RV bearing based speed reducer

A technology of reducer and bearing, applied in the direction of components with teeth, transmission parts, gear transmission, etc., can solve the problems of complex working conditions of RV reducer, inconvenient maintenance and replacement, and difficulty in guaranteeing life, and achieve the assembly process. The specification is smooth, the assembly process is simple, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described below in conjunction with accompanying drawing:

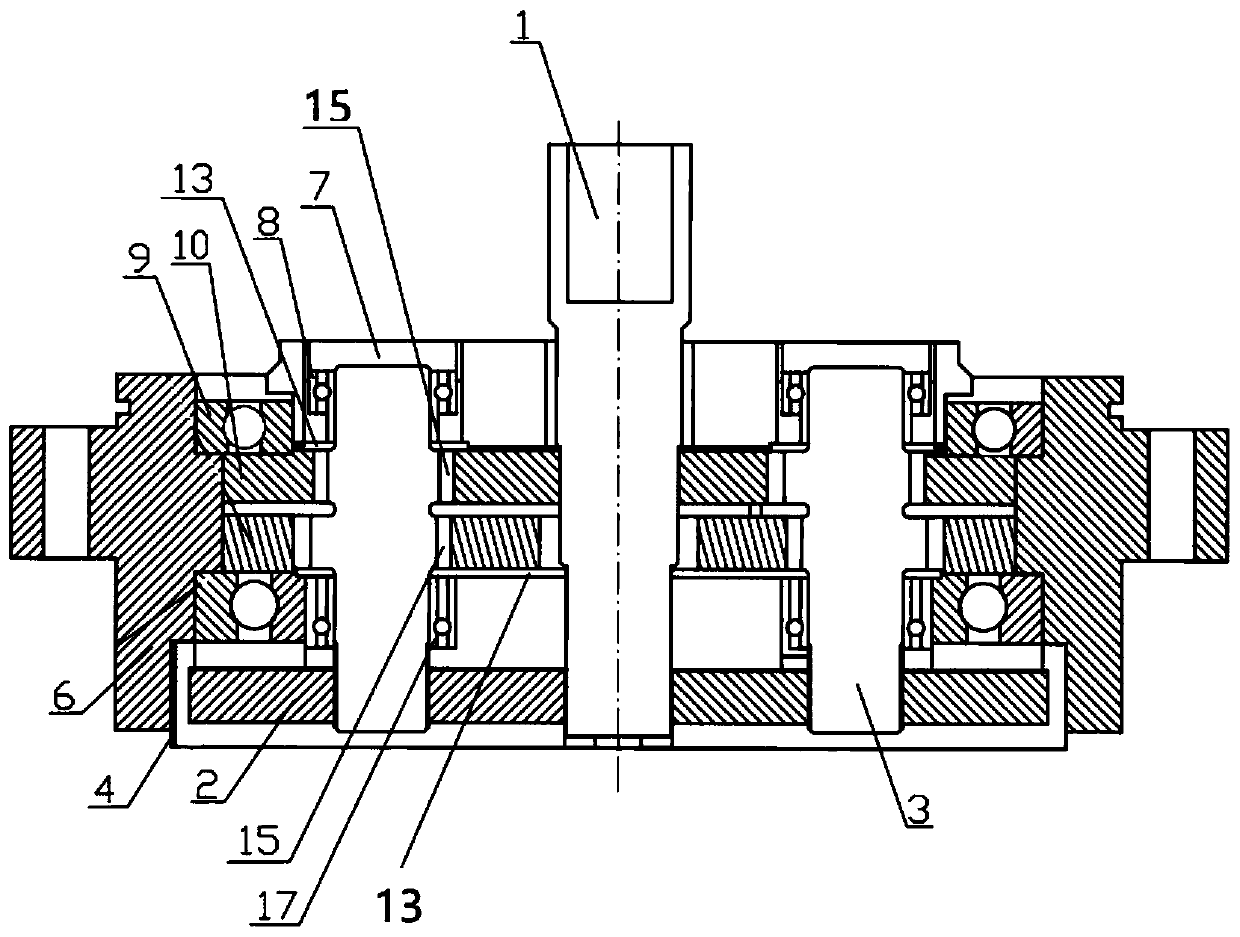

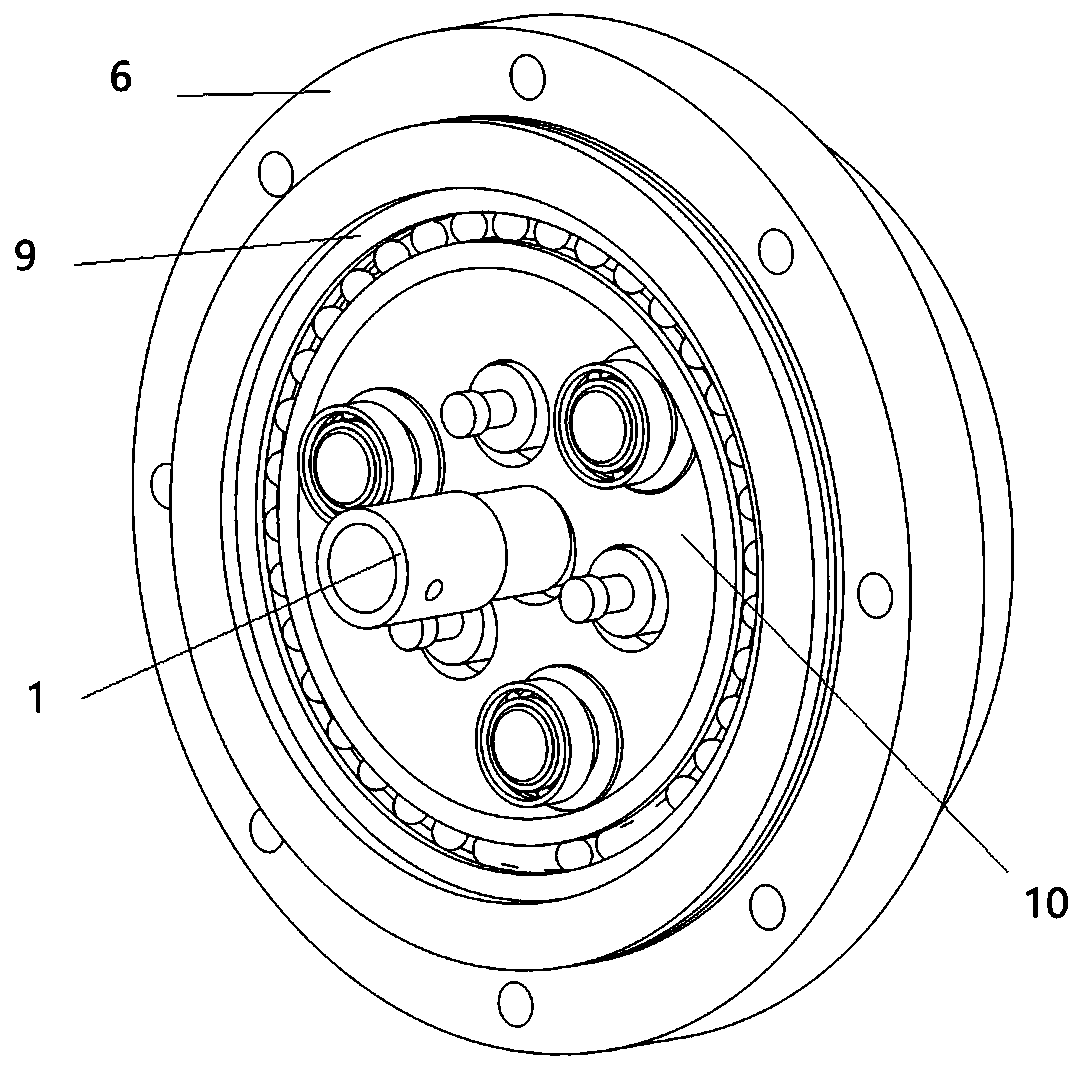

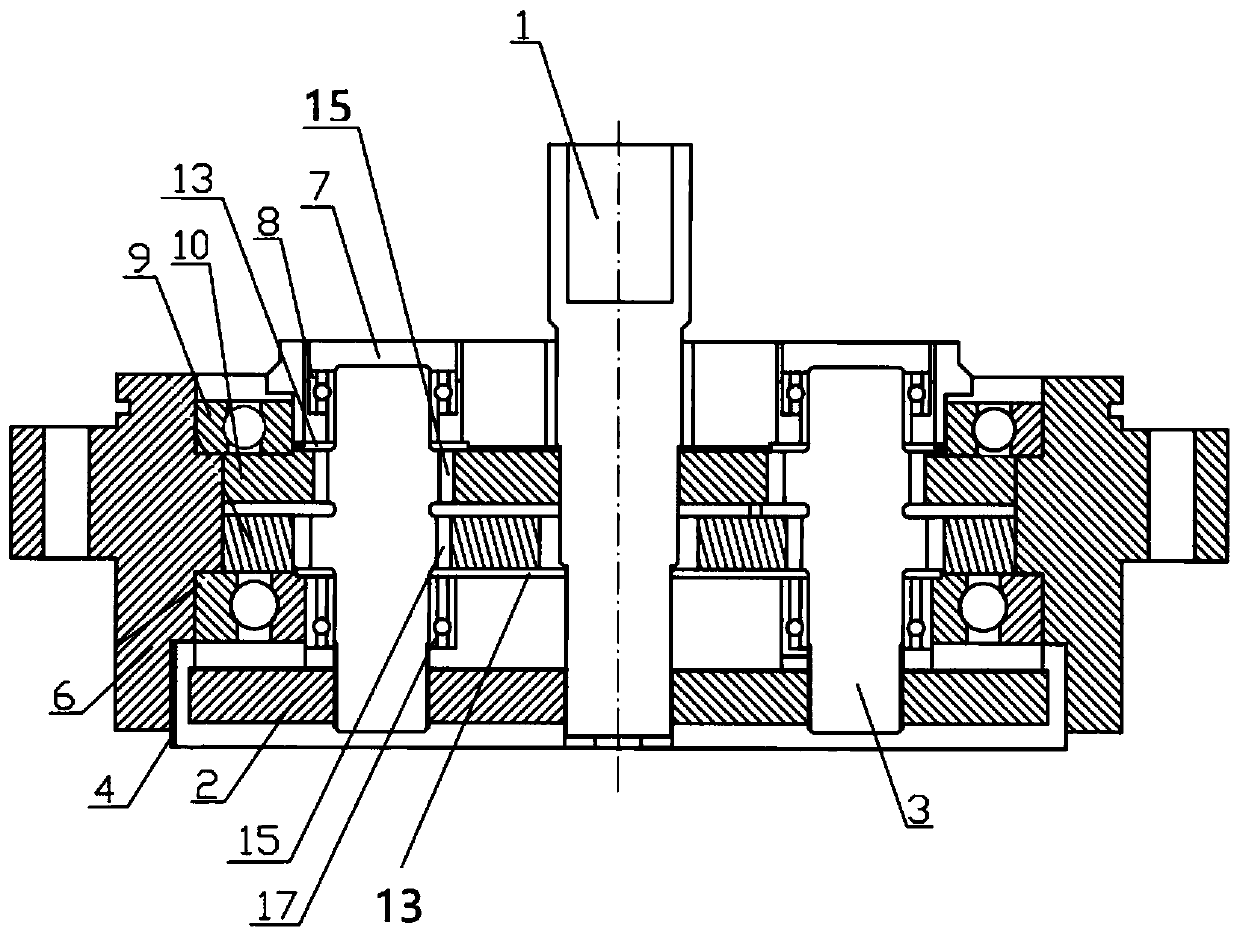

[0019] see figure 1 with figure 2 , a reducer based on RV bearings, including a main shaft 1, a planetary wheel 2, a crankshaft 3, an RV bearing 15, a housing 6 and a cycloidal pin wheel 10; The geometric center of the housing 6; the three crankshafts 3 are parallel to the main shaft 1 and arranged on a circle centered on the main shaft 1; the lower end of each crankshaft 3 is fixed with a planetary wheel 2, and the lower end of the main shaft 1 is fixed with a gear , the gears mesh with all the planetary gears 2; each crankshaft 3 is fixedly set with two RV bearings 15, and the main shaft 1 is set with two cycloidal pinwheels 10, and the cycloidal pinwheels 10 have holes at the position of the crankshaft. The crankshafts are arranged through the holes, and the two RV bearings 15 on each crankshaft are located in the holes of the cycloidal pinwheel 10; the inside wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com