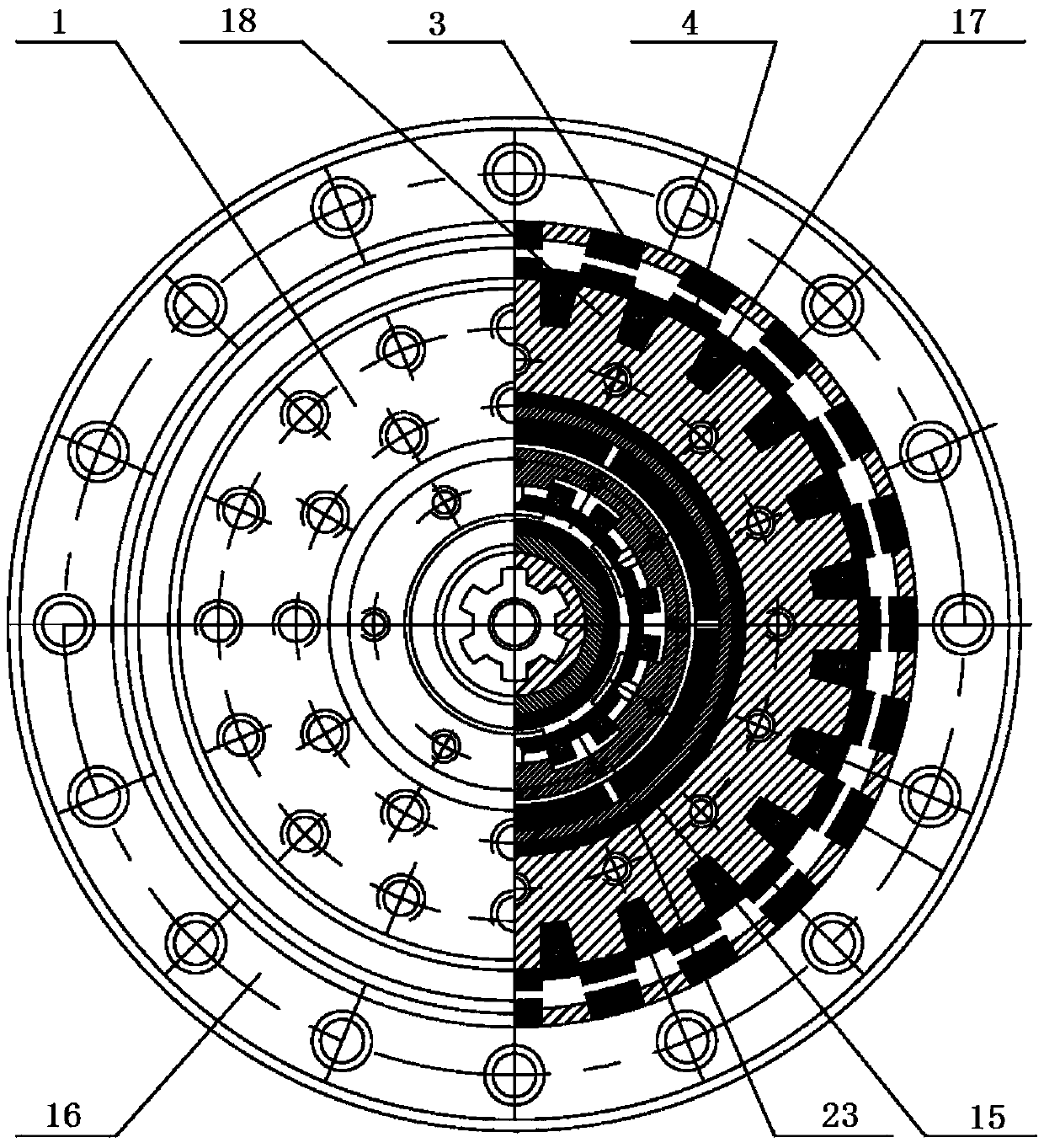

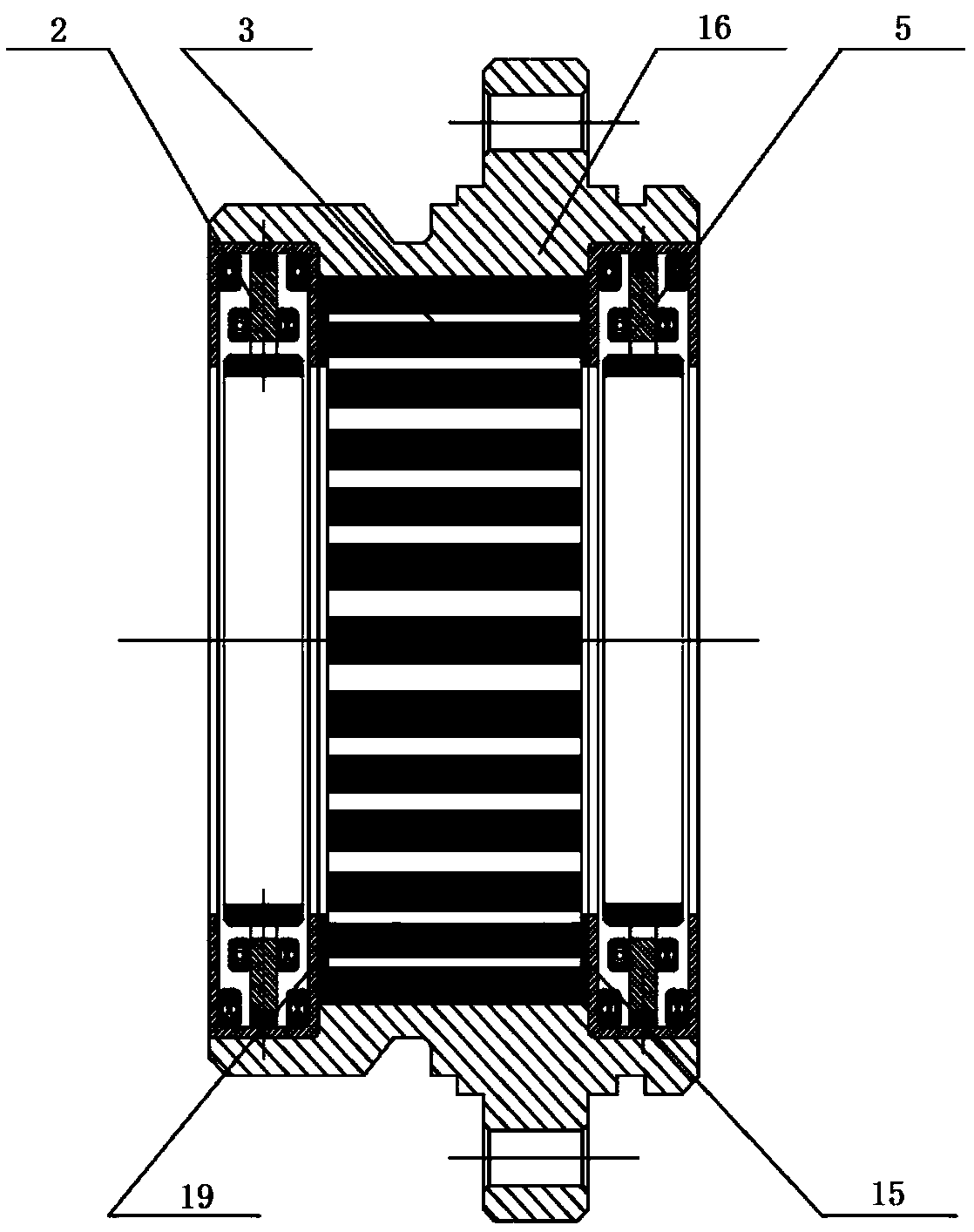

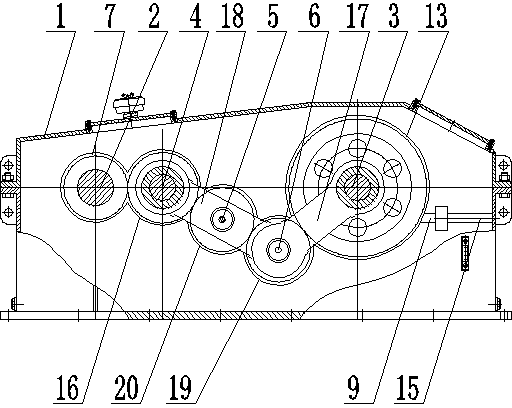

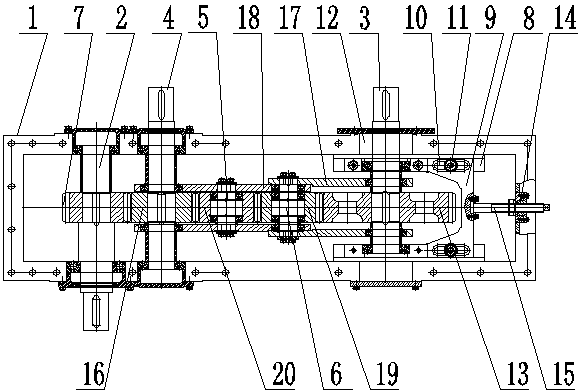

Magnetic suspension intelligent flexible reducer system of robot and control method thereof

PendingCN109676612ASolve lossSolve replacementProgramme-controlled manipulatorReduction driveData acquisition

The invention provides a magnetic suspension intelligent flexible reducer system of a robot and a control method of the magnetic suspension intelligent flexible reducer system of the robot. The magnetic suspension intelligent flexible reducer system of the robot comprises an intelligent flexible reducer system and an intelligent control electrical system. The intelligent flexible reducer system comprises a precise mechanical reducer and a magnetic suspension transmission system. The intelligent control electrical system comprises a man-machine interaction system, a remote wireless communication system, a data collection and feedback system, a control system and a mechanism execution system. The magnetic suspension intelligent flexible reducer system of the robot adopts an advanced intelligent control technology and conducts intelligent control and automatic operation, real-time data collection, storage, display, remote wireless communication, data transmission and control of displacement change of a reducer rotating shaft are adopted, the magnetic suspension intelligent flexible reducer system of the robot has the functions of system self-actuator variation stability control and fault self-diagnosis, all tasks of the magnetic suspension intelligent flexible reducer of the robot are achieved, and the magnetic suspension intelligent flexible reducer system of the robot provides the indispensable effective and reliable key equipment for intelligent manufacturing, environmental protection and energy saving.

Owner:谢立波

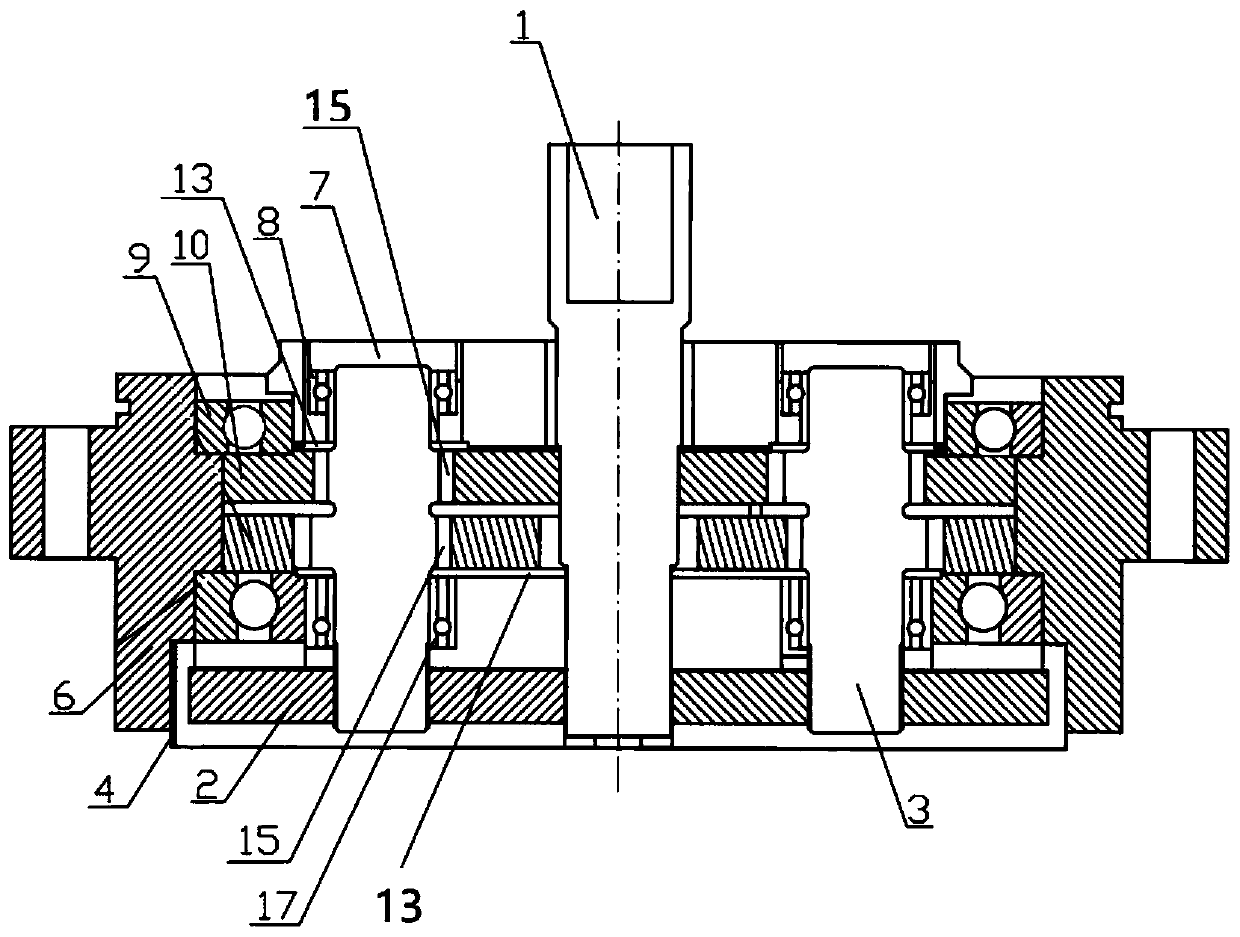

Parallel shaft speed reducer adjustable in center distance

The invention relates to a parallel shaft speed reducer, in particular to a parallel shaft speed reducer adjustable in center distance. The parallel shaft speed reducer is composed of a speed reducer shell, an input shaft, an output shaft A, an output shaft B, a mandrel A and a mandrel B, the input shaft is mounted at one end in the speed reducer shell, slide rails are mounted at the other end in the speed reducer shell, a baseplate is mounted on the slide rails, the output shaft A is mounted on the upper surface of the baseplate, the output shaft B is mounted between the input shaft and the output shaft A, a connecting rod A is mounted on the output shaft A, a connecting rod B is mounted on the output shaft B, the mandrel A is fixedly mounted on the connecting rod B, and the connecting rod A and the connecting rod B are connected through the mandrel B. Adjusting of various center distances can be realized through the connecting rod A and the connecting rod B, so that the problems that existing speed reducers with standard center distances are often limited by space and cannot be used and custom-making of speed reducers with nonstandard center distances is high in price are solved, and application range is expanded. The parallel shaft speed reducer adjustable in center distance has the advantages of simple structure, high efficiency, stability in operating, small impact and large impact load.

Owner:YANGTZE UNIVERSITY

Optical mirror magnetic suspension supporting device

InactiveCN109531343AReduce negative impactAvoid destructionOptical surface grinding machinesEngineeringPrimary mirror

The invention discloses an optical mirror magnetic suspension supporting device. The optical mirror magnetic suspension supporting device comprises an axial electromagnetic guiding device, a radial electromagnetic guiding device and an optical mirror fixing device. In the axial electromagnetic guiding device, electromagnets I are uniformly mounted on a bottom plate at the lower end of the opticalmirror fixing device, and permanent magnets I are uniformly mounted at the bottom of the optical mirror fixing device. In the radial electromagnetic guiding device, electromagnets II are uniformly mounted on the inner sides of vertical mounting plates on the edge of an electromagnet mounting frame through screws, and permanent magnets II are uniformly mounted on the outer wall of the optical mirror fixing device through set screws. The side face of an optical mirror to be processed is limited and fixed to the optical mirror fixing device through locking screws. The optical mirror magnetic suspension supporting device can implement height supporting and posture adjustment on the mirror in the optical primary mirror processing process. The supporting device is effectively protected against damage caused by processing impact or vibration through flexible supporting. Meanwhile, the problems of friction, leakage, stagnation and the like occurring through an original supporting method are solved. The optical mirror magnetic suspension supporting device is easy to maintain and convenient to operate.

Owner:SHANDONG ZHONGHENG OPTOELECTRONIC TECH CO LTD

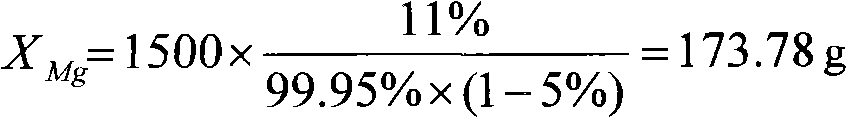

Composite low-temperature lead-free solder paste and preparation method thereof

PendingCN112743256AImprove conductivityImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaThermal fatigueShock resistance

The invention discloses a composite low-temperature lead-free solder paste and a preparation method thereof. The composite low-temperature lead-free solder paste comprises tin-based solder alloy powder, metal Mg powder, metal In powder and flux paste, and is characterized in that the solder paste comprises the following components by weight: 85%-90% of tin-based solder alloy powder, 0.5%-1% of metal Mg powder,1%-2% of metal In powder and 8%-12% of paste flux. According to the selected materials, the component proportion and the production process, the solder paste has good conductivity and mechanical properties. The metal element Mg and the metal element In have the characteristics of high specific strength and specific stiffness, strong shock resistance, capability of bearing larger impact load, good thermal fatigue performance, high electrical conductivity, high thermal conductivity and the like, and are added to the solder paste so that the welding strength, the electrical conductivity and the thermal conductivity of the composite low-temperature lead-free solder paste are remarkably improved, and the solder paste can completely pass an SMT push-pull force test; and the thixotropy is excellent, and the requirements of different printing processes can be met.

Owner:深圳市朝日电子材料有限公司

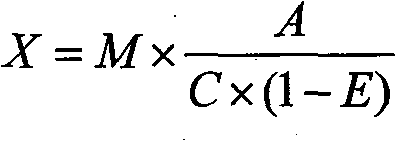

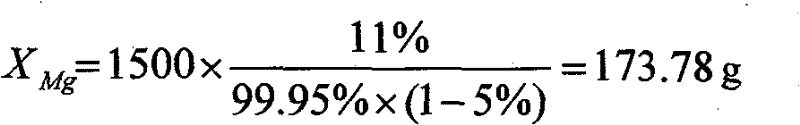

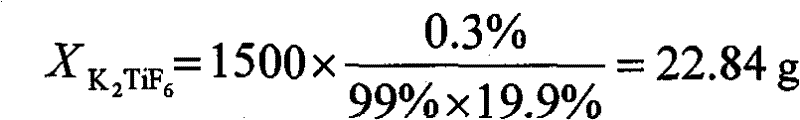

Preparation method of high-toughness casting aluminum alloy

The invention discloses a high-toughness casting aluminum alloy containing the following components in percentage by weight: 9.5-11.0 percent of Mg, 0.1-0.4 percent of Ti, 0.1-0.3 percent of RE, 0.15-0.30 percent of Si and the balance of Al and unavoidable trace impurities, wherein the content of single elements in the trace impurities is less than 0.10 percent, and the total content of the trace impurities is less than 0.50 percent. The invention also discloses a preparation method of the high-toughness casting aluminum alloy. The high-toughness casting aluminum alloy has the advantages of high tensile strength, high elongation, low price of raw materials, short production flow, easy control on the process flow and the like, and complicated smelting equipment and subsequent thermal treatment hot standby are not needed; on the premise of satisfying the mechanical properties of the members, the overall production cost is lower.

Owner:宁波旭润铝业有限公司 +1

Multifunctional double-swing rod impact tester

The present invention discloses a multifunctional double-swing rod impact tester. According to the multifunctional double-swing rod impact tester, a removable swing rod position limitation mechanism is arranged on the host machine rack, a lifting system and a braking system are connected through a swing shaft and are arranged on the top end of the host machine top end, the upper swing rod is suspended on the middle of the swing shaft so as to achieve the lifting and the braking of the double-swing rod system, the upper swing rod and the lower swing rod form a hinged connection in the double-swing rod system, the lower end of the lower swing rod is connected with a pendulum, the hinged connection position of the upper swing rod and the lower swing rod is provided with an angle adjusting device, a buffer device is arranged between the upper swing rod and the lower swing rod, a measurement system is arranged on the base through a buffer pad, and a high speed sensor and a high speed data acquisition device are adopted to display the change curve of the force values in the horizontal direction and the vertical direction along with the time, the change of the variant feature point along with the time and the like through a computer during the impact process. The present invention provides the multifunctional double-swing rod impact tester with characteristics of high impact force, good buffer effect and safety on operators.

Owner:QINGDAO BOYANDA IND TECH RES INST GENERAL PARTNERSHIP

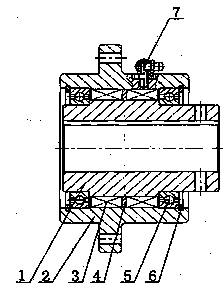

Novel sprag overrunning clutch for novel self-rotation air hammer

The invention relates to a novel sprag overrunning clutch for a novel self-rotation air hammer. The clutch comprises an outer ring body, an inner ring body, elastic check blocks, an elastic collar, pin rollers, sealing rings and an oil cup, wherein the elastic check blocks, the elastic collar, the pin rollers and the sealing rings are arranged between the outer ring body and the inner ring body; two elastic check blocks are arranged; the elastic collar is arranged between the two elastic check blocks; the pin rollers are respectively arranged on the outer sides of the elastic check blocks; the outer sides of the pin rollers are provided with the sealing rings; the oil cup is arranged on the outer ring body. The novel sprag overrunning clutch is simple in structure, large in impulse load and long in service life, the drilling speed is improved, and the operation torque is increased.

Owner:JIANGSU SINOPETRO SUPERBSKILL MACHINE

Paddy field beater

PendingCN107535096AIncreased Strength and RigidityLarge impact loadTilling equipmentsClutchAgricultural engineering

The invention discloses a paddy field beater. The paddy field beater comprises a gearbox and a middle rack assembly; cutter shaft transmission cases are symmetrically arranged at the left side and theright side of the middle rack assembly, and folding assemblies are symmetrically arranged at the left side and the right side of the middle rack assembly; the output ends of the gearbox are connectedwith the input ends of the cutter shaft transmission cases, and the output ends of the cutter shaft transmission cases are connected with the input ends of the folding assemblies through clutches; each folding assembly comprises folding drive mechanisms, a blade, rack side plates and a folding rack, wherein the rack side plates are fixedly connected to the middle rack assembly, the clutch blade is supported on the folding rack, folding rack plates are fixed to the folding rack and are in pivot connection with the rack side plates, and the folding rack plates and the rack side plates are connected through the corresponding folding drive mechanisms. The folding mechanism of the paddy field beater is high in strength and rigidity, capable of bearing large impact loads and not prone to damage, an oil cylinder drives the folding mechanism to turn over through a rack and pinion mechanism, and the paddy field beater has the advantages of being simple in structure and low in fault rate.

Owner:常州回回机械科技有限公司

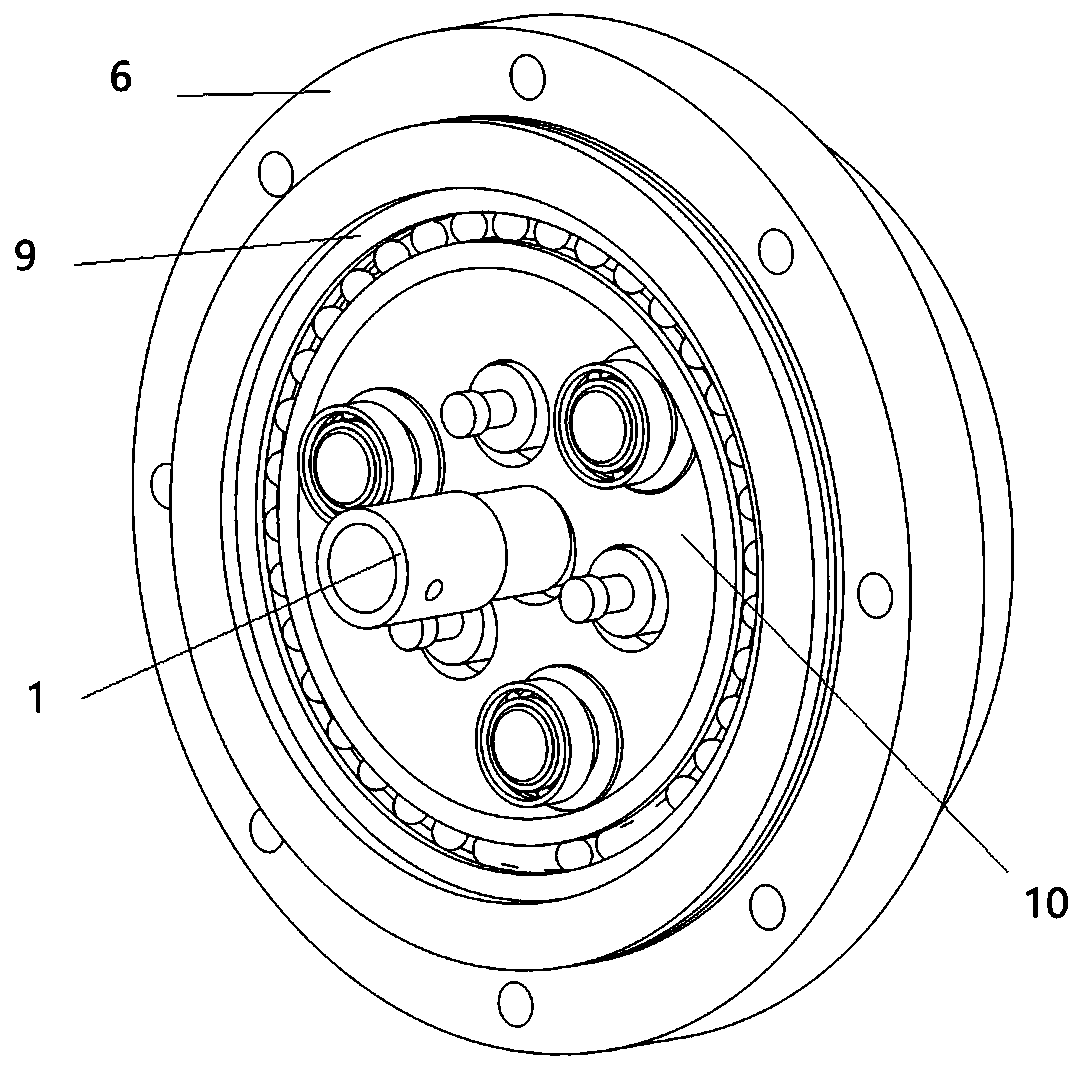

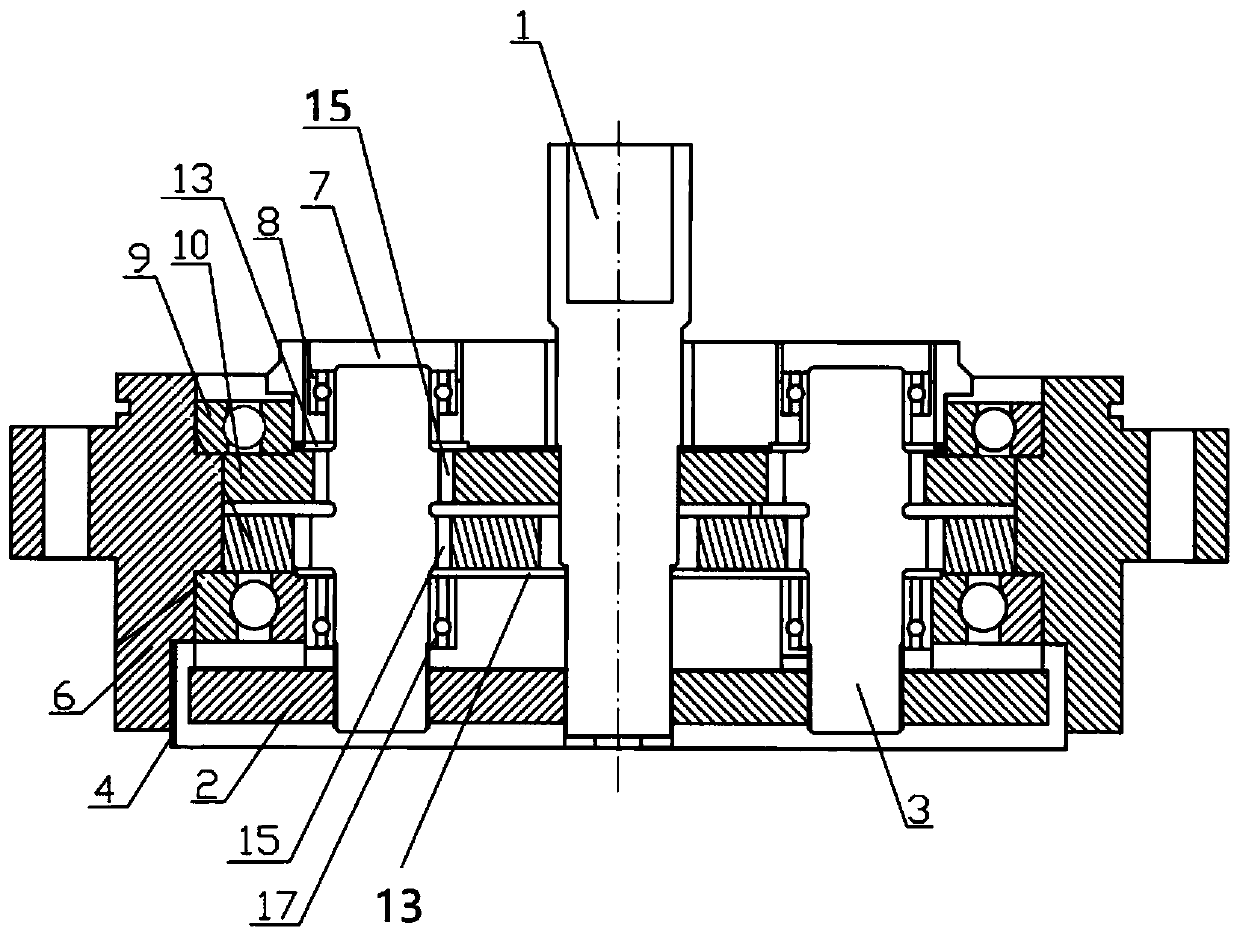

RV bearing based speed reducer

InactiveCN109854687AAccurate speed regulationExtended service lifeGearboxesToothed gearingsReduction driveBarrel Shaped

A RV bearing based speed reducer comprises a main shaft, planetary wheels, crankshafts, RV bearings, a housing and cycloidal-pin wheels, wherein a housing is of a hollow barrel shaped structure; the main shaft is coaxially arranged in the geometric center of the housing; three crankshafts are arranged with the same radian on a circle of which the center is the main shaft in a manner of being parallel to the main shaft; the planetary wheels are fixedly arranged at the lower ends of the crankshafts; a gear is fixedly arranged at the lower end of the main shaft and is engaged with all planetary gears; two RV bearings fixedly sleeve each crankshaft; two cycloidal-pin wheels sleeve the main shaft, and pores are formed in positions, where the cycloidal-pin wheels are positioned, on the crankshafts; the crankshafts penetrate the pores; two RV bearings on each crankshaft are positioned into the pores in the cycloidal-pin wheels; inner teeth which are engaged with the side edges of the cycloidal-pin wheels are arranged on the inner sidewall of the housing; and a cycloidal-pin wheel set is engaged with the inner teeth. According to the RV bearing based speed reducer, an RV speed reducer is adopted, so that the speed can be accurately adjusted; and meanwhile, high impacting load can be borne; in addition, the service life of the speed reducer can be effectively prolonged.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com