Novel sprag overrunning clutch for novel self-rotation air hammer

An overrunning clutch and air hammer technology, applied in the clutch field, can solve the problems of small application range, poor stability, short service life, etc., and achieve the effect of increasing drilling speed, increasing working torque and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

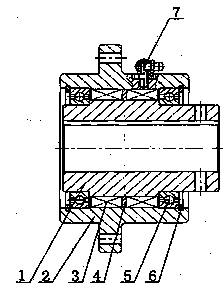

[0008] A new type of sprag overrunning clutch for a new self-rotating air hammer. The clutch includes an outer ring body 1, an inner ring body 2, an elastic block 3, an elastic retaining ring 4, a roller 5, a sealing ring 6 and an oil cup 7. The elastic retaining block 3, the elastic retaining ring 4, the roller 5 and the seal ring 6 are arranged between the outer ring body 1 and the inner ring body 2, and the elastic retaining block 3 has two pieces, and the elastic retaining ring 3 is arranged between two elastic blocks 3, the outer sides of the elastic blocks 3 are provided with rollers 5, the outer sides of the rollers 5 are provided with sealing rings 6, and the oil cup 7 is arranged on the outer ring body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com