Method for determining feed liquid application uniformity in cigarette charging process

A technology of uniformity and feed liquid, which is applied in the field of quantitative evaluation of the uniformity of feed liquid application, which can solve the problems of heavy workload, large error, and inability to fully reflect whether the distribution of feed liquid is even or not.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described below in conjunction with embodiments, but does not limit the present invention.

[0021] The test object is the cigarette feeding process of a domestic cigarette enterprise production line.

[0022] 1. Detect the content of 1,2-propanediol in the raw material of tobacco leaves before feeding. No 1,2-propanediol was detected.

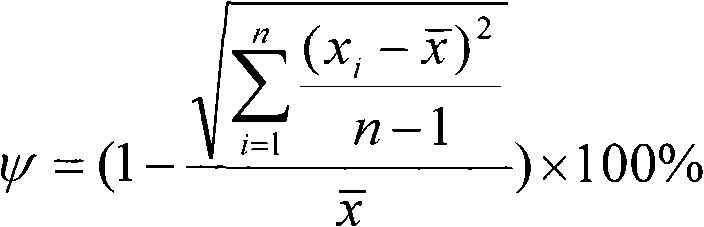

[0023] 2. At the outlet of the smoke feeder, take samples 30 times at equal intervals in accordance with the requirements of GB / T19616, and the sample amount is 30g each time.

[0024] 3. According to the requirements of YC / T 243-2008, the obtained smoke sample is dried at 40℃ and then ground into smoke dust. After passing through a 40-mesh sieve, the test sample is prepared. After random numbering, according to YC / T The 243-2008 standard method detects the content of 1,2-propanediol in the prepared samples, and the test results are shown in the following table:

[0025] X1

0.424

X11

0.386

X21

0.310

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com