Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

340results about "Beryllium compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reinforcing aluminum-based filler and rubber composition comprising such a filter

A reinforcing aluminum-based filler which can be used for reinforcing diene rubber compositions intended for the manufacture of tires, comprising an aluminum (oxide-)hydroxide corresponding, with the exception of any impurities and the water of hydration, to the general formula (a and b being real numbers):the specific BET surface area of which is between 30 and 400 m2 / g, the average particle size (by mass) dw of which is between 20 and 400 nm and the disagglomeration rate, alpha, of which, measured via an ultrasound disagglomeration test at 100% power of a 600-watt ultrasonic probe, is greater than 5x10-3 mum-1 / s is provided. A rubber composition suitable for the manufacture of tires comprising said aluminum-based filler as reinforcing filler.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

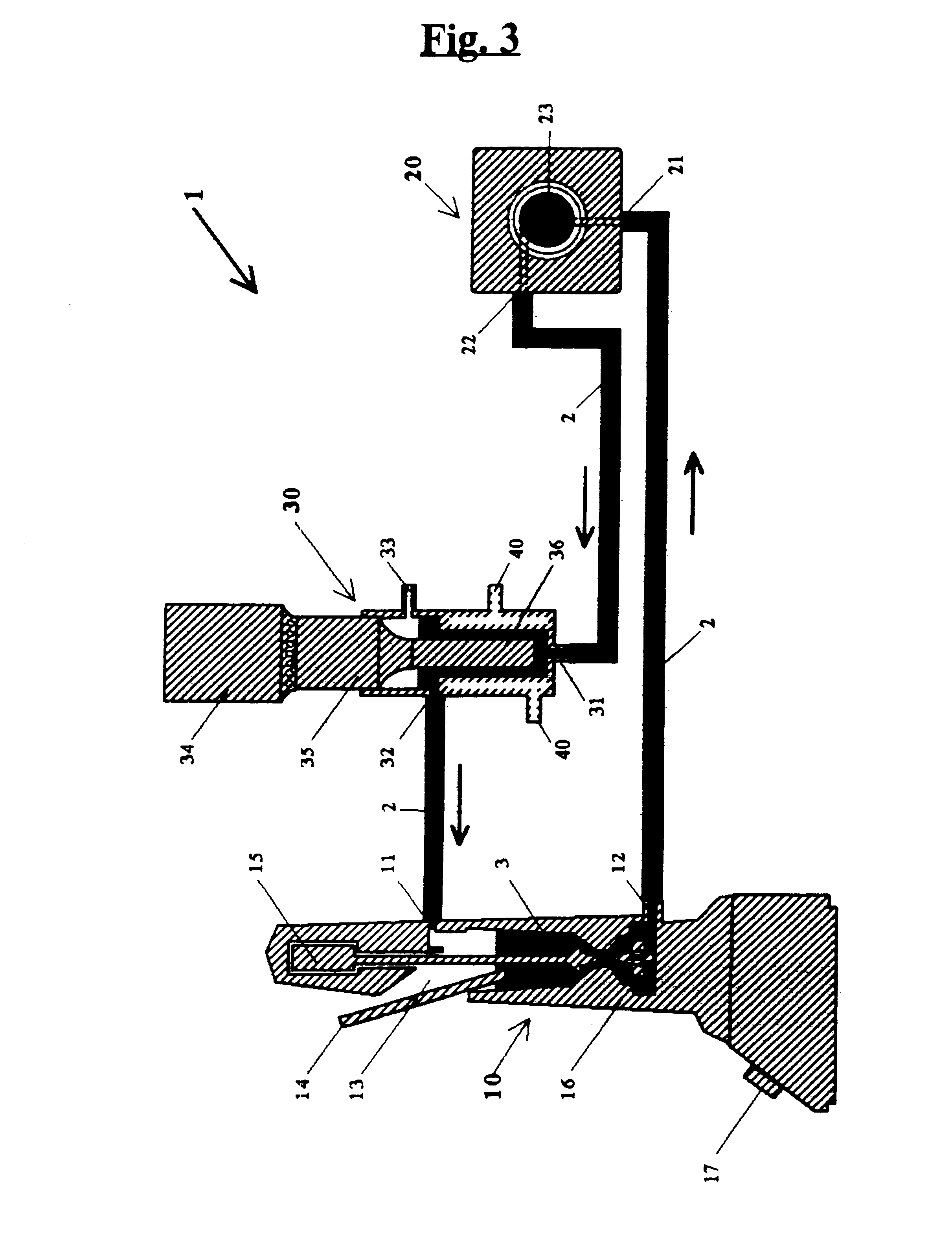

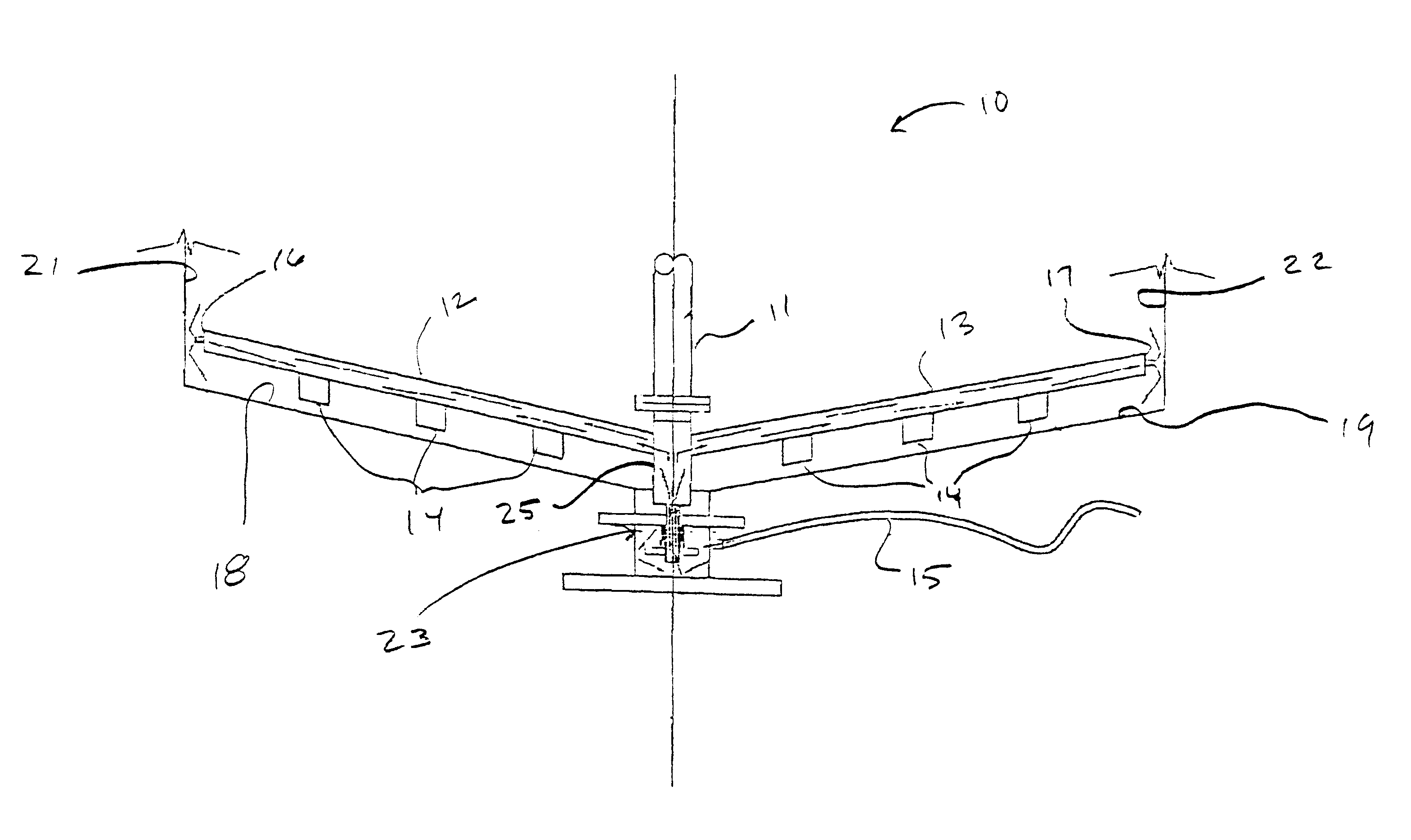

Rheology modification of settled solids in mineral processing

InactiveUS6365116B1Low viscosityIncrease speedRotary stirring mixersTransportation and packagingEngineeringSlurry

The present invention comprises a method for reducing the viscosity of the settled mud or underflow of a raked thickener thereby reducing the torque necessary to move the rake blade through the settled mud. The method includes the step of delivering a viscosity modifier to the settled mud and in front of the rake blade by pumping the viscosity modifier down the rake arm to an area in front of the rake blade. The method also includes an improved rake mechanism that includes a means for delivering viscosity modifier to the settled mud and in front of the rake blade. The present invention also includes a method for increasing the rate of consolidation of flocculated solids in a slurry.

Owner:ECOLAB USA INC

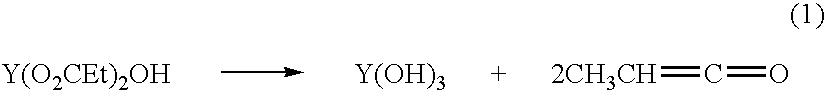

Mixed-metal oxide particles by liquid feed flame spray pyrolysis of oxide precursors in oxygenated solvents

Liquid feed flame spray pyrolysis of solutions of a metal oxide precursor which is an alkoxide or C1-6 carboxylate and at least one second metal oxide precursor and / or second metal compound dissolved in oxygenated solvent by combustion with oxygen lead to the formation of sub-micron mixed-metal oxide powders not accessible by other processes or by the pyrolysis of metal chlorides or nitrates. The powders have numerous uses in advanced materials applications including particulate solid state lasers, advanced ceramic materials, and as catalysts in organic synthesis and automobile exhaust systems.

Owner:TAL MATERIALS +1

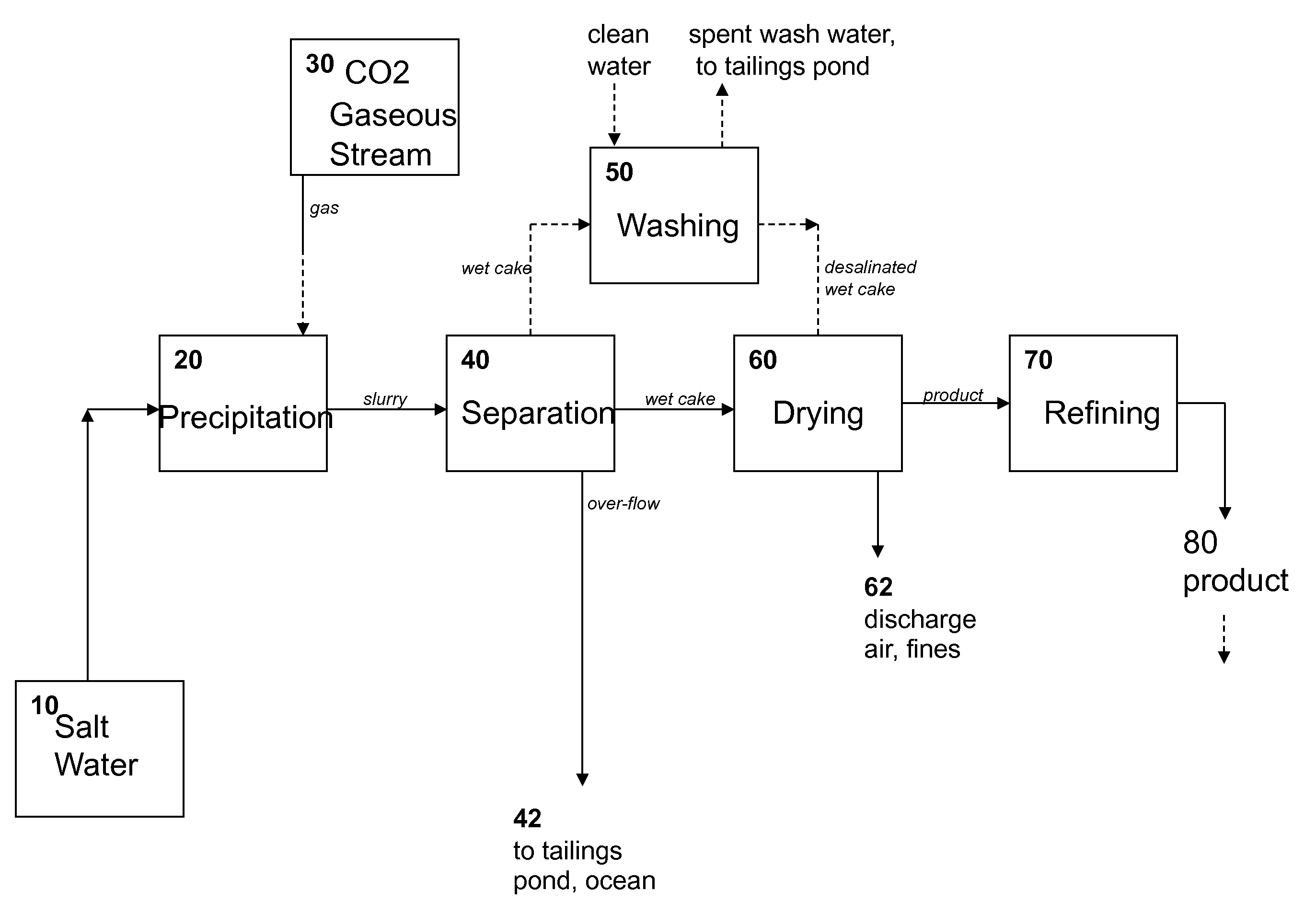

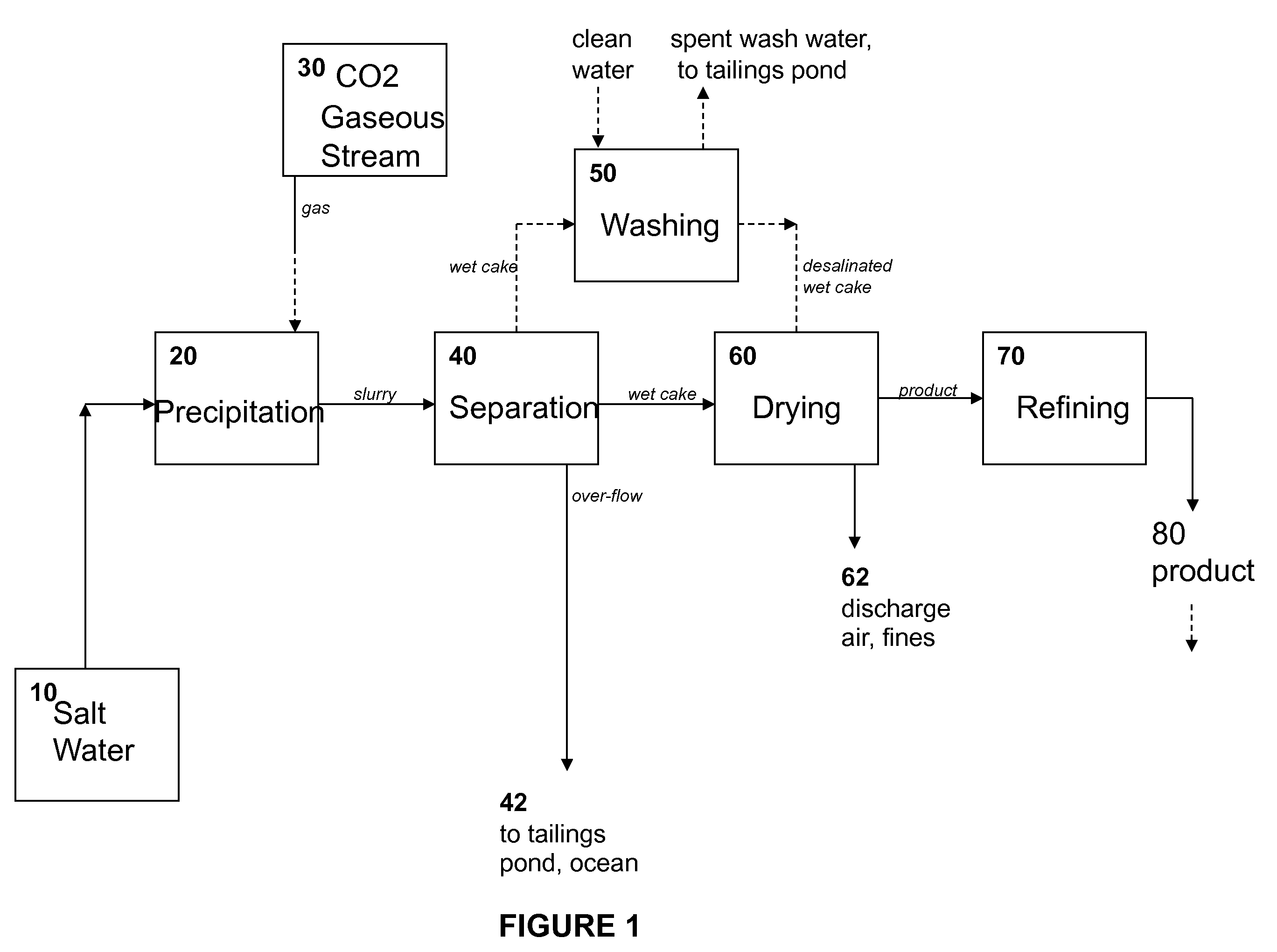

Non-cementitious compositions comprising co2 sequestering additives

Non-cementitious CO2 sequestering compositions are provided. The compositions of the invention include a CO2 sequestering additive, e.g., a CO2 sequestering carbonate composition. Additional aspects of the invention include methods of making and using the non-cementitious CO2 sequestering compositions.

Owner:CALERA CORP

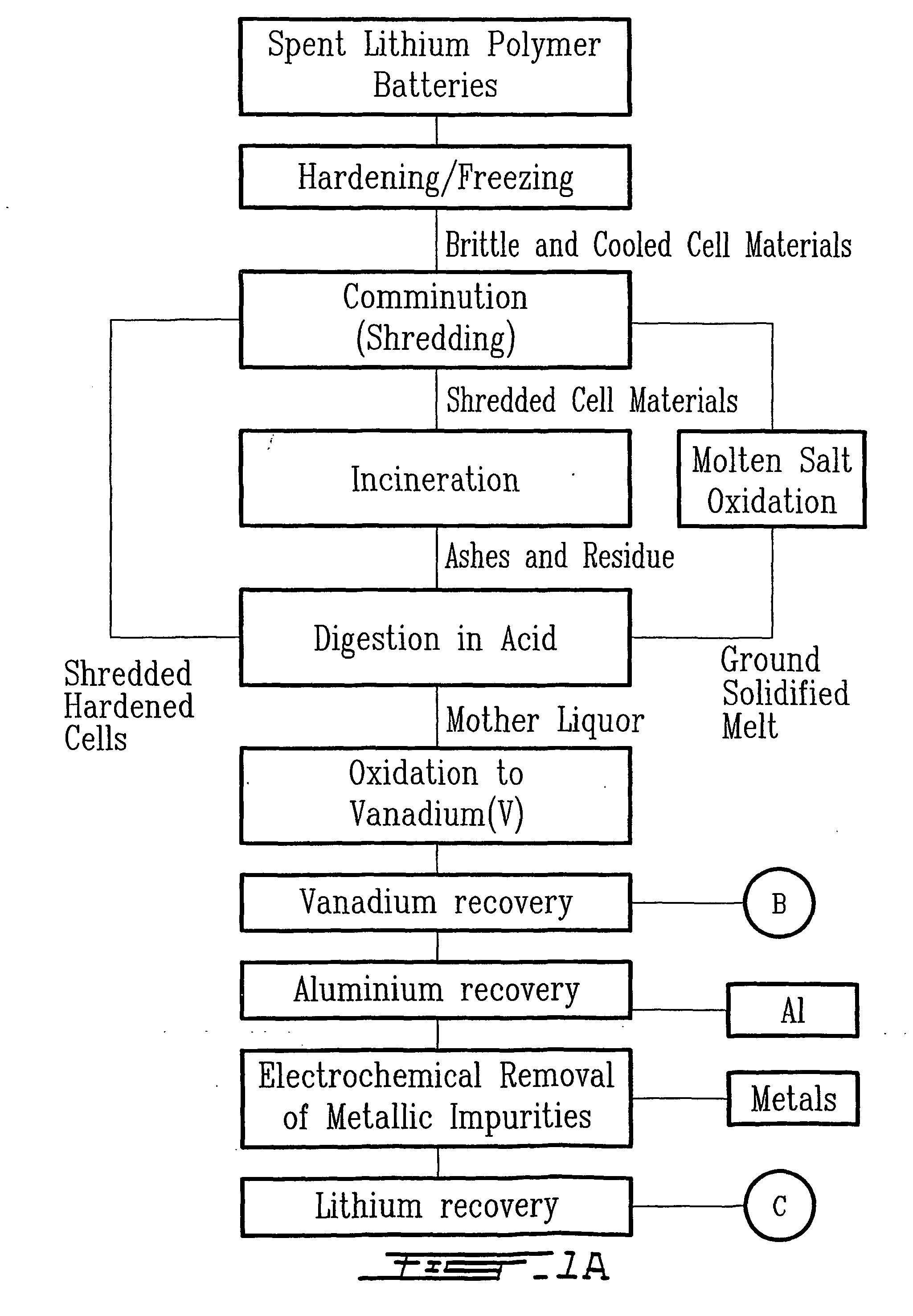

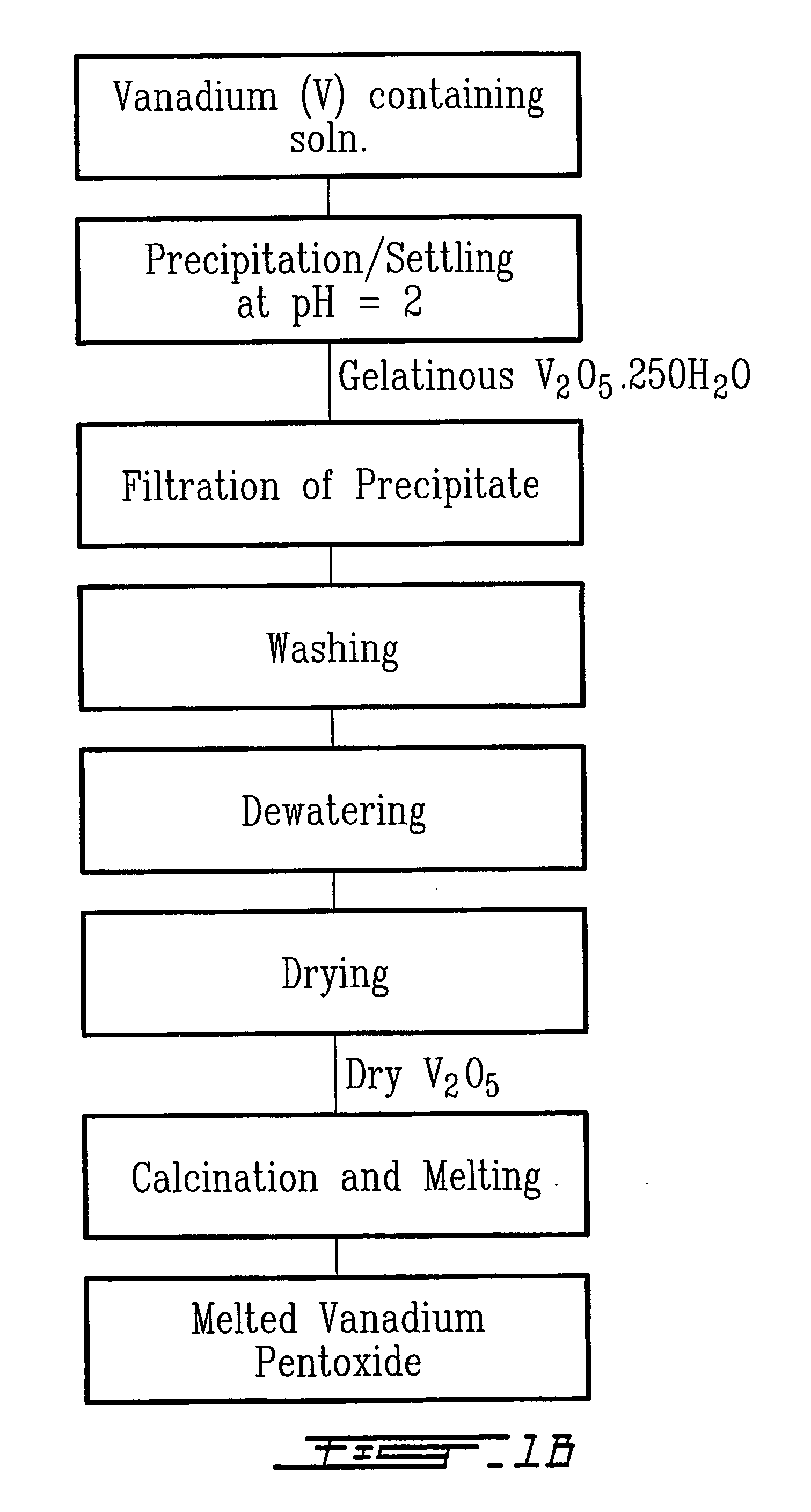

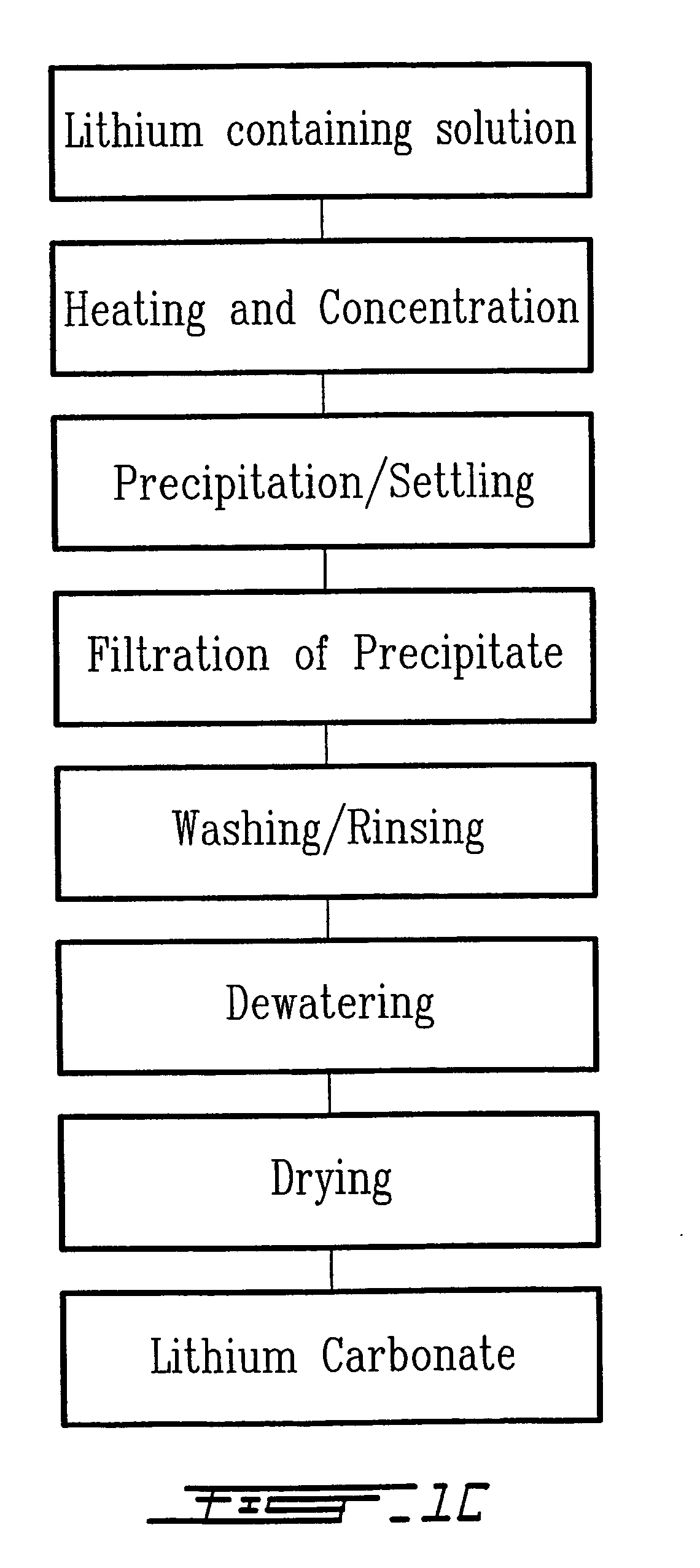

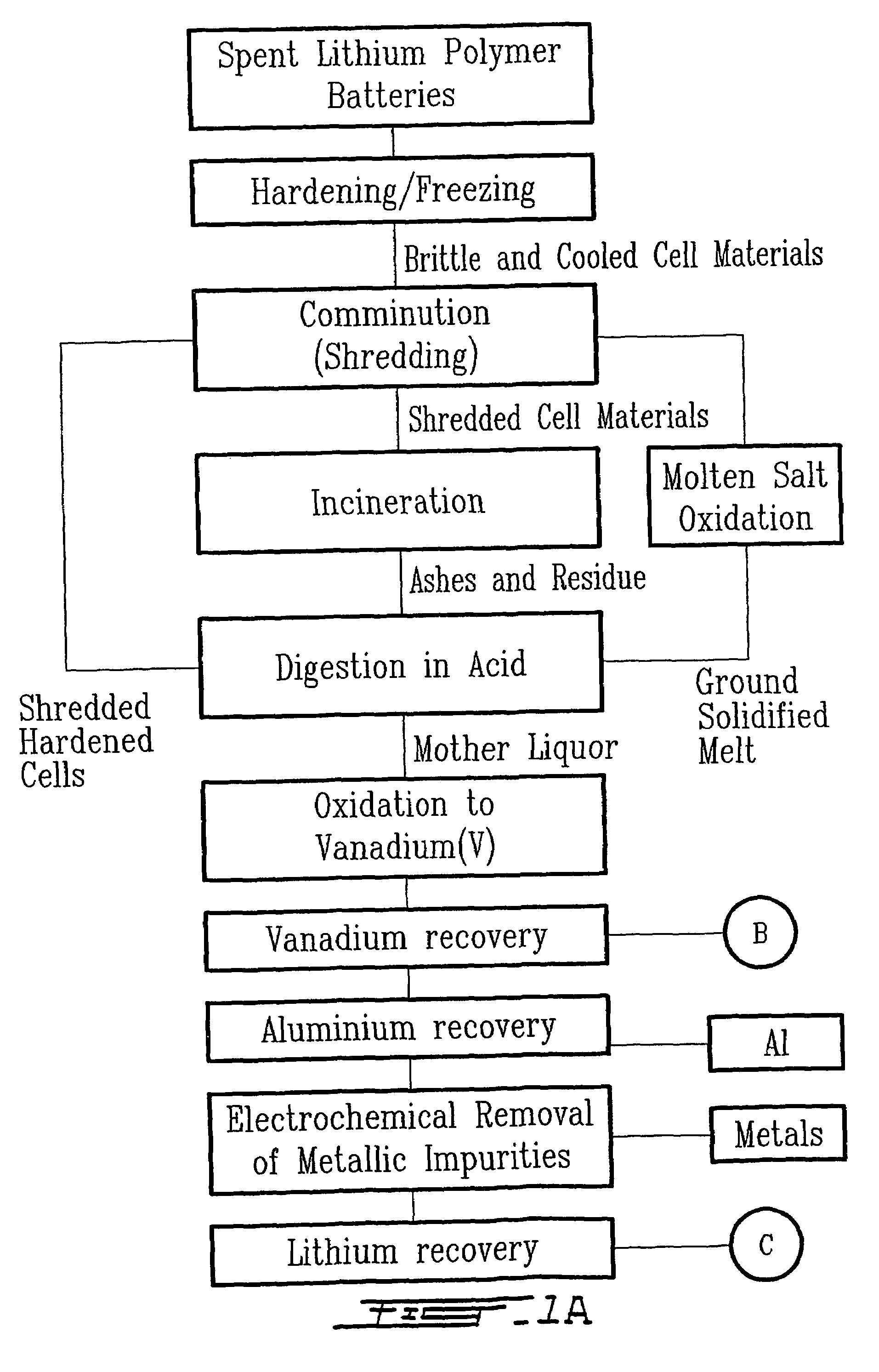

Method for recycling spent lithium metal polymer rechargeable batteries and related materials

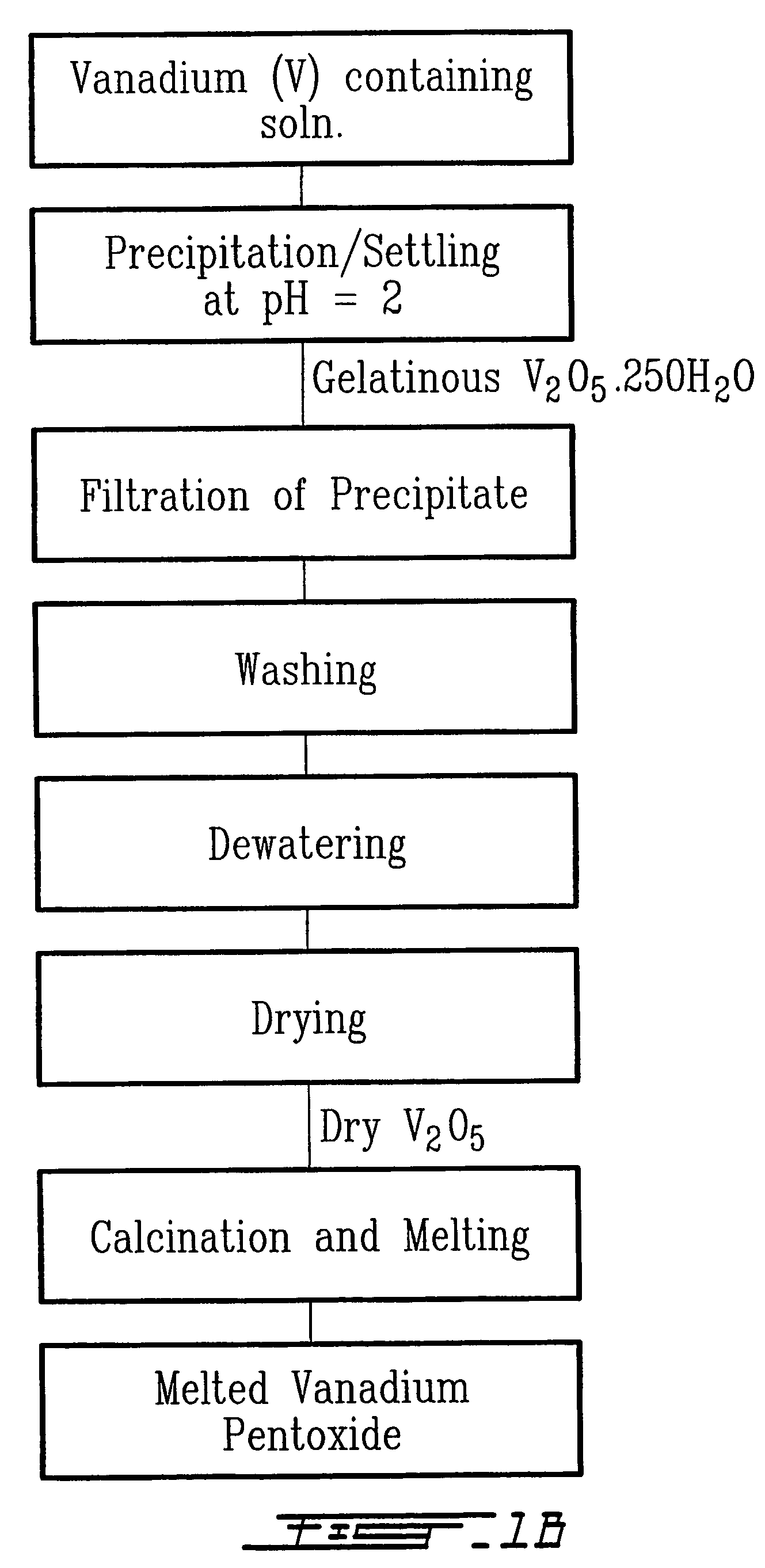

The method relates to a pyrometallurgical and hydrometallurgical process for the recovery and recycling of lithium and vanadium compounds from a material comprising spent rechargeable lithium batteries, particularly lithium metal gel and solid polymer electrolyte rechargeable batteries. The method involves providing a mass of the material, hardening it by cooling at a temperature below room temperature, comminuting the mass of cooled and hardened material, digesting with an acid its ashes obtained by incineration, or its solidified salts obtained by molten salt oxidation, or the comminuted mass itself, to give a mother liquor, extracting vanadium compounds from the mother liquor, separating heavy metals and aluminium therefrom, and precipitating lithium carbonate from the remaining solution.

Owner:AVESTOR

Method for growing group III-nitride crystals in a mixture of supercritical ammonia and nitrogen, and group III-nitride crystals grown thereby

ActiveUS20080102016A1Avoid dissociationHigh speed growthPolycrystalline material growthAluminium compoundsSource materialNitrogen

A method of growing group III-nitride crystals in a mixture of supercritical ammonia and nitrogen, and the group-III crystals grown by this method. The group III-nitride crystal is grown in a reaction vessel in supercritical ammonia using a source material or nutrient that is polycrystalline group III-nitride, amorphous group III-nitride, group-III metal or a mixture of the above, and a seed crystal that is a group-III nitride single crystal. In order to grow high-quality group III-nitride crystals, the crystallization temperature is set at 550° C. or higher. Theoretical calculations show that dissociation of NH3 at this temperature is significant. However, the dissociation of NH3 is avoided by adding extra N2 pressure after filling the reaction vessel with NH3.

Owner:JAPAN SCI & TECH CORP

Method for producing fine particles of metal oxide

A method for producing fine particles of metal oxide characterized in that metal halide is hydrolyzed in the presence of organic solvent. According to this invention, under hydrolysis of titanium tetrachrolide, anatase type titanium oxide can be obtained by selecting hydrophilic organic solvent, and rutile type titanium oxide can be obtained by selecting hydrophobic organic solvent.

Owner:SHOWA DENKO KK

Alumina abrasive for chemical mechanical polishing

InactiveUS20050194358A1Reduce amountSlowing rate of settlingPigmenting treatmentOther chemical processesCompound (substance)Slurry

Methods of manufacturing alumina abrasive for use in chemical mechanical polishing are described, wherein the abrasive is in a slurry having gamma alumina formed in a low temperature fuming process, water, an acid sufficient to maintain the pH below about 7, wherein the slurry does not settle appreciably in an 8 to 24 hour period. Advantageously, the alumina is wet-milled without the use of wet-milling salt additives.

Owner:VERSUM MATERIALS US LLC +1

Method of producing aluminum oxides and products obtained on the basis thereof

InactiveUS6841497B1Increase contentMaterial nanotechnologyPretreated surfacesNanoparticleCrystal structure

The invention relates to the field of technical ceramics and specifically relates to a method of synthesis for aluminum oxides of different crystalline structure and to the products obtained by the method. The aim of the invention is to provide a method of producing redispersible nanoparticulate corundum and nanoporous Al2O3 sintered products, the method using precursors and being viable on a commercial scale. To this aim, inter alia, a method of producing redispersible nanoparticulate corundum of an average particle size of D50<100 nm is used which method includes the addition of crystal nuclei. According to the method, organic or chlorine-free inorganic precursors are dissolved or processed to a sol and hydrolyzed. The substance is then dried and calcinated at temperatures of between 350 and 650° C. and is then further heated by increasing the temperature to ≦950° C. The aim of the invention is also attained by using a method of producing nanoporous Al2O3 sintered products according to which organic or chlorine-free inorganic precursors are dissolved or processed to a sol and hydrolyzed. The substance is then dried and calcinated at temperatures of between 350 and 750° C.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

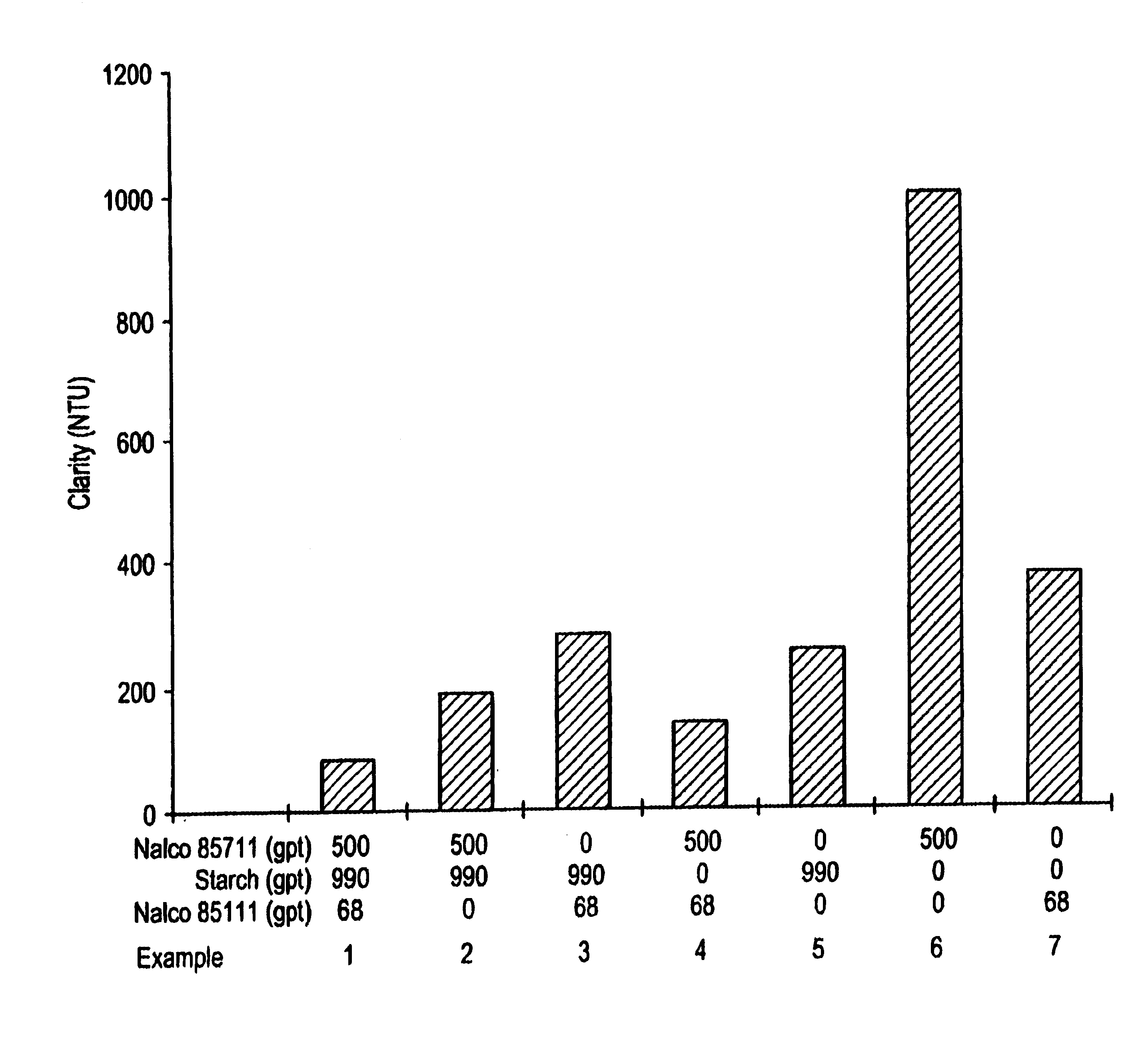

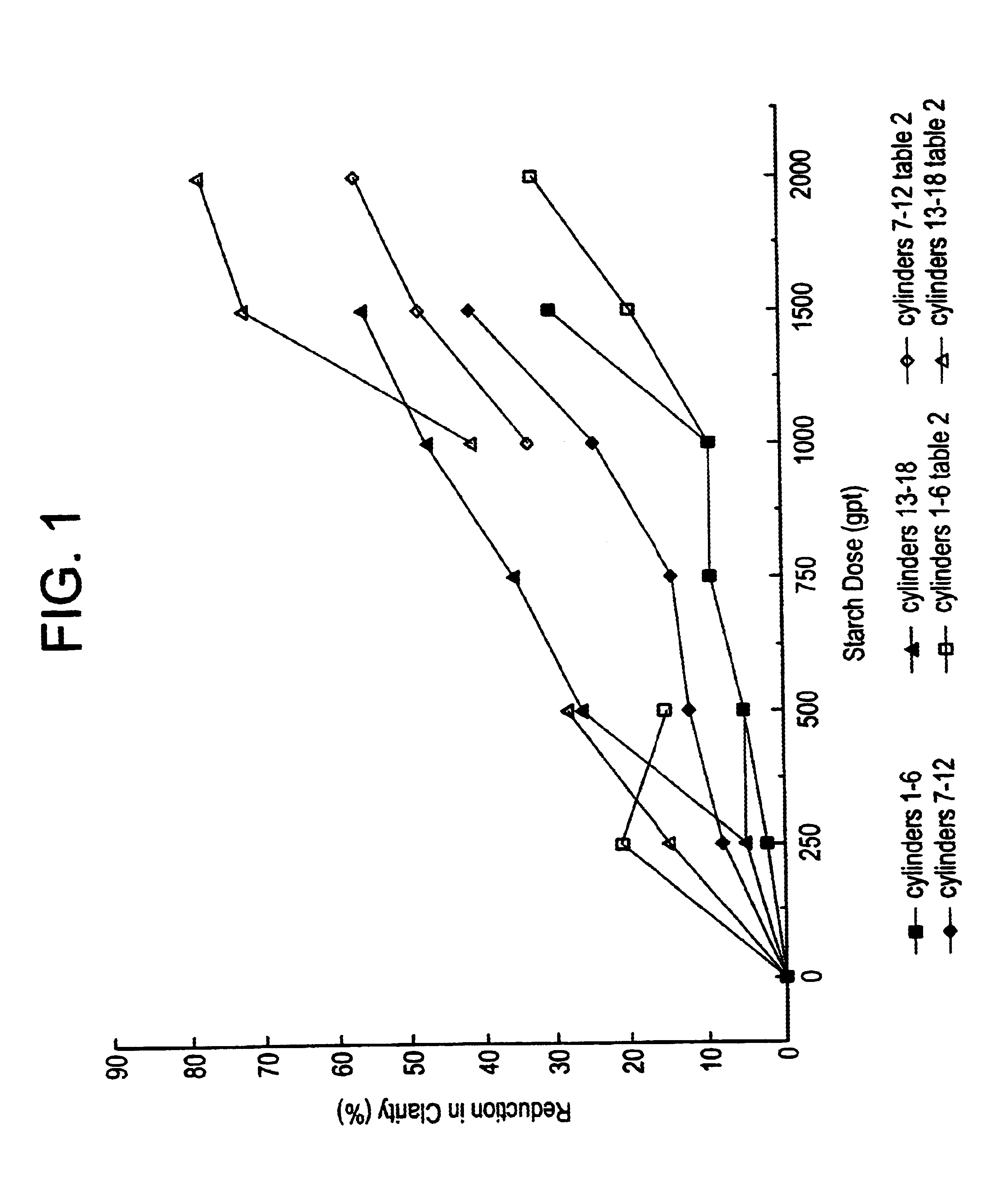

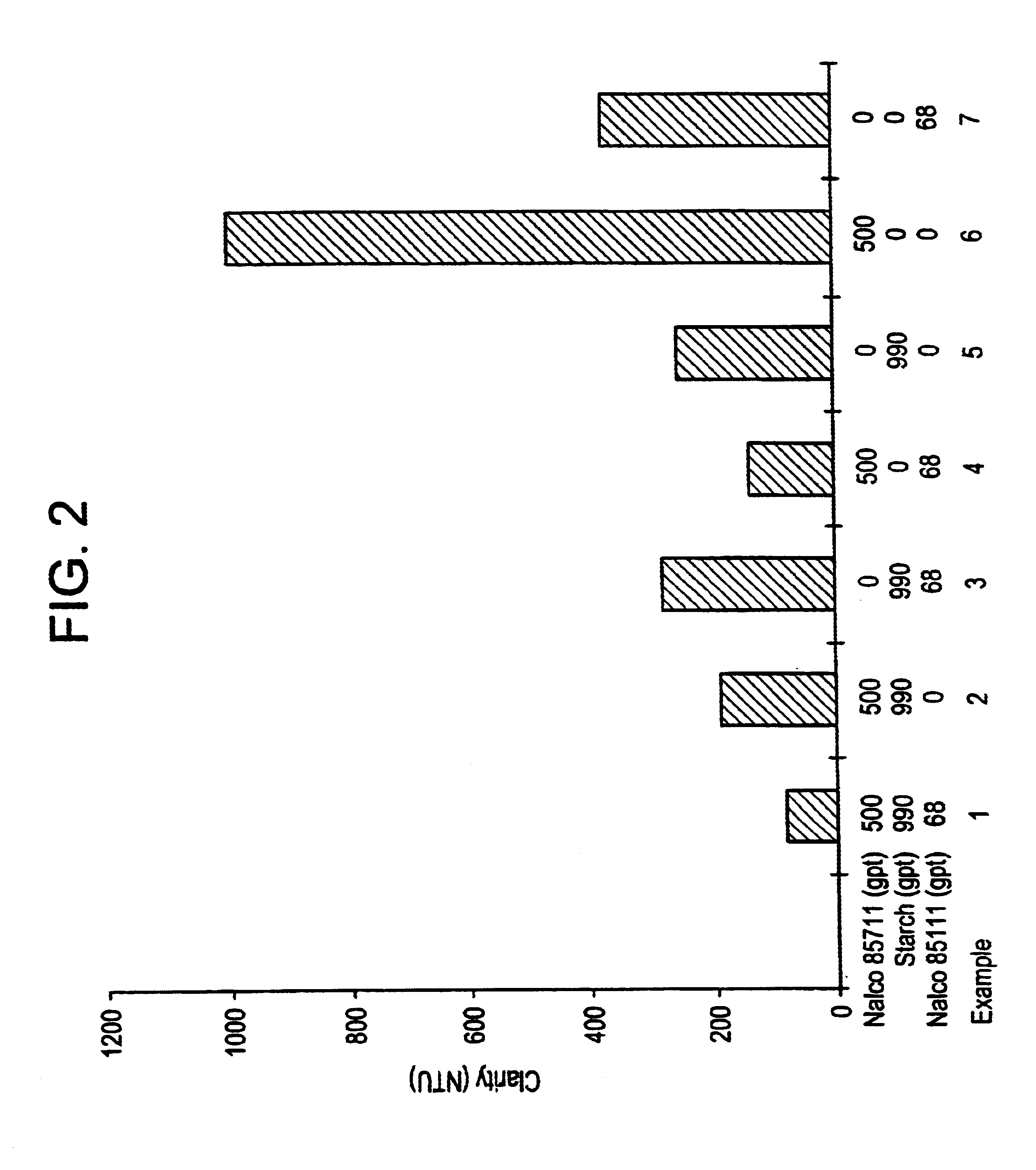

Dextran starch and flocculant combination for improving red mud clarification

InactiveUS6726845B1Easy to separateGallium/indium/thallium compoundsCentrifugal force sediment separationFiltrationCentrifugation

The claimed invention is a method for separating Bayer process red mud from a Bayer process liquor which comprises adding to a Bayer process liquor containing red mud an effective amount of a water soluble synthetic flocculant, dextran and starch combination. The flocculant is added anywhere in the slurry containing the red mud suspended in Bayer process liquor, or in a liquor slurry containing bauxite prior to or during digestion. Once the flocculant combination is added, it is mixed sequentially with the Bayer process liquor and the red mud contained in the Bayer process liquor is removed by sedimentation, centrifugation or filtration.

Owner:ECOLAB USA INC

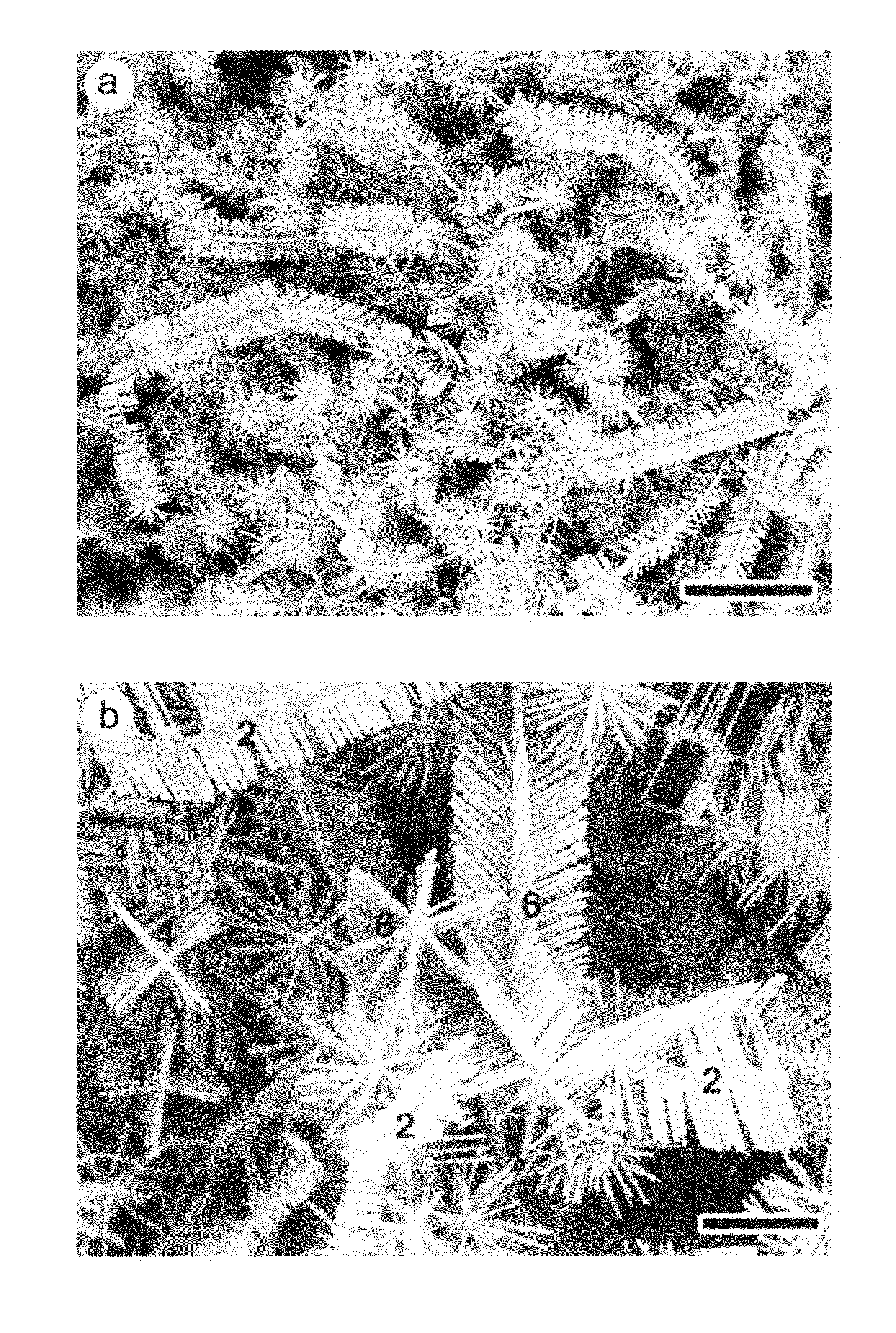

Metal oxide nanostructures with hierarchical morphology

InactiveUS7294417B2Reduce synthetic pressureStable emissionsMaterial nanotechnologyOxide/hydroxide preparationNanostructureMetal

The present invention relates generally to metal oxide materials with varied symmetrical nanostructure morphologies. In particular, the present invention provides metal oxide materials comprising one or more metallic oxides with three-dimensionally ordered nanostructural morphologies, including hierarchical morphologies. The present invention also provides methods for producing such metal oxide materials.

Owner:TRUSTEES OF BOSTON COLLEGE THE

Process for recovery of gallium

InactiveUS20040042945A1High yieldHigh purityAluminium compoundsPhotography auxillary processesGallium alloyChemistry

The present invention relates to a process for the recovery of gallium from Bayer process liquors. Bayer process liquor is obtained from alumina industries and contains 450 g / L Na2O, 80 g / L Al2O3 and 190±20 ppm of gallium. The present invention utilizes an organic and inorganic phase for a two stage separation process to recover gallium with high purity.

Owner:COUNCIL OF SCI & IND RES

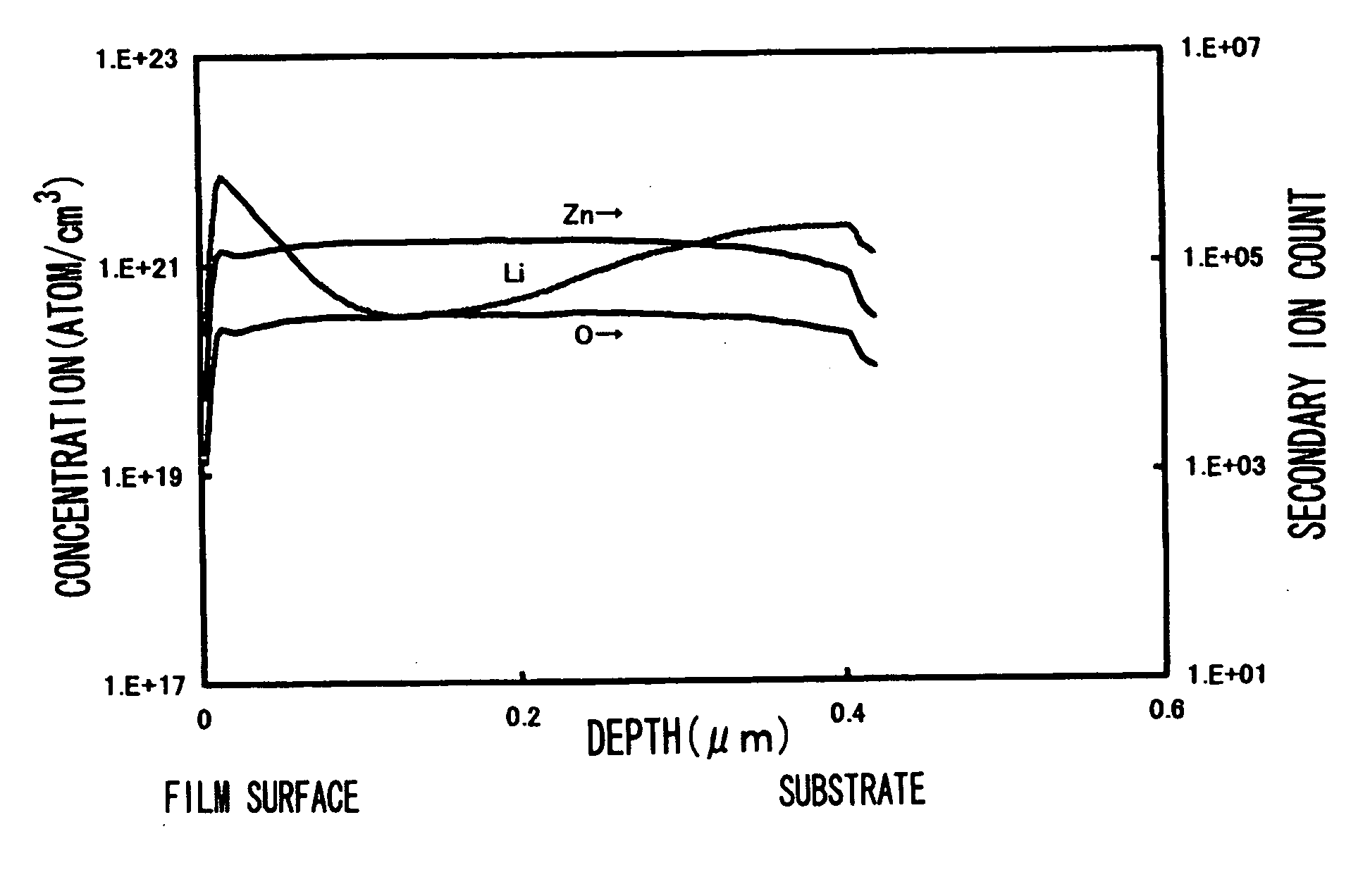

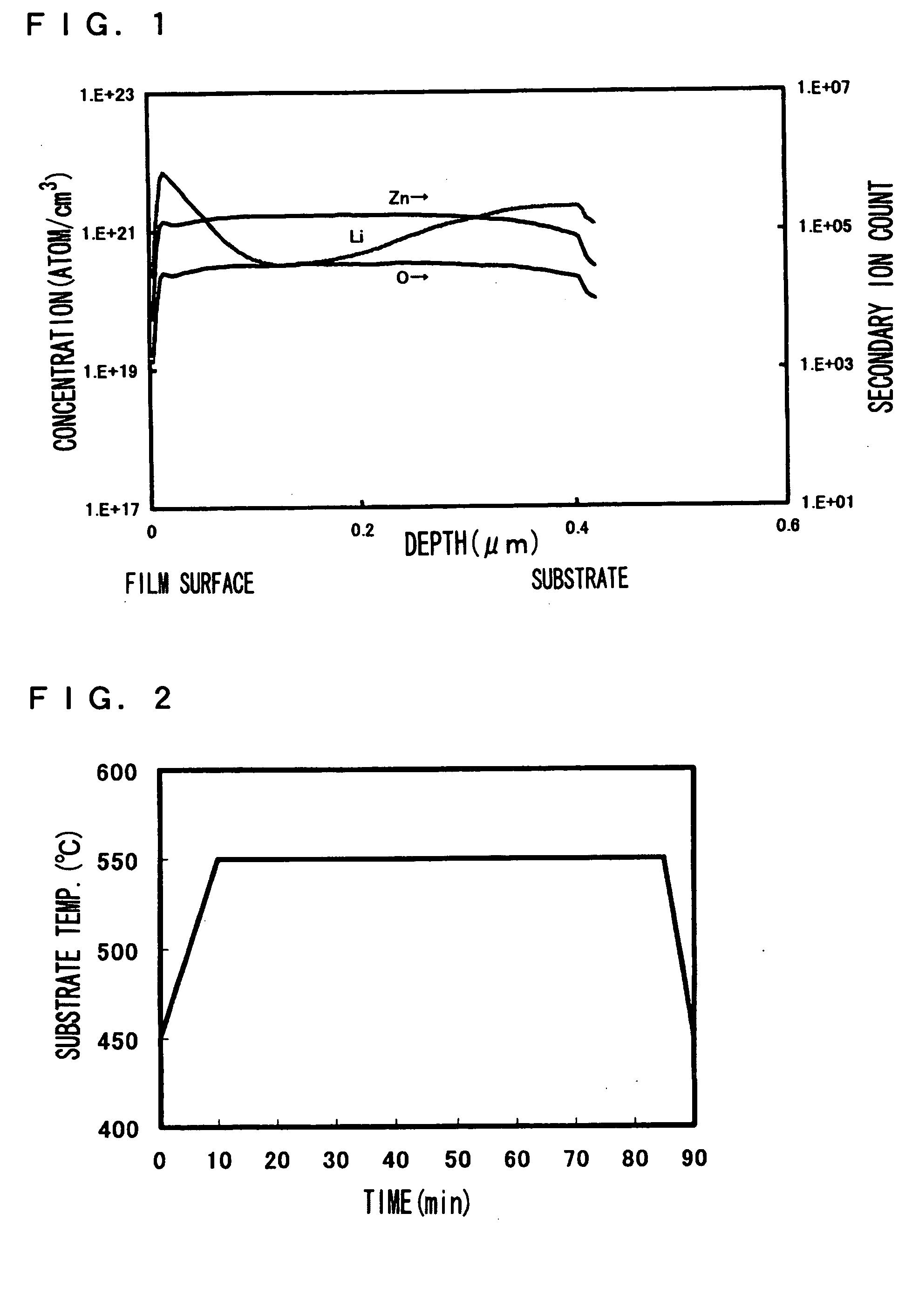

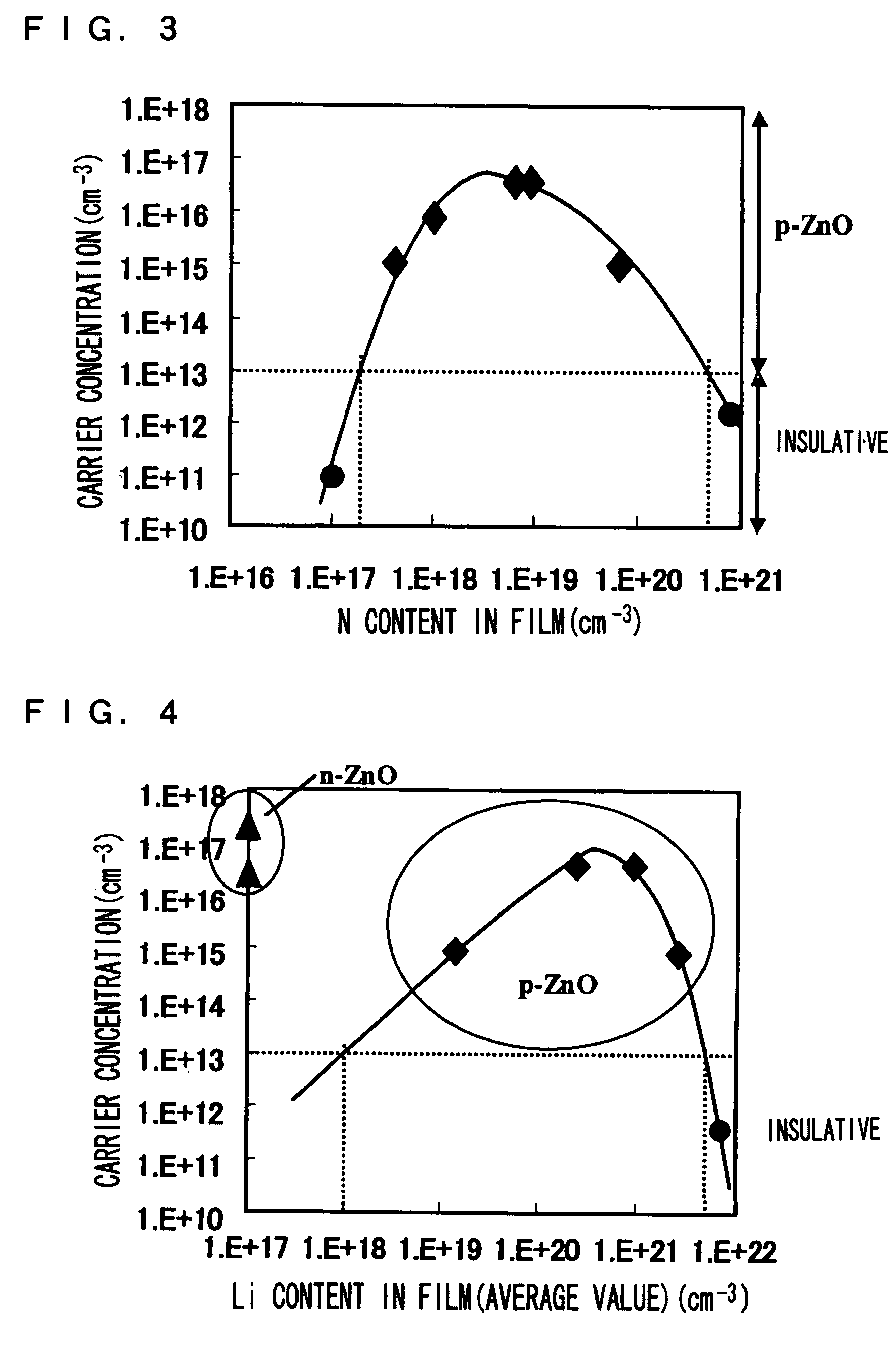

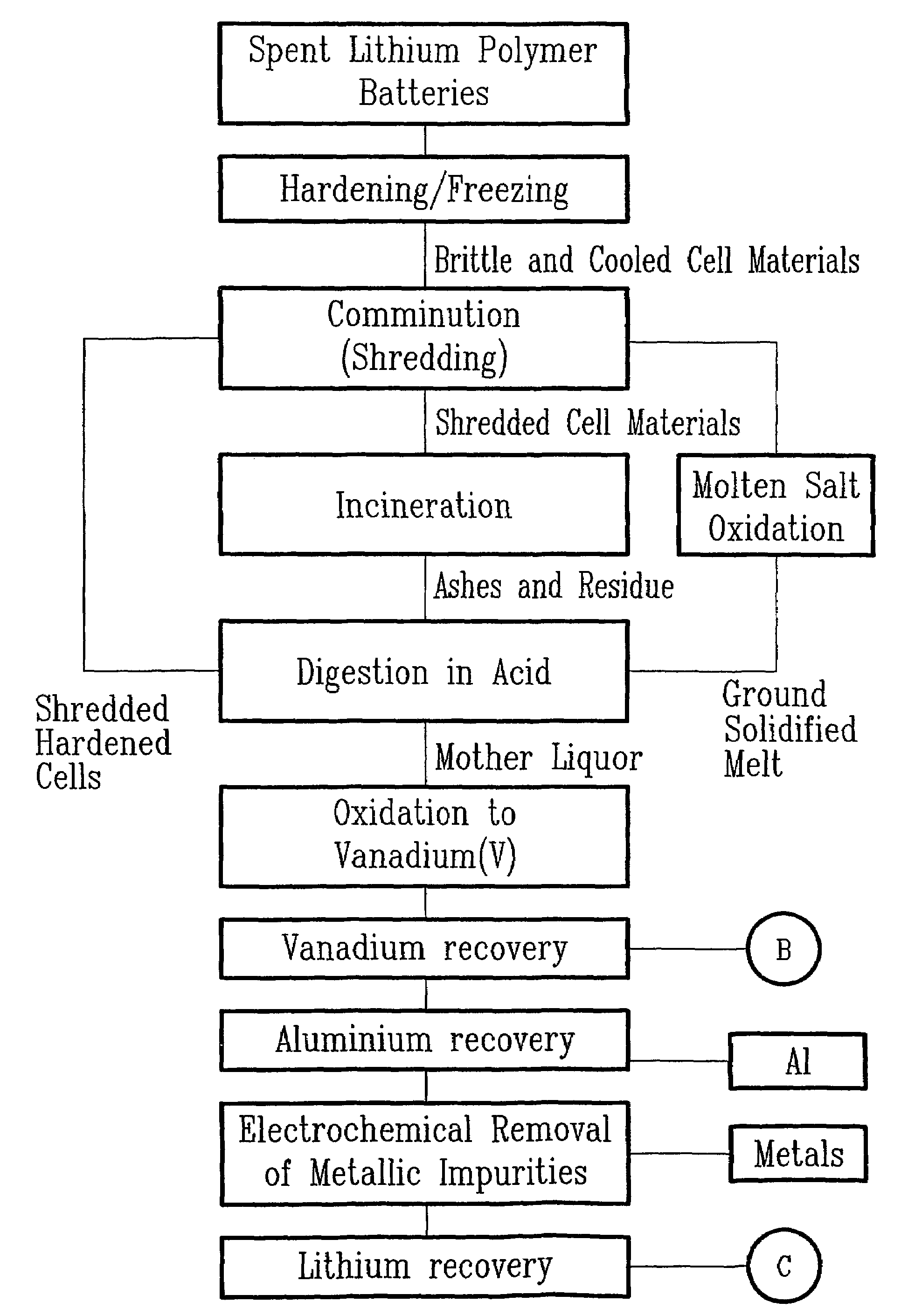

P-type zinc oxide semiconductor film and process for preparation thereof

InactiveUS20050170971A1Effective compensationConductive materialVacuum evaporation coatingNitrogenZinc

A p-type ZnO semiconductor film comprised mainly of Zn and O elements is disclosed. The film is characterized as containing an alkali metal and nitrogen. Preferably, the alkali metal is contained such that its concentration is distributed to increase toward an end or toward both ends in the thickness direction of the film. More preferably, the alkali metal is contained in the concentration range of 1×1018-5×1021 cm−3 and the nitrogen in the concentration range of 2×1017-5×1020 cm−3.

Owner:SANYO ELECTRIC CO LTD

Method for recycling spent lithium metal polymer rechargeable batteries and related materials

The method relates to a pyrometallurgical and hydrometallurgical process for the recovery and recycling of lithium and vanadium compounds from a material comprising spent rechargeable lithium batteries, particularly lithium metal gel and solid polymer electrolyte rechargeable batteries. The method involves providing a mass of the material, hardening it by cooling at a temperature below room temperature, comminuting the mass of cooled and hardened material, digesting with an acid its ashes obtained by incineration, or its solidified salts obtained by molten salt oxidation, or the comminuted mass itself, to give a mother liquor, extracting vanadium compounds from the mother liquor, separating heavy metals and aluminium therefrom, and precipitating lithium carbonate from the remaining solution.

Owner:AVESTOR

Carbon black

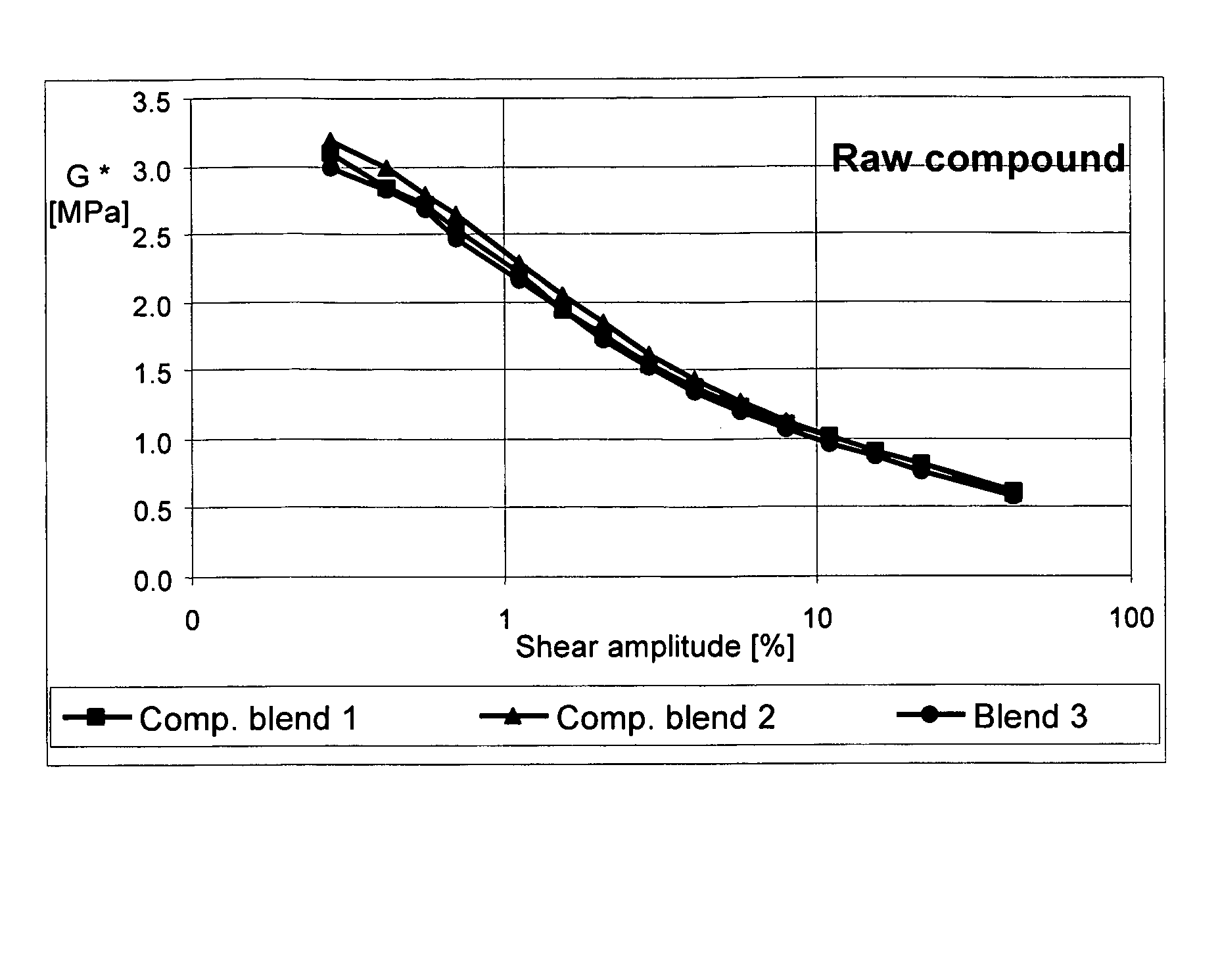

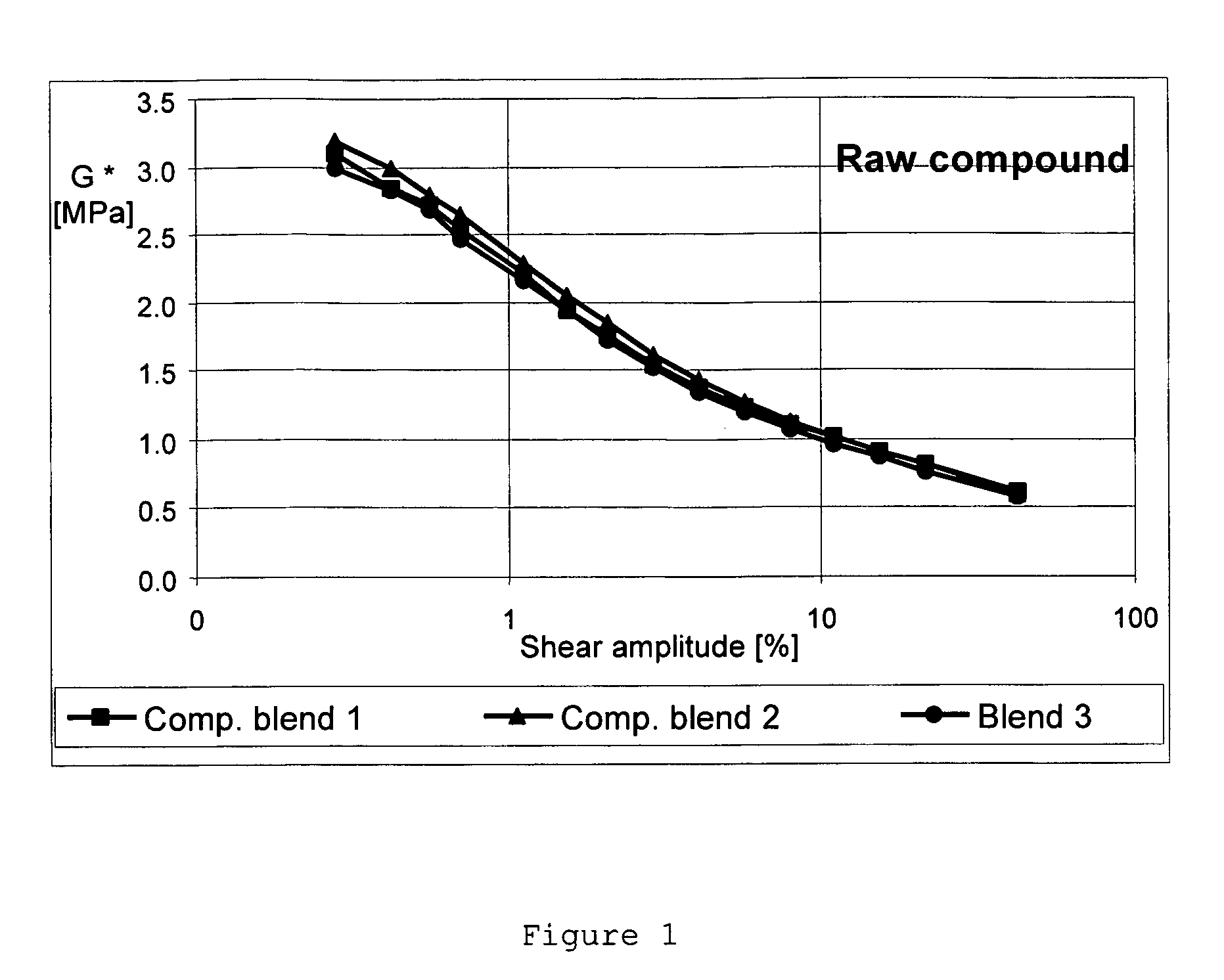

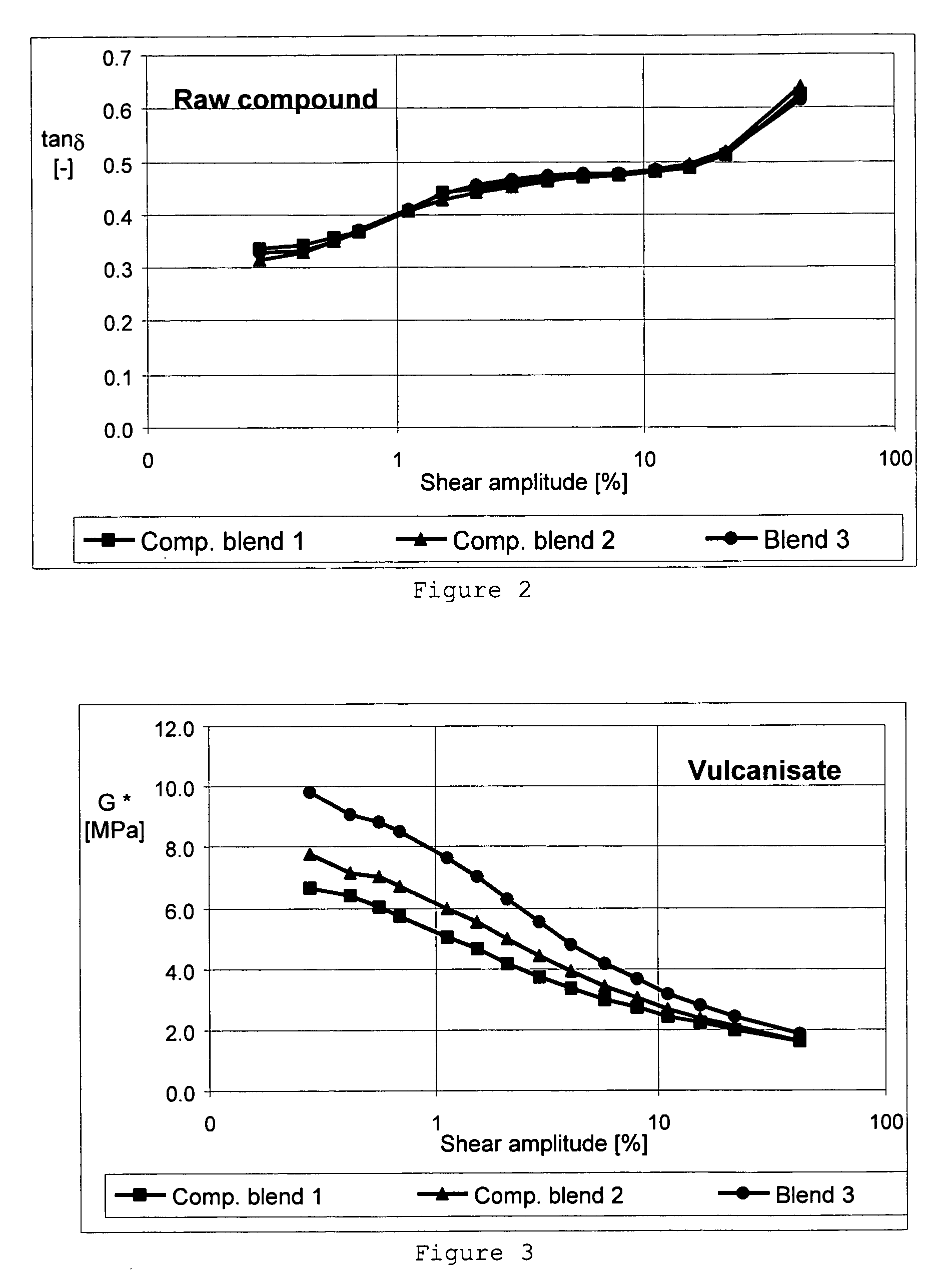

ActiveUS7300964B2Improve dynamic rigidityReduce hysteresisOrganic chemistryOther chemical processesOrganic groupOrganic compound

Carbon black having organic groups, the organic group containing a thiocyanate group. Also described is a process for the production of the carbon black, wherein carbon black is reacted with organic compounds containing a C—C double or triple bond, which is not part of an aromatic system, whose C—C double or triple bond is activated by at least one substituent, and the organic compound contains at least one thiocyanate group. The carbon black according to the invention can be used in rubber compounds.

Owner:UBS AG

Recovery of the transition metal component of catalyst used in heavy feed hydroconversion

The invention relates to a process for recovering the transition metal component of catalysts used in the hydroconversion of heavy hydrocarbonaceous materials. In accordance with the invention, a slurry of a transition metal catalyst and hydrocarbon is catalytically desulfurized resulting in a desulfurized product and a solid residue containing the transition metal. The transition metal may be recovered by coking the residue and then dividing the coker residue into two portions are combusted with the flue dust from the first combustion zone being conducted to the second combustion zone. The flue dust from the second combustion zone is treated with ammonia and ammonium carbonate in order to obtain ammonium molybdate.

Owner:EXXON RES & ENG CO

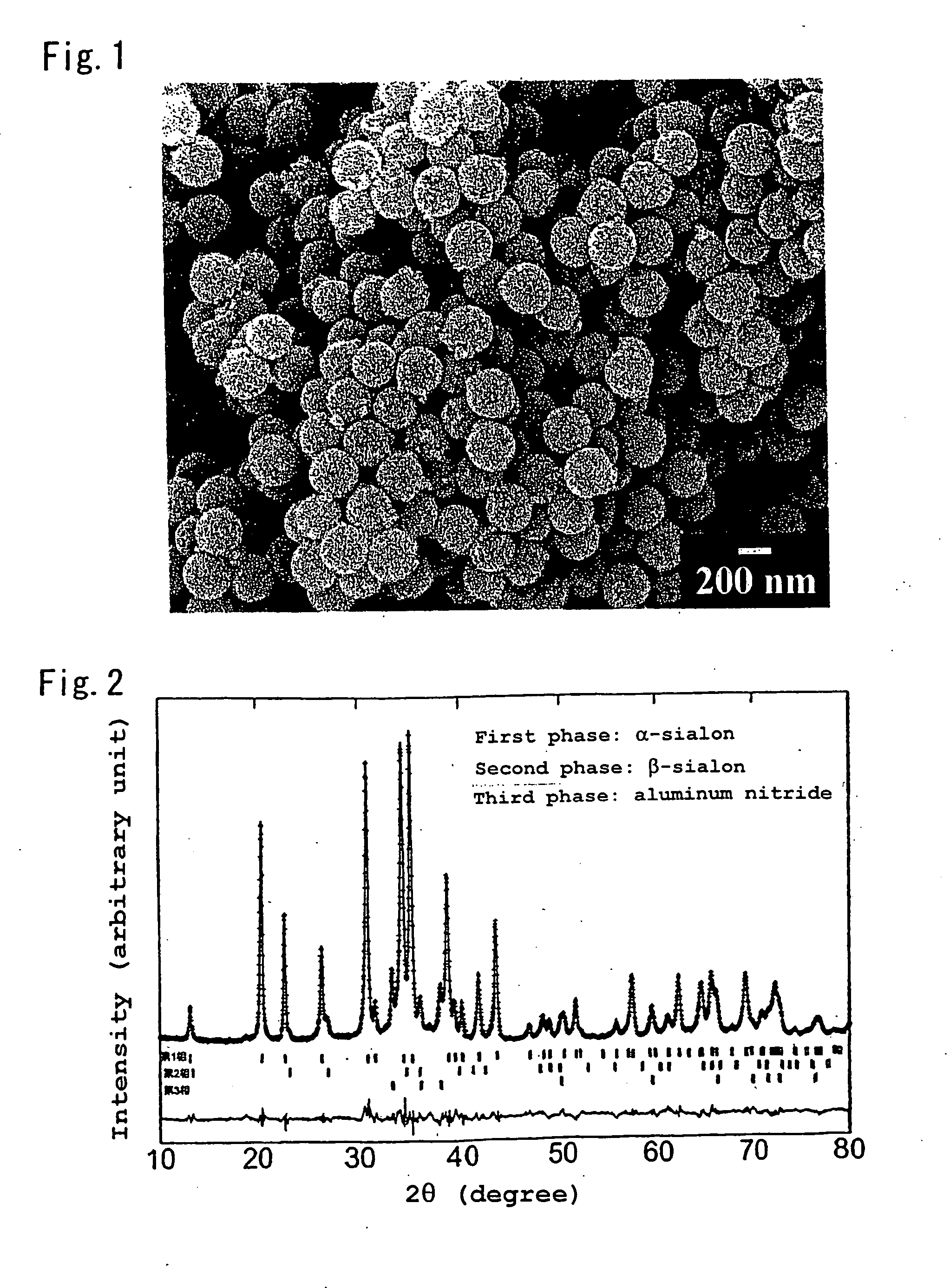

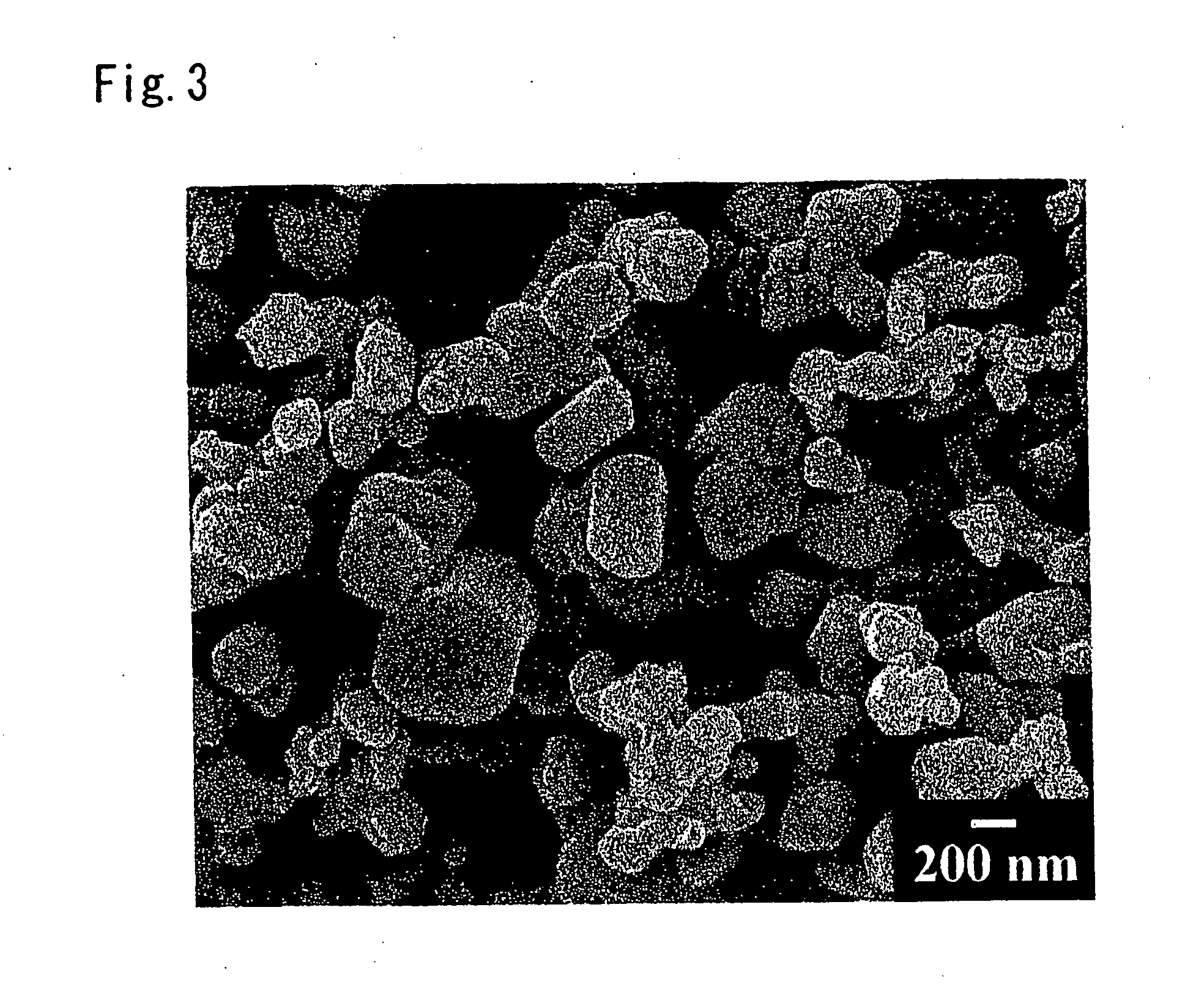

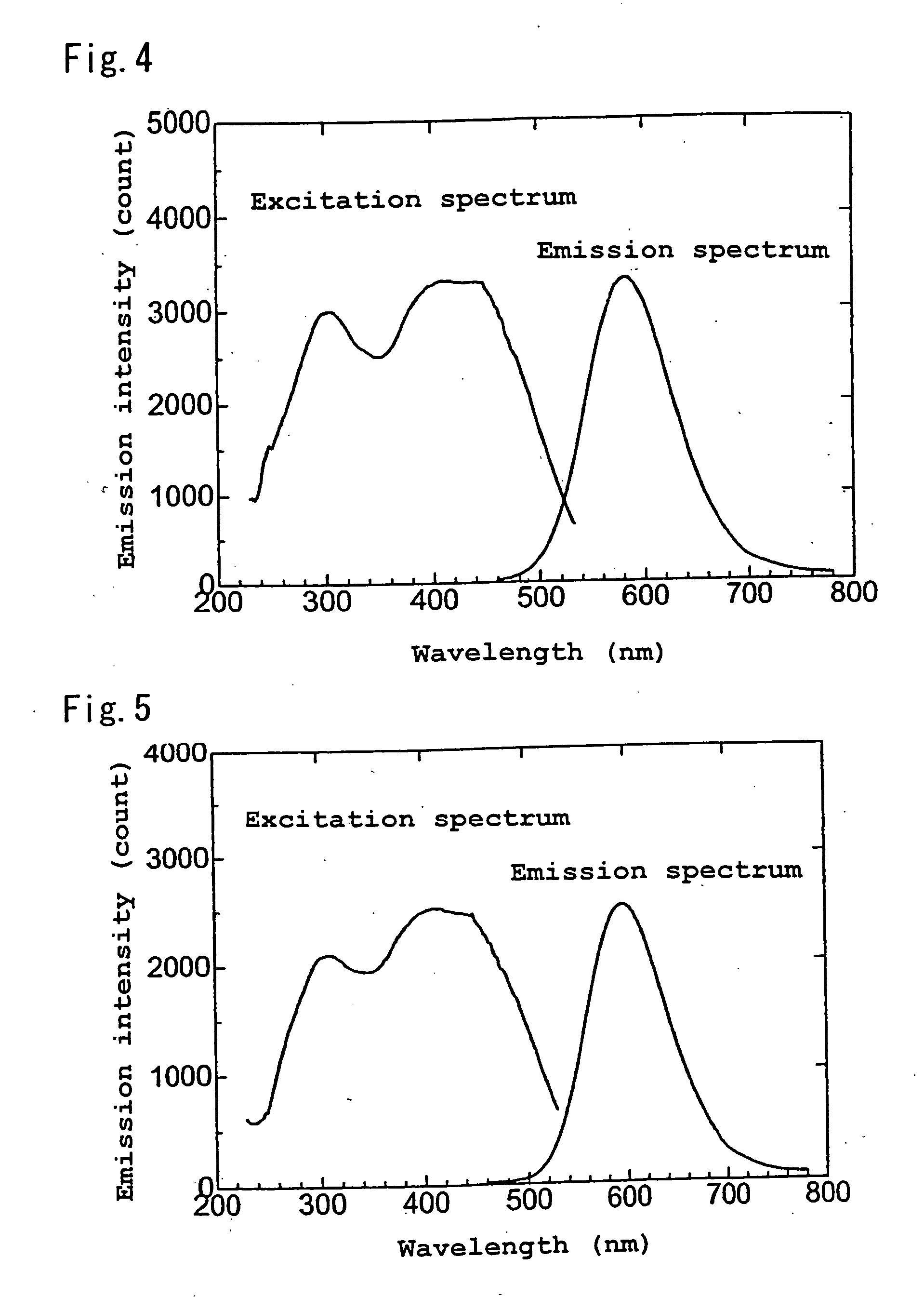

Oxynitride powder and production method thereof

ActiveUS20070166218A1Low oxygenHigh nitrogen contentAluminium compoundsAluminium silicatesPhosphorNitrogen

It is aimed at providing an oxynitride powder, which is suitable for usage as a phosphor, is free from coloration due to contamination of impurities, and mainly includes a fine α-sialon powder. An oxynitride powder is produced by applying a heat treatment in a reducing and nitriding atmosphere, to a precursor compound including at least constituent elements M, Si, Al, and O (where M is one element or mixed two or more elements selected from Li, Mg, Ca, Sr, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu), thereby decreasing an oxygen content and increasing a nitrogen content of the precursor.

Owner:NAT INST FOR MATERIALS SCI

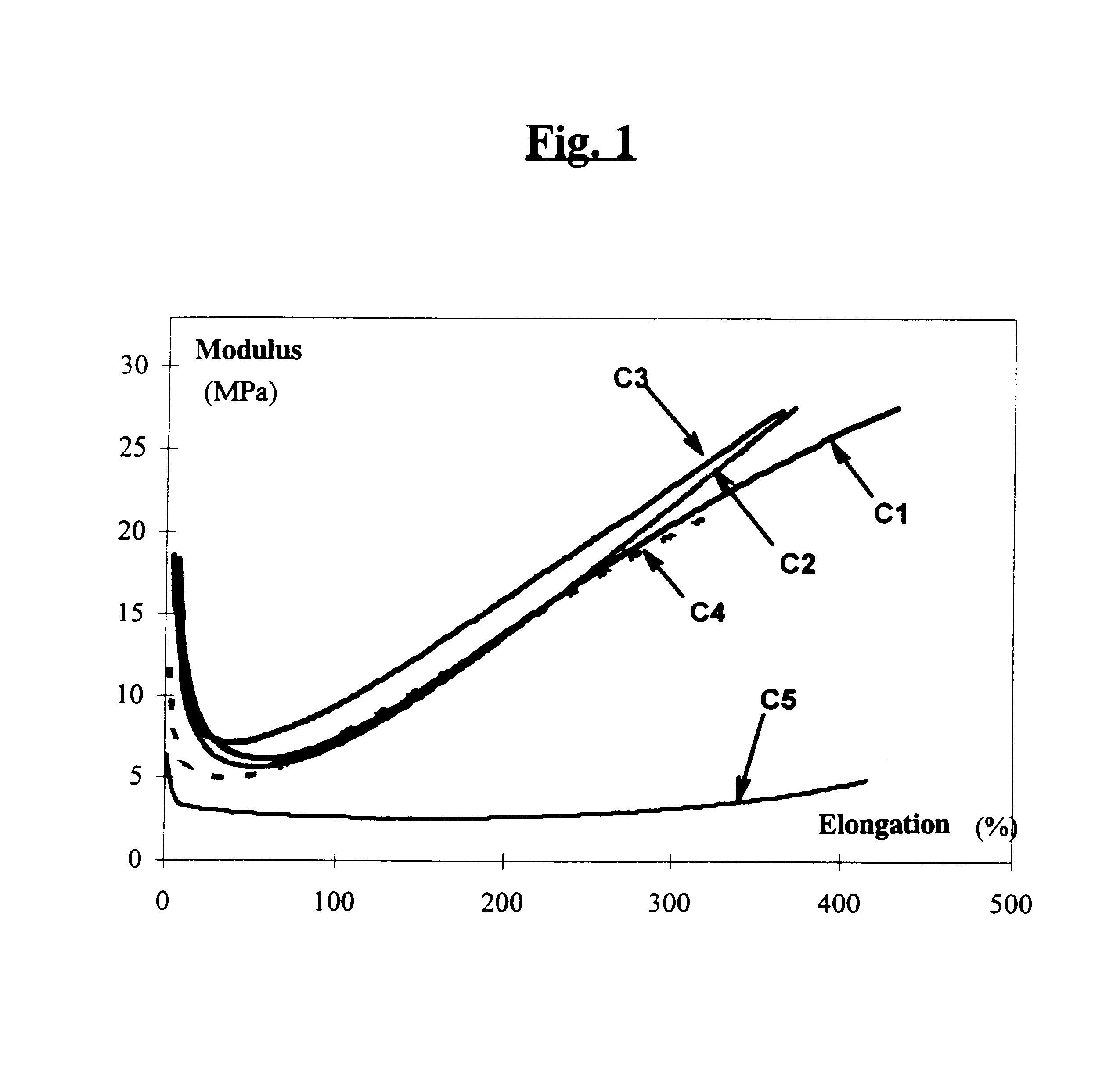

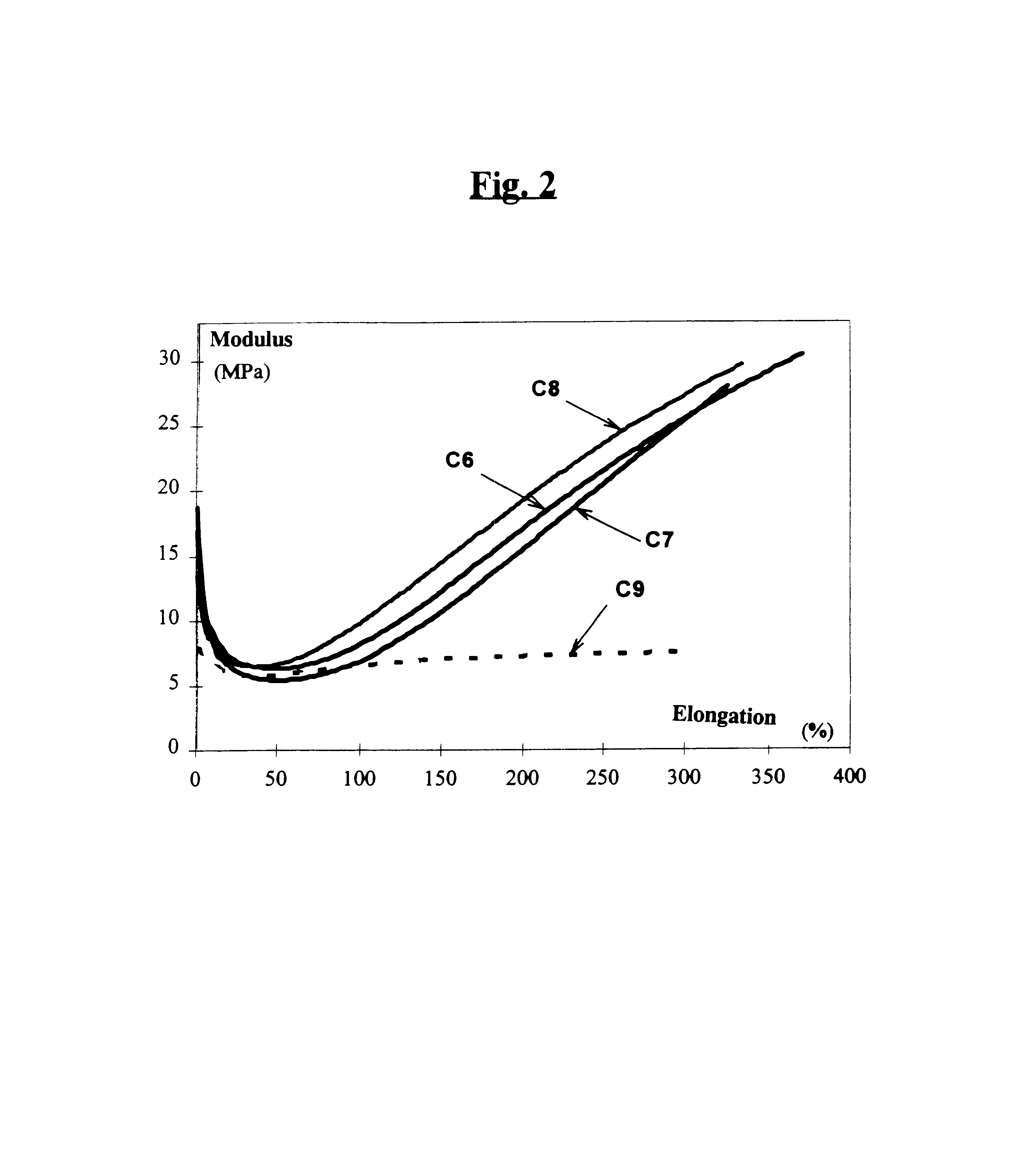

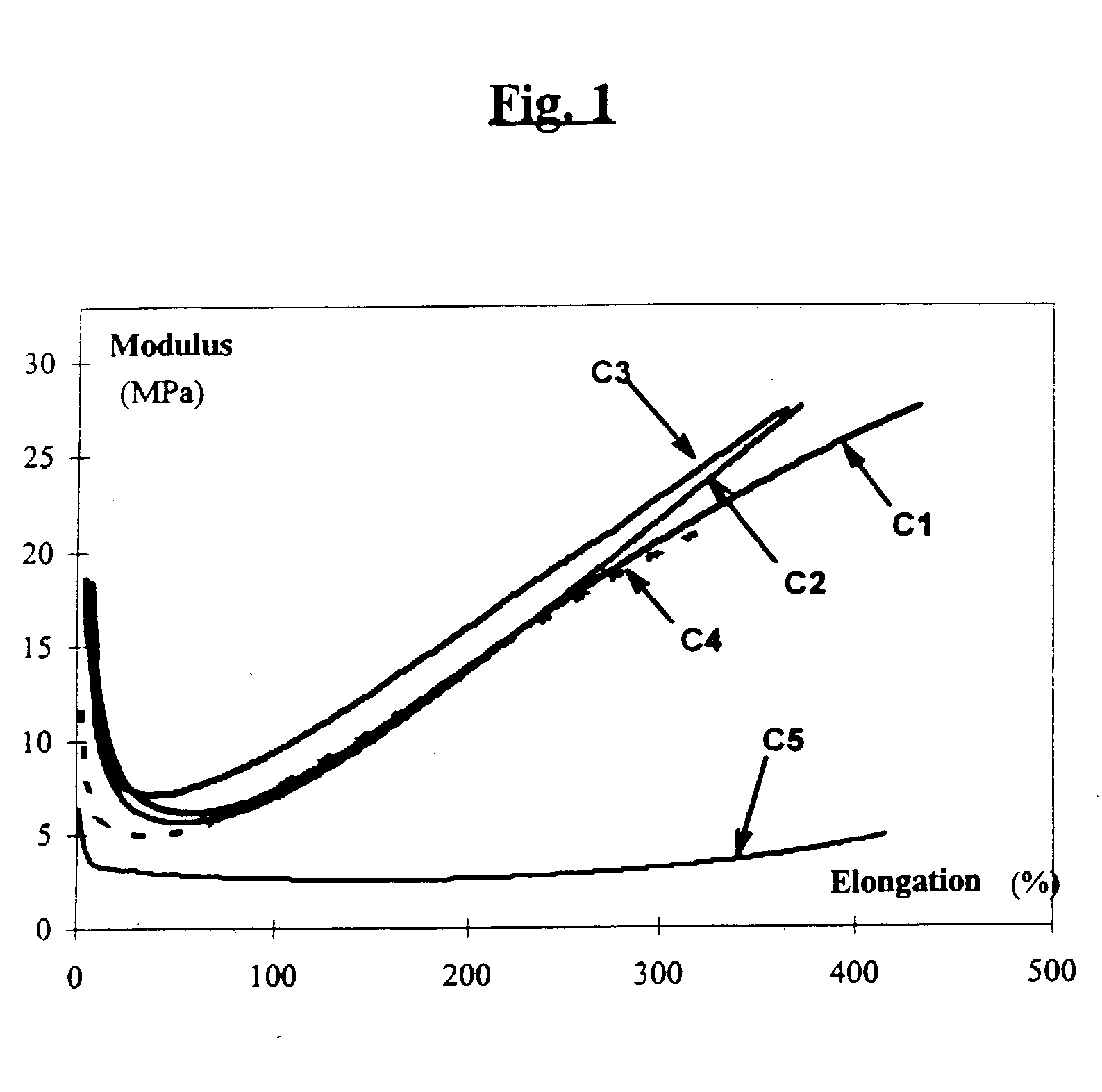

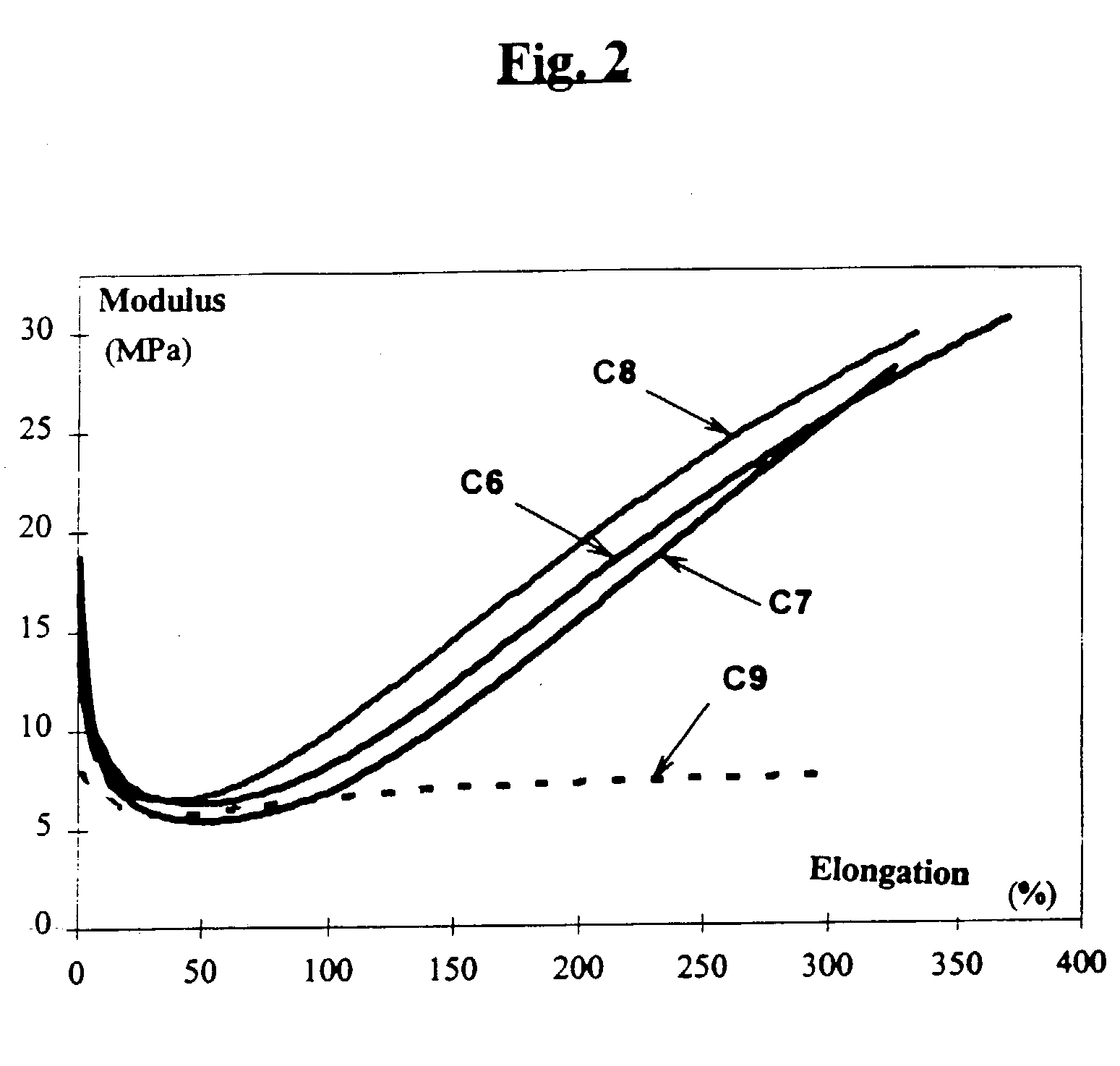

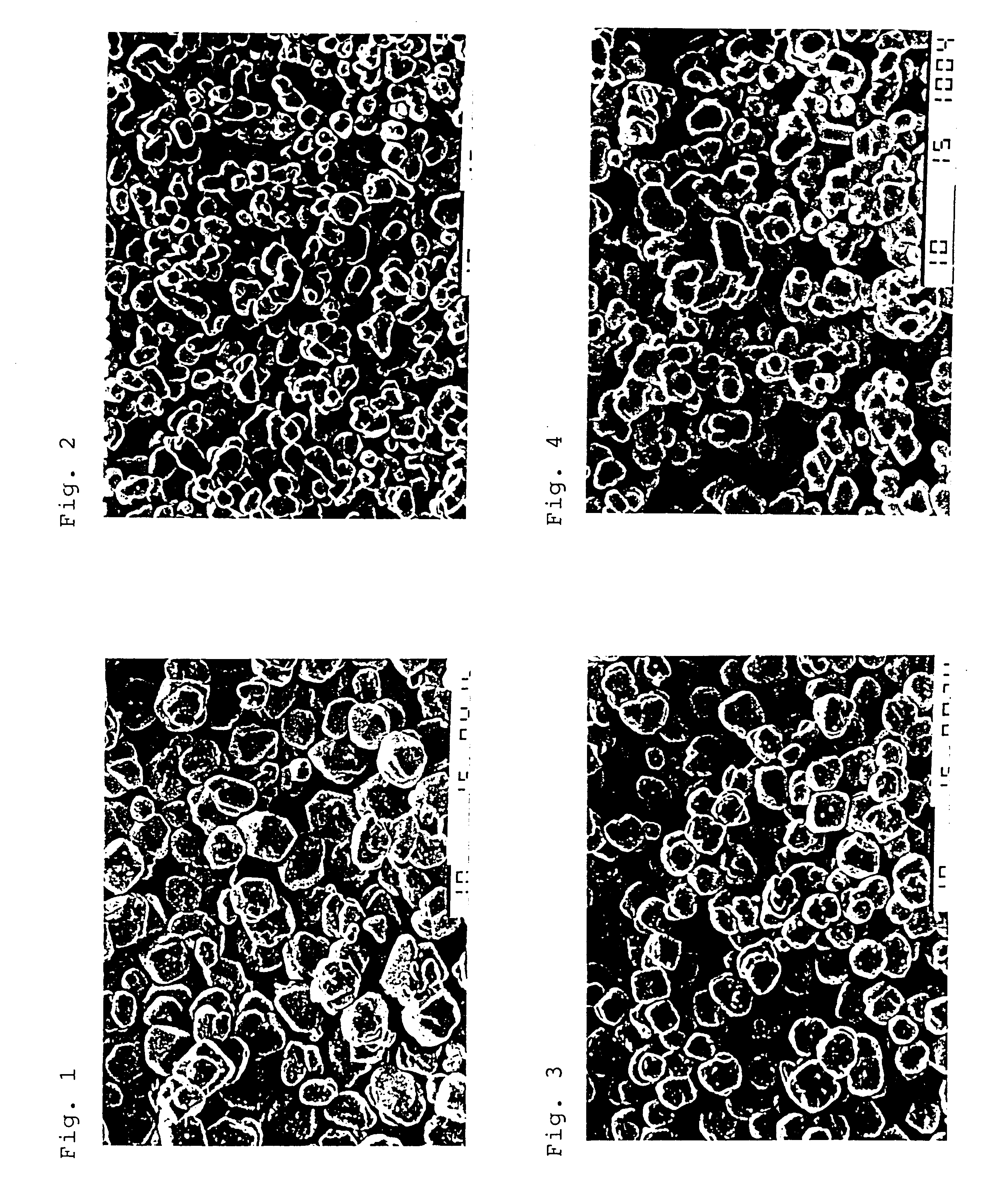

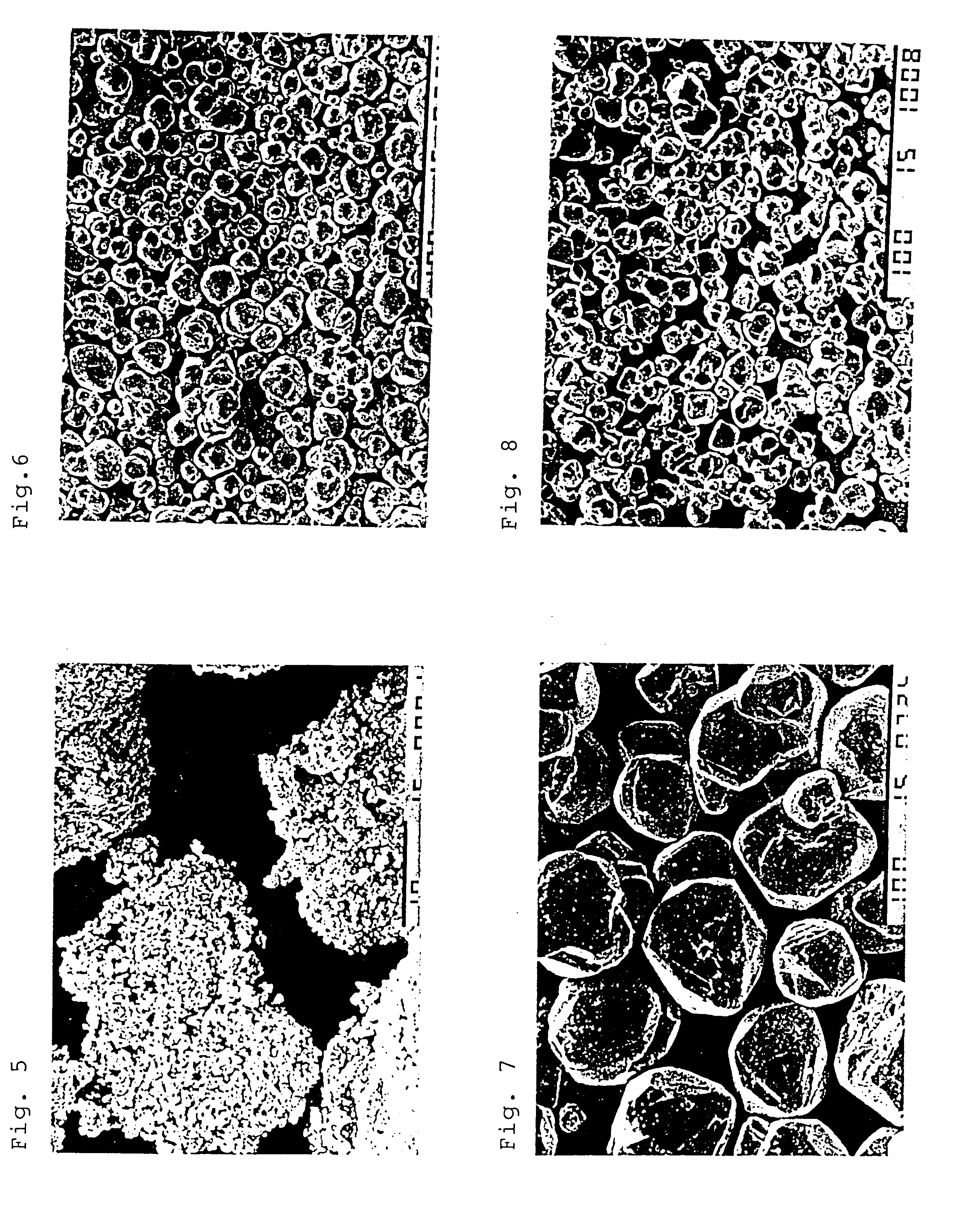

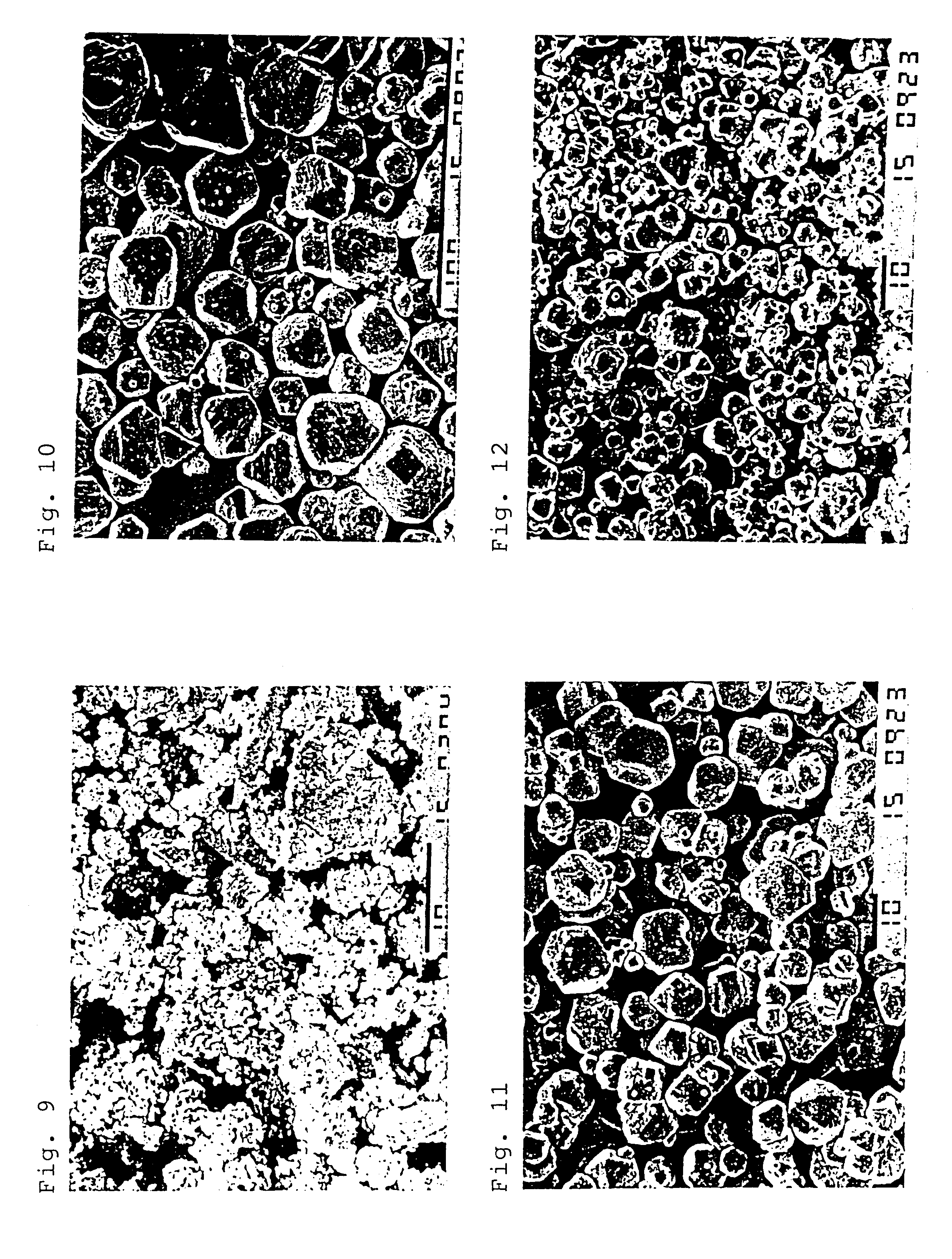

Reinforcing aluminum-based filler and rubber composition Comprising such a filler

A reinforcing aluminum-based filler which can be used for reinforcing diene rubber compositions intended for the manufacture of tires, comprising an aluminum (oxide-)hydroxide corresponding, with the exception of any impurities and the water of hydration, to the general formula (a and b being real numbers): Al(OH)aOb, with 0<a<=3 and b=(3-a) / 2, (I) the specific BET surface area of which is between 30 and 400 nm<2> / g, the average particle size (by mass) dw of which is between 20 and 400 nm and the disagglomeration rate, alpha, of which, measured via an ultrasound disagglomeration test at 100% power of a 600-watt ultrasonic probe, is greater than 5x10<-3 >mum<-1> / s is provided. A rubber composition suitable for the manufacture of tires comprising said aluminum-based filler as reinforcing filler.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Recovery of alumina trihydrate during the bayer process using cross-linked polysaccharides

ActiveUS8298508B2Accelerated settlementEnhanced inhibitory effectGallium/indium/thallium compoundsAluminates/aluminium-oxide/aluminium-hydroxide purificationCross-linkCellulose

The invention provides methods and compositions for improving the production of alumina hydrate. The invention involves adding one or more polysaccharides to liquor or slurry in the fluid circuit of the production process. The one or more polysaccharides can be a cross-linked polysaccharide (such as cross-linked dextran or cross-linked dihydroxypropyl cellulose). The various polysaccharides can impart a number of advantages including at least some of: greater flocculation effectiveness, increasing the maximum effective dosage, faster settling rate. The production process can be a Bayer process.

Owner:NALCO CO

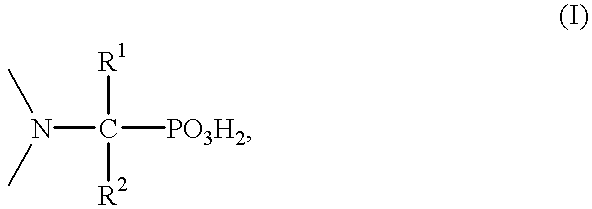

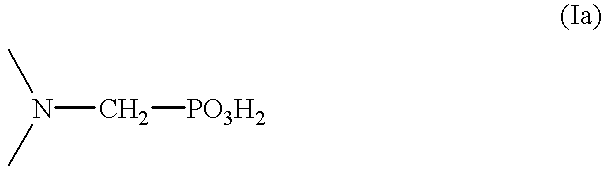

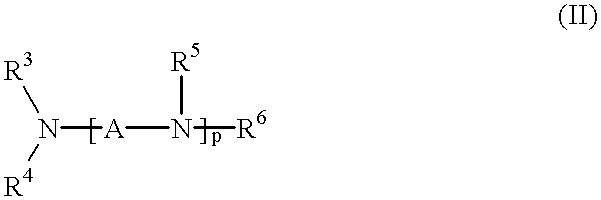

Method for effecting solvent extraction of metal ions using hydrocarbon soluble aminomethylene phosphonic acid compounds

Solvent extraction of one or more metal ions from an aqueous solution in the presence of hydrocarbon-soluble aminomethylenephosphonic acid derivatives.

Owner:BASF AG +1

Recovery of alumina trihydrate during the bayer process using cross-linked polysaccharides

ActiveUS20120034142A1Accelerated settlementEnhanced inhibitory effectGallium/indium/thallium compoundsAluminates/aluminium-oxide/aluminium-hydroxide purificationCross-linkCellulose

The invention provides methods and compositions for improving the production of alumina hydrate. The invention involves adding one or more polysaccharides to liquor or slurry in the fluid circuit of the production process. The one or more polysaccharides can be a cross-linked polysaccharide (such as cross-linked dextran or cross-linked dihydroxypropyl cellulose). The various polysaccharides can impart a number of advantages including at least some of: greater flocculation effectiveness, increasing the maximum effective dosage, faster settling rate. The production process can be a Bayer process.

Owner:NALCO CO

Indium oxide-tin oxide powders and method for producing the same

InactiveUS6051166ADecrease productivityImprove sputtering efficiencyAluminium compoundsGallium/indium/thallium compoundsSaline waterIndium

A method for producing an indium oxide-tin oxide powder, which comprises supplying to react an aqueous solution of an indium salt, an aqueous solution of a tin salt and an aqueous alkaline solution into water at 40 DEG C. or more and less than 100 DEG C. so that the pH during the reaction is maintained within the range from 4 to 6, forming a precipitate, washing the formed precipitate after solid-liquid separation, and calcining the precipitate at 600 DEG C. or more and 1300 DEG C. or less.

Owner:SUMITOMO CHEM CO LTD

Lithium-manganese composite oxide granular secondary particle, method for production thereof and use thereof

ActiveUS20050123832A1Improve output characteristicsMaintain good propertiesAluminium compoundsLithium compoundsMicrometerCompound (substance)

The invention provides granular secondary particles of a lithium-manganese composite oxide which are granular secondary particles made up of aggregated crystalline primary particles of a lithium-manganese composite oxide and have many micrometer-size open voids therein, the open voids having an average diameter in the range of from 0.5 to 3 μm and the total volume of the open voids being in the range of from 3 to 20 vol. % on average based on the total volume of the granules. These particles are suitable for use as a constituent material for non-aqueous electrolyte secondary batteries showing high-output characteristics. The invention further provides a process for producing the granular secondary particles of a lithium-manganese composite oxide which includes spray-drying a slurry prepared by dispersing a fine powder of a manganese oxide, a lithium source, an optional compound containing at least one element selected from Al, Co, Ni, Cr, Fe, and Mg, and an agent for open-void formation to thereby granulate the slurry and then calcining the granules at a temperature of from 700 to 900° C.

Owner:TOSOH CORP

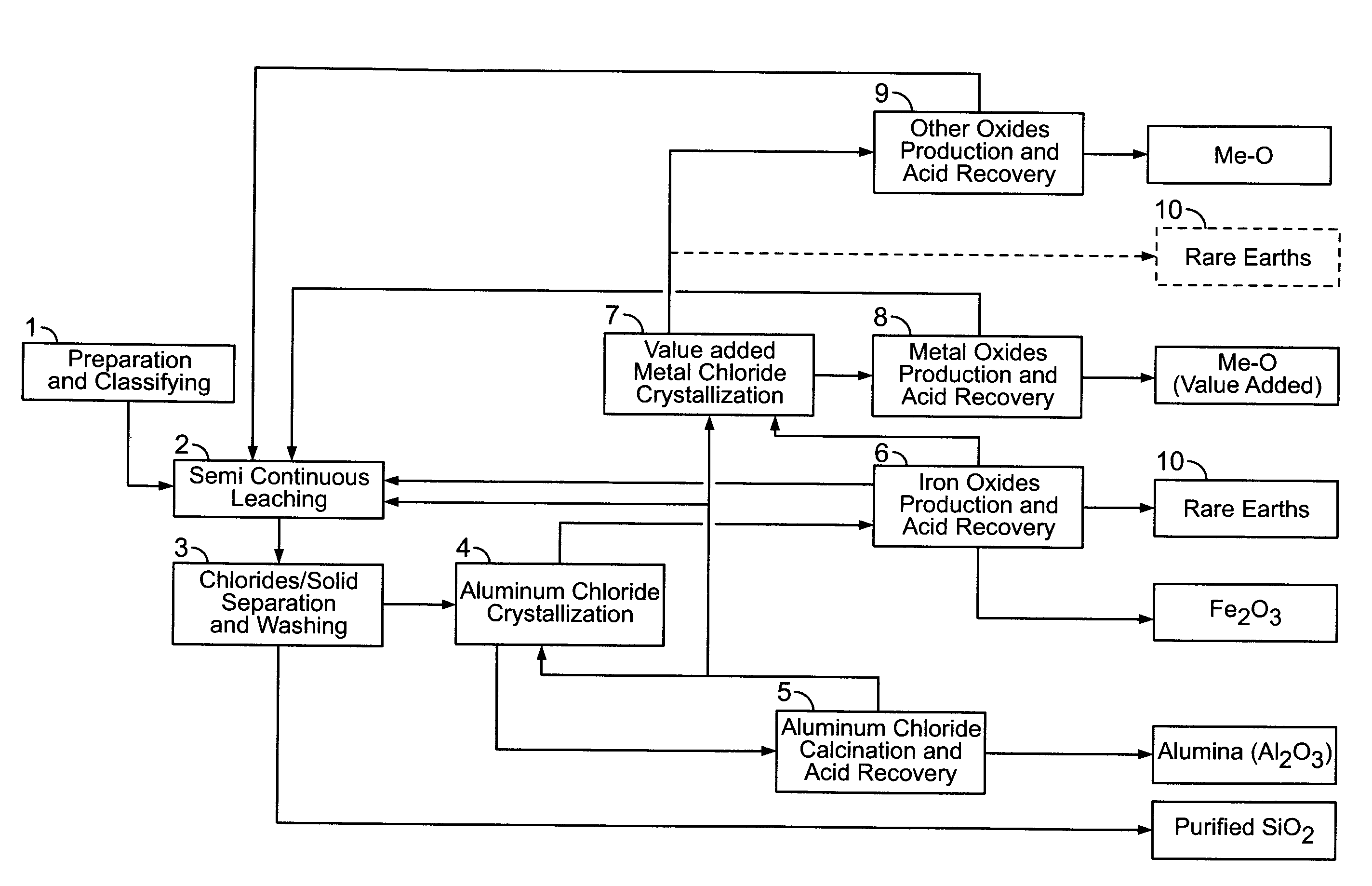

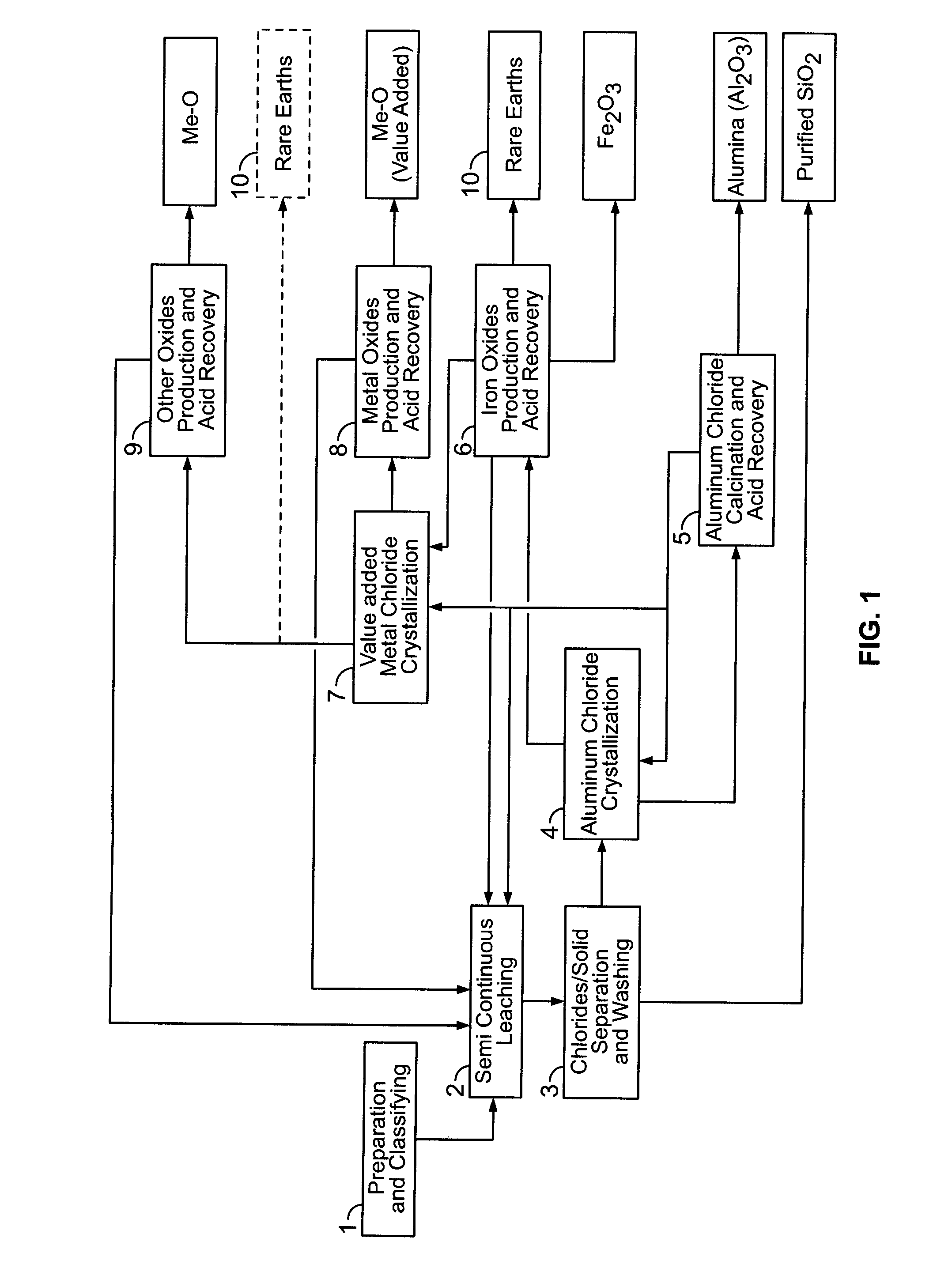

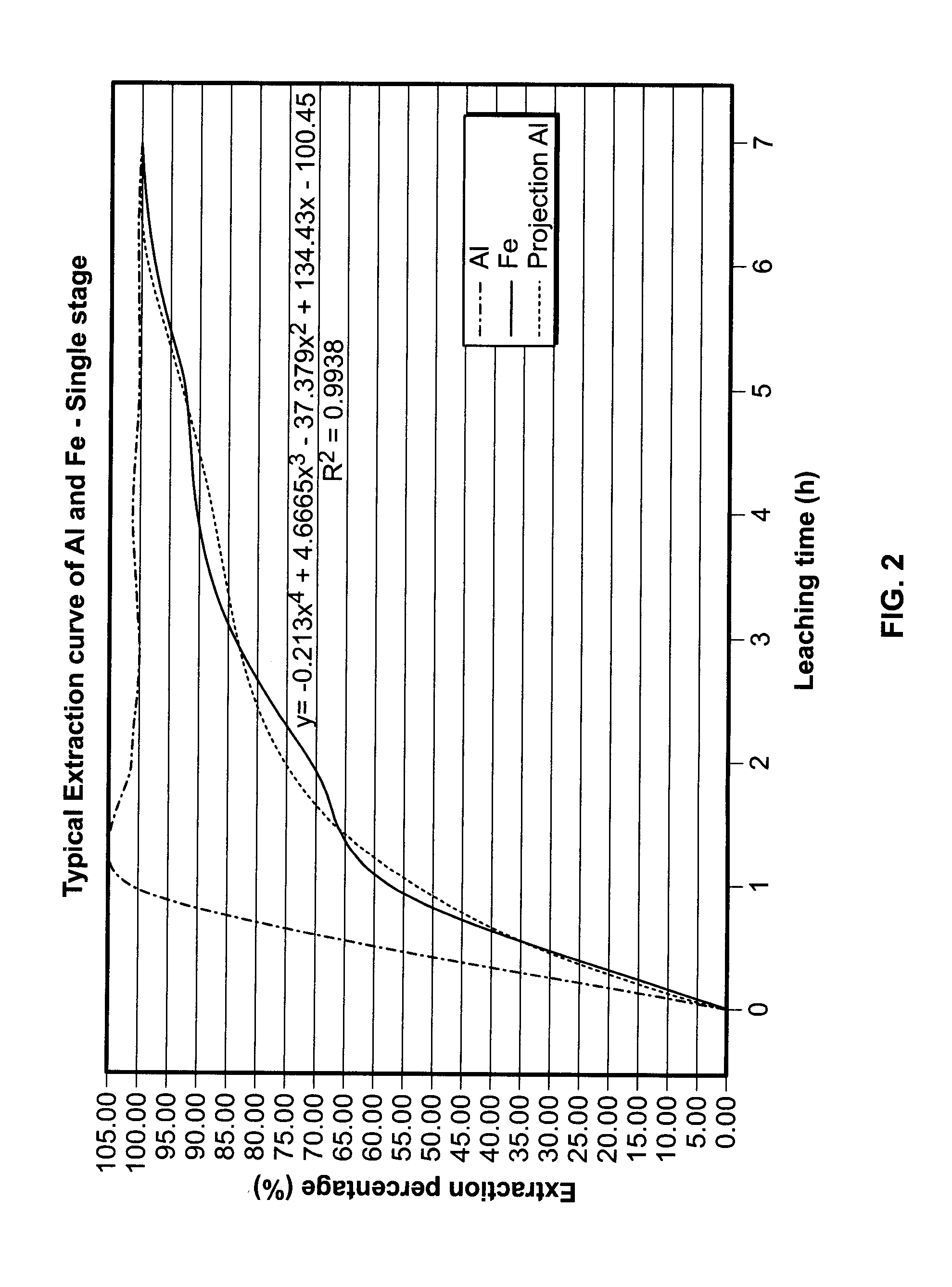

Processes for treating red mud

ActiveUS20140369907A1Simple and efficientLow costAluminium compoundsSolvent extractionPregnant leach solutionRare-earth element

There are provided processes for treating red mud. For example, the processes can comprise leaching red mud with HCl so as to obtain a leachate comprising ions of a first metal (for example aluminum) and a solid, and separating said solid from said leachate. Several other metals can be extracted from the leachate (Fe, Ni, Co, Mg, rare earth elements, rare metals, etc.). Various other components can be extracted from solid such as TiO2, SiO2 etc.

Owner:ORBITE ALUMINAE INC

Metal oxide powder and method for the production of the same

InactiveUS6303091B1Industrially advantageousTantalum compoundsFerric oxidesGranularityParticle-size distribution

A metal oxide powder except alpha-alumina, is disclosed comprising polyhedral particles having at least 6 planes each, a number average particle size of from 0.1 to 300 mum, and a D90 / D10 ratio of 10 or less where D10 and D90 are particle sizes at 10% and 90% accumulation, respectively from the smallest particle size side in a cumulative particle size curve of the particles. This metal oxide powder contains less agglomerated particles, and has a narrow particle size distribution and a uniform particle shape.

Owner:SUMITOMO CHEM CO LTD

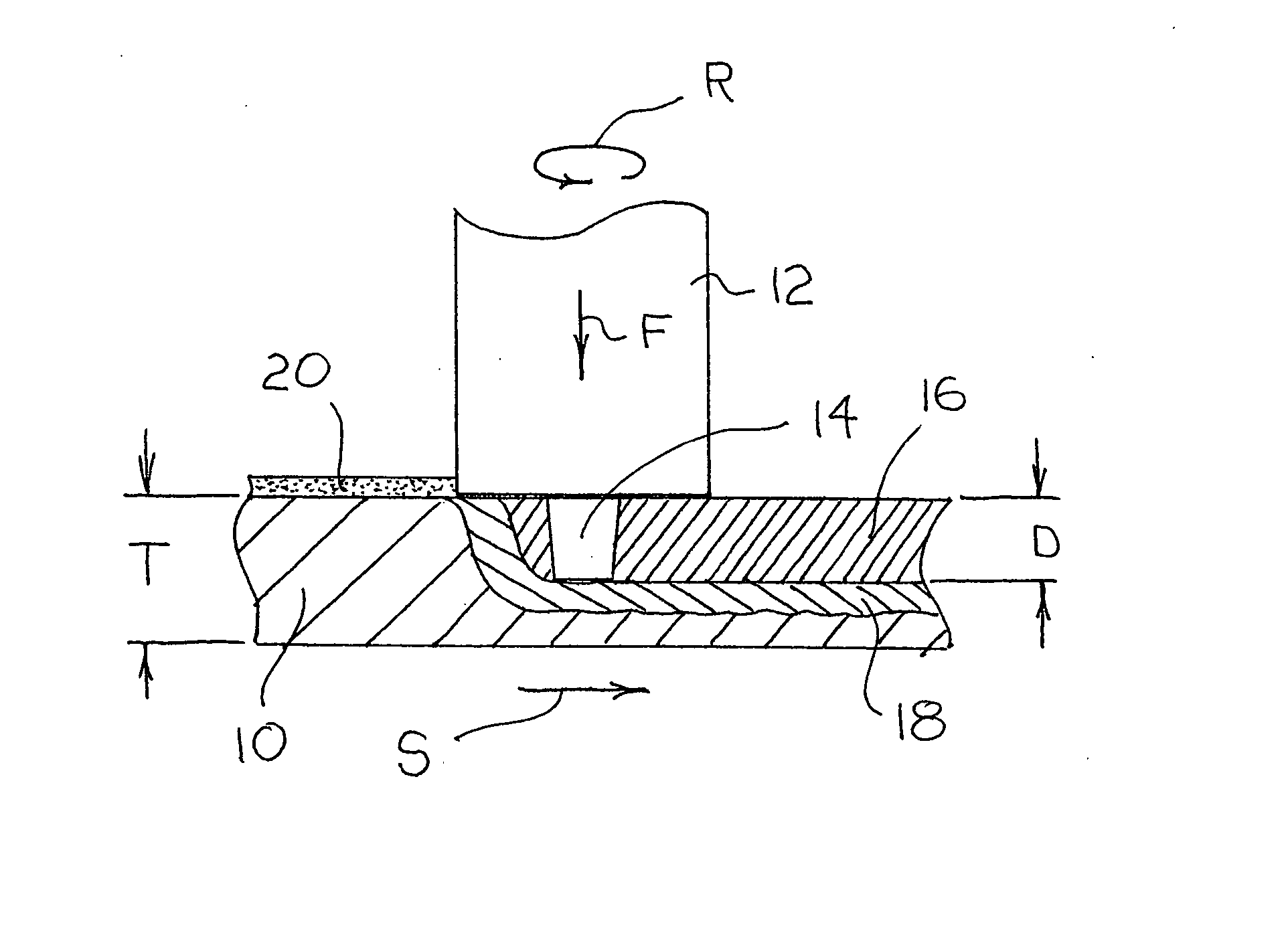

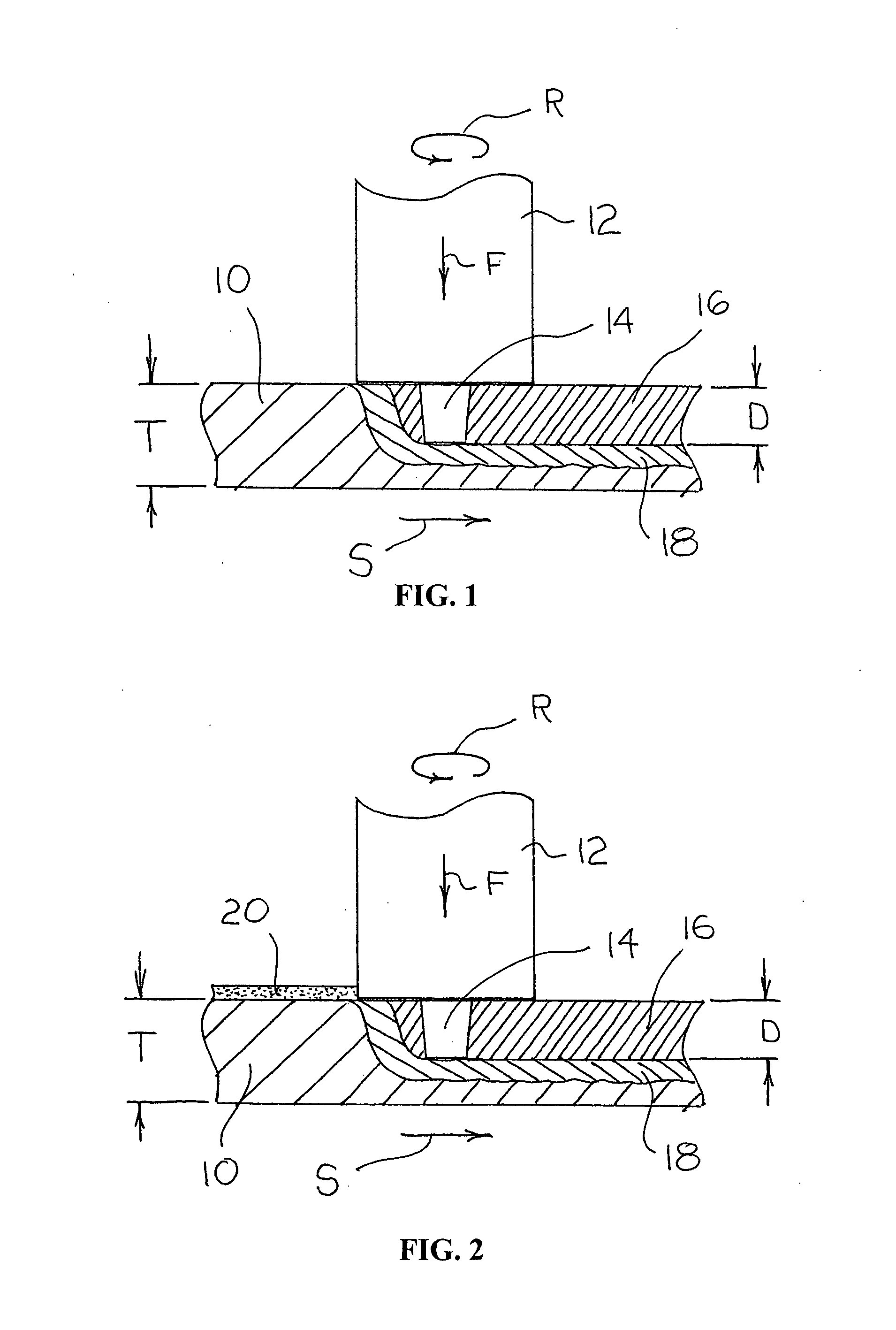

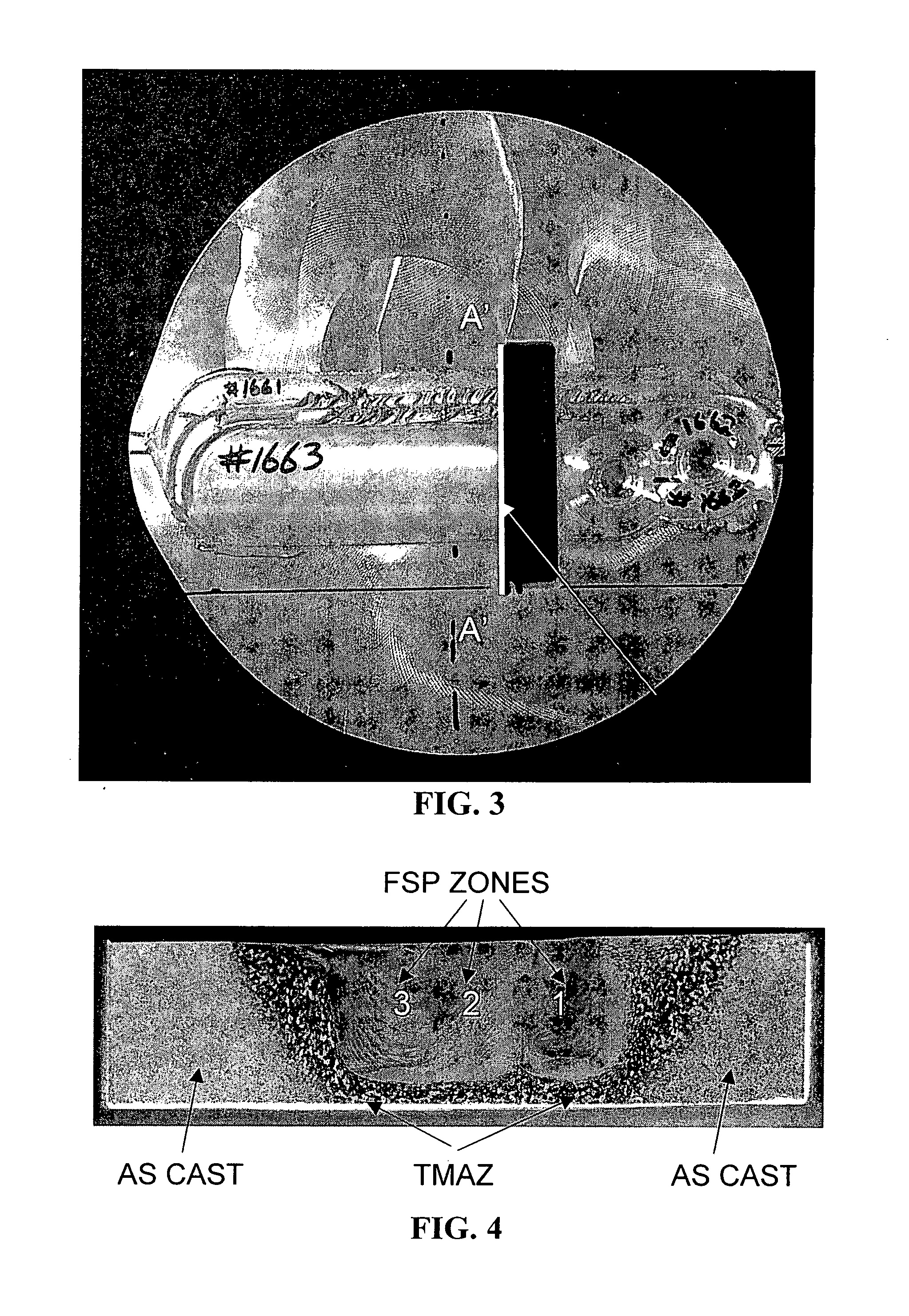

Stir processed cast aluminum-scandium structures and methods of making the same

InactiveUS20070297935A1Improve mechanical propertiesImprove corrosion resistanceAluminium compoundsGallium/indium/thallium compoundsFriction stir processingScandium

Friction stir processing is applied to an aluminum-scandium alloy workpiece in either a wrought or cast state including scandium-containing precipitates. The process selectively modifies the microstructure of the aluminum-scandium workpiece, for example, by reducing grain size and recrystallization of the substrate. Benefits include increased physical properties of the aluminum-scandium alloys as well as the ability to form unique alloy structures.

Owner:LANGAN TIMOTHY +2

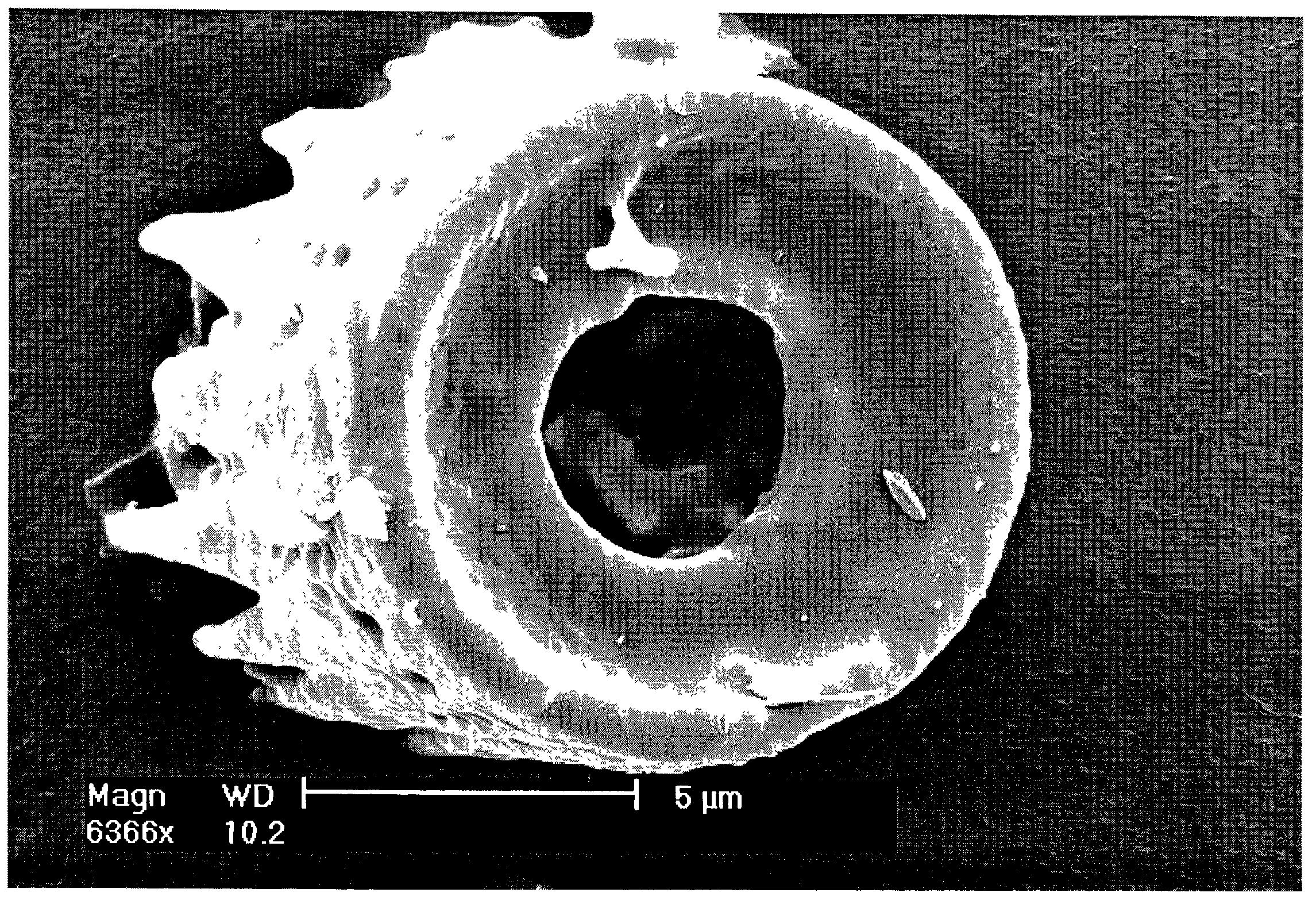

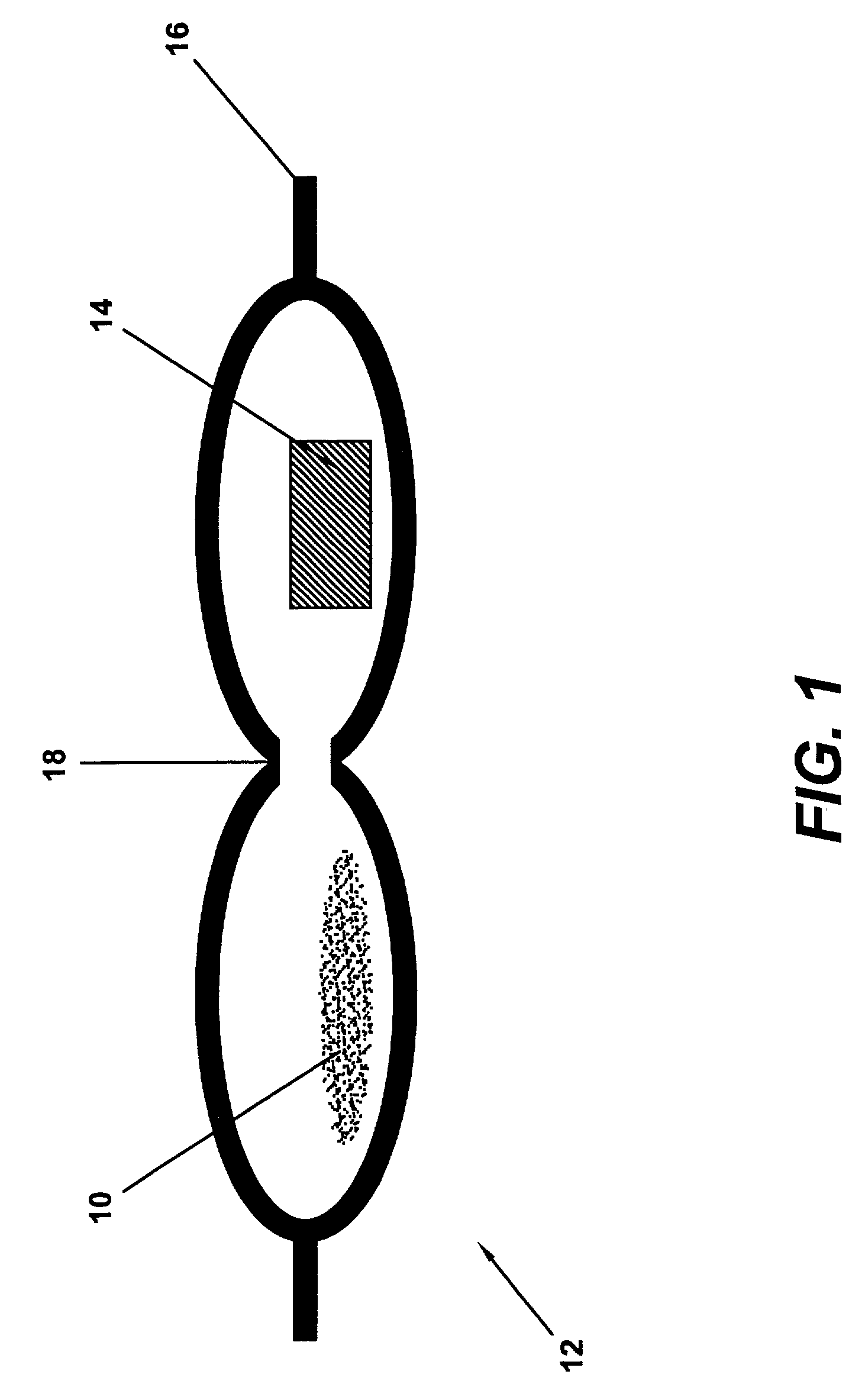

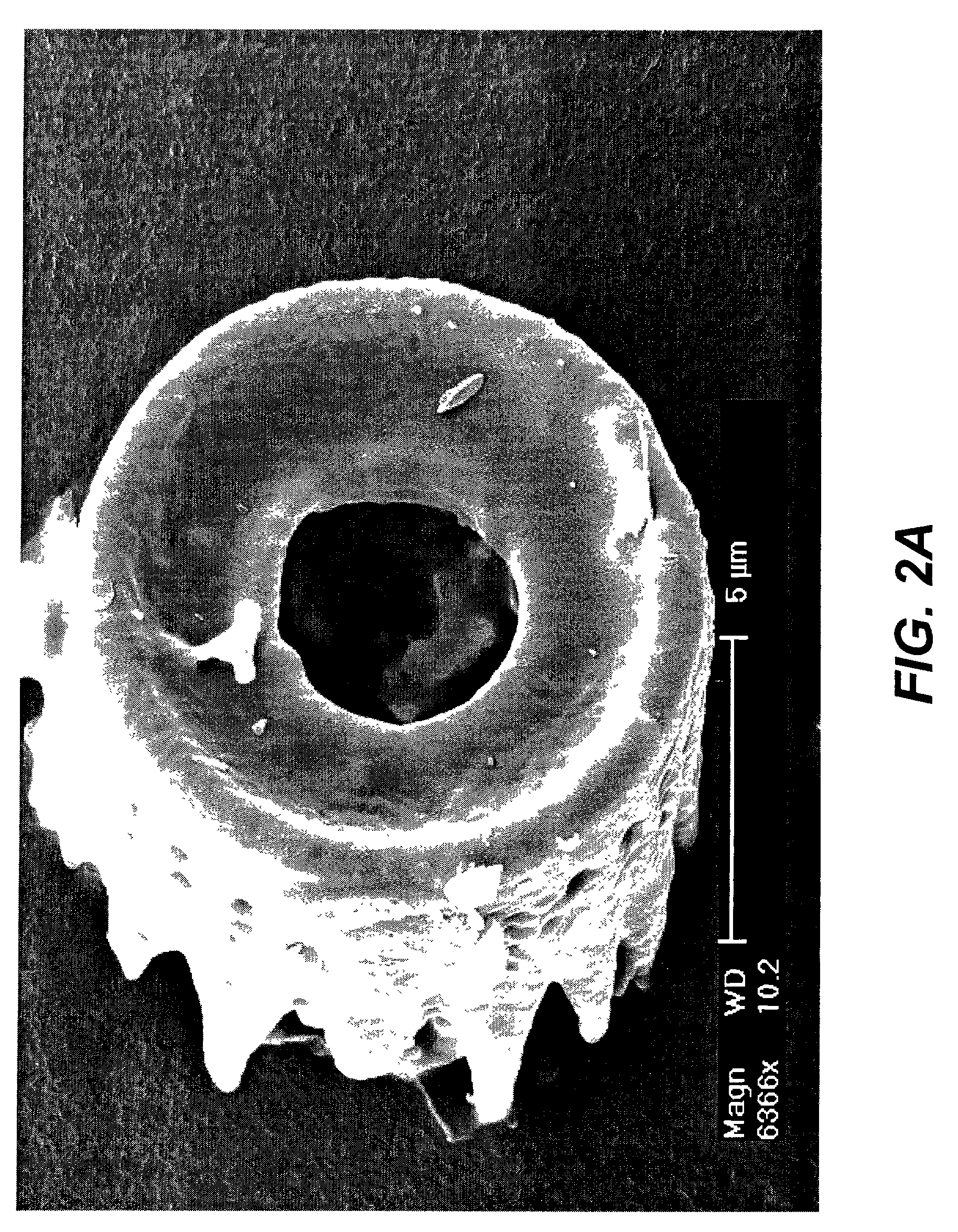

Shaped microcomponent via reactive conversion of biologically-derived microtemplates

InactiveUS7067104B2Well mixedLow-cost (highly-scaleablePowder deliveryZirconium compoundsGenetic engineeringReproduction

The present invention is focused on a revolutionary, low-cost (highly-scaleable) approach for the mass production of three-dimensional microcomponents: the biological reproduction of naturally-derived, biocatalytically-derived, and / or genetically-tailored three-dimensional microtemplates (e.g., frustules of diatoms, microskeletons of radiolarians, shells of mollusks) with desired dimensional features, followed by reactive conversion of such microtemplates into microcomponents with desired compositions that differ from the starting microtemplate and with dimensional features that are similar to those of the starting microtemplate. Because the shapes of such microcomponents may be tailored through genetic engineering of the shapes of the microtemplates, such microcomposites are considered to be Genetically-Engineered Materials (GEMs).

Owner:THE OHIO STATES UNIV

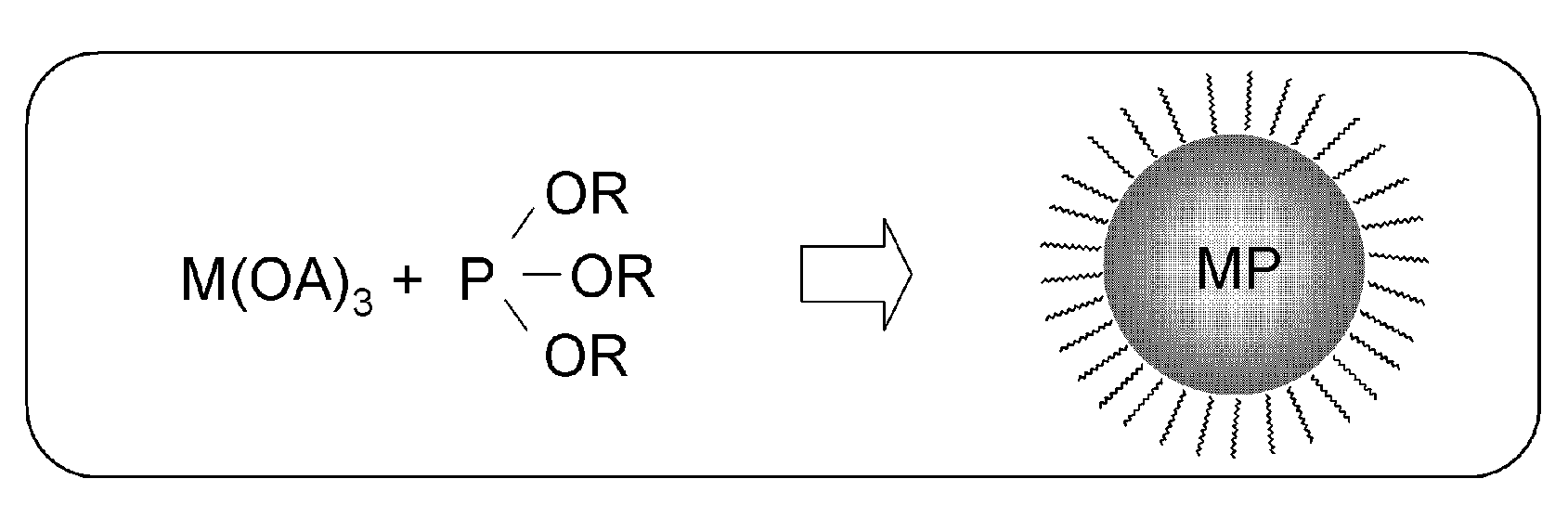

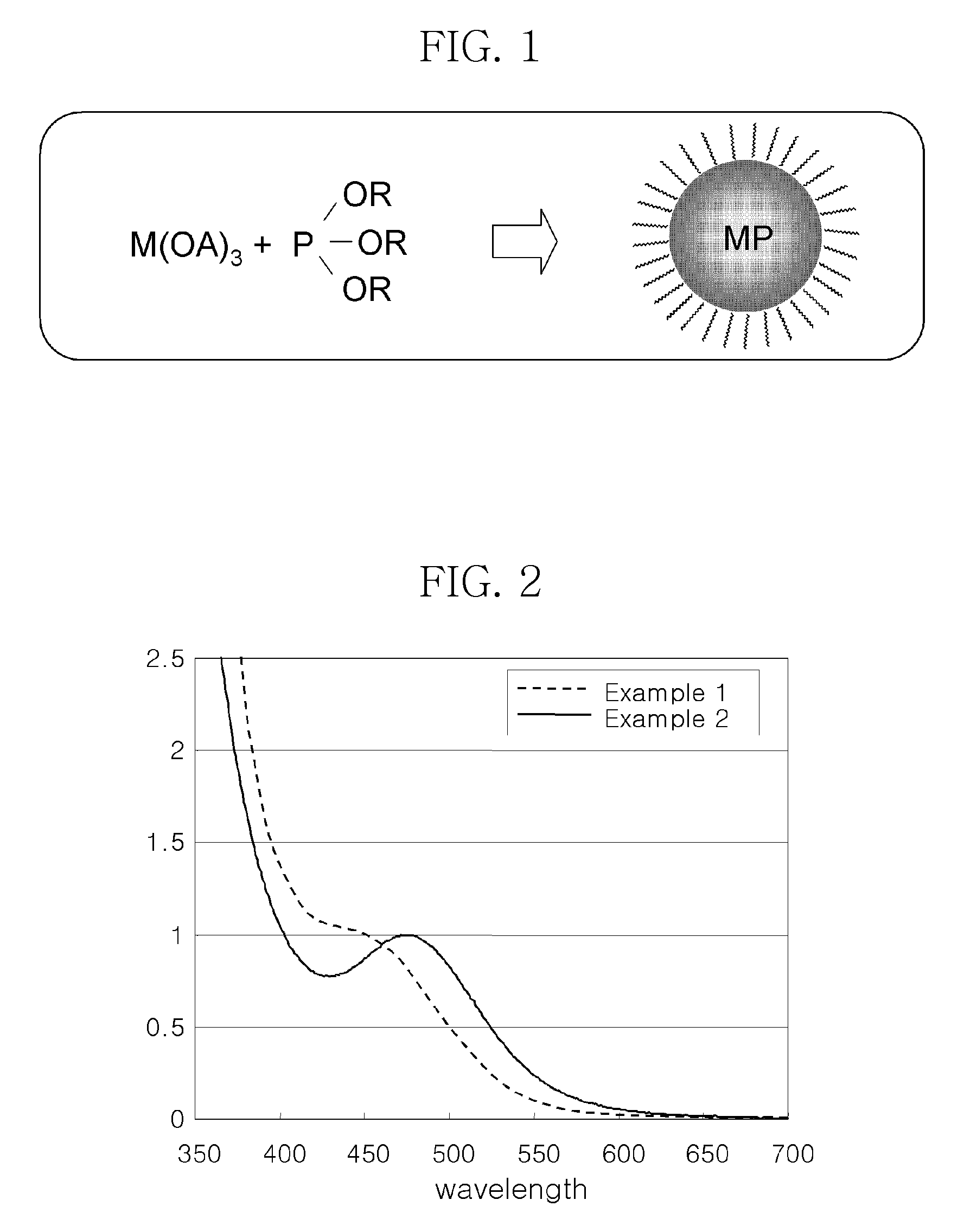

Method for preparing metal phosphide nanocrystal from phosphite compound and method for passivating nanocrystal core with the same

Disclosed herein is a method for the preparation of metal phosphide nanocrystals using a phosphite compound as a phosphorous precursor. More specifically, disclosed herein is a method for preparing metal phosphide nanocrystals by reacting a metal precursor with a phosphite compound in a solvent. A method is also provided for passivating a metal phosphide layer on the surface of a nanocrystal core by reacting a metal precursor with a phosphite compound in a solvent. The metal phosphide nanocrystals have uniform particle sizes and various shapes.

Owner:SAMSUNG ELECTRONICS CO LTD

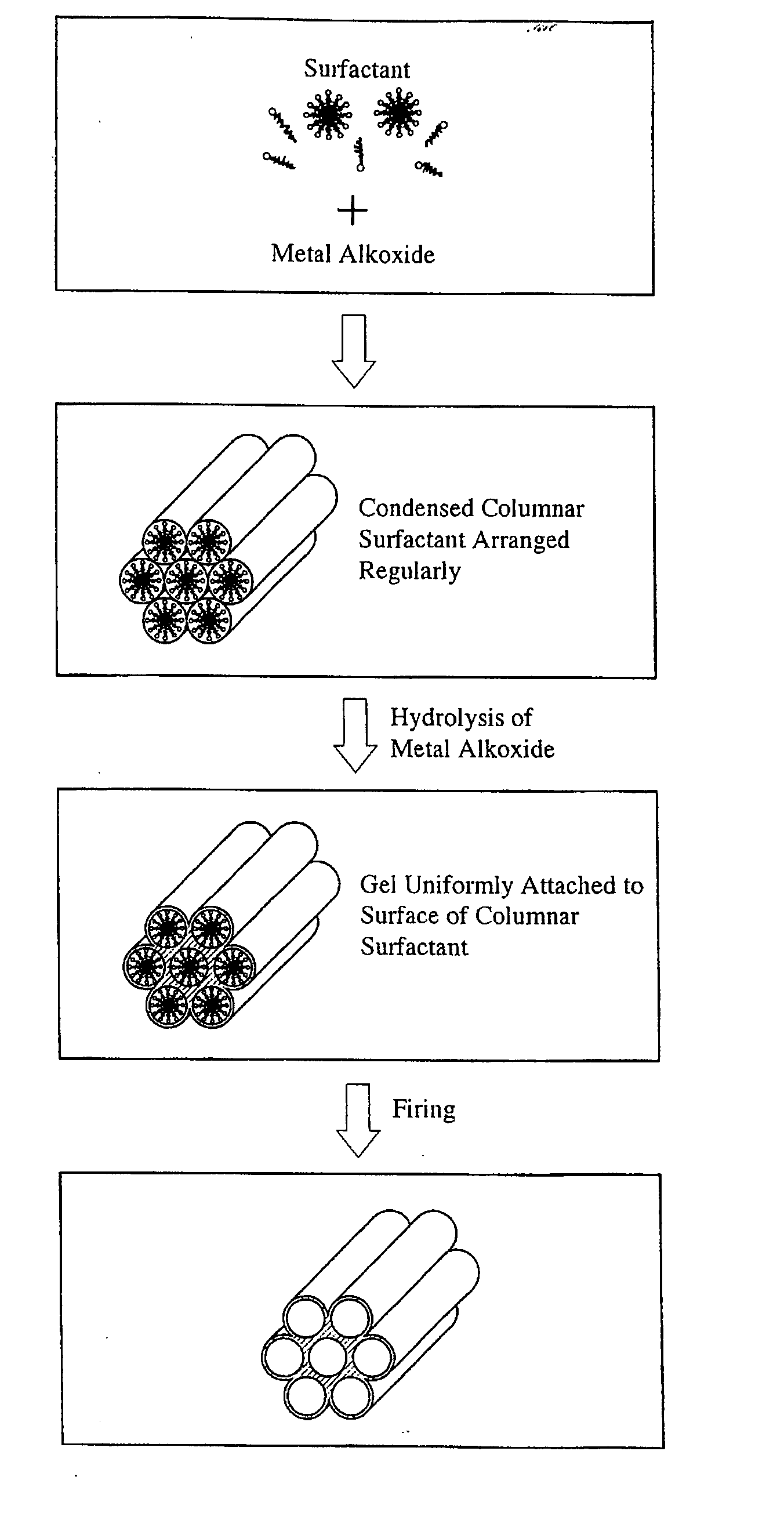

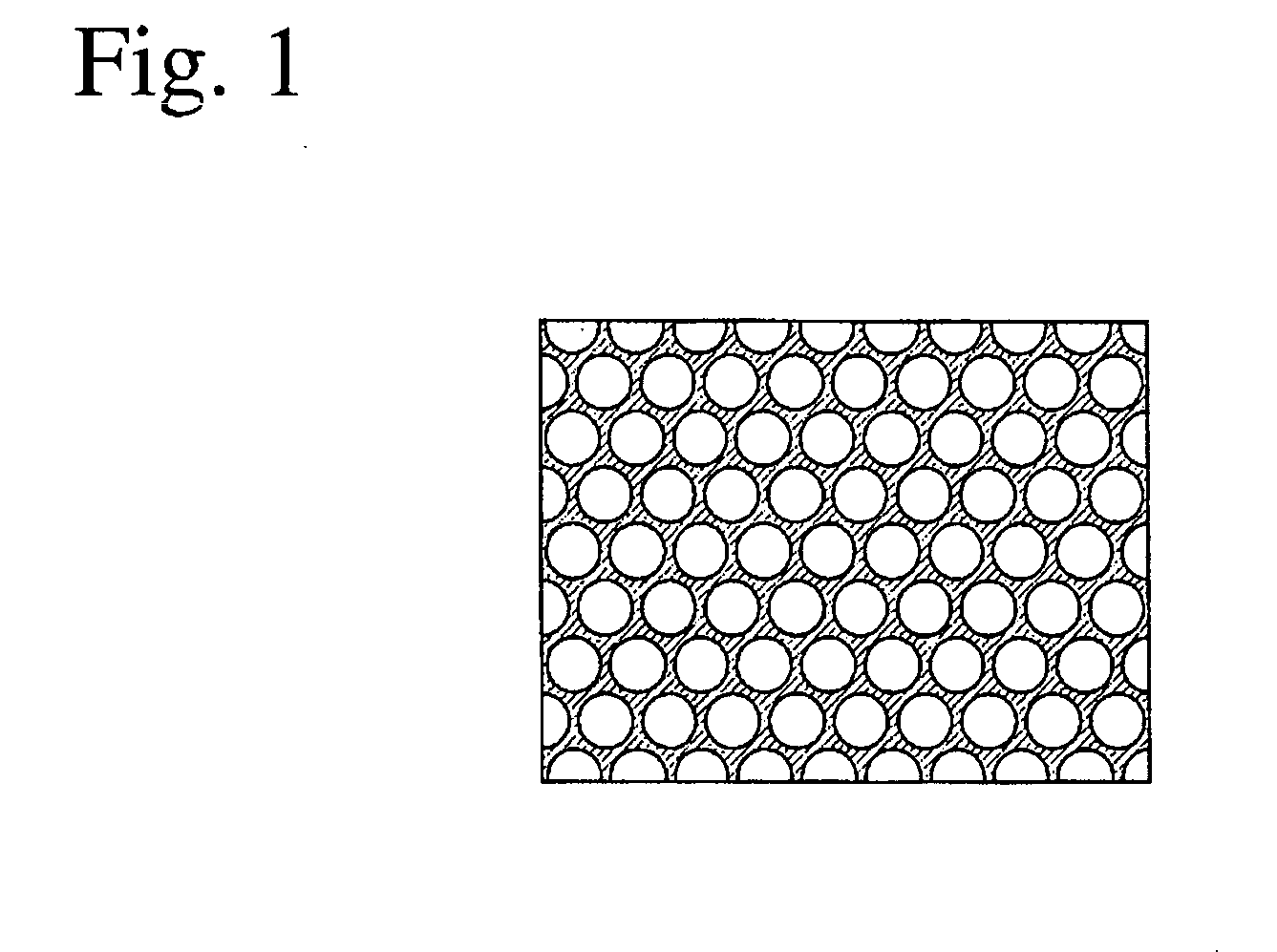

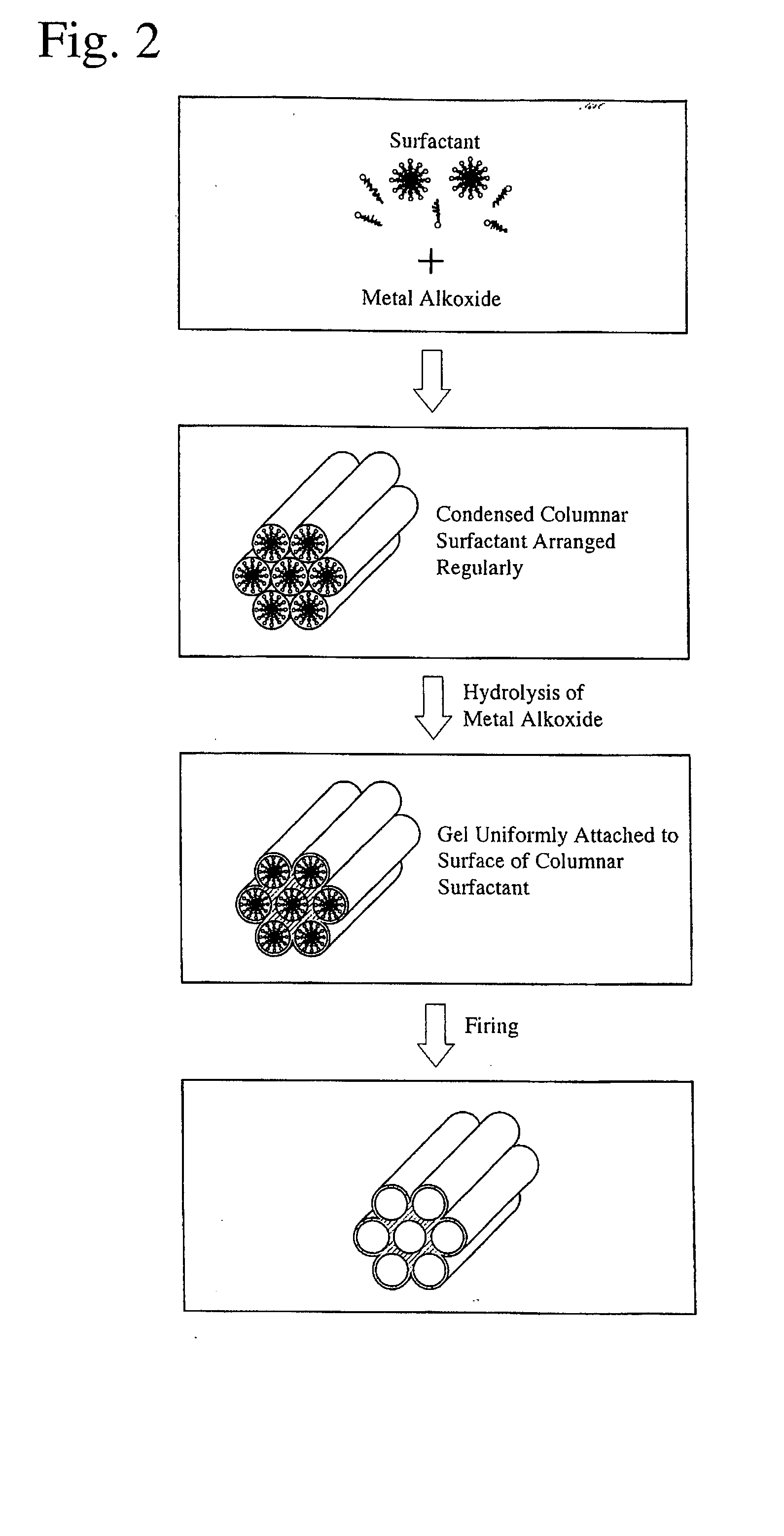

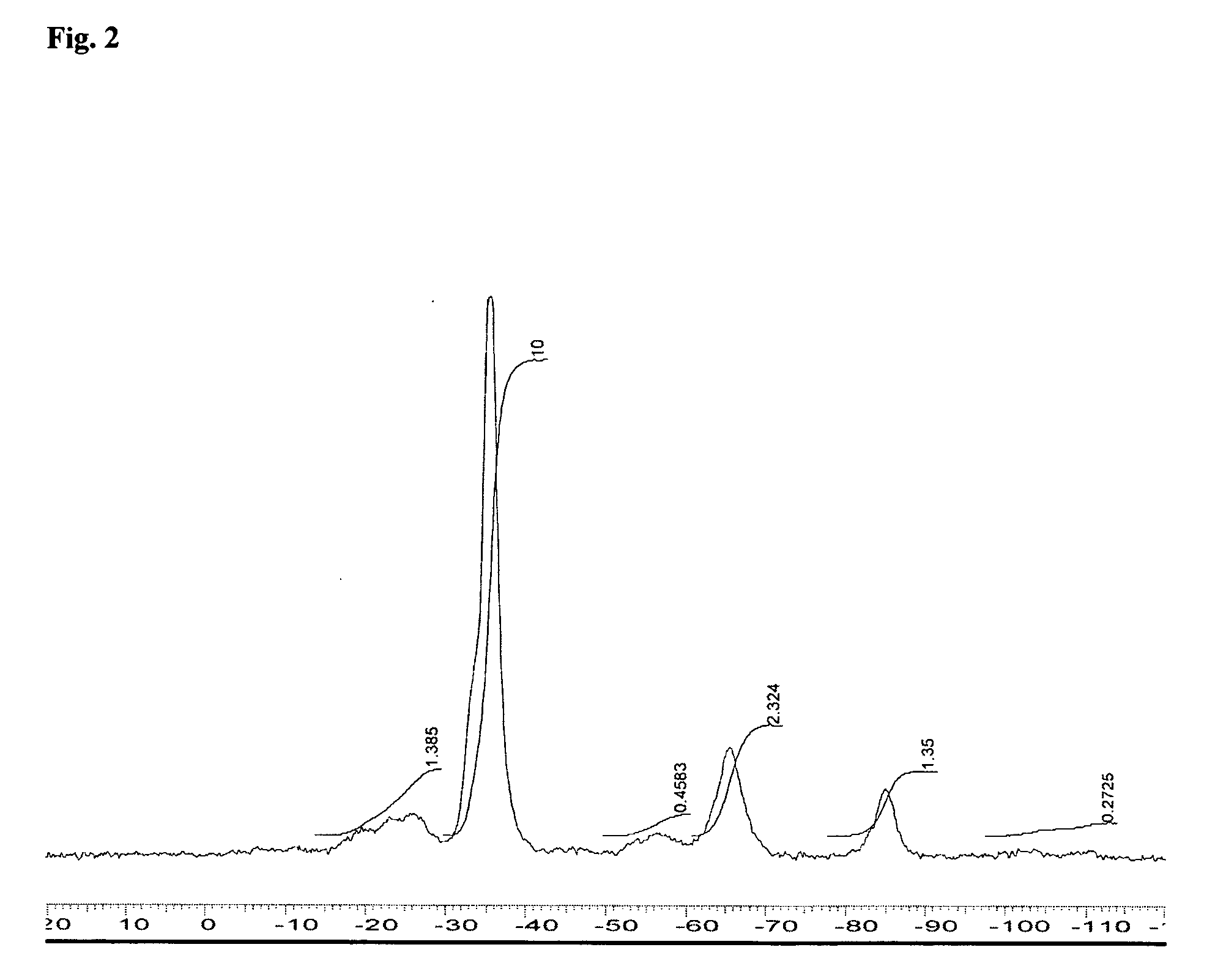

Three dimensional high regular nano-porous inorganic material having fine pores and method for preparation thereof, and method for evaluation thereof

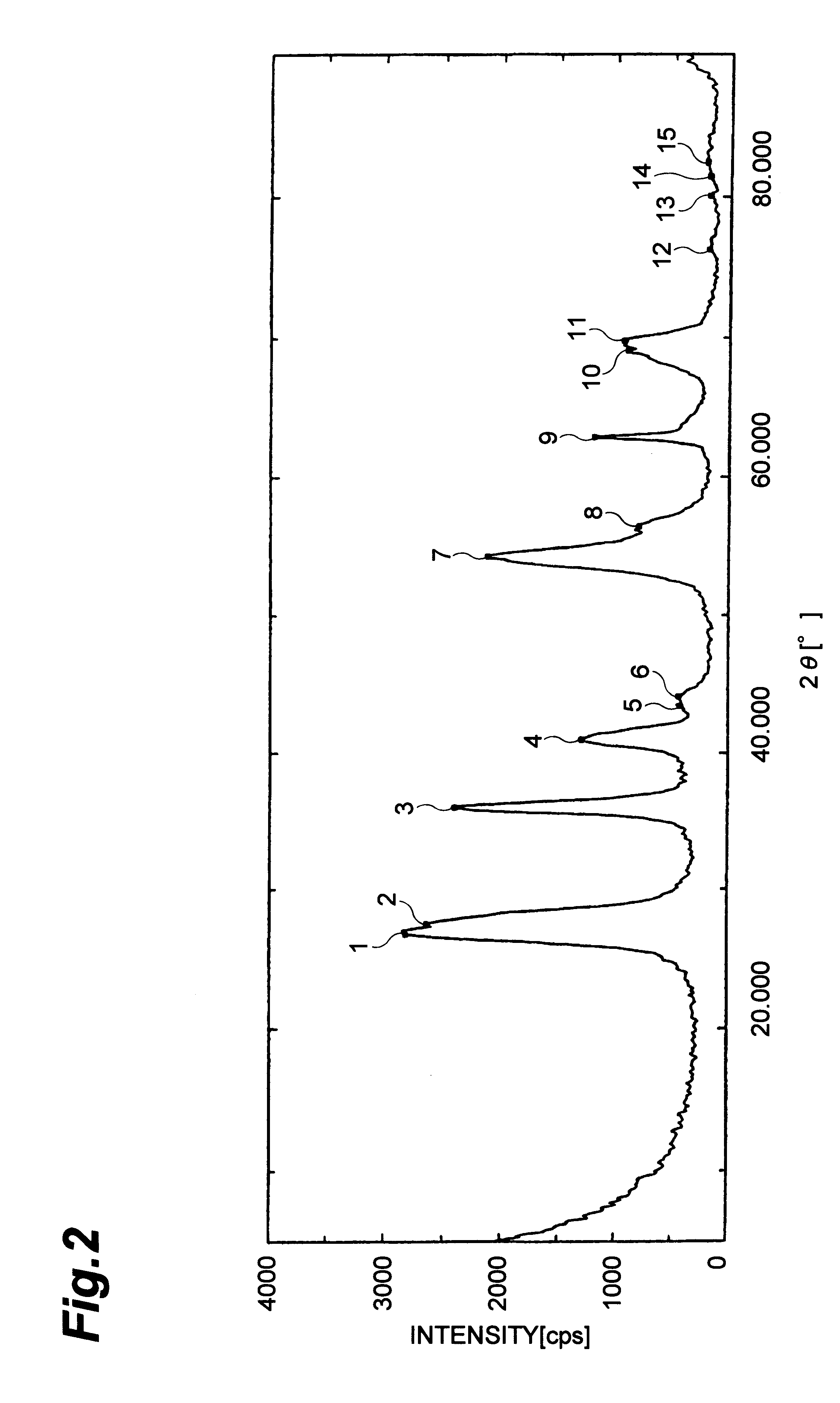

InactiveUS20060078487A1Improve regularityLow costOxygen/ozone/oxide/hydroxideSilicaCrystallographyX-ray

A nanoporous inorganic material with high three-dimensional regularity having a large number of fine pores having a nanometer-order size in an inorganic skeleton structure, which has a pore size of 0.5 to 5 nm at a peak of a pore size distribution determined from a nitrogen adsorption isotherm, and a half-width of 1 (2θ / degree) or less in an X-ray diffraction peak of a (100) plane.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Gel and powder making

A method of forming a gel and / or powder of a metallic oxide, metalloid oxide and / or a mixed oxide or resin thereof from one or more respective organometallic liquid precursor(s) and / or organometalloid liquid precursor(s) by oxidatively treating said liquid in a non-thermal equilibrium plasma discharge and / or an ionised gas stream resulting therefrom and collecting the resulting product. The non-thermal equilibrium plasma is preferably atmospheric plasma glow discharge, continuous low pressure glow discharge plasma, low pressure pulse plasma or direct barrier discharge. The metallic oxides this invention particularly relates to are those in columns 3a and 4a of the periodic table namely, aluminium, gallium, indium, tin and lead and the transition metals. The metalloids may be selected from boron, silicon, germanium, arsenic, antimony and tellurium. Preferred metalloid oxide products made according to the process of the present invention are in particular oxides of silicon including silicone resins and the like, boron, antimony and germanium.

Owner:DOW CORNING IRELAND

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com