Anti-collision alignment method for aluminum electrolytic multifunctional crane

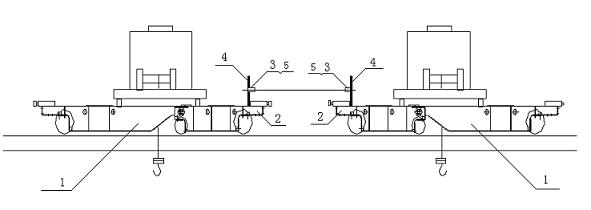

A multi-functional, aluminum electrolysis technology, applied in the field of aluminum electrolysis, can solve problems such as reduced reliability of cranes, damage to crane components, unstable parking of cranes, etc., to improve safety and stability, improve automation, reduce The effect of operating failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] ,working principle

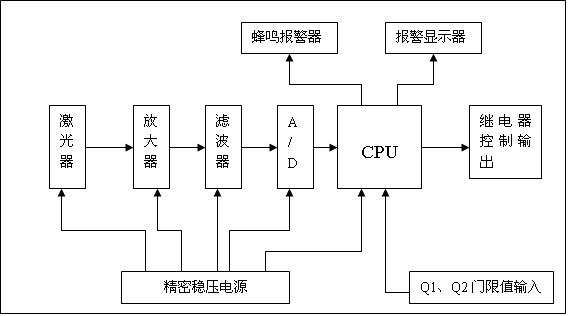

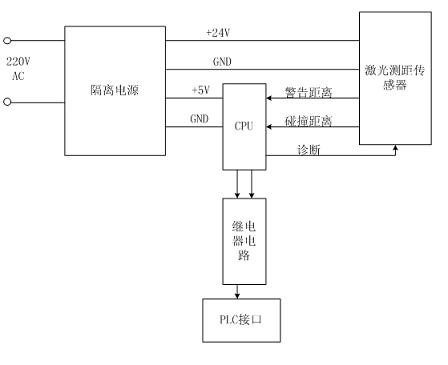

[0039] A laser generator is installed on the crane to emit a continuous pulsed laser beam. Through the emission of obstacles (or target reflectors on obstacles), the distance between the crane and obstacles is determined by its phase and time. Receive the sensor and convert it into a voltage signal. This signal is amplified by a high-performance amplifier, filtered by hardware, and then sent to the CPU threshold value for comparison and judgment through A / D conversion. When the threshold value of Q1 and Q2 is reached, the output drive controller outputs The relay IC signal controls the crane, and at the same time starts the buzzer alarm for different types of sound alarms and the corresponding indicator lights of the alarm display.

[0040] ,hardware design

[0041] 2.1 Hardware composition of laser anti-collision device

[0042] The whole anti-collision device is composed of laser transmitter, laser receiver, control calculator and reflector....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com