Biobased artificial stone and production process thereof

A production process, artificial stone technology, applied in the field of artificial stone and its production process, can solve the problems of seldom used effectively, environmental pollution, etc., achieve excellent ultraviolet aging resistance, reduce environmental pollution problems, and reduce weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

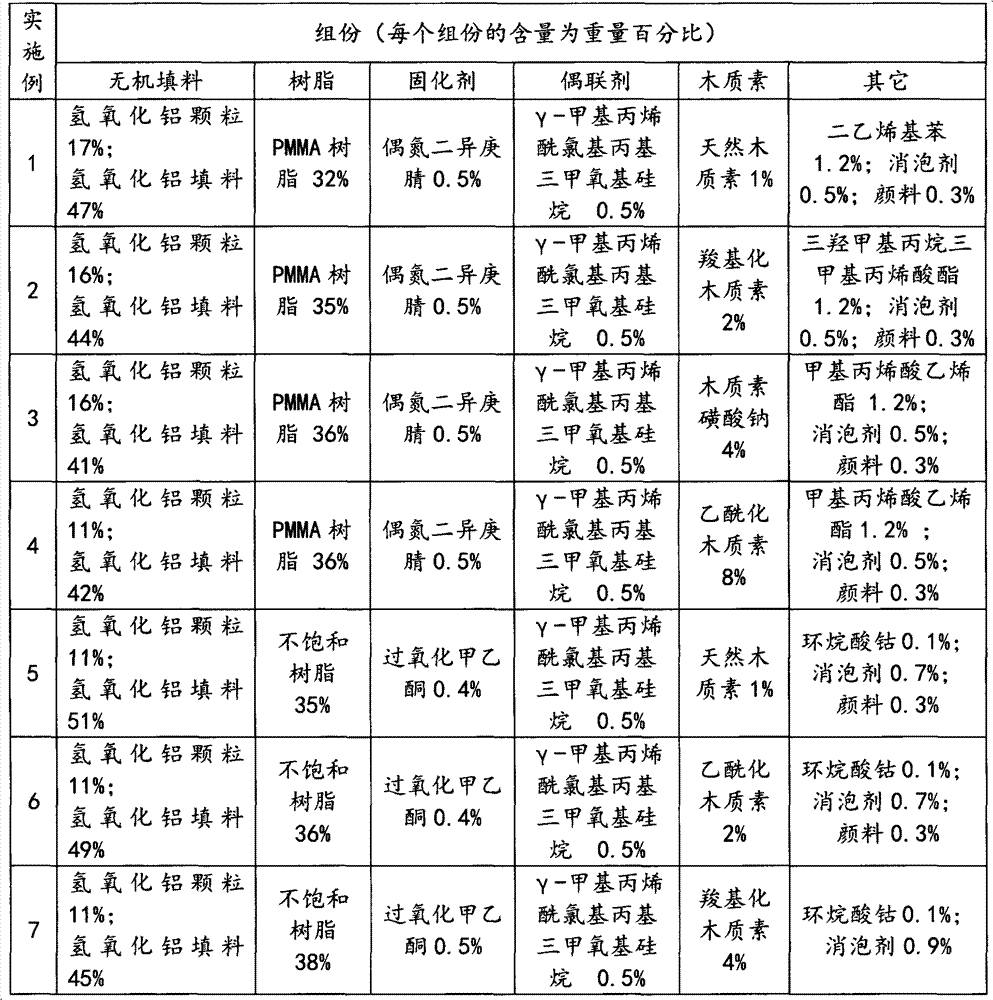

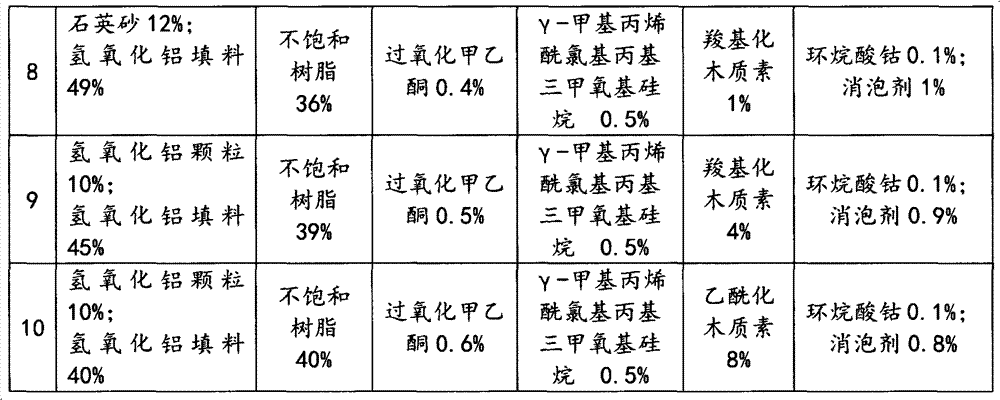

Embodiment 1~4

[0058] First prepare PMMA resin, dissolve 25 parts by weight of PMMA in 75 parts by weight of MMA monomer, and stir until dissolved. Then according to the formula ratio batching of each material in embodiment 1~4 respectively, add PMMA resin, coupling agent, crosslinking agent, curing agent, lignin powder, inorganic filler and pigment in vacuum mixer, in vacuum tightness be-0.05 Stir and mix for 10-15 minutes at ~-0.06MPa, then transfer the mixed material to a vacuum press, vibrate and compact under vacuum (vacuum degree -0.05~-0.06MPa), transfer the compacted material into Curing in an oven, keep the curing temperature at 80°C during the initial curing process, after the initial curing for 40 minutes, then raise the temperature to 130°C and keep it for 80 minutes, so that the mixed material completes the post-curing process, and finally demoulding, thickness setting, polishing, Finished products are cut.

Embodiment 5~8

[0060] According to the formula ratio batching of each material in embodiment 5~8, first add unsaturated resin, crosslinking agent, coupling agent, curing agent and accelerator, lignin powder inorganic filler and pigment in mixer, stir and mix for 10 minutes, Then transfer the mixed material to a vacuum press, then evacuate it to -0.09~-0.095MPa, vibrate and compact it under vacuum, and then transfer it to an oven and keep it warm for 40 minutes at 50°C for preliminary curing , and then heat up to 130°C for post-curing, heat preservation for 80 minutes, demoulding, and finally thickness setting, polishing, and cutting to obtain finished products.

Embodiment 9~10

[0062] According to the formula ratio batching of each material in embodiment 9~10, first add unsaturated resin, crosslinking agent, coupling agent, curing agent and accelerator etc. in mixer, add lignin powder inorganic filler and pigment after stirring thoroughly, Stir and mix for 10 minutes, then pour the mixed material into shape, then evacuate it to -0.09~-0.095MPa, keep it at 50°C for 40 minutes for preliminary curing, then raise the temperature to 130°C for post-curing, and keep it warm for 90 Minutes later, the mold is demoulded, and finally the thickness is determined, polished, and cut to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com