Method for preparing borosilicate foam glass

A foam glass and borosilicate technology, applied in a field, can solve the problems of poor acid corrosion resistance, difficulty in obtaining closed-cell structure foam glass, poor uniformity of apparent bubbles in foam glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

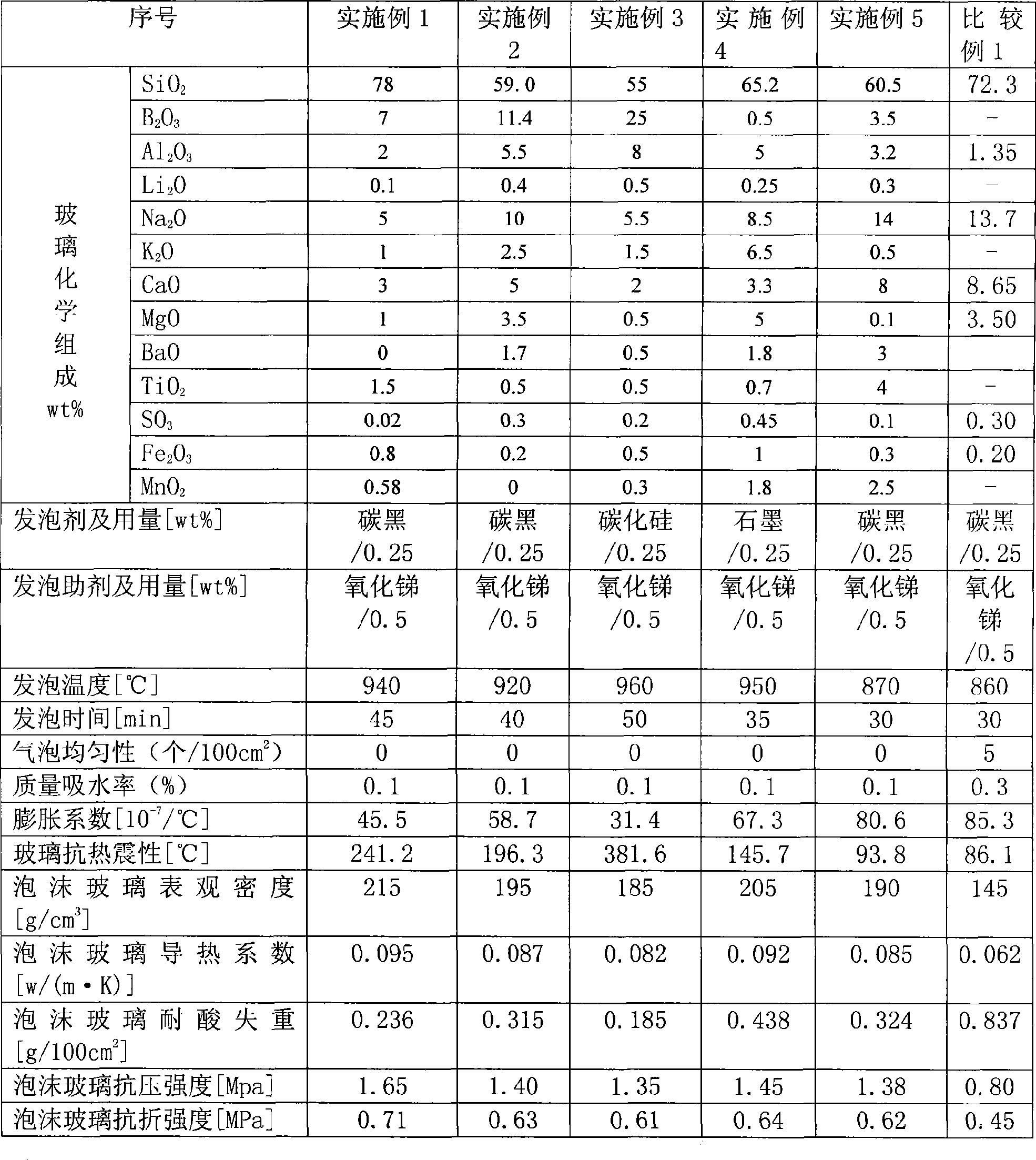

[0047] The present invention is described based on the embodiments, and Table 1 is the composition and performance of the embodiments of the present invention and comparative examples.

[0048] . First, select raw materials according to the composition of borosilicate glass in Example 1 in Table 1, so that the ingredients meet the chemical composition of borosilicate glass in Example 1, and then use a 1L platinum crucible to melt at 1520° C. for 24 hours. After melting, a small amount of it was shaped into a bulk glass material and then annealed for expansion coefficient measurements. The rest are rolled into 0.3-1.5mm glass flakes. The borosilicate foam glass ingredient formula is: add 0.25g carbon black and 0.5g antimony oxide to every 100g borosilicate glass raw material. Grinding, the particle size reaches 325 mesh, put it into a heat-resistant steel mold, the foaming temperature is 940°C, and the foaming time is 45 minutes. After foaming, foam glass is formed. The foam g...

Embodiment 2

[0056] The composition of borosilicate foam glass is selected according to the composition of borosilicate glass in Example 2 of Table 1, so that the ingredients meet the chemical composition of borosilicate glass in Example 2, and the preparation process of the raw materials in Example 1 is adopted. The borosilicate foam glass ingredient formula is: add 0.25g carbon black and 0.5g antimony oxide to every 100g borosilicate glass raw material. Grinding, the particle size reaches 325 mesh, put it into a heat-resistant steel mold, the foaming temperature is 920°C, and the foaming time is 40 minutes. After foaming, foam glass is formed. The apparent density, bubble appearance uniformity, and Mass water absorption, acid weight loss, compressive strength, flexural strength and other properties. From the relevant performance parameters in Example 2 in Table 1, the thermal shock stability reaches 196.3°C, and the bubble uniformity is 100cm 2 There are 0 air bubbles exceeding the diam...

Embodiment 3

[0058] The composition of borosilicate foam glass is selected according to the composition of borosilicate glass in Example 3 in Table 1, so that the ingredients meet the chemical composition of borosilicate glass in Example 3, and the preparation process of the raw materials in Example 1 is adopted. The borosilicate foam glass ingredient formula is: add 0.25g silicon carbide and 0.5g antimony oxide to every 100g borosilicate glass raw material. Grinding, the particle size reaches 325 mesh, put it into a heat-resistant steel mold, the foaming temperature is 960 ° C, and the foaming time is 50 minutes. After foaming, foam glass is formed. The apparent density, bubble appearance uniformity, and Mass water absorption, acid weight loss, compressive strength, flexural strength and other properties. From the relevant performance parameters in Example 3 in Table 1, the thermal shock stability reaches 381.6°C, and the bubble uniformity is 100cm 2 There are 0 bubbles exceeding the dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com