Method for inorganically synthesizing organized mesoporous alumina

A technology for mesoporous alumina and inorganic synthesis, applied in chemical instruments and methods, preparation of alkali metal aluminate/alumina/aluminum hydroxide, and other chemical processes, etc., can solve the problem of high raw material cost, acid-base pollution, operation Complicated and other problems, to achieve the effect of low cost, reduced raw material cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A. Synthesis reaction: Add 200ml of 1mol / L NaAlO at 60°C and 500rpm with continuous stirring 2 In the solution, slowly add 100ml of 1mol / L AlCl at a rate of 0.6ml / min 3 Solution, that is, control the molecular ratio of the two aluminum salts to be 2:1, add 12.0g template methylcellulose powder (concentration is 40g / L) when PH=11, continue to insulate and stir the reaction for 3 hours after the addition is complete;

[0029] B. Aging: Aging the precursor obtained in step A at 60°C for 15 hours;

[0030] C. Filtration, washing: after the mixture obtained in step B is vacuum filtered, wash with deionized water;

[0031] D. drying: drying the filter cake obtained in step C at 60°C for 12 hours;

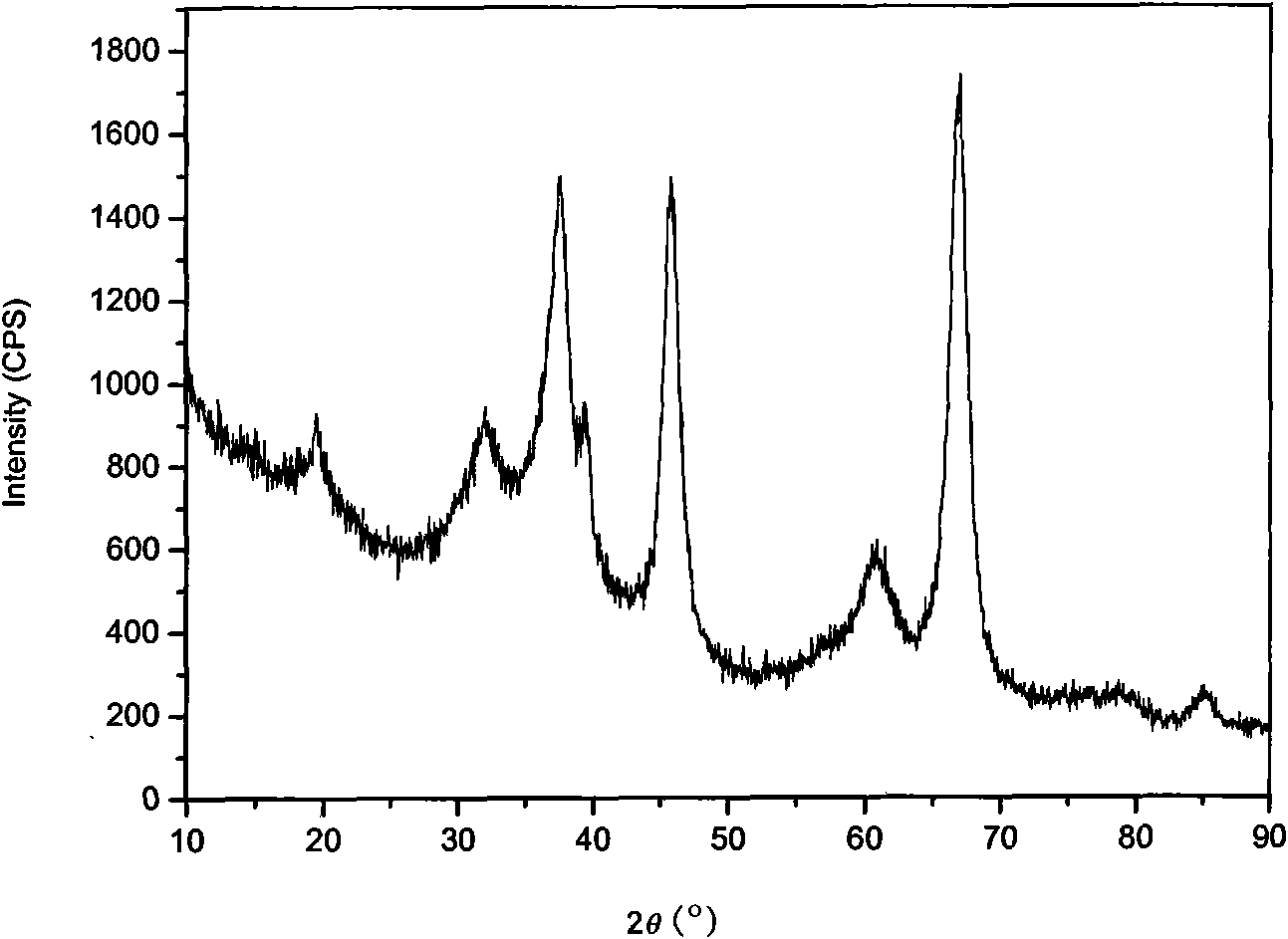

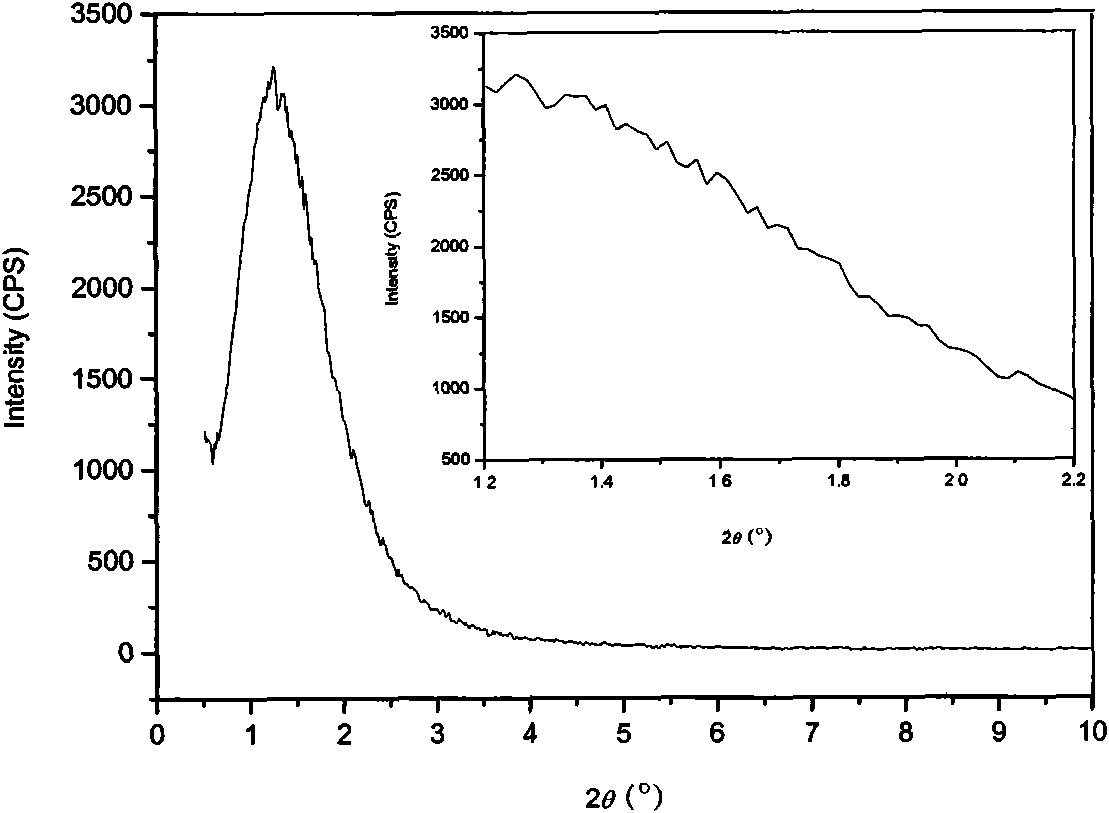

[0032] E. Calcination: Put the precursor powder obtained in step D in a muffle furnace, heat up to 650°C at a rate of 100°C / hour and keep it for 3 hours to prepare mesoporous Al 2 o 3 .

[0033] After diluting the filtrate obtained by vacuum filtration in step C, the concentra...

Embodiment 2

[0036] A. Synthesis reaction: 150ml of 3mol / L NaAlO 2In the solution, slowly add 150ml of 3mol / L AlCl at a rate of 1ml / min 3 Solution, that is, control the molecular ratio of the two aluminum salts to be 1:1, add 12.0g template methylcellulose powder (concentration is 40g / L) when PH=11, continue to insulate and stir the reaction for 10 hours after the addition is completed;

[0037] B. Aging: aging the precursor obtained in step A at 50°C for 15 hours;

[0038] After diluting the filtrate obtained by vacuum filtration in step C, the concentration of methylcellulose in the filtrate was determined by diphenylamine colorimetry to be 12.79 g / L (accounting for 32.0% of the total amount).

[0039] C. Filtration, washing: the mixture obtained in step B is vacuum filtered and washed;

[0040] D. drying: drying the filter cake obtained in step C for 96 hours at 20°C;

[0041] E. Calcination: Put the precursor powder obtained in step D in a muffle furnace, raise the temperature to 10...

Embodiment 3

[0044] The operating process is the same as in Example 1 except that the following steps are different.

[0045] A. Synthesis reaction: Add 150ml of 2mol / L NaAlO under constant stirring at 80°C and 400rpm 2 In the solution, slowly add 50ml of 2mol / L AlCl at a rate of 2ml / min 3 Solution, that is, control the molecular ratio of the two aluminum salts to be 3:1, add 20.0g template methylcellulose powder (concentration is 100g / L) when PH=11, continue to insulate and stir the reaction for 2 hours after the addition is completed;

[0046] B. aging: aging the precursor obtained in step A at 50°C for 8 hours;

[0047] After diluting the filtrate obtained by vacuum filtration in step C, the concentration of methylcellulose in the filtrate was determined by diphenylamine colorimetry to be 35.7 g / L (accounting for 35.7% of the total amount).

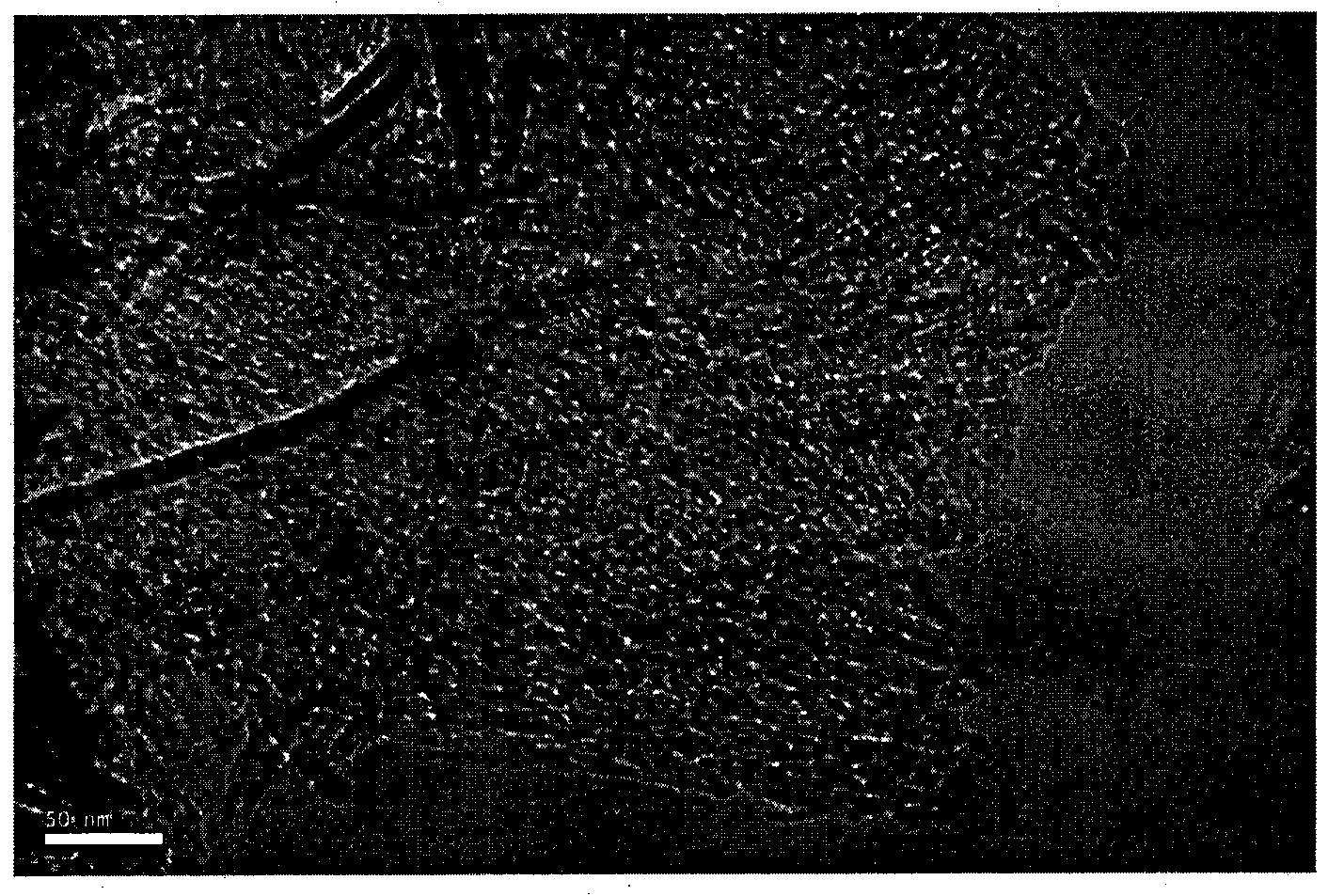

[0048] The specific surface area of the prepared ordered mesoporous alumina product is 290.6m 2 / g, the pore volume is 0.27cm 3 / g, the pore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com