Preparation method of nontoxic plasticizer

A production method and plasticizer technology, applied in the field of biomass plasticizer production, can solve the problems of difficult biodegradation, high production cost, environmental pollution, etc., and achieve the effects of low product cost, easy operation, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

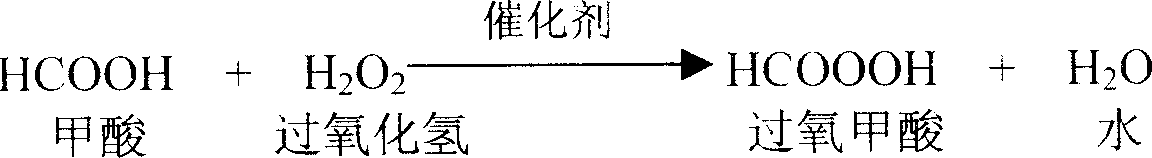

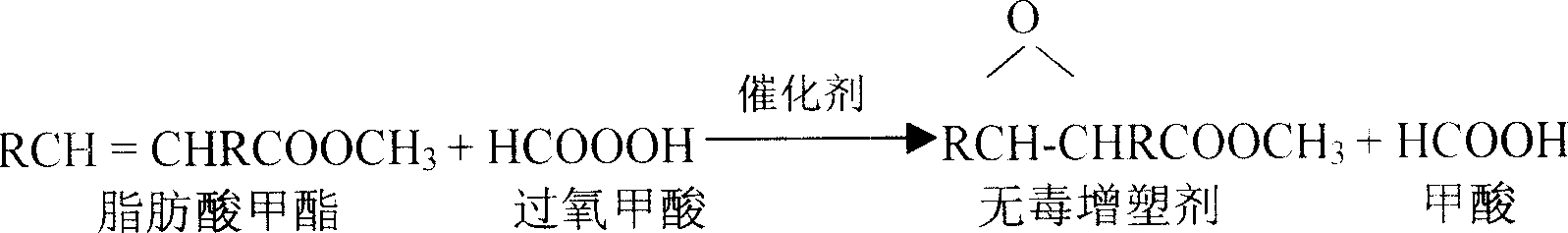

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: in the enamel kettle of 5000 liters, charge coefficient is by 0.75, and material weight ratio is by fatty acid methyl ester: hydrogen peroxide: organic acid: catalyst: complex stabilizer=1: (0.30.6): (0.1-0.12): (0.005-0.006): (0.0010.003), the organic acid adopts formic acid, the concentrated sulfuric acid is used as the catalyst, and urea is used as the stabilizer to ensure that peroxyformic acid has certain stability under the reaction environment; Put fatty acid methyl ester, formic acid, sulfuric acid and urea into the enamel kettle first, heat up to 48°C while stirring, stop heating, and start to drop hydrogen peroxide with a concentration of 35%; since it is an exothermic reaction, use cooling The temperature of the water is adjusted to keep the temperature in the kettle at 50-70°C; the time for adding hydrogen peroxide is controlled at 3.5-4.5 hours, and the temperature is kept for 3-4 hours after the addition is completed, so that the epoxidation r...

Embodiment 2

[0020] Embodiment 2: the organic acid is replaced with acetic acid formic acid, other technical parameters and operation steps are the same as in embodiment 1, and the finished product of non-toxic plasticizer is obtained.

Embodiment 3

[0021] Embodiment 3: the concentration of hydrogen peroxide is 25%, and the time of adding hydrogen peroxide is controlled at 2.5-3.5 hours, and after dropping, it is incubated for another 4-6 hours. Plastic products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com