Aluminum electrolysis anode rod automatic repair annular production line and repair method

A technology of aluminum electrolytic anodes and anode guide rods, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of reduced operating efficiency, high pressure drop of anode steel claws, and increased operating costs of enterprises, so as to increase flexibility, Improve efficiency, work quickly and efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

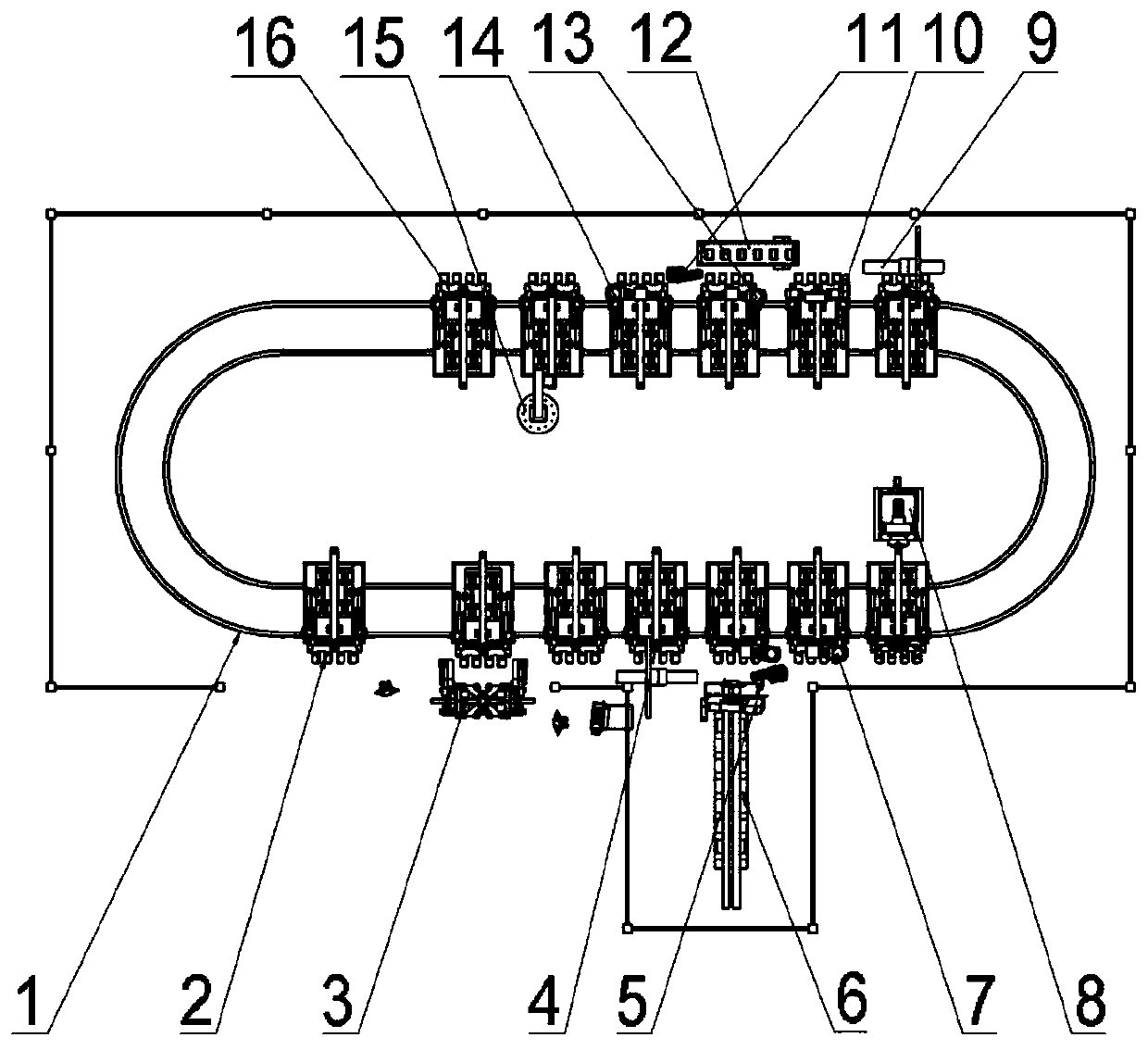

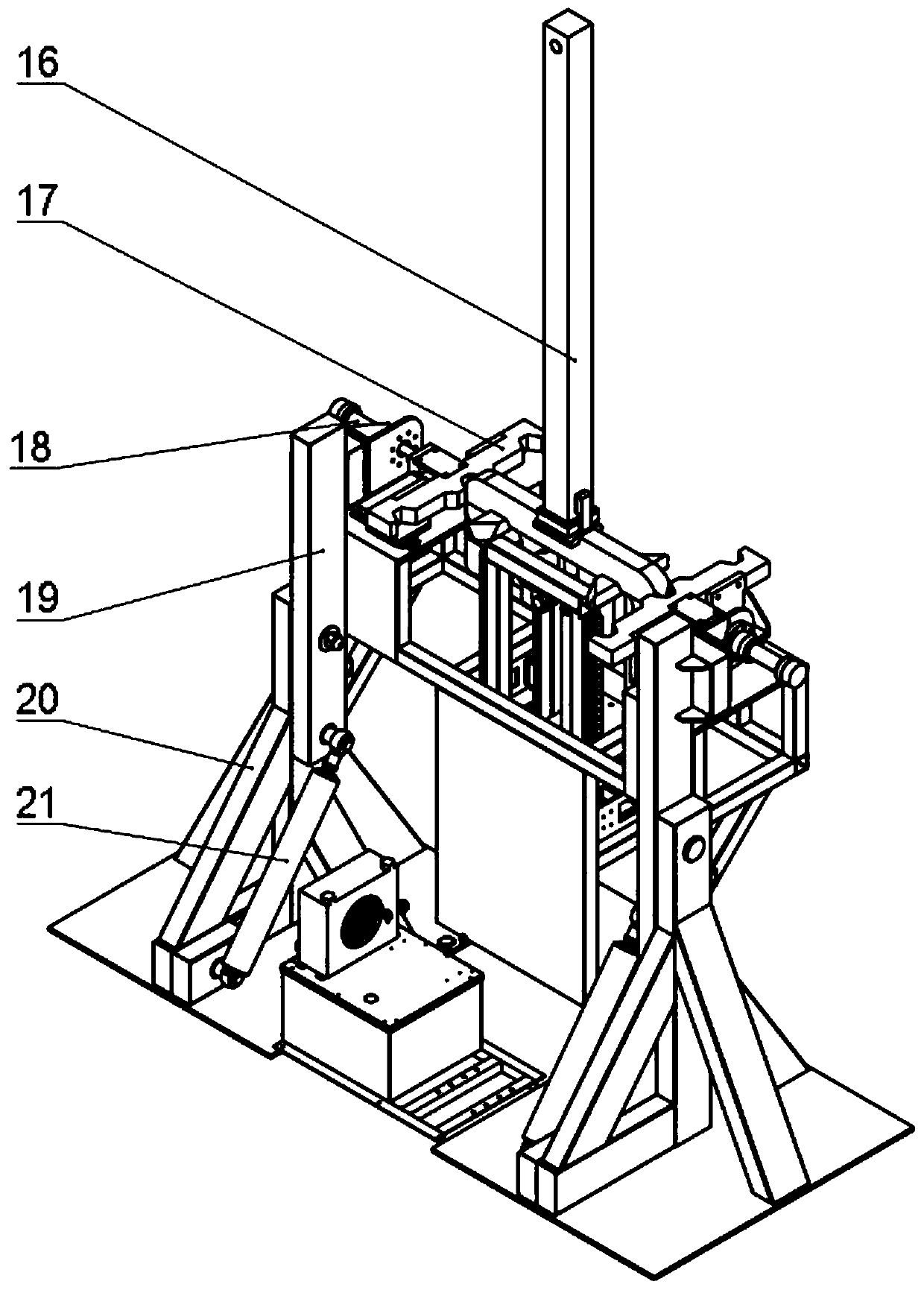

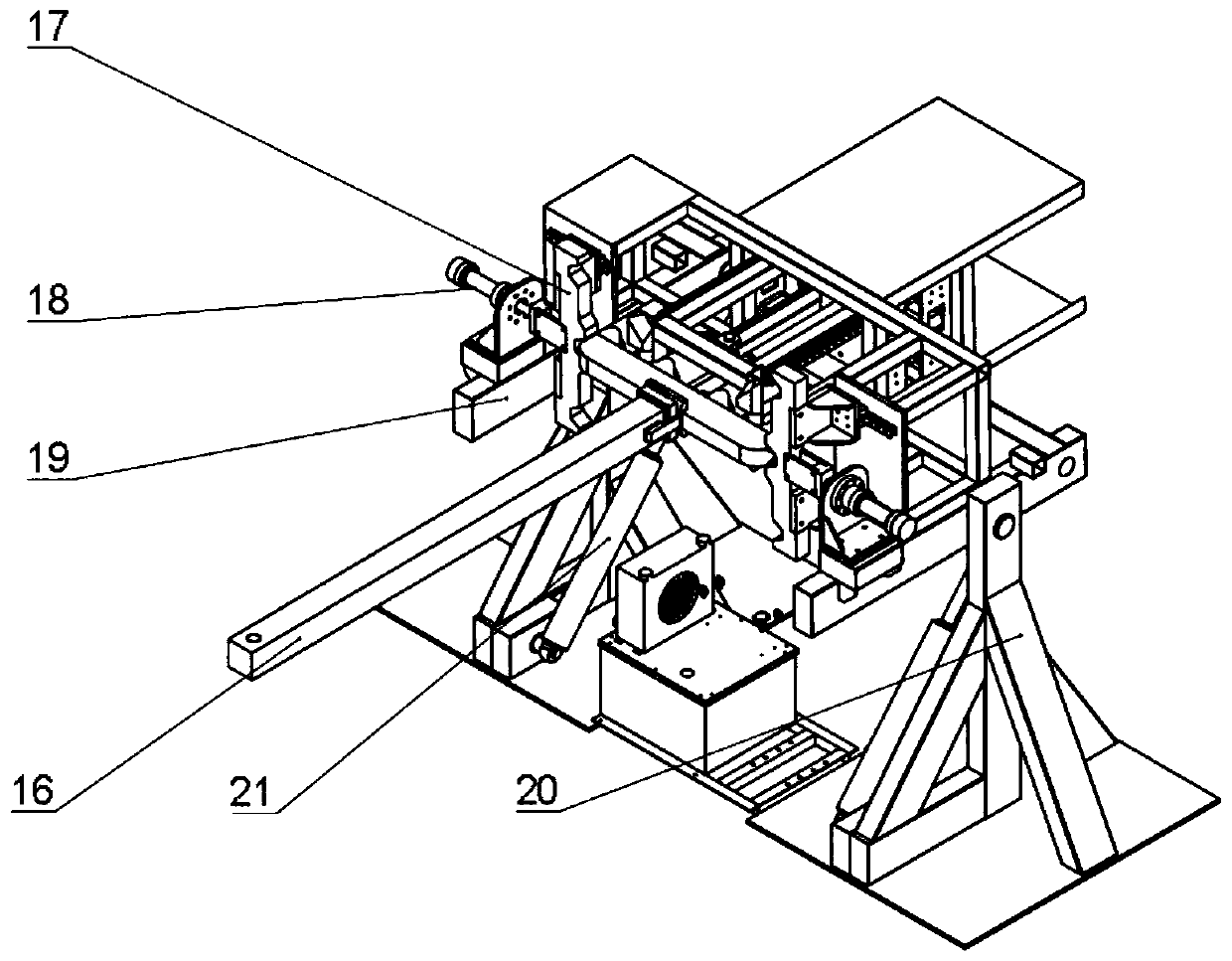

[0022] Embodiments of the invention: as figure 1 As shown, the design of the present invention includes a ground circular track 1, a track trolley 2 with tooling running on the ground track, an upper-line turning table 3 arranged along the circular track 1, a numerically controlled flame cutting machine 4, a steel rod feeding robot 5, a steel Rod feeding device 6, steel claw welding machine 7, double anode turning and shifting machine 8, numerical control flame cutting machine 9, guide rod cutting machine 10, explosion block feeding robot 11, explosion block feeding device 12, explosion block welding special machine 13, Guide rod welding machine 14, guide rod plane milling equipment 15.

[0023] In the present invention, the CNC flame cutting machine 4, the CNC flame cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com