Full-automatic indenting machine for packaging box machining

A fully automatic, box-packing technology, applied in packaging, transportation and packaging, container manufacturing machinery, etc., can solve the problems of inability to achieve automatic indentation, increase the workload of staff, reduce the work efficiency of the device, etc., and achieve good protection. Effect, easy to promote, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

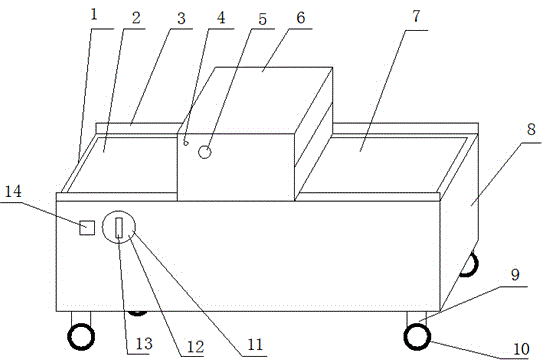

[0022] Such as figure 1 As shown, the operating table 8 is provided with a rotational speed regulator 11 .

[0023] In the present invention, the rotational speed regulator 11 on the console 8 facilitates effective regulation and control of the rotational speed of the motor 19, thereby effectively controlling the rotational speed of the conveying device.

Embodiment 2

[0025] Such as figure 1 As shown, the rotational speed regulator 11 is provided with an adjustment dial 12 , and the adjustment dial 12 is provided with an adjustment knob 13 .

[0026] In the present invention, through the speed dial 12 on the speed regulator 11 and the adjusting knob 13 provided on the speed dial 12, the speed adjustment can be made more precise, the accuracy is greatly improved, and the working efficiency of the device is improved at the same time.

Embodiment 3

[0028] Such as figure 1 As shown, each side of the bottom of the console 8 is provided with a support rod 9 , and one side of the support rod 9 is provided with a roller 10 .

[0029] In the present invention, the support rods 9 on each side of the bottom of the console 8 and the rollers 10 arranged on the support rods 9 facilitate the movement of the entire device, and can be easily moved to a suitable position when the device needs to be moved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com