High-stability tool changer rotating indexing mechanism

An indexing mechanism and a technology of rotating indexing discs, which are applied in the field of processing and manufacturing, can solve problems such as deformation, high cost, and reduced durability, and achieve the effects of stable operation, fast rotation speed, and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

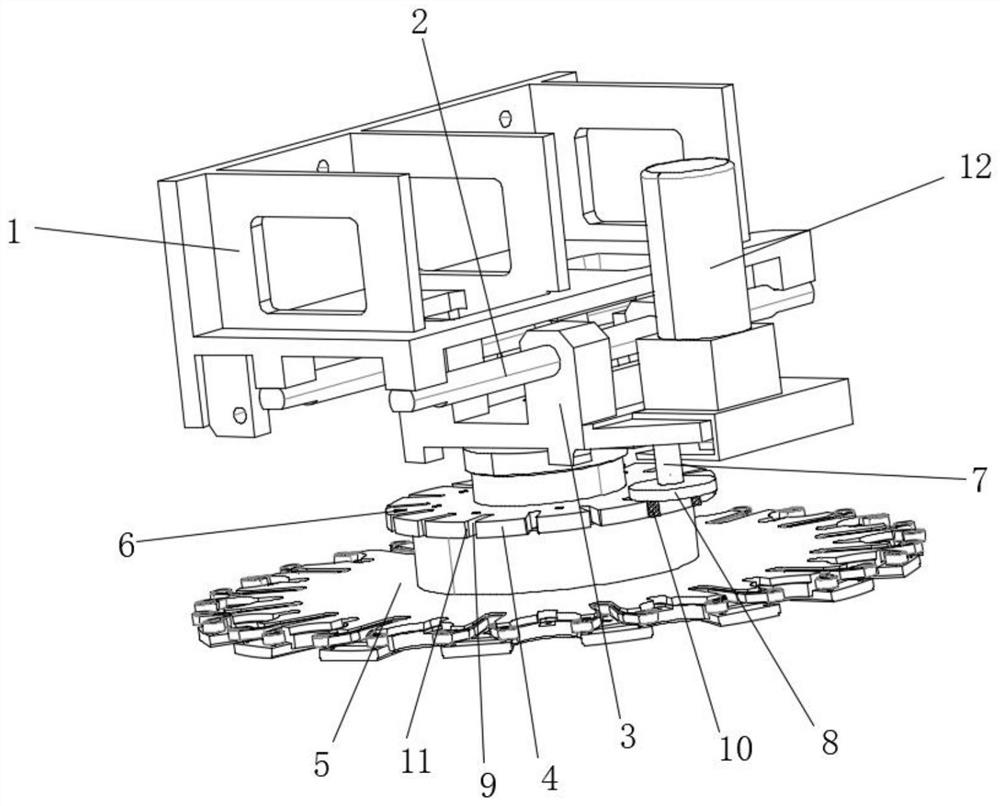

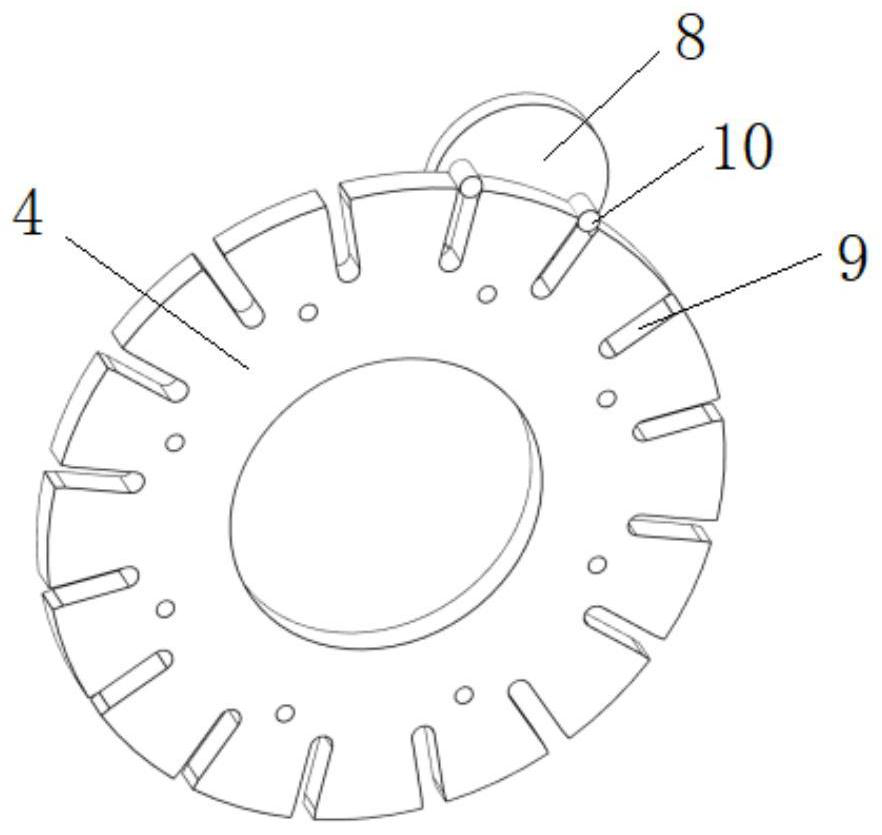

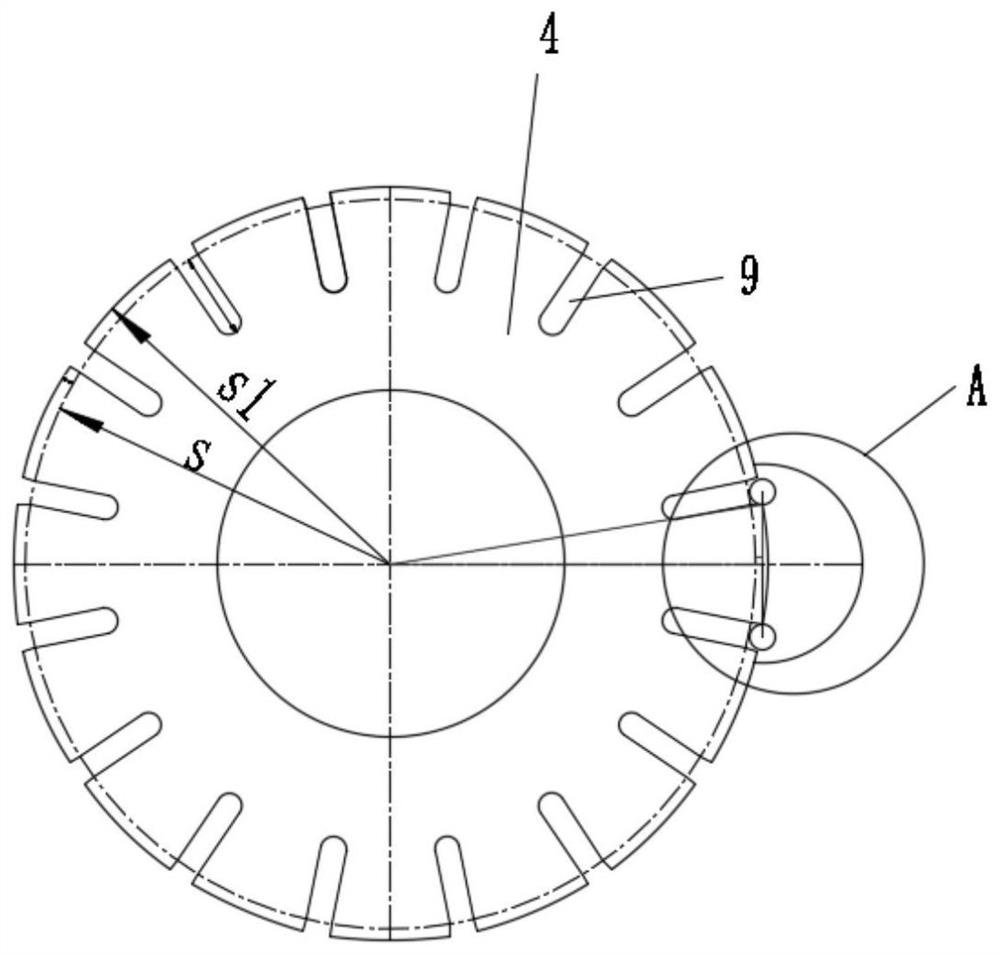

[0031] Embodiment: a kind of tool library rotation indexing mechanism with high stability, such as Figure 1-2 As shown, it includes a base body 1, a pair of slide rails 2 are arranged at the bottom of the base body 1, a moving seat 3 is arranged between the pair of slide rails 2, and a rotating index plate 4 is arranged at the bottom of the moving seat 3, and the rotating indexing plate 4 is arranged at the bottom of the moving seat 3. The bottom of the dial 4 is fixed with a tool magazine disk 5, and the moving seat 3 is provided with an indexing and indexing mechanism 6 that drives the rotating indexing disk 4 to rotate. 3 the dial 8 at the bottom, the rotary indexing plate 4 is provided with n wheel grooves 9 equidistantly arranged, wherein n>8; the dial 8 is provided with two Engaged round pin 10, a transition arc 11 is provided at the outer end of the wheel groove 9, so that the wheel groove 9 extends outward to form an improved groove, and the moving seat 3 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com