Electromechanical switching control mechanism of double-pulse speed governor

A control mechanism and governor technology, which is applied in engine control, fuel injection control, machine/engine, etc., can solve the problems of small working capacity and poor reliability, and achieve the goal of improving reliability, facilitating full automation, and realizing full automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

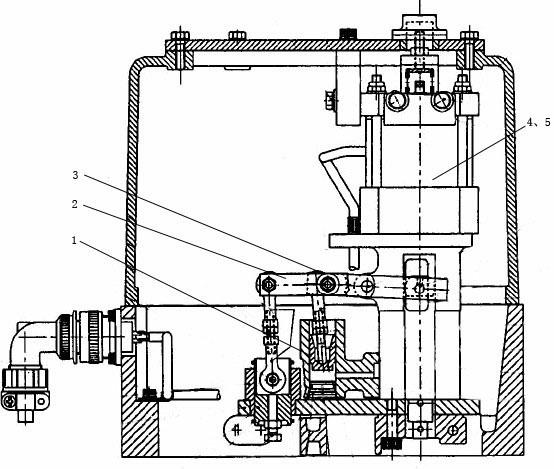

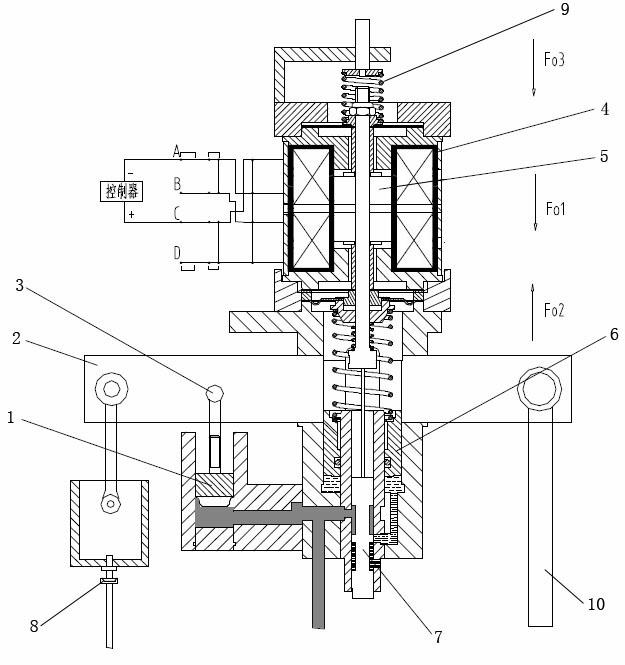

[0024] see figure 1 , the electromechanical switching control mechanism is a part of the double-pulse governor actuator, which is a set of electromagnetic conversion pilot servo adjustment structure, including electromagnetic coil 4, ring permanent magnet 5, pilot control slide valve 7 and servo piston 6, switching Lever 2, feedback lever 3, reset piston 1 and other parts. The ring-shaped permanent magnet 5 is installed in the magnet coil 4 , the inner ring surface of the ring-shaped permanent magnet 5 is fixed on the core rod of the pilot control slide valve 7 , and a bias spring 9 is installed on the upper end of the core rod. The upper end of the reset piston 1 is fixedly connected to one end of the feedback lever 3 , and the other end of the feedback lever 3 is fixedly connected to the switching lever 2 . One end of the switchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com